The project of this week is connected with composites. I decided to do propeller for helicopter.

This task was as exercise and I don't plan to use composites in my final project, that is why I took the form of propeller at the site and simplified it.

Archive with original design files.

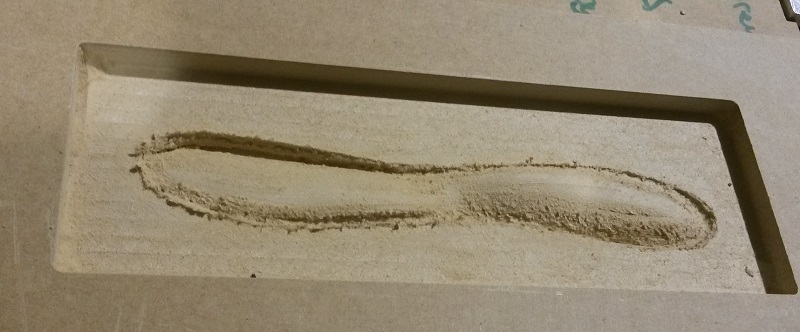

I used 8 mm tool, 1500 mm/min working feedrate and 15000 rpm for spindle at first and 1000 mm/min for finishing. Material was 0,03*2.4 m MDF.

Milling took much time than I suppose, because at first model was some mistakes with cutting regimes.

The form for propeller I have done at week 8

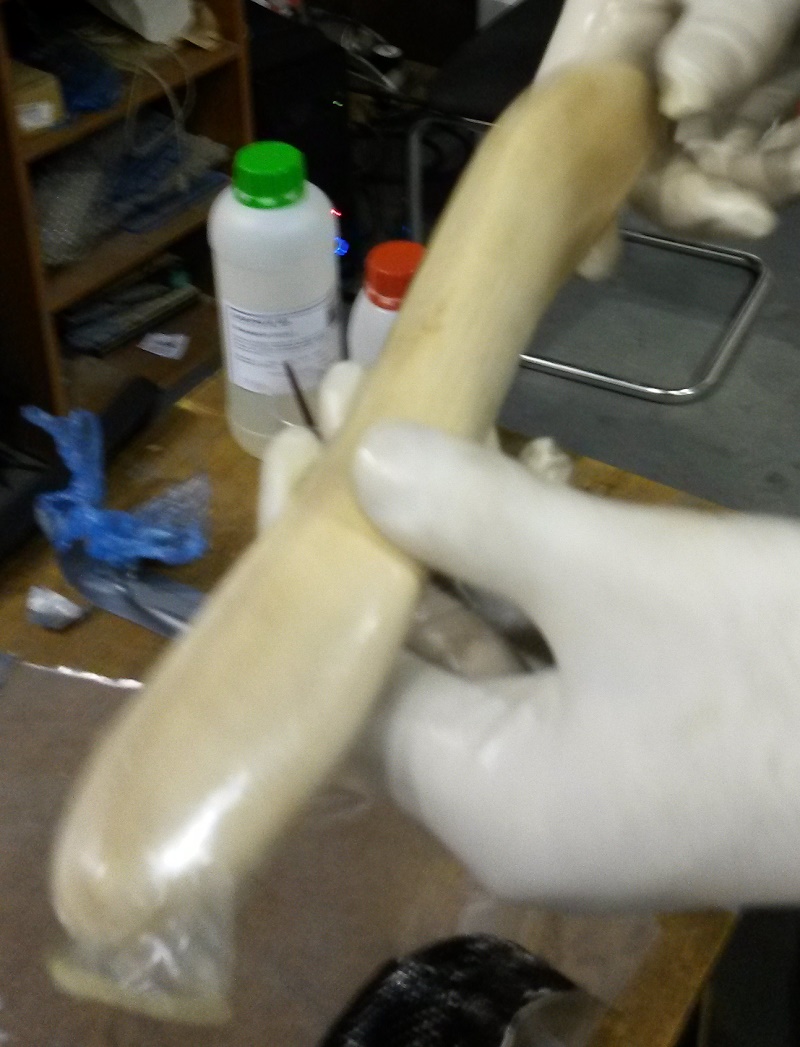

It should put the form into rubber film. I use condom because it is thin and adjacent to the form very well and repeat all bends of the form. I this case the form doesn't adhere to the product.

I use carbon fibres and epoxy to form.

You should soaked carbon fiber with a mixture. I use a flat brush to blend penetrated between the fibers better.

After that put the form into the vacuum for 12 hours.

It was difficult process to do vacuum in the package. At the and I used the clothes bag with the apertures with a check valve and a vacuum cleaner.

When the mixture is frozen I use a saw for metal to make the right board of propeller.