3D Printing and Scanning

Assignment

Design and 3D print an object (small, few cm) that could not be

made subtractively. Also, 3D scan an object (extra credit: print

the object and make the scanner).

Ideas and Approach

I have been fortunate to have been able to make a few items this

year with our school's Replicator 2X and Digitizer. That

being the case, I decided to work on three different challenges

this week...

1) Create a part for a new "exploratorium" wall at the school

where PK/K students will build marble wall for constructing a cool

sculpture.

2) Scan, cleanup print/generate a simple 3D object (a Dunkin

Donuts cup), and

3) Take a 123D Catch scan of myself and, after cleaning up the

model, printing it.

Files

Steps Taken

Marble Parts

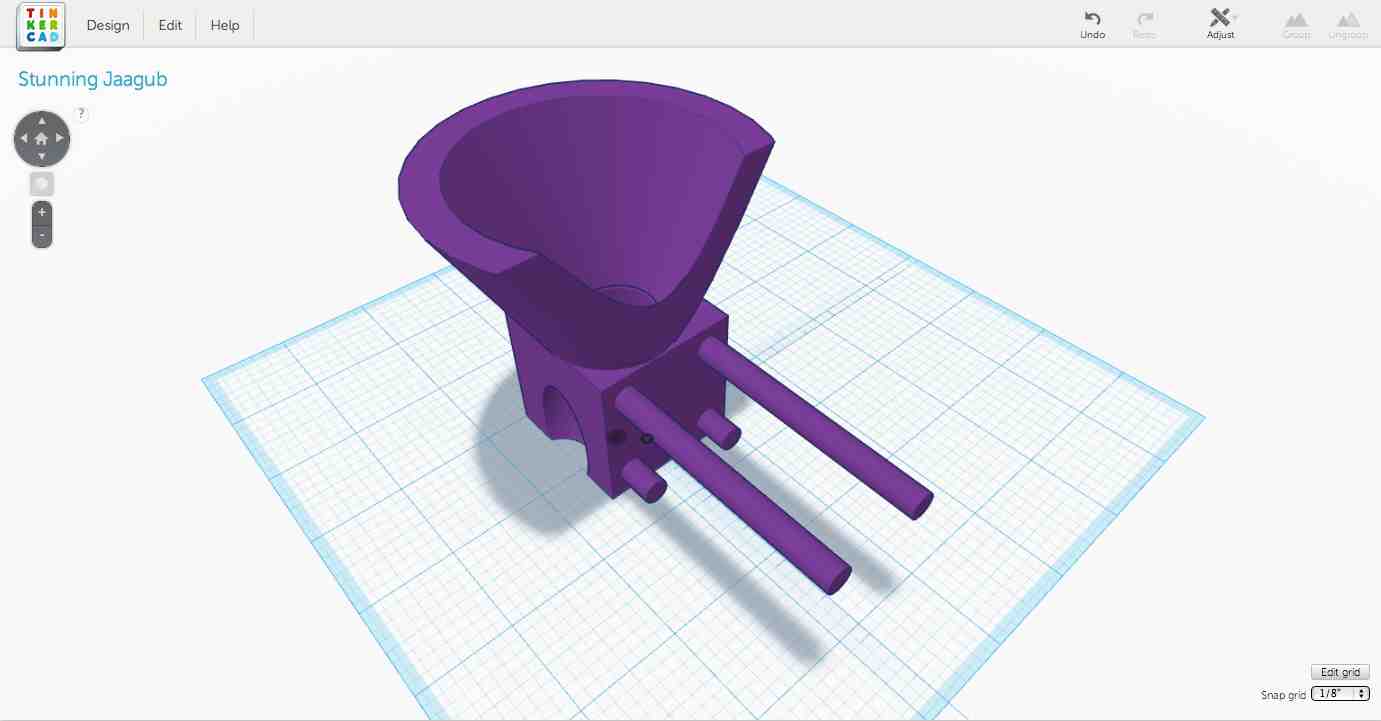

For the first part of the assignment I decided to help a fellow

teacher who wanted to create a "marble wall" for students.

|

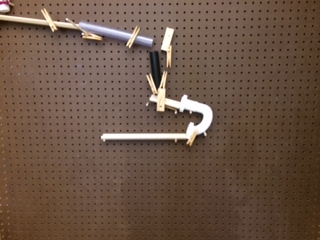

Here's a creative "marble wall" that our

primary school librarian is building. Her goal is to

make a wall where students can create a contraption that

will move the marble down the wall. Her hope is to

make this a way to explore everything from angles to

probabilities to simple physics.

