This week's summary

This week's exercise was to fabricate and assemble an In System

Programming board using an existing fab lab design.

At a high level, this board (once programmed) allows you to

program other boards that will be made as part of fab lab.

Fabrication Notes

The board was fabricated using the Modela milling

machine.

Traces were cut with a 1/64 inch diameter bit.

The outline was cut using a 1/32 inch diameter bit.

We used the existing settings for speed and depth on the machine.

The material was FR1 which is in effect a 2 layer board.

Traces were cut on one side only.

The material was secured to the bed using double sided tape which

worked well.

Changing the bits is relatively easy but a little tricky at first.

Assembly Notes

I had some prior experience soldering so after a

rocky start I got the hang of it.

It is important to use flux to assist in the flow of solder.

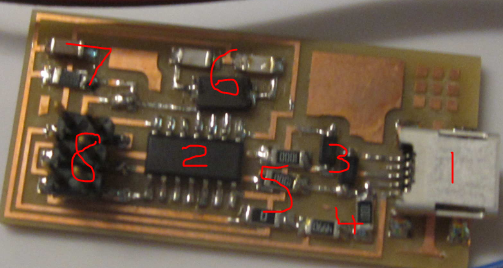

Order of components - USB connector first, IC second, then other

components from center to outside of board (photo at bottom of

page).

Tape the board to the workbench using double sided tape.

I found it useful to tilt the board towards me at approx. 40

degree angle when soldering the USB connector (taped the board to

a piece of bent cardboard).

Don't be afraid to create bridges, they are easily removed using

braided wicking material.

Connections can be checked as you progress using a continuity

meter.

The Outcome

Miraculously, the board worked on first attempt and we were

able to download the program.

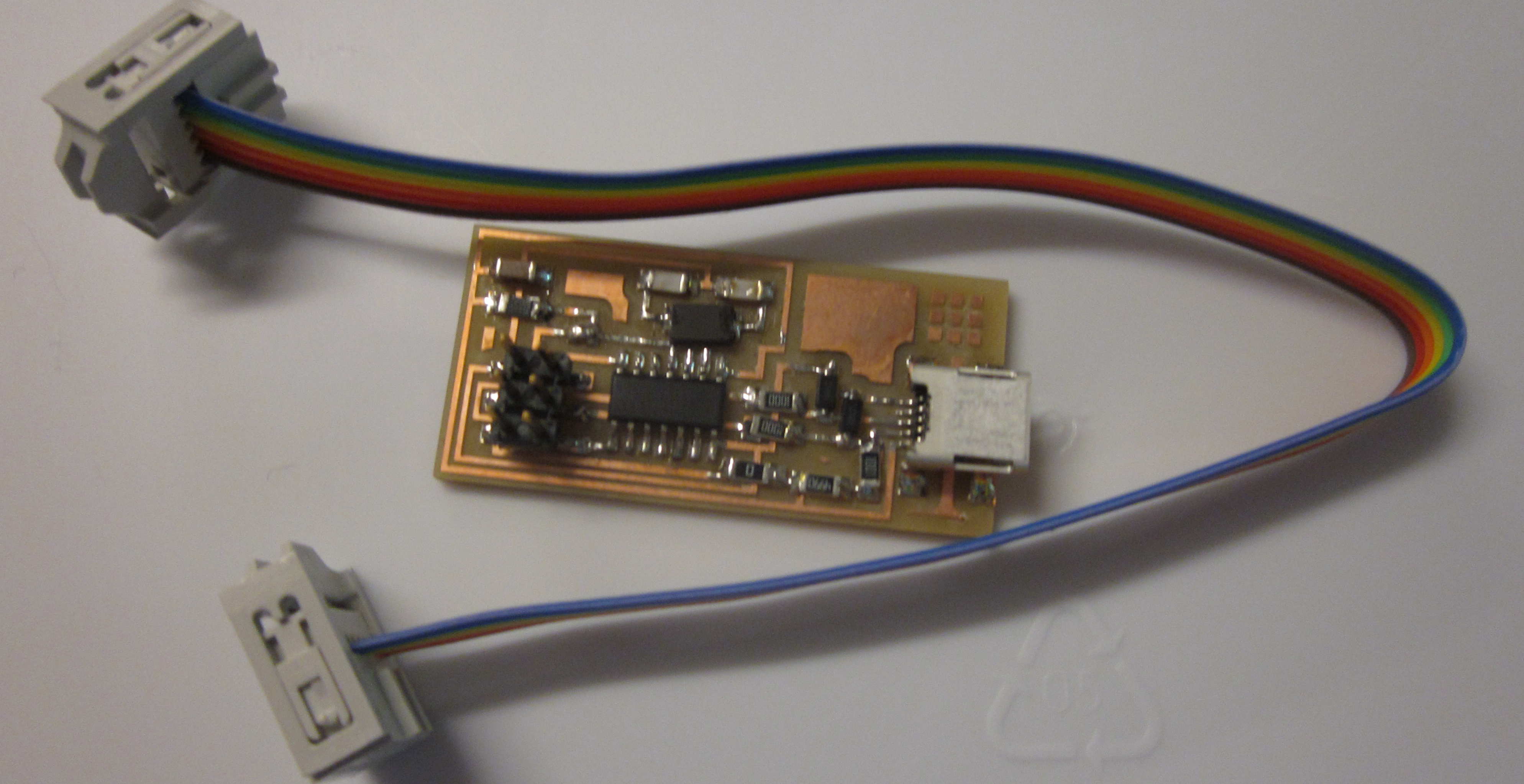

We also built a ribbon cable which is a simple process.

Other Ideas and Reference

For future projects on assembly, we may try to

create a stencil to screenprint solder paste on to the board and

then reflow in an oven.

Challenges

The assembly soldering process was not trivial. I found it best

to follow the order shown below. The USB connector is the hardest

part and you need maximum access to solder it correctly.