|

The

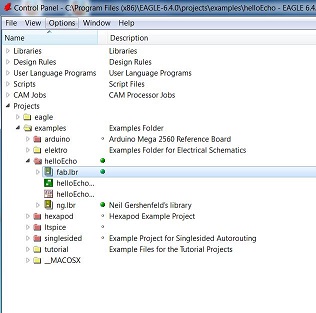

assignment started by downloading Eagle 6.4.0

software. I was able to download the software with

ease to my Windows machine with the Cygwin

interface.

I was able to use tutorials posted by Anna Kazunas France

to add the appropriate libraries and add components.

The tutorial was quite helpful.

I

tried the same download on a dual boot Windows/Ubuntu

platform logged into the Ubuntu side. I was not

successful at this attempt. The dual boot computer

seems to have died/frozen. I will be returning

that to the campus tech support and returning the loaner

computer. I will look into purchasing my own

computer and loading an older, more stable, version of

Ubuntu (version 10 perhaps?).

|

|

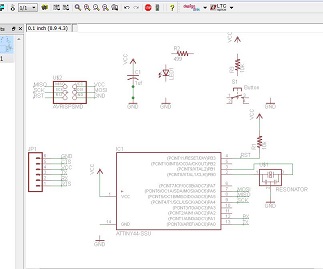

After some effort

I was able to get a completed circuit and stitch the nets

together.

I saved the file to continue during the next day.

When I came back to call the file up I noted that only one

of two portions had been saved. I will need to start

the process over in order to complete the exercise and

mill the boards.

As I worked through the problem I noted that it was

difficult to re-size the board to get all of the

components to fit. I would consider resizing the

board before I started adding components. There is

also the trick of adding a 0 ohm resistor to jump traces

but I did not try that.

|

|

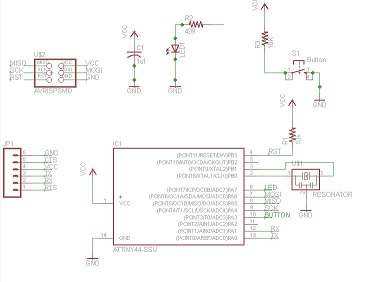

Attempt 2 was

more successful. I was able to place components and

save the file. This time I saved both

files after placing just a few components and

then opening the file to make sure that I was using a process of saving/opening files that was

correct. I believe

my problem the first

time was that I saved

the .sch file but

got click happy and did not save

the .brd file.

|

|

I really wanted to

understand the connections on the board and how the

components were referenced to one another relative to pin

numbers, grounds and voltages. I spent some time

hand drawing a schematic for myself that enabled me to

make the mental connection between the schematic and the

board layout. This took some time but helped me to

see how the components were connected, which pins were

connected to which devices, polarity of devices and the

like. It was worth the extra effort for me as I

understood the circuit much better after this.

|

|

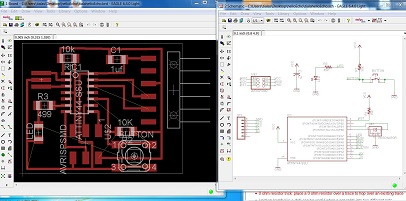

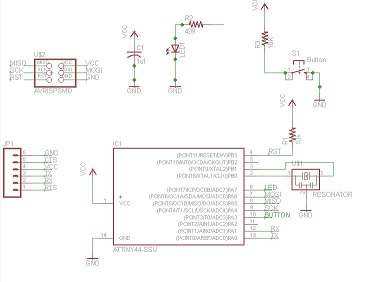

My

schematic is

complete.

I am not sure

if I need to

indicate

wire junctions

when two components

meet with a

straight wire

and no

intersection.

Anna's

tutorial indicate

that some are

and some are

not

connected.

Also, when I

go to move

components

in the board

layout view

there are multiple

traces

connected to a

component.

