Electronics Design Assignment

This assignment was in its own way, very interesting, as I was able to

get out of my comfort zone and learn a little more about electronics.

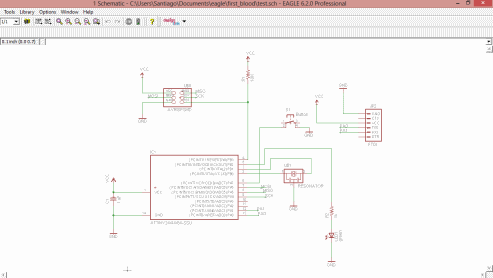

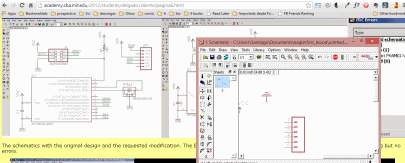

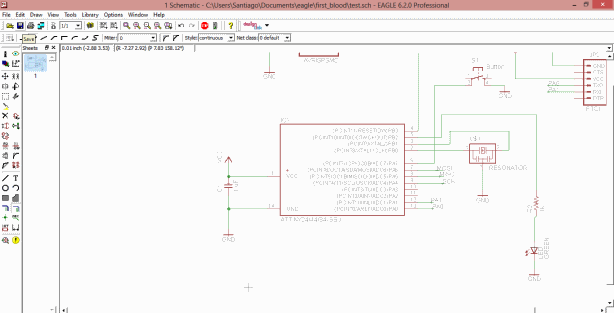

We first started from the Hello Board:

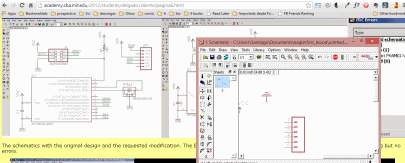

As I was

designing, I used the Board Reference model in this stage, which

helped. The ERC check showed warnings, not errors..

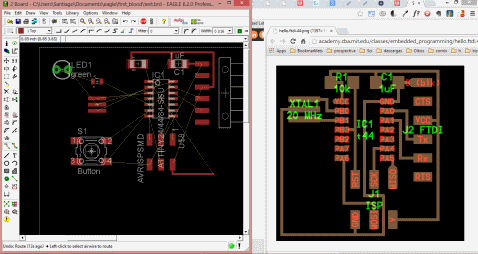

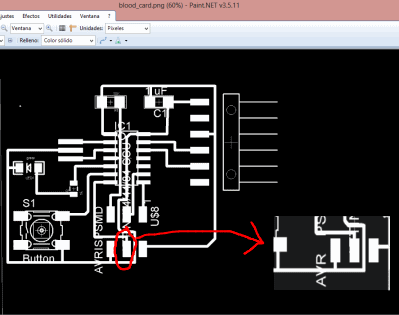

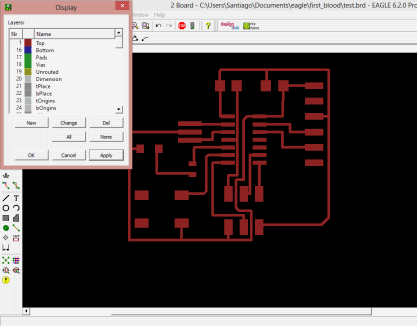

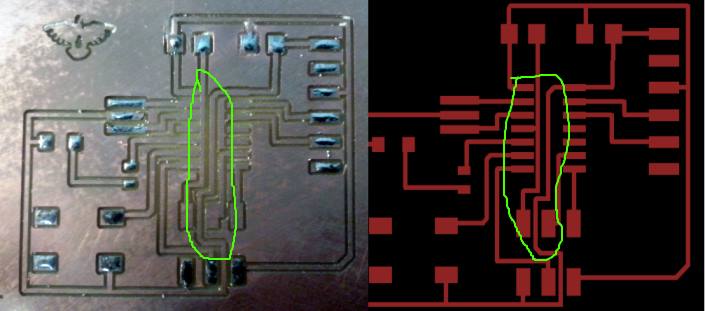

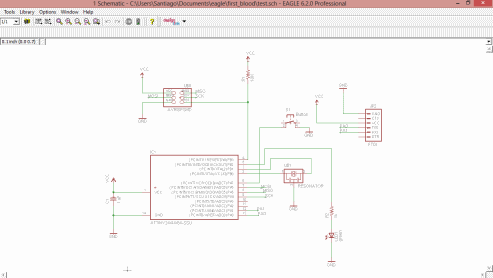

At that point, I did not know how to select which design layers would

actually be exported for the milling, so I ended with a PNG that would

need a lot of work erasing and cloning pixels to get it to proper

shape, fortunately, a friend helped me to correct this mistake. Still,

befor doing this, I realized I had made a few blunders in the milling.