Given this week's assignment, I thought it would be cool to

make something that would catch the marble and redirect

it. It needs to have a hole for the marble to fall

through and then a path that will redirect the marble back

or straight down.

|

|

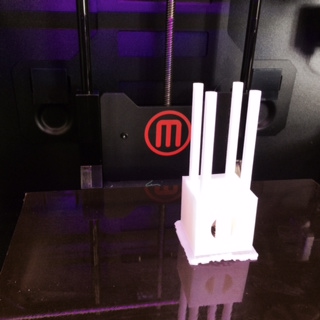

Here's a printout of my first draft. It

has a few issues...

1) The prongs are long because there are two sheets of

pegboard (they put one behind the first to make the pegs

more secure). The thing is, they aren't perfectly

aligned, which I didn't realize until I tried to mount

it. FIX: In the next round I am going to shorten the

bottom ones so they only need to go through the first piece

of pegboard.

2) I felt like a total idiot, but I didn't realize the

bottom hold pushes the marble out "the front" rather than

through the side. FIX: Rotate the hold to the left or

the right.

3) The hole is the right size, but the marble flies right

over it. FIX: I need to add a backstop that acts like

a funnel.

|

|

Here's another picture of the first draft

mounted on the board. Some of the issues mentioned

above are more easily seen here.

|

|

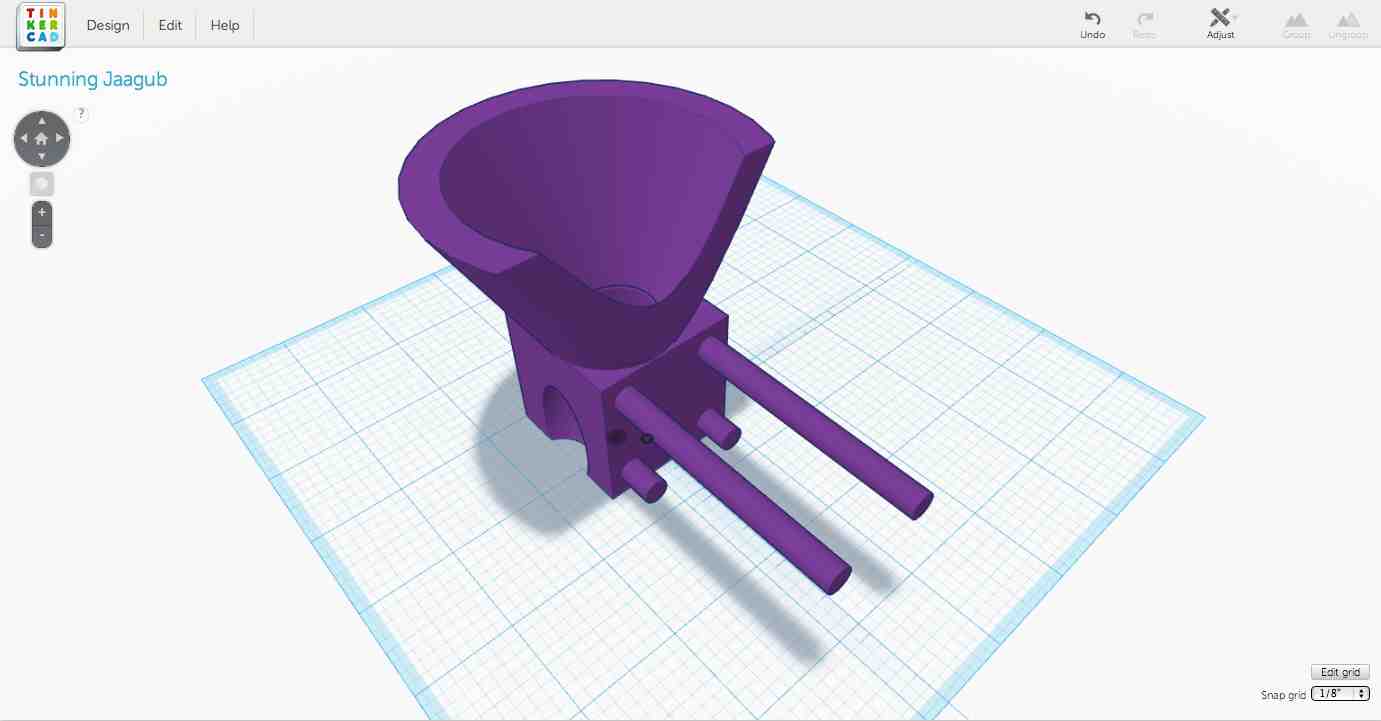

Here's the STL file / version 2 with all of

the changes proposed above...

