How to make a composite

I decided to make handles for my final project, so firstly I make a handles from wood using CNC router.I used two kinds of mills and thick (40 mm) MDF. First mill was conical and the second was 8 mm end mill:

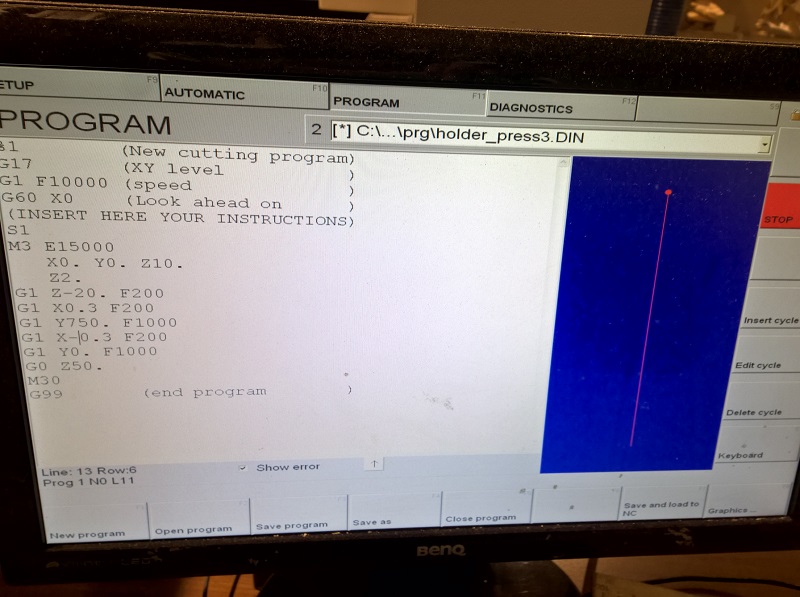

Using these mills and manually created g-code I made mold:

G-code:

M3 E15000

G0 X0 Y0 Z10

Z2

G1 Z-3 F200

X720 F600

Y20

X0

Y0

Z-6 F200

X720 F600

Y20

X0

Y0

G0 Z50

M30

and

M3 E15000

G0 X0 Y0 Z10

Z2

G1 Z-20 F200

Y 0.3

X750 F1000

Y -0.3 F200

X0 F1000

G0 Z50

M30

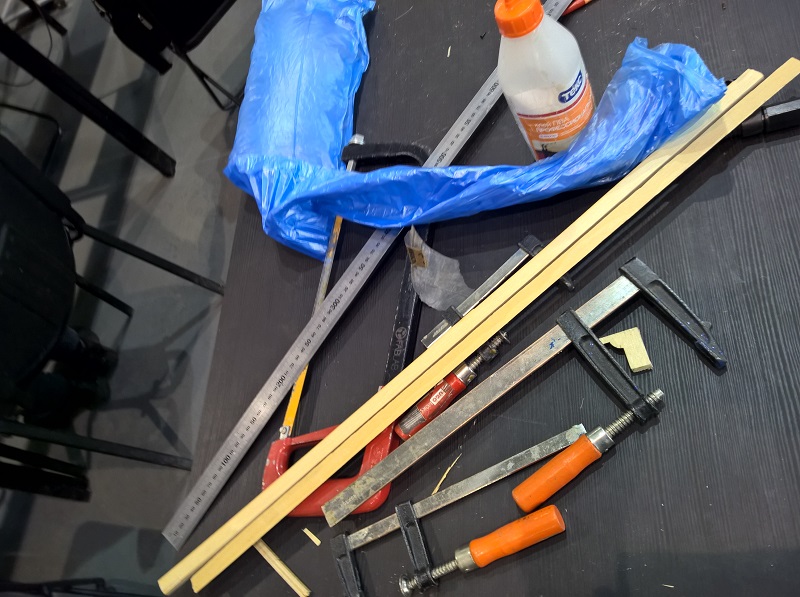

I made handles from two glued plywood parts and form for making a composite.

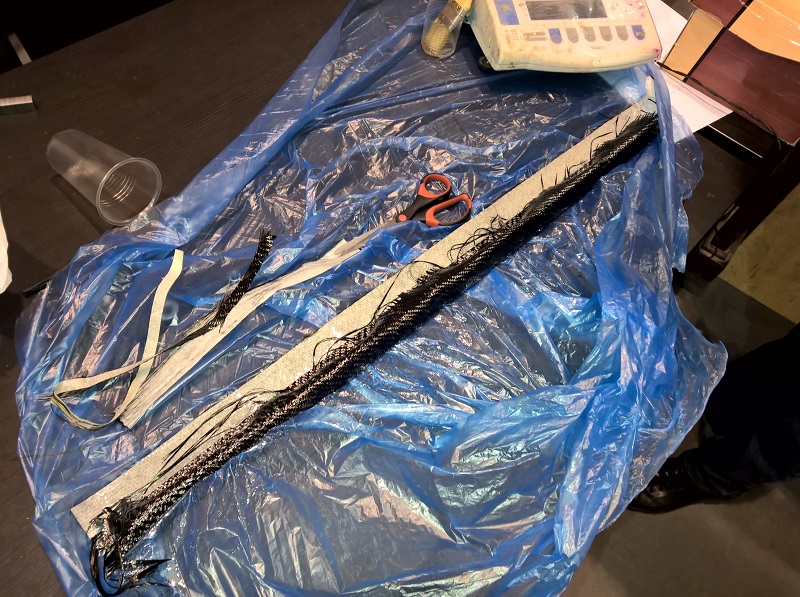

For creating a composite I used carbon texture and epoxy. I mixed the epoxy and used brush to coat the texture with epoxy (be careful and use respirator and gloves during the work). Use tape and sharp scissors to cut carbon texture otherwise the edge of the texture will not be smooth and straight. I covered my wood long handle with composite, put it inside the form and fixed by board:

After two hours I took the composite from the form and cutted it into several pieces:

As you see, there is a fring of texture in several places because they weren't covered by the epoxy well (it's my fault).