I have tried

deleting

and adding connecting

dots but this

does not seem

to

impact board

layouts.

|

|

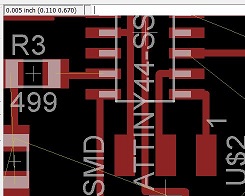

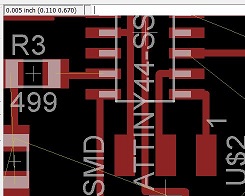

I am concerned at

how close the connections are within the board. I am

particularly concerned about the traces going underneath

the ATTINY 44-SSU chip. I took a look at the

measurements in the upper left corner and determined that

a 1/16 inch bit would in fact be able to mill out the

circuit. I also found a way to enlarge the board so

that I have more room to lay out components.

I am trying to make sure that I understand the software as

much as I am trying to conserve materials and get the most

efficient layout. I have decided to enlarge the

board in order to experiment with gaining skill in the

software.

|

|

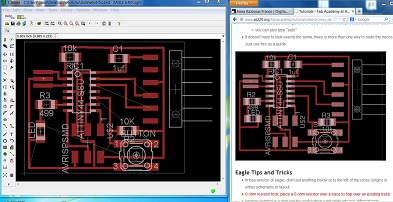

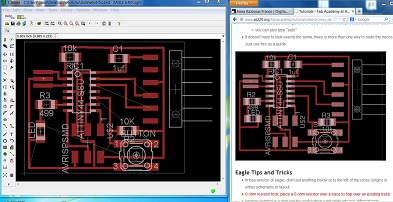

I have changed my

layout from Anna's tutorial a bit to demonstrate that I

did more than copy and paste. Some thought was given

to the layout. Differences in the LED, the 499 ohm

resistor, capacitor placement and the 10K ohm resistor on

the lower right side of the circuit are slightly different

than in the example layout on the right hand side.

|

|

The schematic as

well as the board layout are complete. I have saved

the boards as .png files and I am ready to prepare the LED

and button board for milling.

|

|

As per the

tutorial I am downloading Gimp. I am a bit nervous

about this because during the first week of class when I

was looking at software options it seemed as though Gimp

may be problematic on a Windows machine. I

downloaded Gimp without problems and was able to upload my

exported files.

I did have problems saving the files. The files

could only be exported or saved in files that were not

compatible with the mill. I used gimp to add

text. I found out when I went to mill the board that

I was not successful in making a file that milled the

exterior of the board. I cut the exterior of the

board by hand as we only had one mill and others were

waiting to use the mill. I will need to work on this

part of the process.

|

|

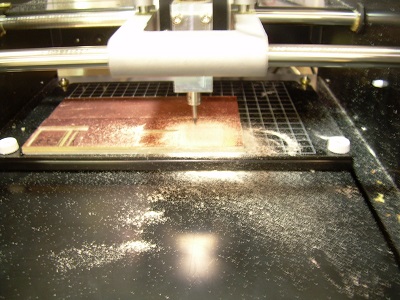

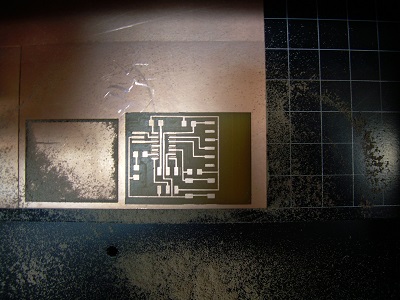

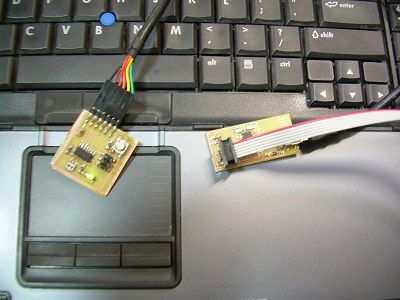

The LED and button

board have been milled successfully but not before a

considerable effort. The file uploaded fine, the

setting seemed to be correct. However, the Modela

mill would not go the

110x and 2y coordinates I specified. Abu, Scott,

Mike and I worked for a

bit over an hour on the machine. This included restarting the machine, reloading

files, and finally checking connections. We finally

discovered that our new cable linking the computer to the

Modella was defective. Very frustrating. We

had a spare cable which we used and then all worked

well. Note that I have placed components and solder

them in preparation for the week 8 lab. We will see

if the board works.

|

|