|

|

|

When all was said and done (and after four different revisions of

the part, here's what we we finally ended up with (with the entire

Marble Mover) pictures. Checkout the green starter part in

the top :->...

Dunkin Donuts Cup Scan

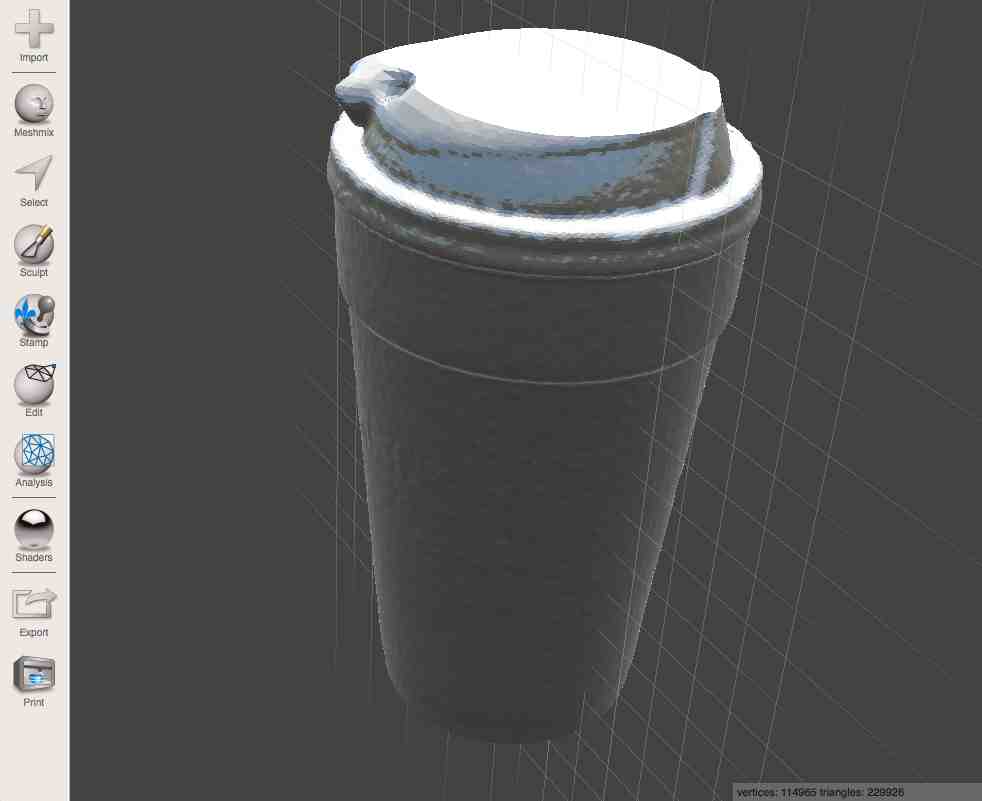

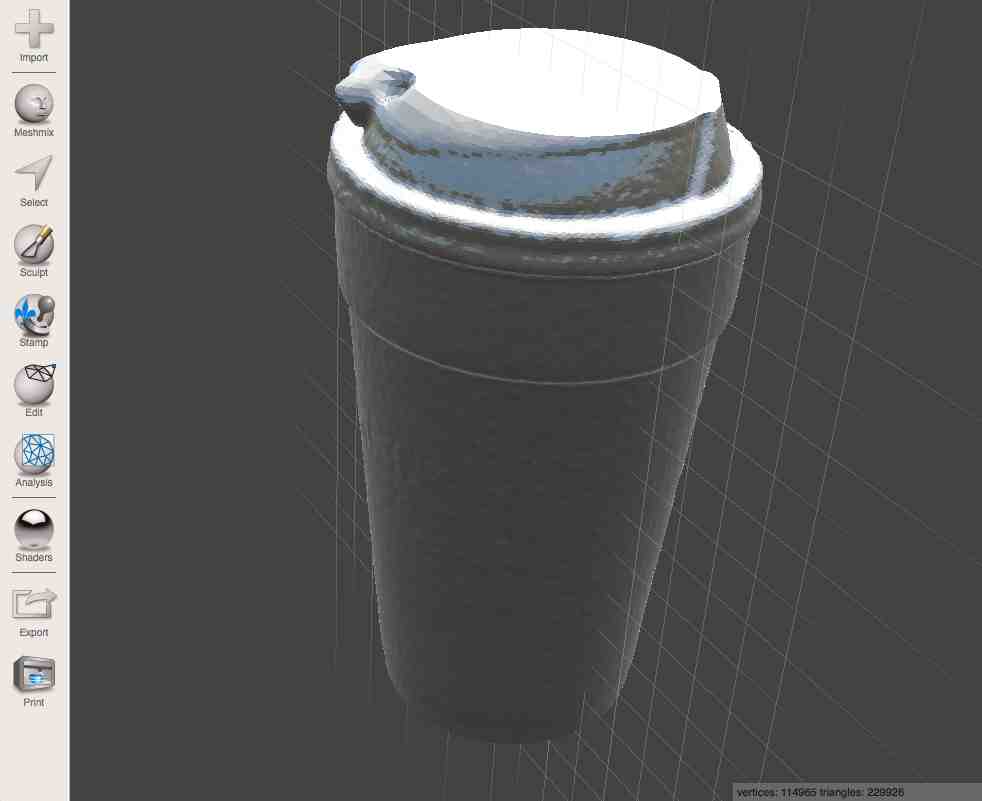

Using the school's MakerBot Digitizer. I scanned a Dunkin

Donuts coffee cup. I had two goals with this: 1) show

different ways of outputting the model once it was done , and 2)

learn to do simple editing of a mesh.

|

Here's what the coffee cup looked like right

after it was scanned in using the MarkerBot Digitizer.

Notice the strange growth on the left side of the cup.

That's what I will eventually try to get rid of.

|

|

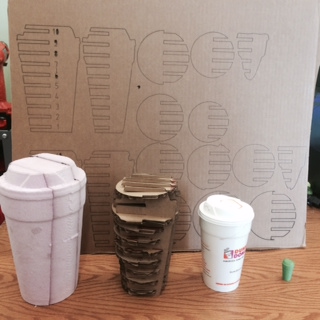

Here are three different kinds of output that

I generated once I had the STL file of the coffee cup (from

left to right):

1) 2Bot Subtractive Cutaway: Using the 2Bot milling machine, I cut three

pieces of 2" think foam insulation out into the three pieces

of the coffee cup. The cup is just under 12".

2) 123D Make Cutaway: Using 123D Make, I was able to get the

laser cut plans that would turn the coffee cup STL into

linkable parts. The cardboard behind the

different coffee cups shows how the parts were laid out on a

piece of cardbard after they were cut (I didn't use enough

power so this cut didn't go through).

3) That's the original

4) That's the shrunk MakerBot version of the coffee

cup.

|

|

Using MeshMixer, I was finally able to clean

up the lid (a bit). While it wasn't perfect, I did get

it much better so there isn't as big a growth on the far

side.

