I like working with milling machine that is why I use it this week.

I look for something with difficult form.

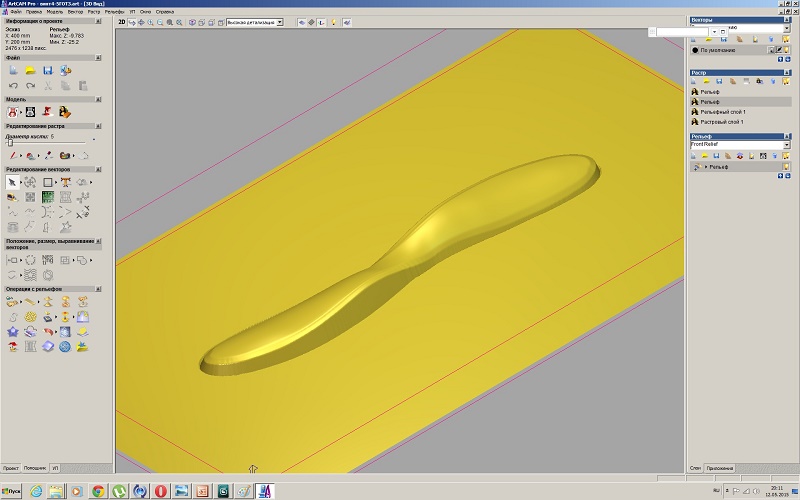

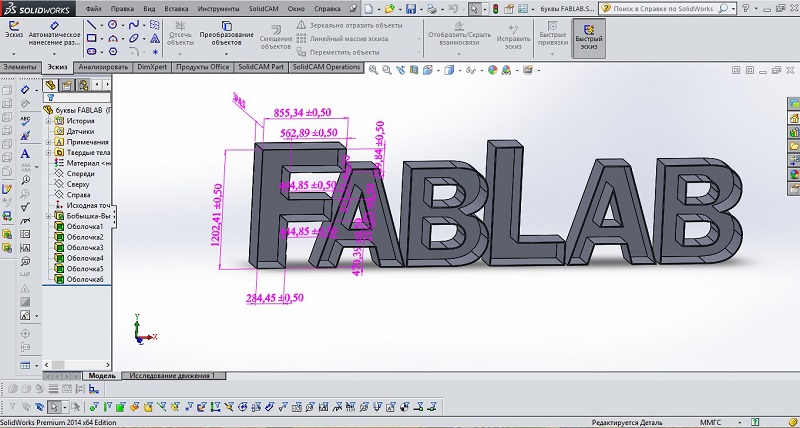

I use the program for 3D modelling

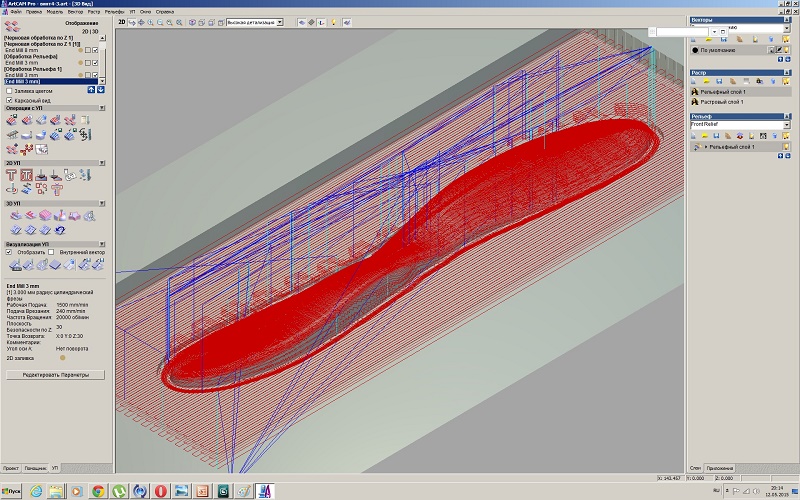

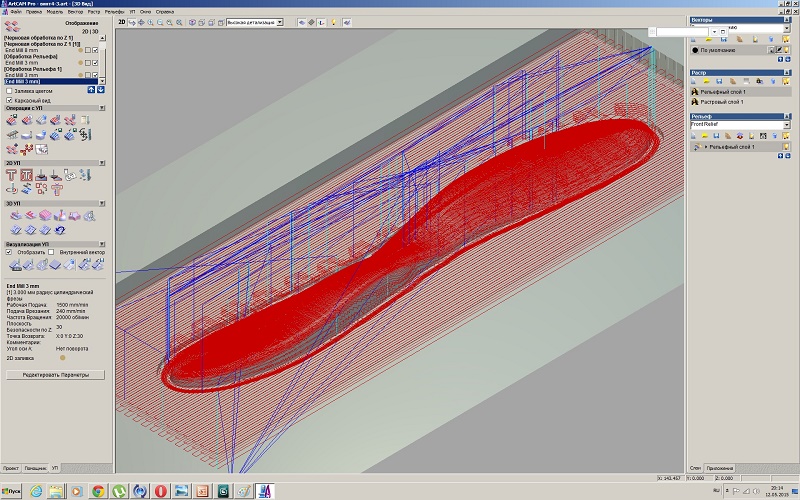

Slice the model to prepare for the milling.

Model is ready.

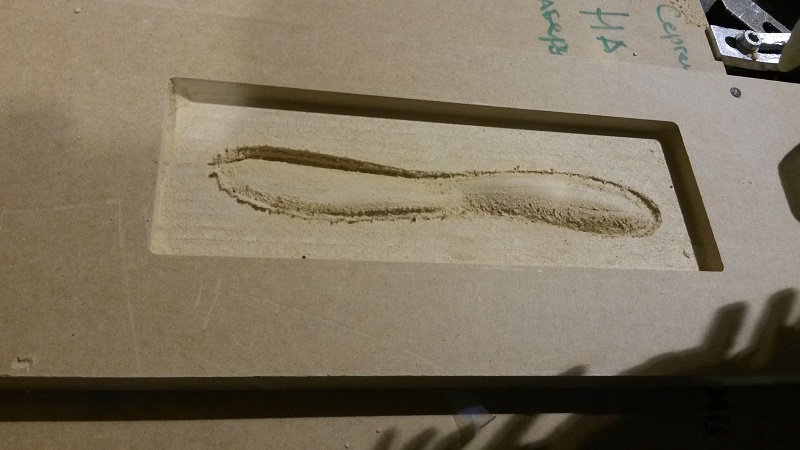

Stages of milling

Final result.

I use one size milling, because it will be form for composites formation.

For two side milling you may do some holes and flip piece and make those holes concentric, fix the piece and mill the second side.

I used 8 mm tool, 1500 mm/min working feedrate and 15000 rpm for spindle at first and 1000 mm/min for finishing. Material was 0,03*2.4 m MDF.

Also we need to do something big. I have done the letters, which we put as art-object before entrance to our FabLab.

Items are made of plywood and held together with screws. There were made slits for bending.

Here you can see how it looks like: