Design, make, and document a press-fit construction kit.

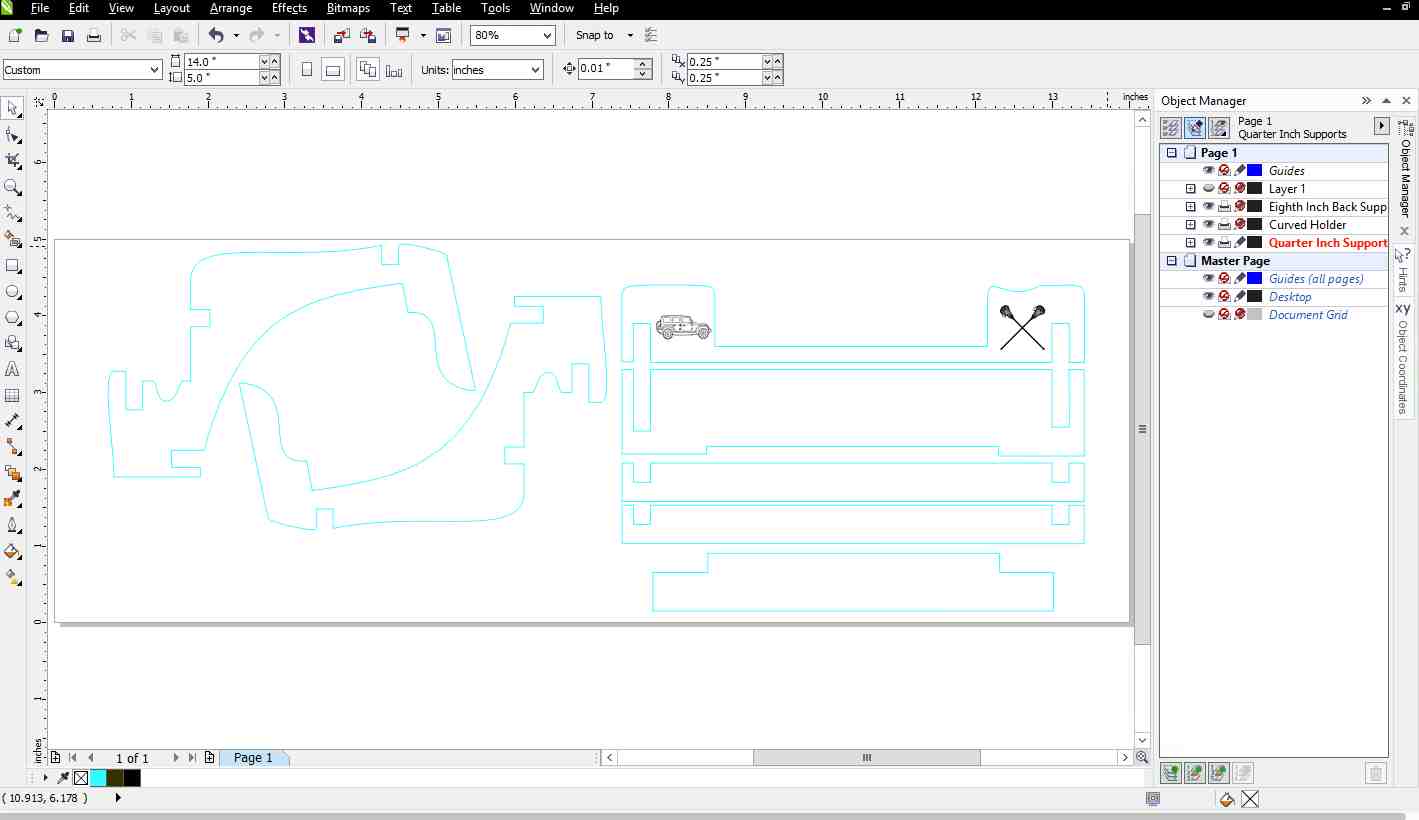

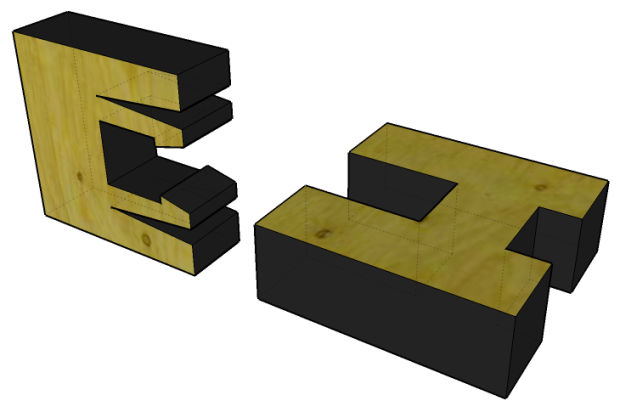

For this assignment, I wanted to push myself to work on new kinds

of joints and flexible wood. We have had our laser cutter

for a few months and already we've done tons of projects with

cardboard. For example, I had already created my Jeep iPhone

holder with the following plans using press-fit

construction. Another teacher at our school also made a

press-fit kit for Pre-K and Kindergarten students to make

sculptures.

|

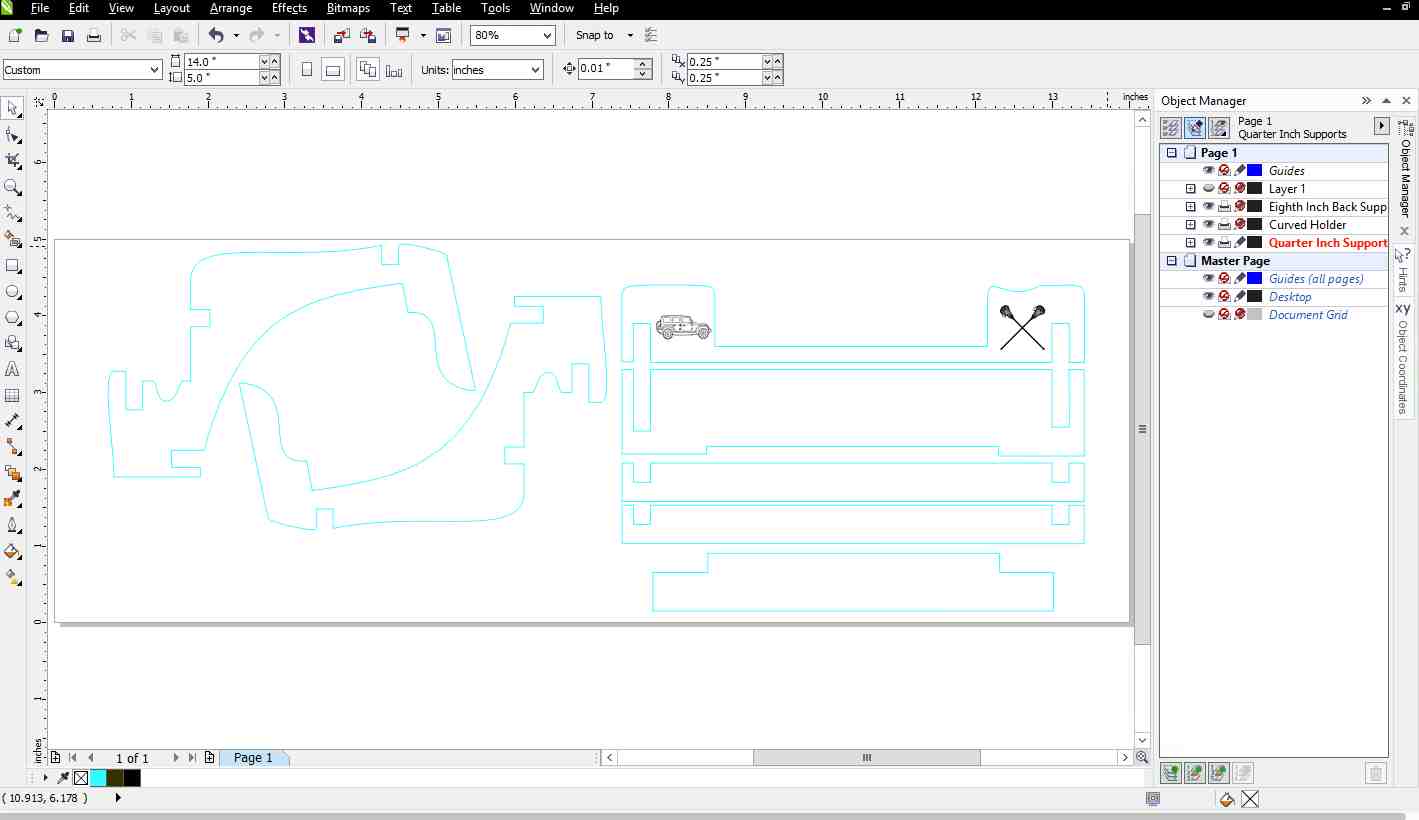

So...because I've already built or seen these things built with

press-fit construction, I wanted to try something that would be a

bit harder with different kinds of joints used throughout...so I

decided to try to build a charging station that will hide the

wires using no glue and only press-fit joints. Here's my

inspiration...

First, I decided to look for inspiration for different designs

and ways I could put it all together. I found the following

designs that helped me figure out what I was going to like/not

like...

|

|

|

From these designs, I realized the following:

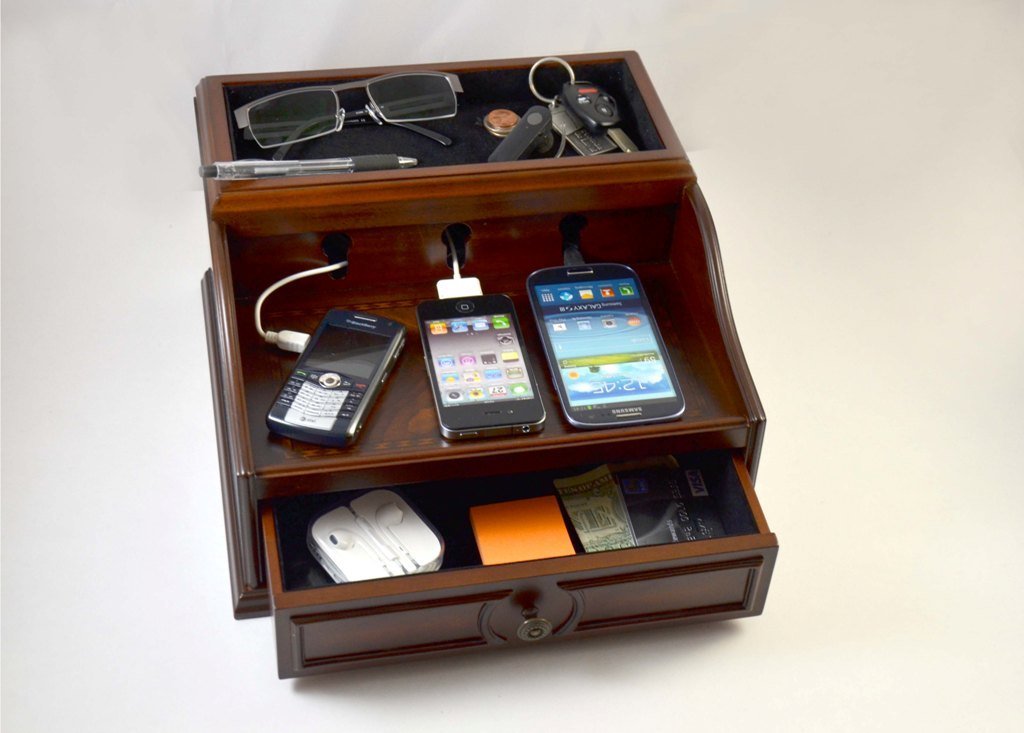

Second, I went to find some cool joints and designs for how to

put it all together. That brought me to these two sites and

example joints that impressed me. I want to find ways to use

each of these in my design...

Kerf-Bending

Joint |

Cross-X

Joint |

Third, here are the measurements of each of the devices (with

covers):

| iPad |

h: 9" 7/8 (875) w: 7" 3/4 (0.75) d: 3/4 (0.75) |

| iPhone: |

w: 2" 5/8

(2.625) h: 5" 1/4 (5.125) d: 9/16 (0.5625) |

| MacBook |

w: 14" 15/16 (14.937) h: 10" 1/8 (10.125) d: 15/16 (0.937) |

I started experimenting with different kinds of kerf

joints because I'd like to have the joints in the corners of the

charging station. The first joint I made ended up breaking

when I bent it more than 15 degrees. So I started changing

the variables...the wood type (soft basswood and solid plywood),

the width of the wood (1/8" and 1/4"), the pattern (different

lengths of cuts) and the width / length of the pattern (1" or

2"). Each time I'd run the cut through the laser cutter and

then would measure how far it would bend. Here's a picture

of the different cuts when I tried three kinds of wood (solid

alder, alder plywood and soft basswood), two depths (1/4" and

1/8") three patterns (wide gap and small cuts) and two

widths/lengths (1" and 2").

