Molding and Casting Assignment

Week of March 26, 2014:

This week's assignment is design a 3D mold, machine it, and

cast parts from it. My garden and geese could use multiple

scarecrows/scarelions as there are fox and coyote in the

neighborhood. My plan is to design a stylized lion face,

cast it from HydroStone and embed reflectors into the facial

features. I will add a mane of Mylar ribbon for more startle

effect. |

1. I found a lot of lion faces and also cast lions via

Google Images but this Dreamstime.com lion was the most

inspiring to me.

|

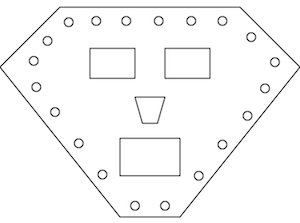

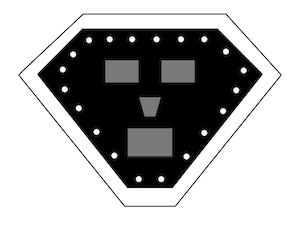

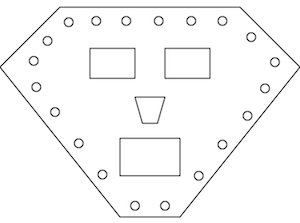

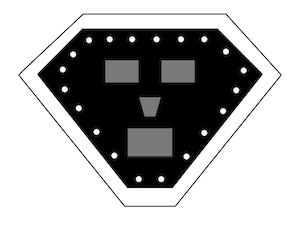

2. I used Photoshop to create a grayscale image 500dpi and

saved it as a png.

|

3. Then I transformed my 2D image into a height map.

|

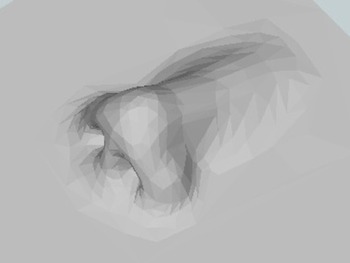

4. Everything changed when I had the blocks of wax in my

hands - the size of the block became the limiting factor and

my lion face modling and casting project moved to the

Shopbot as my composite project. I decided instead to

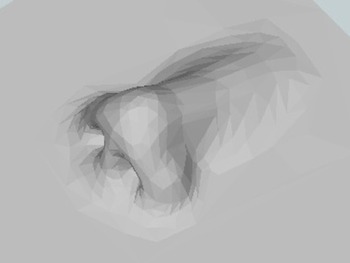

fabricate a nose. Shawn helped me locate a nose.stl on

Thingiverse and then we converted the stl to a png.

|

5. The 90 minute rough cut milling process took six and a

half hours to complete. The cable between the Modela and Fab

computer was suspect at one point. Several starts and sstops

were due to the drill bit or collar rubbing against the side

of the mold. A utility knife took care of that. I learned to

slide a piece of paper under the drill bit to set the z

axis. The smooth milling took another two hours. But at last

I had a wax mold.

|

6. Creating the Smooth-On rubber mold was a far less time

consuming step.

|

7. My error - I let the Smooth-On plastic cure for 2 hours

instead of the 15 minutes as directed on the package. More

was not better. I thought the rubber/plastic combination did

not need a release agent. I had to carve the rubber mold

away from the plastic nose with a utility knife and I had to

start again with a second rubber mold.

|

8. At fifteen minutes (package directed time for curing),

the plastic was very sticky and still liquid under the

surface. At twenty-five minutes, the plastic was solid but

still warm, the exothermic curing reaction still occurring.

AND the plastic was definitely "stuck" to the rubber. I'm

wondering if the reagents have been compromised because they

were stored at temperatures cooler than 70 F. Plus the

packaging reminds us the shelf life of the materials is

short...

|

9. I'm wondering if the reagents have been compromised

because they were stored at temperatures cooler than 70 F.

Plus the packaging reminds us the shelf life of the

materials is short...

|

10. Here is the rubber mold, iteration three, with the wax

mold a little worse for the wear. The rubber mold has five

coats of universal release agent upon it and is far less

sticky to the touch.

|

11. Nose success - universal mold release was the missing

ingredients. Curing time was 25 minutes, not the 15 minutes

on the package directions.

|

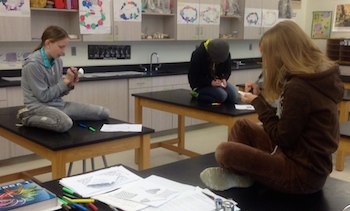

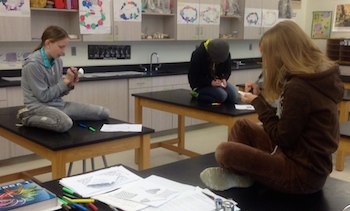

12. Eventually I will create a

classroom set for my students and they will decorate them:

some "hot" because the nasal passage warm the air we

breathe, some "wet" because of the moistening function, and

some like screens or nets or colanders, etc because of the

filtering function. Here are the first three noses being

worked upon by students.

|

5/16/14 - Here are the students' noses up close.

Mickie Flores Home

|