Electronics Design

Assignment

Redraw the echo hello-world board, add (at least) a button and

LED (with current-limiting resistor), check the design rules, and

make it.

Ideas and Approach

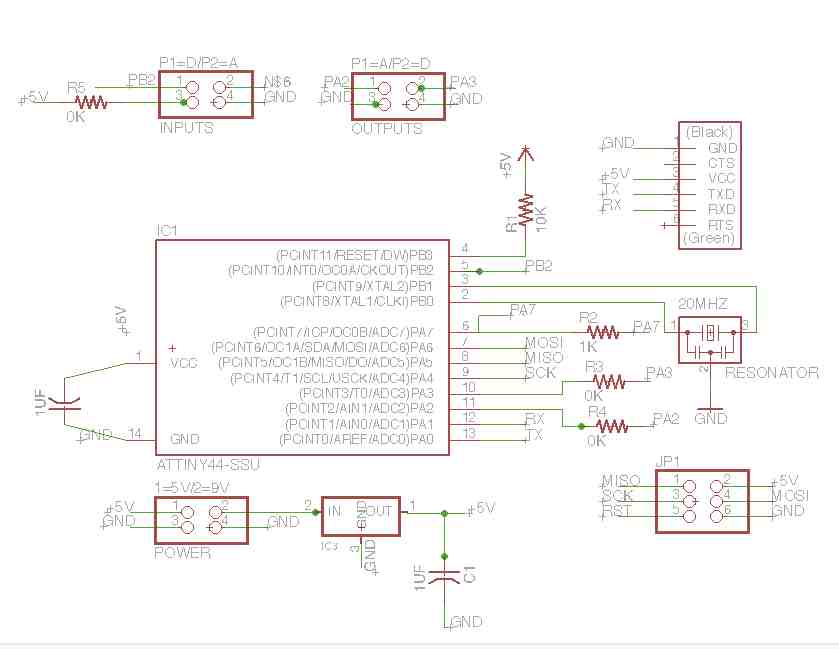

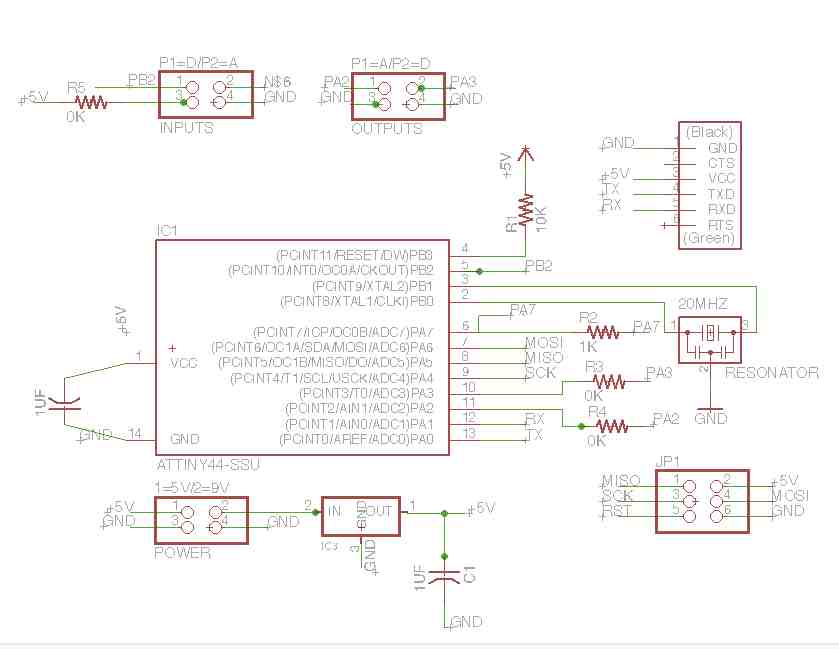

I decided to make a board that would be quite versatile. I

wanted to make it so that I could exchange inputs and outputs to

test certain components. To that end, I wanted to have 2 2x2

headers (one for inputs and one for outputs). And with each

of these headers, I wanted to have one analog and one digital

"port". That way I could easily attach new components and

test. I am ultimately hoping that this is something I can

use to teach students how all this works using simple connections

(e.g. just connecting a component to a header).

