| Index About Me |

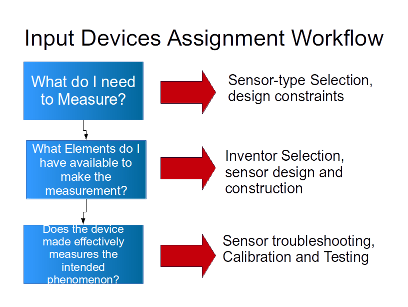

Input Devices AssignmentThis assignment was significantly frustrating and the learning curve for it has not been entirely gone through as I am writing this, a lot to do left.For this particular assignment, the work was clear, measure something, the real thing about it was in the how, so I made this first approach to a workflow before starting:

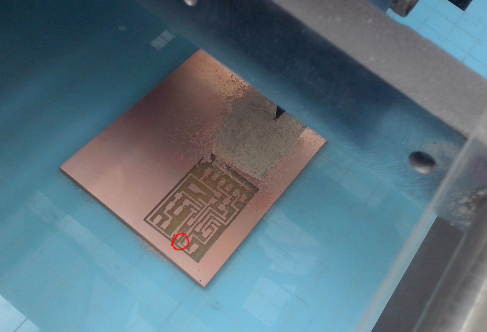

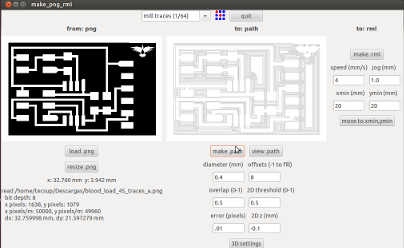

Then, it was time

for the other board, this time I used directly offsets = 5, learning

from previous experience, however, other problems occurred. This time

the double contact tape was not properly bonded into the milling

machine table, so, eventually it got loose and I lost the milling.

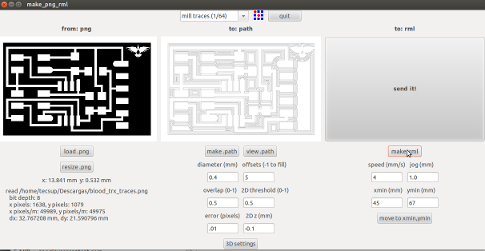

Finally, I got it

right and milled the board, however, as I was removing it, something

curious happened, the traces were milled at a particular angle. So

finally, after trial and error, I got two boards made, one almost made

and one completely lost. It was time for soldering. But first, get the

parts for the assembly.

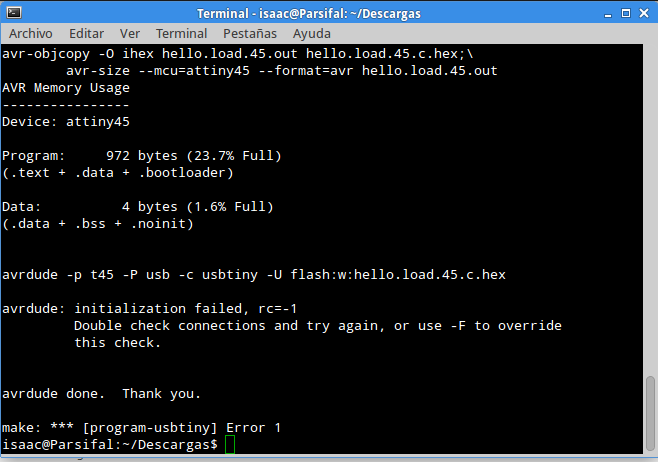

Welding was, apparently no problem, since the parts were quite simple, in the space of time I had in the lab I was able to weld completely the load and txrx boards without incident. It was time for testing. So I downloaded the C code and makefile for the boards and tried tu run it using my FabISP board without success.

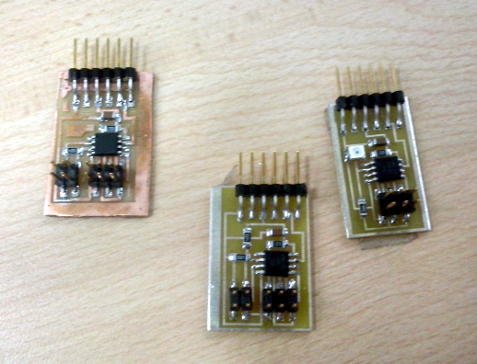

The welding, it was now

clear, was not as well done as I supposed, to checking again was in

order, however as I was reviewing and resoldering some parts of my txrx

board, one of the traces got loose and the connection was lost, so long

to my board. Fortunately, Roberto had some spare boards I could work

on, I got soldered another txrx and a light board:

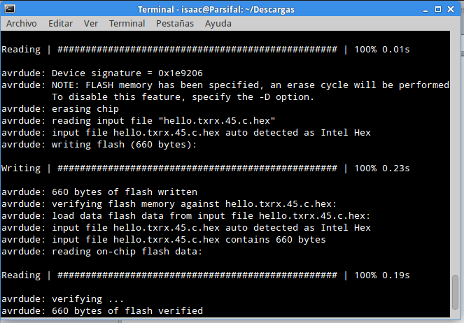

So, time of truth, to see of the soldered boards were actually functional. I tried the hello C code for each board, without success... again. So it was time to recheck, review and redo the soldering, until I got those boards running right. It took a while, and I was specially careful checking on the Tiny 45 pins. In the end, I may never really know which solered pin was the faulty one, or if I tripped welding a resistor or a capacitor, but, however, the boards worked.

In order to program

the boards, both FabISP and the AVR ISP Mk II were used, as I was not

entirely certain that the connections were right, I used the AVR ISP to

check using the LED in it.

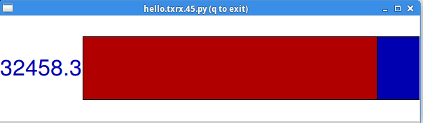

After finding that everything was set right, I downloaded the Python scripts for operating the sensors and started working with them and checking how the measurement works. They worked fine. I checked all three boards using the Python scripts, first he TxRx, using a pair of copper plates connected to some wires to the board, the readings changed as I pressed them.

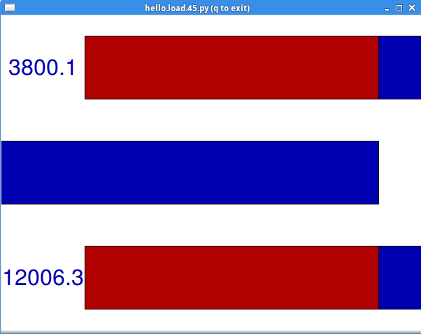

I used the same

plates to test the load sensor, this was not as responsive as the

first, probably becasue of the system used.

Finally I checked the hello light: To-Do-Prepare a customized board to make an acceletometer sensor. -Get my Fabbed Arduino Board done, more to come in the "Output Devices" assignment Conclusions?Design, Design, Design... Still a lot to learn about this Second, No matter how simple the board, soldering is Key Third, this i cannot emphasize enough,read the datasheets before making the boards Fourth,

as previously stated, take into account Hofstadter's law into

assignment planning, it -painfully- works. |