|

Scanning using 123D Catch

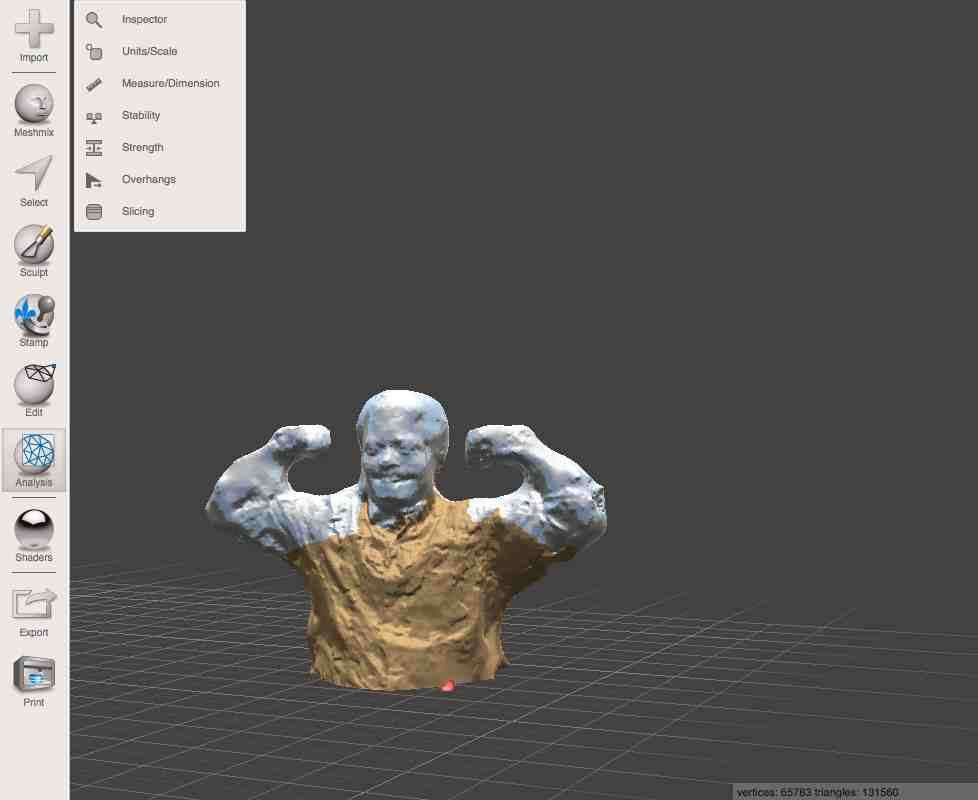

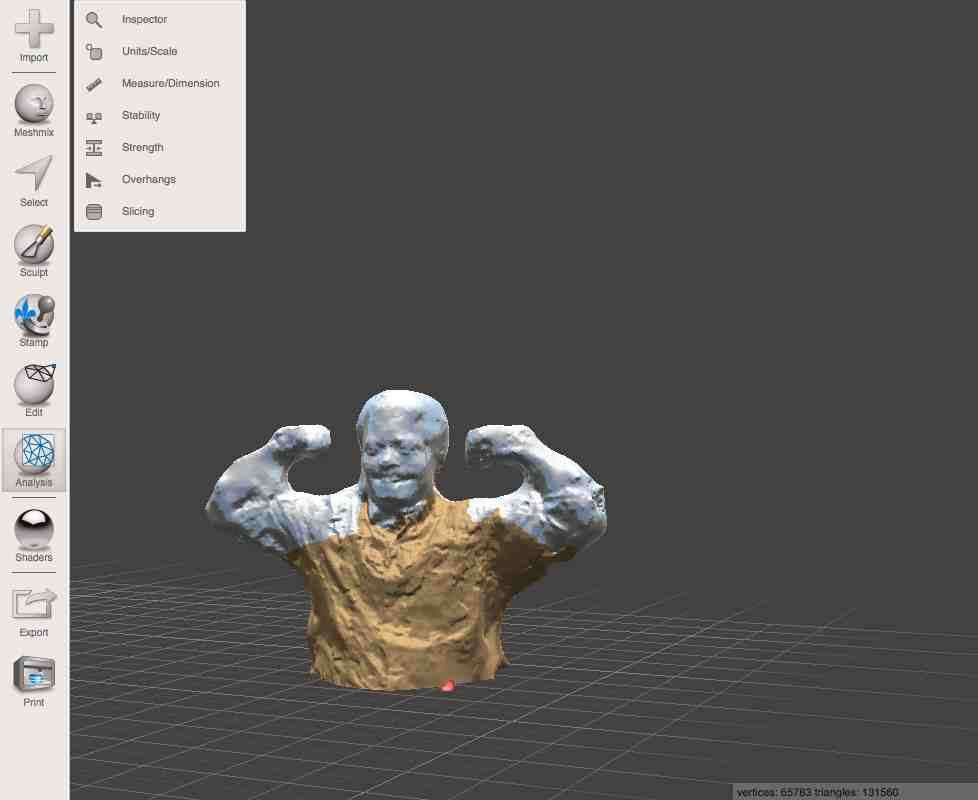

Once I had the simple coffee cup cleaned up a bit (and I was

starting to understand the basics of MeshMixer), I decided to try

something more difficult. So using the iPad (and the 123D

Catch iPad app), I tried to make a funny scan of myself.