At the end, what I came to learn/realize is that the

thing that matters most is the width/length of the pattern on the

wood. And then it dawned on me...depending on the wood

width/type and the pattern, each instance of the pattern gives you

some flexibility (e.g. 5 degrees of bend). Example: if you

want 90 degree bend, you need the pattern (90/5 = 18) 18 times as

each instance of the pattern adds a bit more bend. So, once

you settle on the kind of wood and a pattern you want to use, you

need to find a way to extend the pattern as far as you need to go

to get the complete bend you need. While the physics of all

this might not be perfect, it's a framework for thinking about it

that I think might be right.

When all was said and done with this, I realized

that I would need a REALLY long piece of wood that would be bigger

than my laser cutter if I was going to do the Kerf joints.

So I decided it wouldn't really work to use these in my

design...doh! But, I did learn a ton from trying these and I

expect I will use these in the future in other projects.

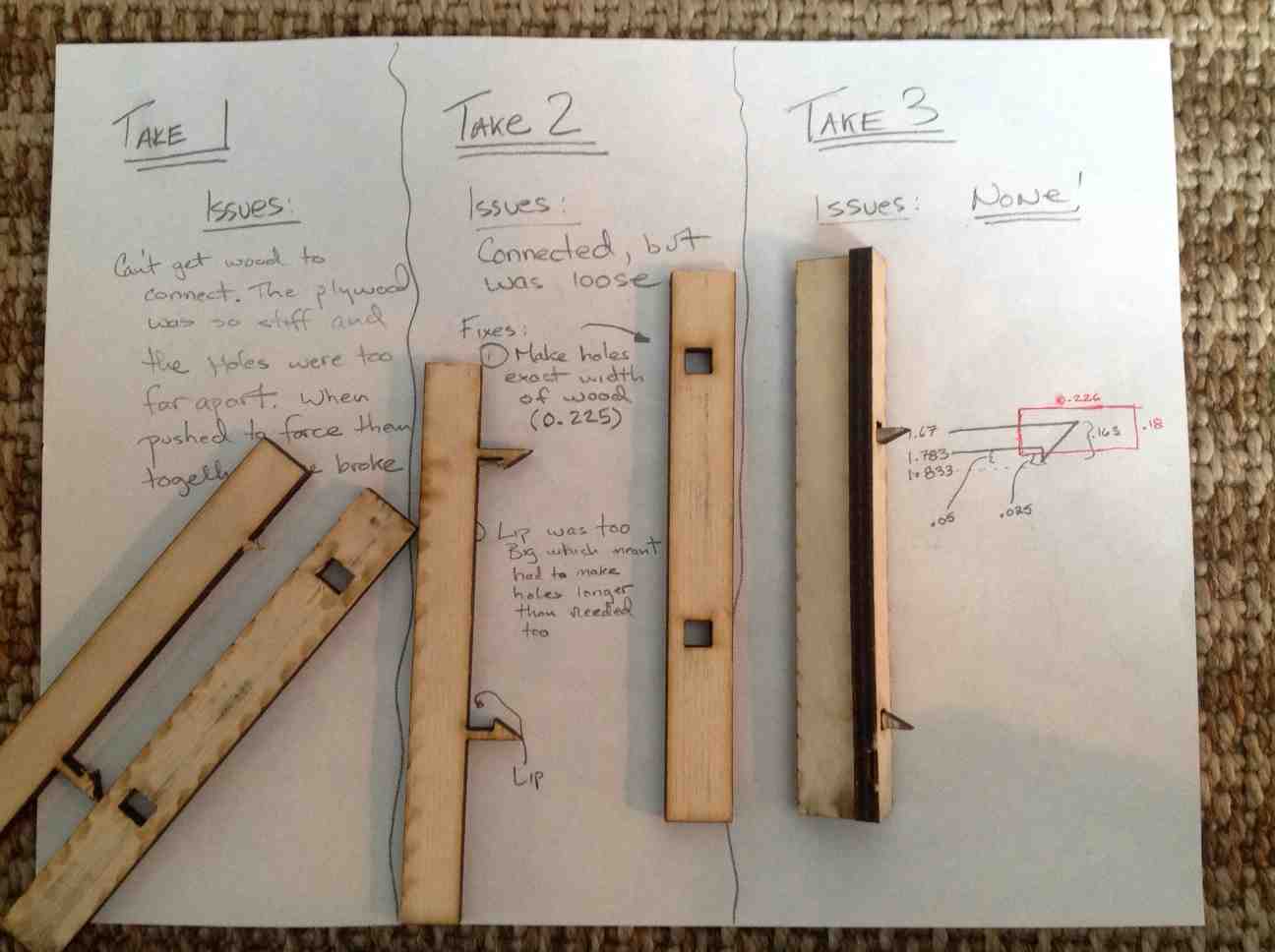

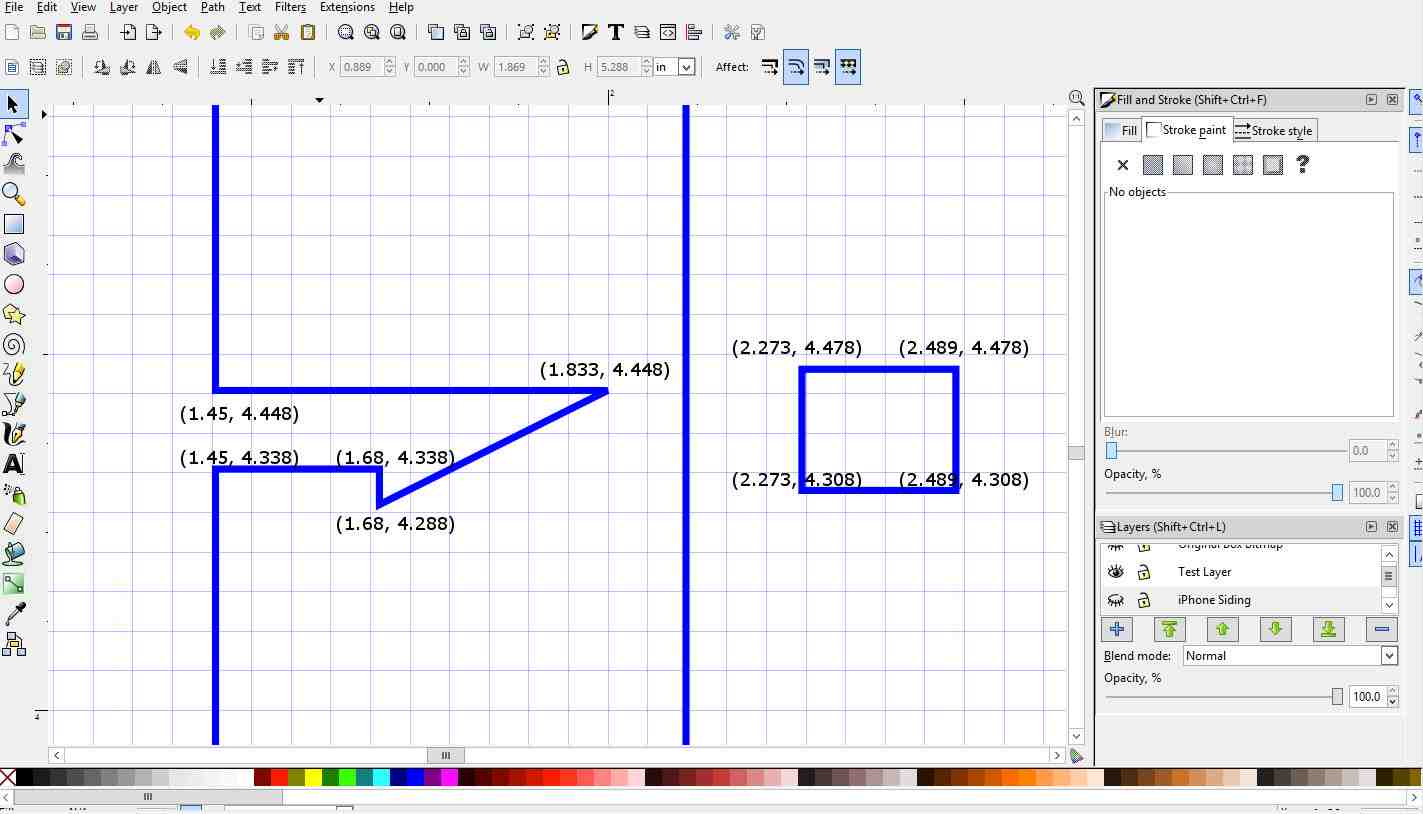

I spent a bunch of time trying to get the joints right. After

three different tries, I ended up getting it right. Here is

a picture of the different versions that I tried and the final

plan with the different coordinates and measurements.

