BRITOV DENIS

Status:

COMPLEATED

Week 3: computer-controlled cutting

This week we get acquainted with laser cutting. Up to this point I have never worked on such equipment, but I just thought up what I can cut. Since the past 2 weeks, I set up Modela, I decided to cut a special bracket that allows you to work without a protective screen.

Using Corel I modeled and carved it out of the plastic.

It looks like:

The first attempt was a success, so I decided to do something more complicated.

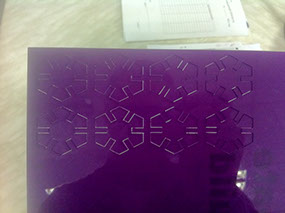

I've been thinking over the form of parts and decided that the optimal form would be а hexagon.

This shape enables connection of 6 additional parts at an angle of 60 degrees.

Next step was to calculate a size of slots. I used 5 mm plexiglass, and at the first attempt i cut parts with 5 mm slots - it was error, couse after connection parts do not hold on to each other.

Next design of the parts uses 4.8 mm slot and it was successful.

Here is a PGN of my parts: Constructor.png

As a basis, I took a sheet of colored plexiglass 5 mm thickness.

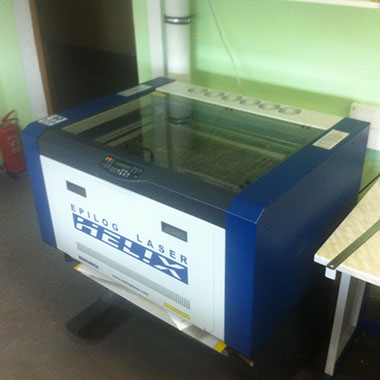

We have an Helix Epilog Laser in our

lab. It cut plexiglass after 5-10 attempts with this settings:

Speed: 10

Power: 100

Freq: 5000

Before sending image to the laser be sure, that it is converted to the vectors. In Corel we used a special function - thin outline and only then print.

Here is my results:

And something looks like an animal =)