Then once I had that scan I tried to fix many of the

problems.

|

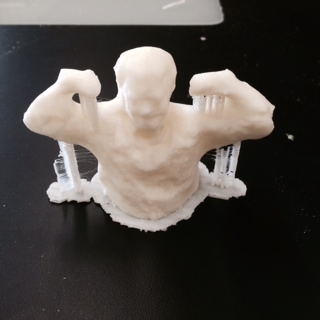

OK, I admit it...I was messing around to see

how it would handle the overhangs. I also thought my

brothers would really enjoy my attempting to flex.

|

|

While my first reaction was that 123D Catch

did a wonderful job of generating the model, I later started

to see many flaws that I realized I was going to need to

fix. Some examples:

1) My right hand is merged with my head.

2)The background is included and mixed in and I need to get

rid of it.

3) My body is hollow on the inside

4) I need a flat cutoff on my torso so it will rest on a

table

5) There are many extra growths in my model. For

example, my left arm has some extra

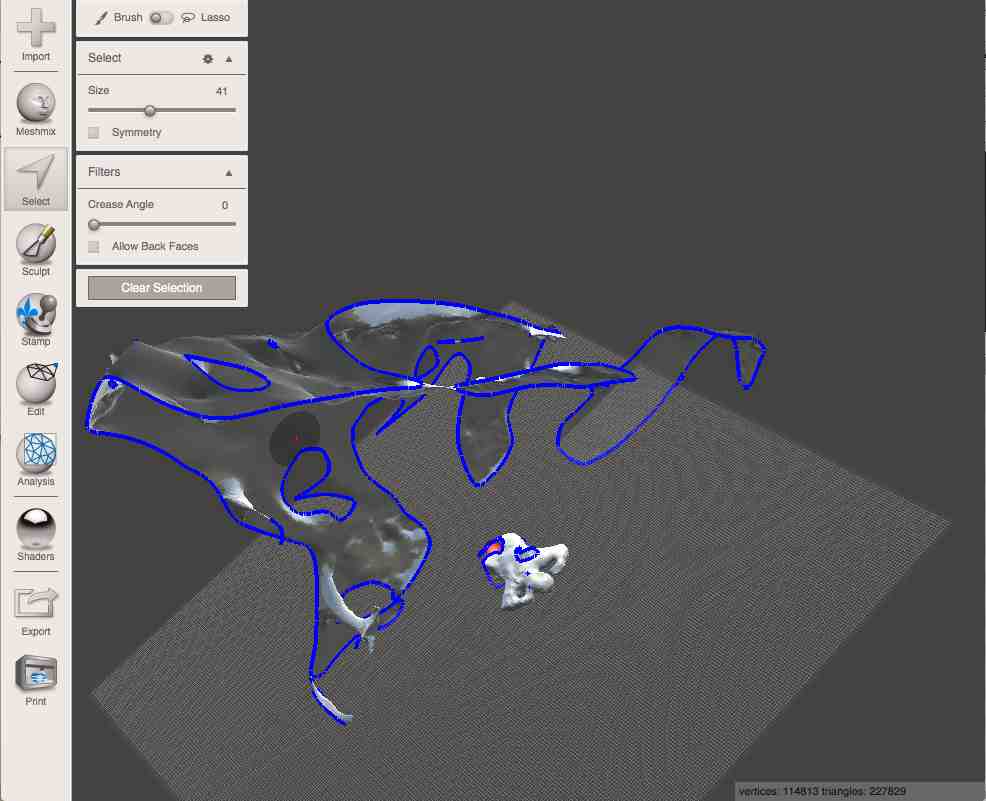

While there were many extraneous parts on the perimeter, I

later found out that these are easy to delete in tools like

MeshMixer.