Marked in red ther is a track was not properly designed. Correction was

in

order.

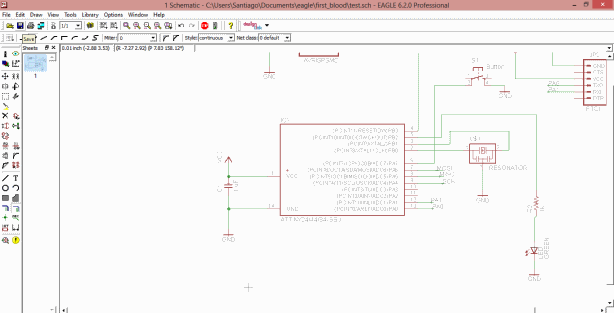

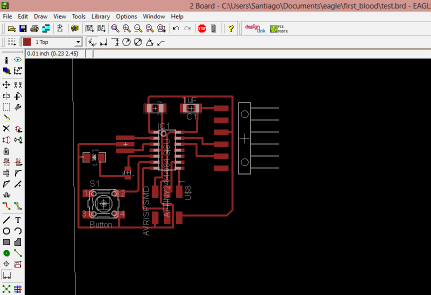

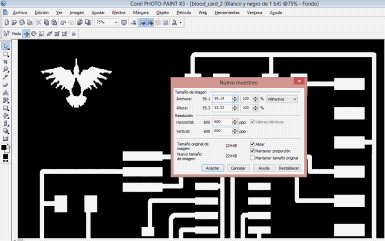

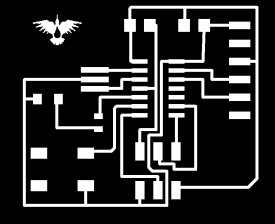

After correcting

the mistakes and selecting the proper layers, I had a PCB 90% ready for

milling:

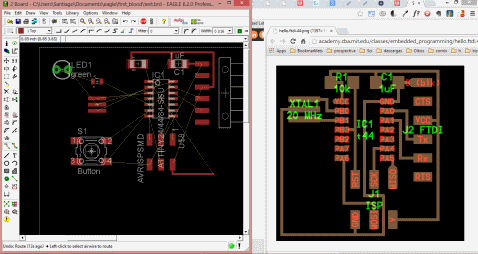

Just added a logo using a photo editing software and then I was ready

for milling.

I made two versions of the card, one as-is and other one with the same

dimensions as the hello board PCB in the academy website, in the end,

it was not necessary.

The milling was not to be without incidents, as the first plate I put

in the modela was not bonded strongly enough, and got loose as it was

milling, Modela 1 - Isaac 0.

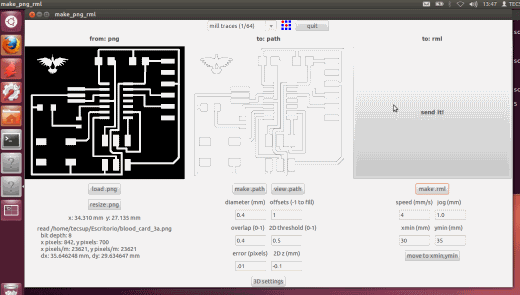

After placing a second plate and checking it was properly bonded, it

worked, although the z-calibration was not optimal and the

tracks were not in its optimal shape, had to try again. The second

time, the tracks went better, but some residues were still in the

tracks, so some sanding was made before the plate could actually be

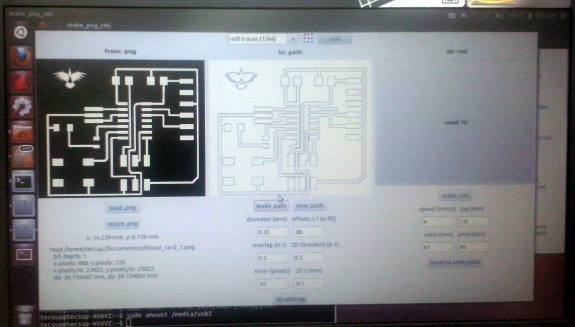

welded. But first I had to cut the plate using the 1/32' mill, for this

I created a new frame for cuttng:

