Computer-controlled cutting:

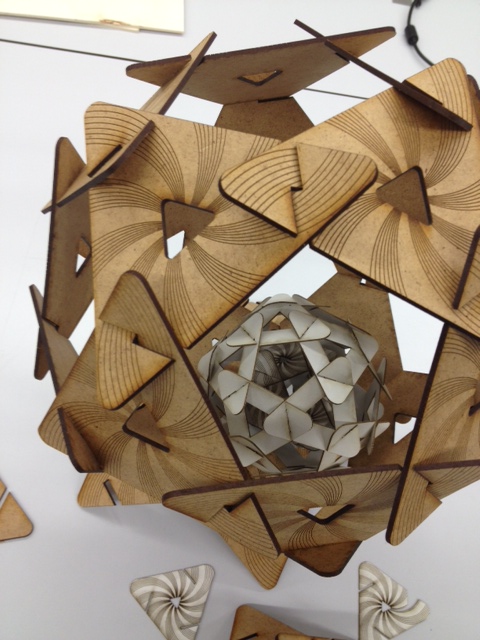

On this assignment it was requested to design and fabricate a press-fit construction model.

I´ve started by doing some research and "google around" for inspiration and references and all that took me to discover some math masters on engineering like

Chuck Hoberman

and origami folding like

Yoshinobu Miyamoto

all such amazing and truly remarkable and worth to further explore into detail.

Due to the short time to acomplish this assignment I took reference the also beautiful and interesting work of

George Hart

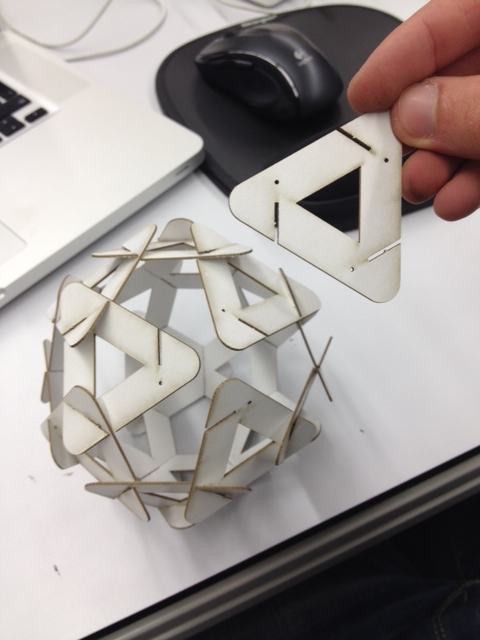

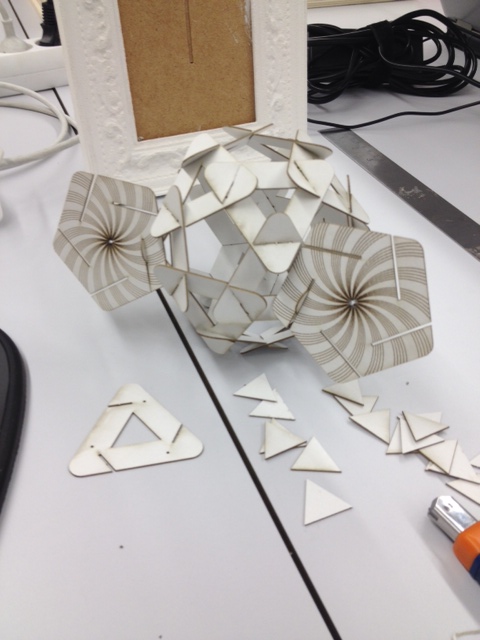

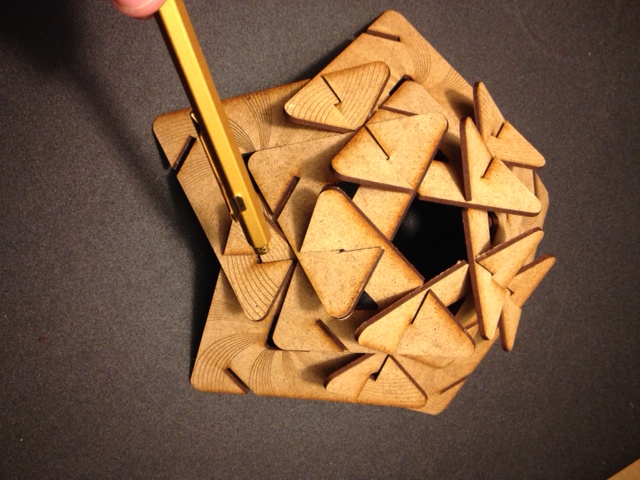

to draw and fabricate a 3D model that I could assemble on time.

I chose to try out rhino+grasshopper parametric modelling to design a single definition that could represent all 7 shapes presented on his "slide-together geometric paper constructions".

Here´s a quick video for the grasshopper definiton (still under development and refining) that created the first triangular shape on paper.

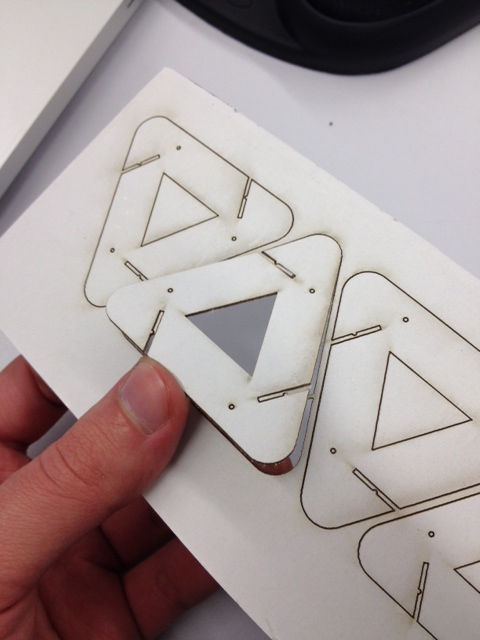

After laser cutting one small set on bristol thick white paper I got all excited with the result. However the laser cut operation is not an 123-done process cause it depends on many small set up adjustments like laser power, speed, frequency (clean laser lens!) as well depending on the cut material properties (a sheet of material is never 100% flat uniformly and that can result on different shapes that remained fixed an not cutted when laser finishes its path).