|

|

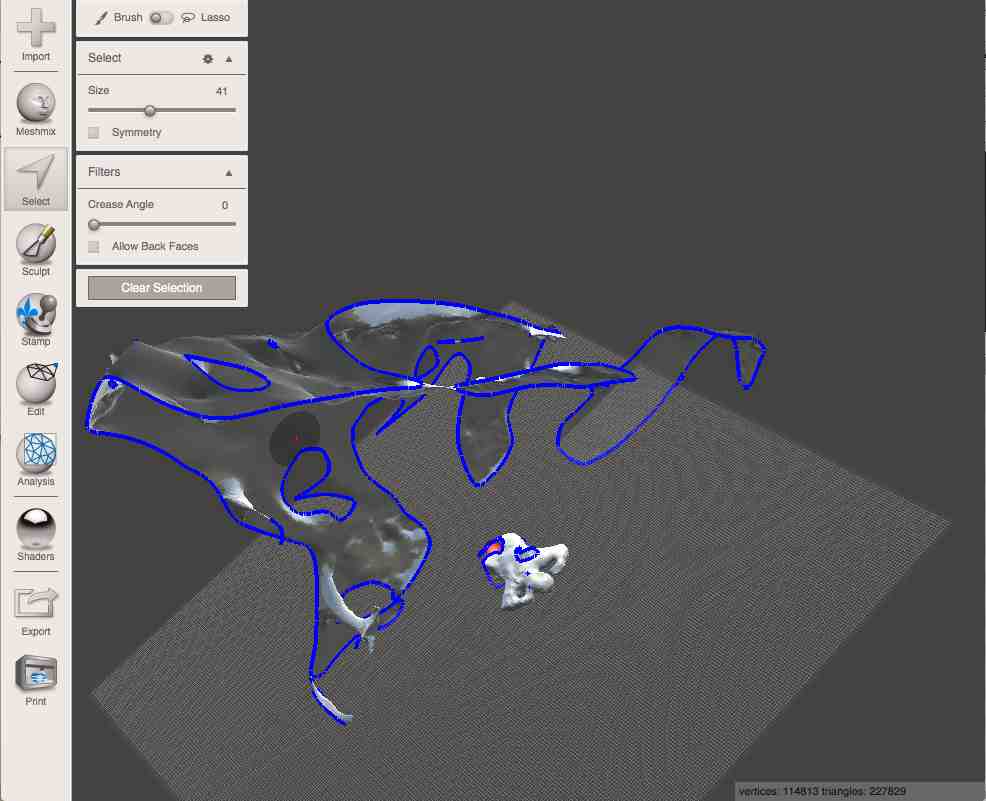

Wow...here's the model after it was imported

into MeshMixer. What a hot mess! You can see how

small I am when all the walls and surrounding mesh are

included. Fortunately, this was quite easy to get rid

of.

|

|

After 90 minutes or so of trying to learn

MeshMixer, I ended up with a halfway decent model of my

silly pose. Here's how it looked in MeshMixer.

|

|

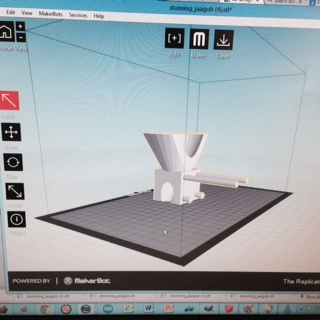

...and here's how it showed up on the

MakerBot print bed.

|

Learnings

Here are my key learnings from this lesson:

- Label Output: Label the parts as you take them out of

the laser cutter. You'll notice that the cutouts aren't in

the perfect order (and we are missing one at the top).

This was because I was speeding through all this and I thought I

could figure out which one went where...I was wrong and I ended

up breaking a piece because the fit was so tight it

ripped.

- MeshMixer (and other mesh editors) will take some

getting used to. I really struggled with learning some of

the basic concepts. For example, there were so many ways

to smooth items and none of them did exactly what I

wanted. I found the quick videos interesting, but a bit

useless because they were all based on an old version of

MeshMixer.

- Planning Pays Off: I made some dumb mistakes with the

marble project. I was rushing and didn't bother drawing

this on a piece of paper first. That was silly so I wasted

a bunch of time. It really pays to draw the pictures on a

blank piece of paper first so you don't waste time.

- 123D Apps are good, but platform matters. Many of

the 123D apps work across all the platforms (Mac, PC,

iDevice). The thing is, some of them are pretty

buggy. The 123D apps seemed to crash a bunch on the

PC. I did have good experiences on the iPad.

- Save Often: Many of the programs I used (123D and

MeshMixer) crashed a bunch. It was a bit of a

bummer. You need to save often.