Design Files

Steps Taken

On the Thursday night after the class, I headed down to AS220

where Shawn (our awesome TA), gave us a great rundown of

electronics/electrical components.

|

|

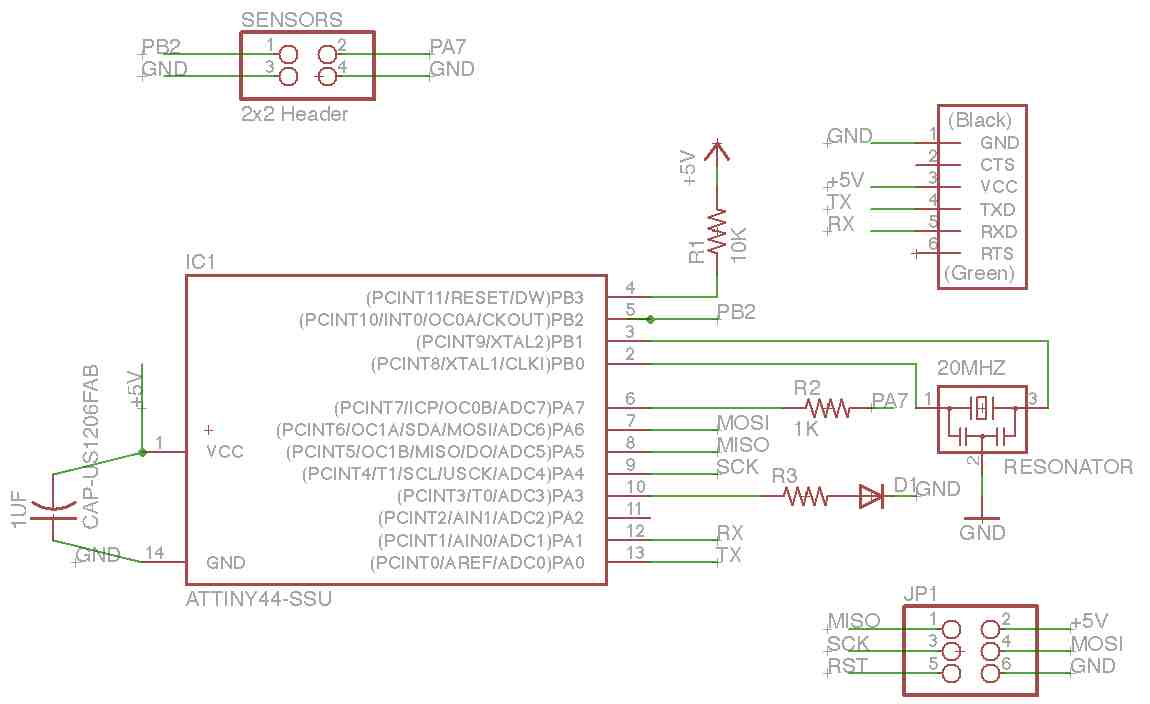

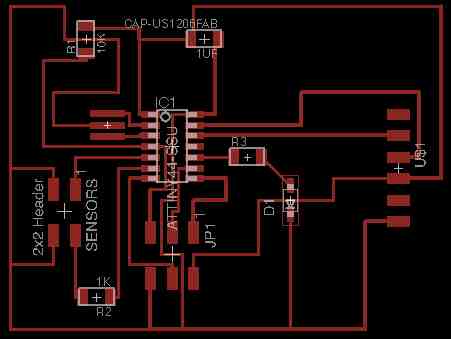

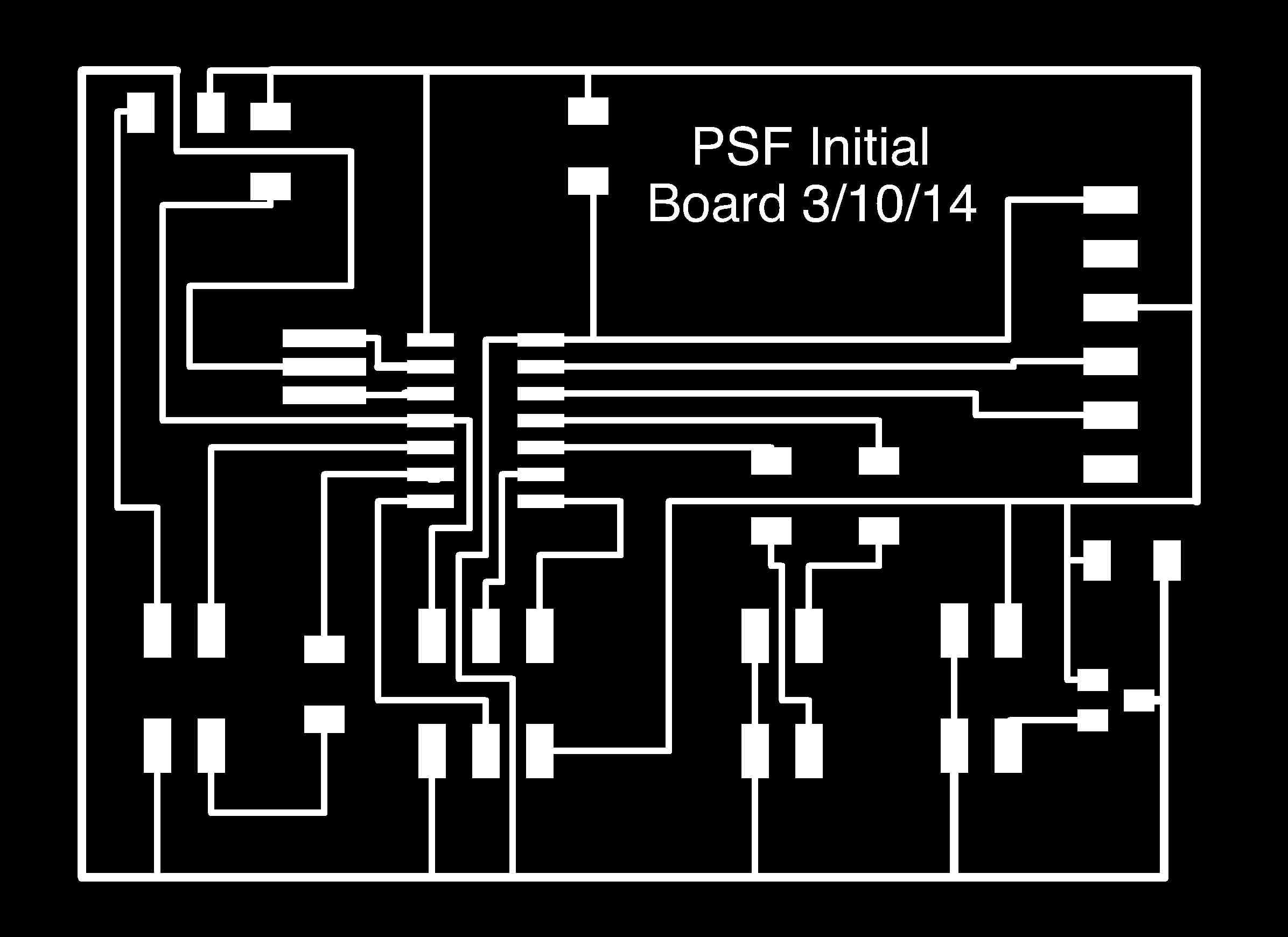

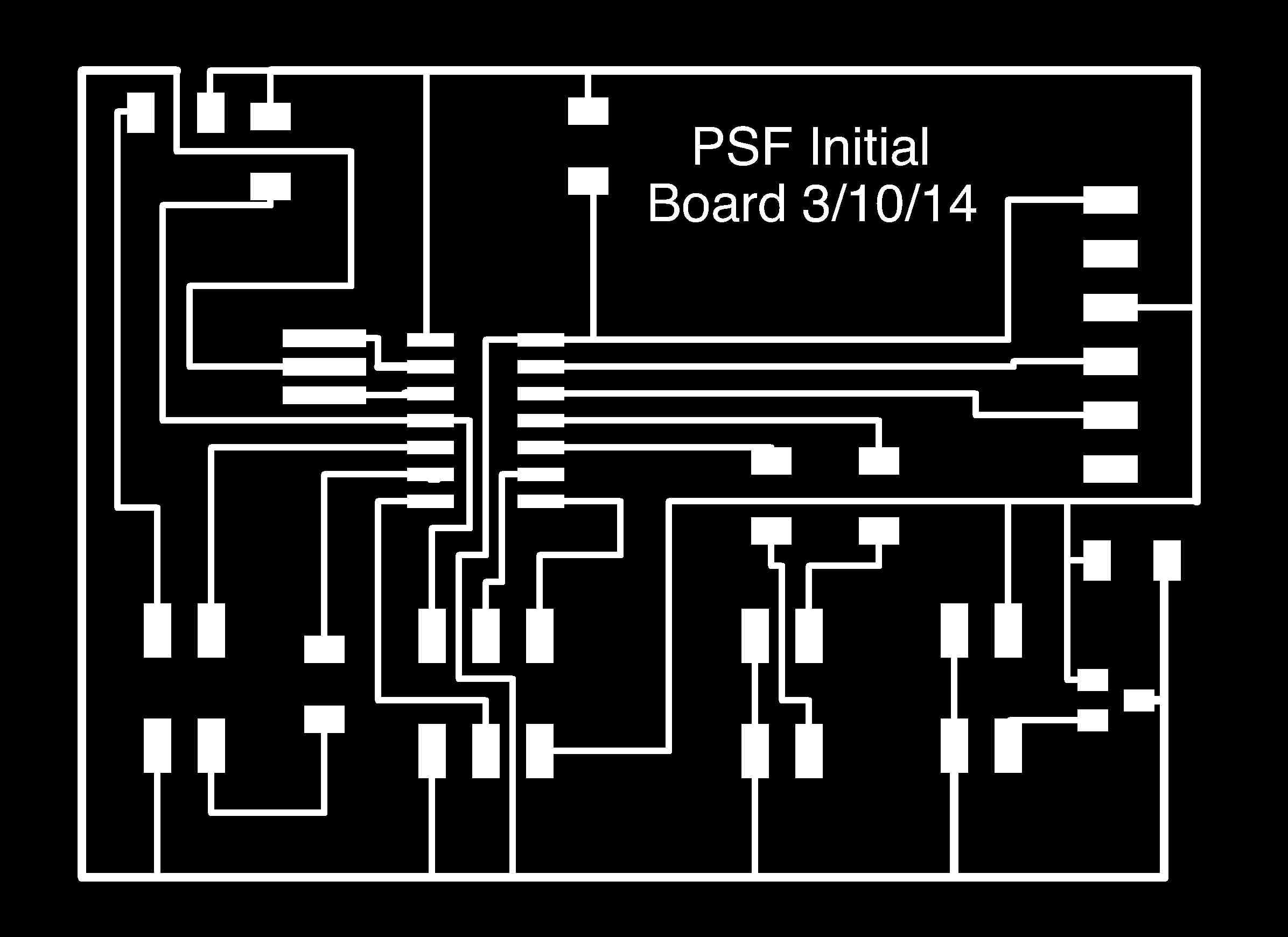

Here's my first draft after leaving

AS220. After not thinking about it for a day and a

half, I went back and reviewed what I had. I realized

I had a few things that were wrong or could be better...

1) There were some traces I realized would be near

impossible to solder. For example, the following

connections/traces wouldn't really work because they had

interior connections that I wouldn't be able to solder...

- pin 9 of the ATtiny

- pin 4 of the 2x3 jumper.

- pin 3 of the

...wait...now I feel like an idiot. I am wrong.

The big areas are the pads that will be soldering to so it

doesn't matter what side of the pad the trace comes in

on. Doh...

2) I realized I should label some parts so that I'd know

what they are when attaching things later on. For

example, I should mark which jumpers are for each pin.

3) I realized there might be some places that I could add

more space to make the soldering a bit easier (e.g. the

crystal & ATtiny are REALLY close). I realize the

crystal needs to be close, but I can move it a small amount

to the left.

