This week's assignment

Measure something: add a sensor to a microcontroller

board that you've designed and read it.

The plan

Make the synchronous detection spread spectrum board

and experiment with that for possible use as a proximity detector

(for bird feeder project). I believe it may not have sufficient

range for the application but it will force me to learn the

concepts and coding related to this type of input device.

References

The AS220

tutorial is an excellent reference for this week's

activities.

Fabrication

The board was fabricated on the Modela milling

machine as outlined in Electronics

Production week.

Assembly

The components were assembled and connected up as

shown below.

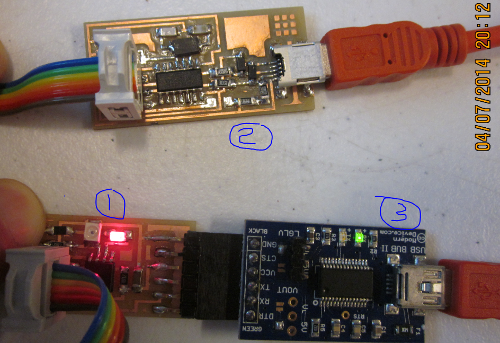

1. Hello Reflect board (newly assembled)

2. FAB ISP (previously assembled)

3. USB/Serial Interface board

Programs and Initial Checking

The following steps were taken to download programs

to my PC and perform initial check on the board.

Python 2.7.3 for Windows 7 64 bit was downloaded.

A path for Python was added using the instructions in tutorial

above.

The corresponding version of PySerial was downloaded.

Tkinter for Windows was downloaded.

PC was rebooted.

Connections were made as shown above (2 red USB cables going to

PC).

The bootloader was downloaded in Arduino environment (Arduino had

been previously downloaded).

Board is AATtiny 85 with 8mHz internal clock.

Programmer is USBtiny ISP.

LED came on and everything seemed to work so far.

Initial Programming and Debug

A modified version of the AnalogInOutSerial

Example program was run in Arduino. The modifications were to add

the software serial code and assign the appropriate LED and Sensor

pins. The purpose of the program is to read the sensor and LED

values and output them to the serial monitor.

Having set up and run the program, it was found that the values

being returned were the highest possible values (1023 and 255).

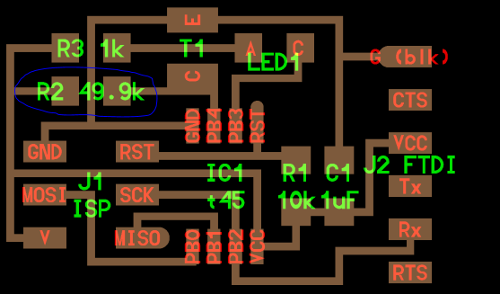

Inspection of the board showed that the resistor at R2 was an

incorrect value (49.9 labeled "49R9" versus 49.9K labeled "4992").

Board layout showing suspect component location

Once this component was removed and replaced the

board worked with dynamic output numbers on the serial monitor.

Those numbers changed with varying amounts of light/shade on the

LED and Sensor.

Further Programming

I ran Neil's hello reflect C program through the

Arduino interface (cut and paste code). This did not work at

first.

We experimeneted with the #define bit_delay_time and found that a

value of 98 worked.

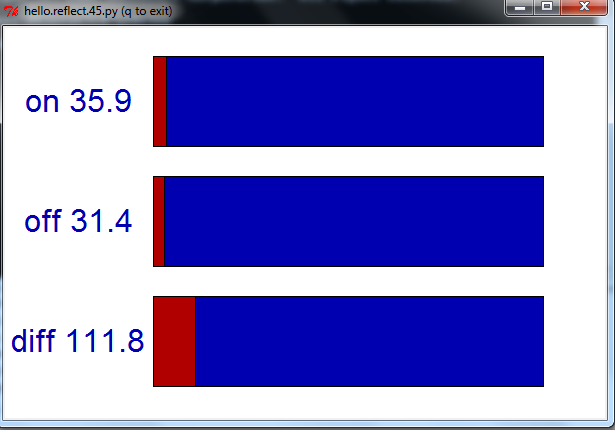

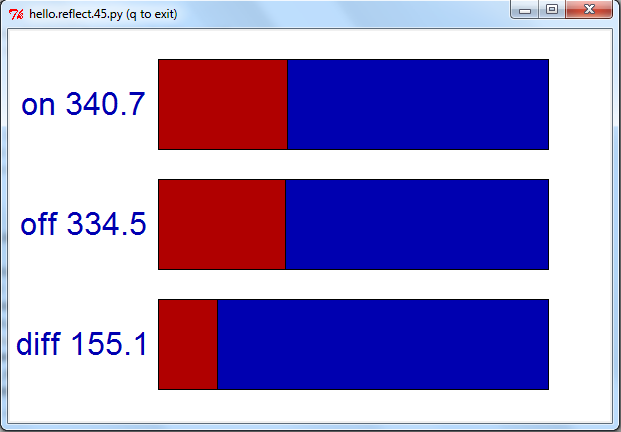

In parallel, I ran the Python file from the Command Line to

capture the output (see below).

Python Output with "regular" light

Python Output with finger in proximity to

LED/Sensor.

Also this week

I started work on the Raspberrry Pi board by

downloading all the software on to a SD card and also procuring

the correct power cable. I will work on this as we move forward

since it will be part of my final project for capturing images.