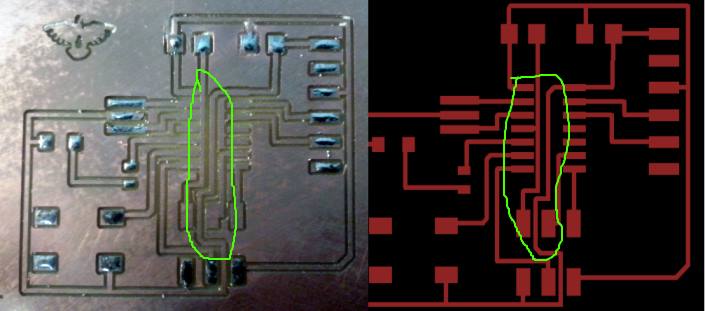

With this I had the plate ready for soldering... or so I thought. As I

was starting to add flux to the terminals I realized the center track

touched all of the Attiny terminals in the left side, when It was

supposed only to touch the fourth from the top, so the most

analog solution was to cut those threads using a scalpel, available at

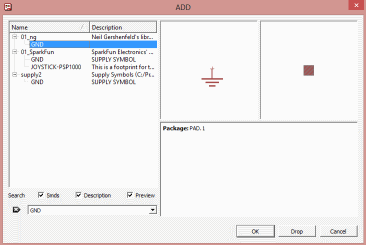

the lab. As a sort of Plan B, I modified the PCB design and changed the

routing, since what caused this was sending too many routes through the

center, under ther Attiny chip.

Modified Routing.

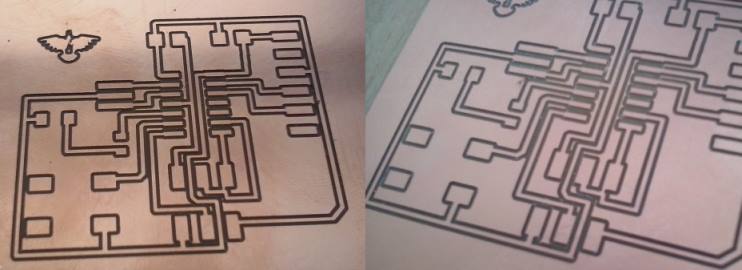

Afterwards, I sent the new design to the Modela, this time without

incidents.

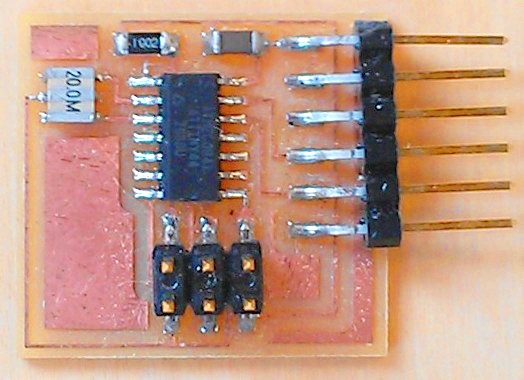

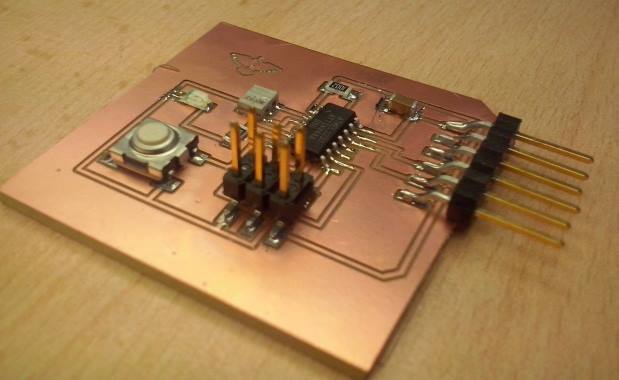

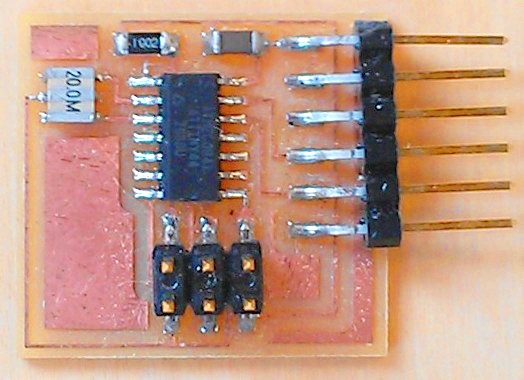

This time the tracks were well milled, no copper residues, no missing

tracks or separations:

Welding, as in

assignment number three, proved somewhat difficult, in particular the

resonator, since you need to solder all of the terminals underneath

it,and your visibility is not the best to do this, however, after some

fully-focused work, it was done:

As a sort of conclusion, I will say that, even though I learnt much

about electronics, there is still much to be learnt in order to get

succesfully to the final project, also, The timeframe was not enough to

get to the circuit simulation, since the learning curve of the

necessary sotfware is somewhat steep.

|