4) I decided I want to add a second 2x2 header for outputs

(one analog and one digital).

|

|

|

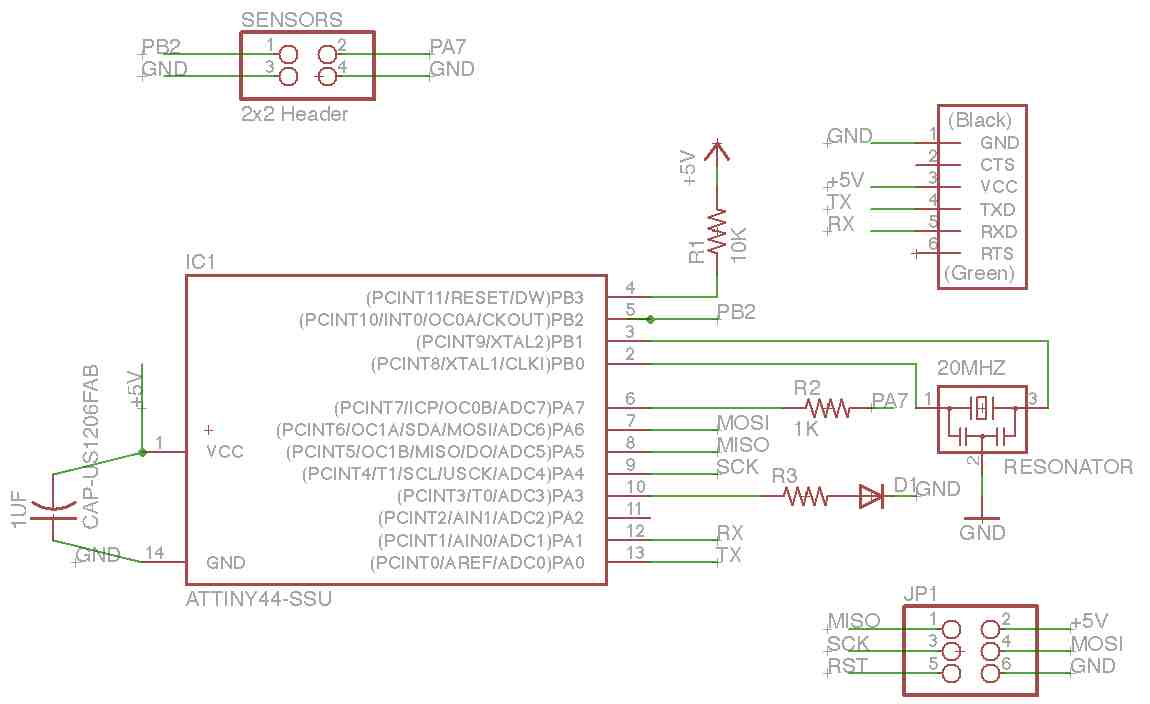

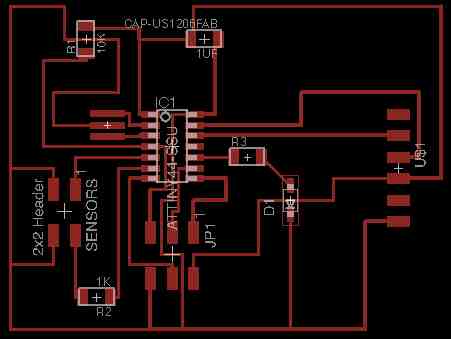

1) I did the pull up resistor wrong. In

general each Analog input needs a +5 (for pullup), GND and

Signal value when doing the header.

2) My R3 resistor wasn't doing anything of value so I

changed it from 1K to 0K ohms (thanks to Shawn for

explaining this).

3) I found I was wrong about labeling. It turns out

you don't want the labels. It messes up the traces if

the words go across the board. Obvious when you go to

mill the board and you see the pictures.

4) My regulator/capacitor connection was wrong. I

through it was supposed to sit in serial in between the

regulator and +5V. That's wrong. It is actually

supposed to be in parallel.

|

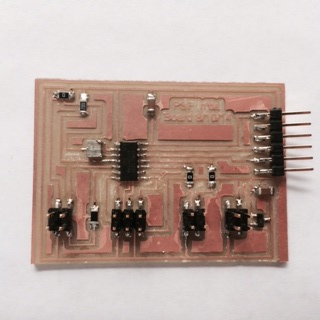

Once I had the board design, I milled out the board and stuffed

it. Here was the final result. I felt much better

about this one because I ended up getting it right the first

time. No jumpers. No big mistakes. And when I

plugged it into the programmer...yeah!...I was able to burn the

bootloader.