{ Fab Academy 2015 : Koichi Shiraishi }

{ Home } { Final project } { Class } { Fab Academy }

- Week 08: Computer-Controlled Machining -

Weekly Assignment

- make something big

1: Using fabmodules

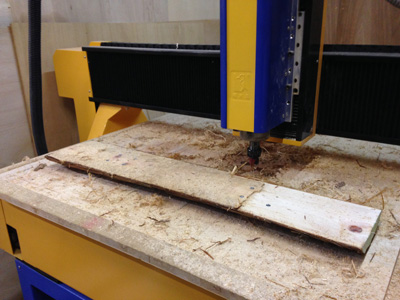

As start of this week, I check to work our CNC router by fabmodules. Our lab has ”AP-1325Y(Woodpecker).”

I draw a test data by SVG and PNG. Both data were calculated the path, these were no problem to save by G code.

The data worked on the machine, but the scale is wrong. These were out-puted smaller. I did not solve this problem. Therefore, I used “Type 3” that we are always using.

About “Minna cargo”

I have a apt project to this week assignment.It is “Minna cargo”.

The ”Minnna cargo” is a toolbox, moving seat and small carrier use inside allotment garden. It is a collaboration work with “Minna noen(NPO)”,”Osamu kokufu(Artist)” and me(FabLab Kitakagaya).

“Minna noen” is a Organization of allotment garden. Mr. Kokufu and me interviewed the farm members about behavior amid farm work. We extracted some function the members needs.

After then, Mr. Kokufu drew a sketch, I made the 3D model according to his growing. I enable to make by CNC router.

We held the making cargo work shop on several times in the year before last.

Afterward Mr. Kokufu passed away due to accident during creating his work.

A year since then, we plan the retrospective exhibition of his work.

I will display the “Minna cargo” in this exhibition. It will be added some new function.

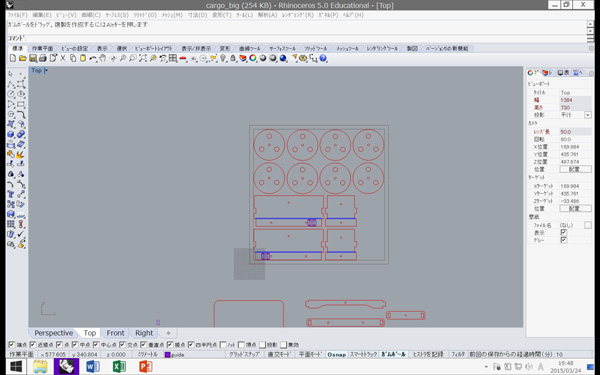

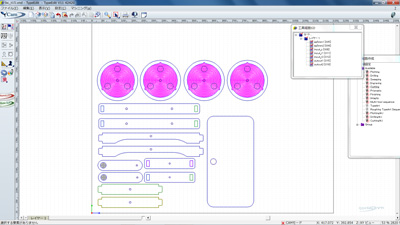

2: Drawing

I used “Rhinoceros” to draw the out line.

I modified the original data to add stepper motor. Because I plan that the new cargo is autonomous Locomotion.

It become a pretty big so as to put into a battery.

I created out lines and engraving areas.

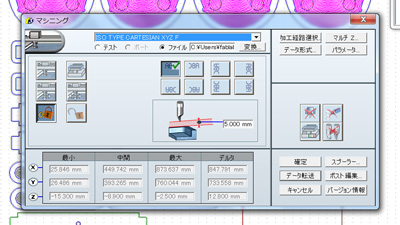

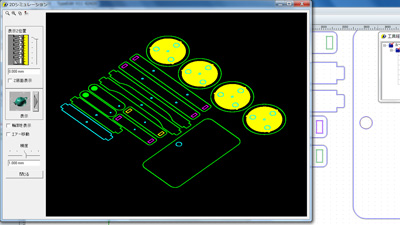

3: Calculating cut path

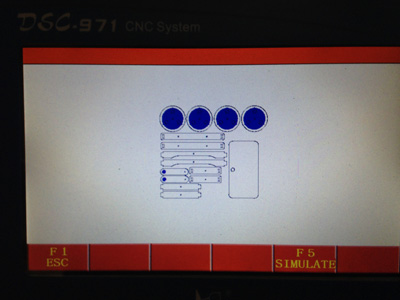

After drawing, I import the data to “Type 3.”

“Type 3” is a cad/cam software. But We usually use only calculated the cut path.

I will show operation method in the following.

- Import the data

- Select a processing type

- Select a tool(mill)

- Put the number into items to create the path

- Select a origin type

- Generate a G code

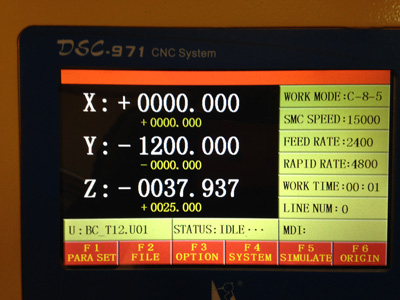

4: Machine setting

I think there are tow important point to use a CNC router.

The first is Origin setting.

Setting Z axis origin especially is important.

I adjust the origin while spindle motor is runing.

I hear tip sound. if the mill contact the work, the sound is changed.

Must not forget checking the mill length.

the other is checking the loaded data.

I am sure to operate the machine without a mill.

I especially check the beginning and ending.

FabLab kitakagaya has AP-1325Y(Woodpecker).

I choose lauan plywoods t12mm/t15mm.

I set the material by screw at 9 points.

Start dust collector, and cut the material. I often paused the machine, and clean the mill.

5: Assembly

I worked up how to assembly “Minna cargo” in “this site.” However, it was wrote by only Japanese. I will try to translate an English as soon as possible.

Cuted files/Resipe

Resipe

Cuted files

Postscript

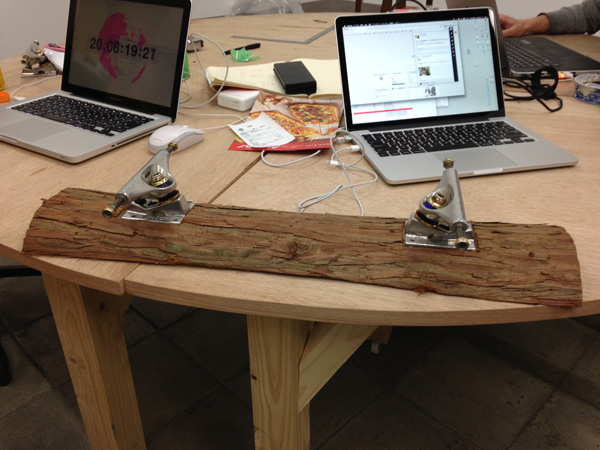

I made it by CNC router recently. I named this one “log skate.”