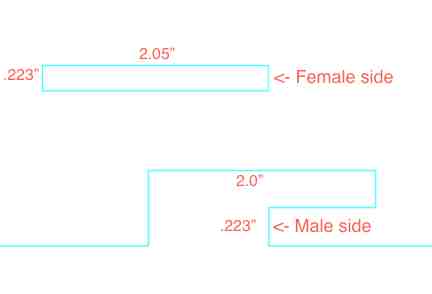

Issue #1: When shift siding with joints, the front gets shifted way off to one side. So need to lengthen on right side and shorten the left side. Fix #1: Make siding 0.713 in long on right side and 1.25" shorter on the left side. |

Issue #2: The holes for the joints were EXACTLY the same size as the parts that were going to have to fit through. I realized given my Jeep iPhone holder that the wood needed some extra space. Fix #2: Make the holes 2.05" rather than 2.0". THANK GOODNESS I CLONED THEM...IT MADE FIXING THIS MUCH EASIER :-> |

Issue #3: Angle is all wrong where siding meets the front. Issue #4: Front is too long so need to shorten. Issue #5: On the high side of the siding (not pictured here), the bottom needs to be lengthened and the top needs to be shorted ++++++++++++++++++++++++++++++++++++++++++++++++++++++ Fix #3: Make it 0.281" longer where siding meets top and 0.117" longer where rounded corner meets bottom Fix #4: Make the front 0.268" shorter. Fix #5: Make the top 0.134" shorterand the bottom 0.336 longer |

Once I made the above fixes, I did a second

version. Unfortunately, on the second revision I still had a

problems with the angles...and...it made me realize I had other

problems. Here's a picture of the second version.

| Issue #1: The angles still weren't

right. I wanted the siding to be flush against the

front (the right side of the picure) and the back (the left

side of the picture). I thought I had fixed this, but

apparently not. Issue #2: It didn't occur to me till I saw the sides, front and back attached to the top, but because of the angle of the side, I realized that the joints I created would work. The joints I made are so precise that the wood needs to be attached by sliding the wood in at a 90 degree angle, which isn't possible for the front and back if the sides are at an angle. Fix #1: I measured the gaps between the sides and the front/back and then extended them. Fix #2: I got front and back off so that the bottom won't attach to them. They will only be attached to the sides. |

After making those changes, I finally had all the

parts that fit together. I ended up with final project that

had cutouts for the cables and a place for both the MacBook 15"

and the iPhone (on the right). The final project

is pictured below. Now I just need to get my wife to agree

to keep in on our kitchen counter.

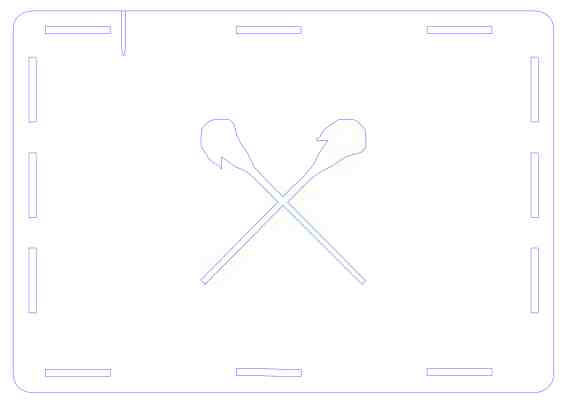

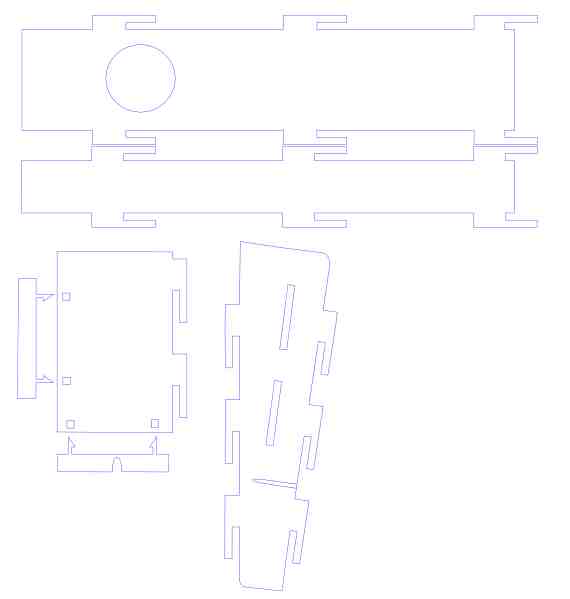

Plans for the top and bottom (with gratuitous carving of lacrosse sticks) |

Plans for back, front, iphone holder and sides. NOTE: the top and the sides don't include the shaving of the bottom joints. This is because I ended up marking and laser cutting them off. |

Below is the final project with the wires organized under the charging station. |

I learned a great deal doing both my Jeep iPhone holder and the

FabLab charging station- two press-fit construction

projects. Here are some examples of key learnings: