This week assignment was to "design a 3D mold, machine it, and cast parts from it".

At first I decided to focuse on casting only because I had some problems with mold machining on the shopbot machine. That would allow to parallelise my work process. But just as sometimes it is, there were some problems too.

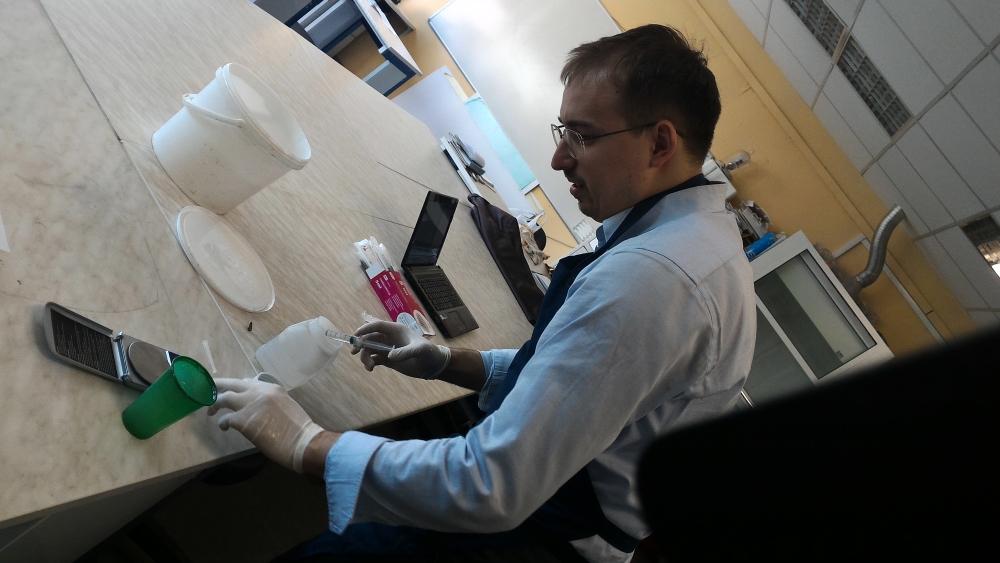

The first step was finding out that we already have some silicone in our lab, and that was a good news. But the problem was that it is really old. The bucket was opened about three years ago and according to the manufacturer's recommendations it expired about a year ago. Thus I had a choise - whether try to purchase some silicone or to try to work with the one I have and make some experiments with it. Omitting unnecessary details, we'll move on to the second option.

First I wanted to understand, what's exactly wrong with expired silicone. The first thing to notice is that it is really dense! The stick I stuck into it was falling really slow!

Well, let's keep experimenting! What if it's ok and we still can cast it despite it's increased density?

Not that fast! When we add the hardener, silicone's density increases instantly, so it is really difficult to stir it well. Because of this it's not well mixed with hardener and when some parts herden, the other are still liquid.

That is the result

Something makes me think, I made couple mistakes in process but the result (I left silicone for 20 hours in the plastic cup where I stirred it with the hardened) looks like this:

Obviously, I have some problems but obstacles train the temper, so let's move on. If shopbot-machine is unaviable at the moment, let's try ti use the modella. And also I desided to make some more experiments with our timed out silicone.

Being resolute, I continued my experiments!

And this time the result was not that bad:

And this time the result was not that bad:

Though, in the very bottom of this plastic glass silicone remains liquid even in couple of weeks after the experiment.

THE PICTURE IS ABOUT TO APPEAR HERE!!!

It seems, that I didn't stirr it well enough. The situation is getting clearer and now I have better understanding of what I need and what I don't need to do to succeed! That's good!

I decided to make the 2.5D-mold of "@" symbol (because it's simple) using fabmodules (Thanks to Denis for borroving his mac for that!)

That's the mold:

It was machined on modella with 3 mm ball-nose tools from blue modelling wax we had in our lab.

That's how it looks like when it's casted:

And that's the same in 20 hours

And in 50 hours...We finally have the result!

|

That is the cast itself! |

And that is the ice-figure I casted it it! It's cracked but STILL COUNTS! :) |