|

This

week's 3D printing and scanning exercise

shows one how items are constructed and deconstructed digitally. I chose to construct a tool holder for

the tweezers and the XActo knives we seem to use all of the

time. Instead of having to

hunt for them I wanted to buy a holder that mounted to

pegboard we have at our lab stations. I

didn't find what I was looking for. This then became an item

I could print

and custom make to my liking.

This fits in with the idea

that the Fab Lab is

intended

for a market of

one.

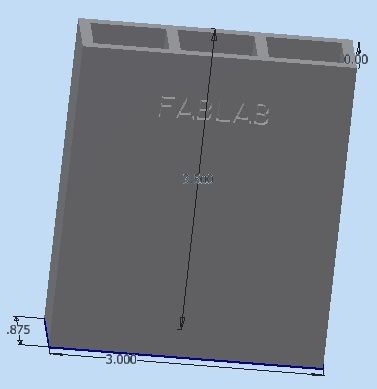

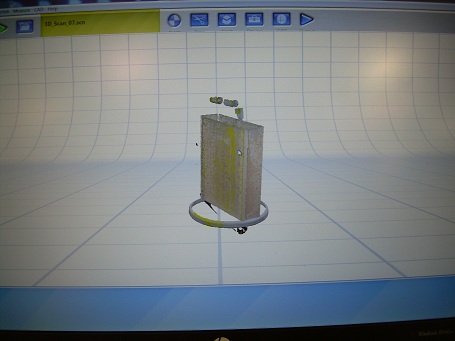

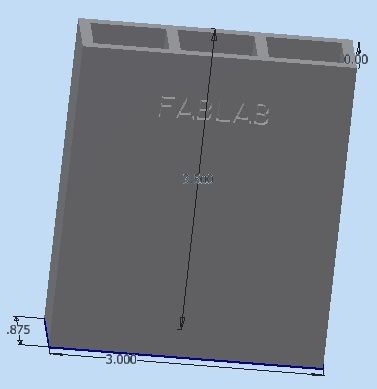

I made the

original model in

Inventor.

I have

experience

with the

program so

this portion

did not take

long.

|

|

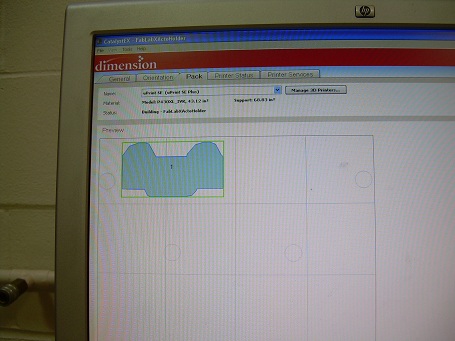

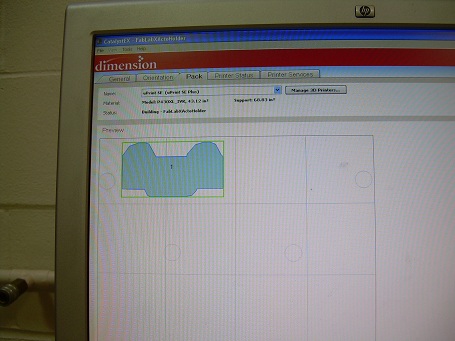

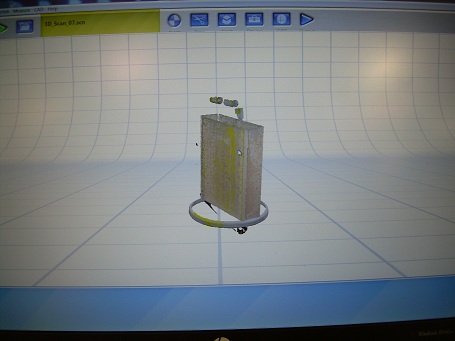

The file

went to the Stratosys 3D

printer. I loaded the file

easily and located the printing location on the base plate using

the software linked to the

printer. I ran through all of the

layers to make sure there weren't any errors.

|

|

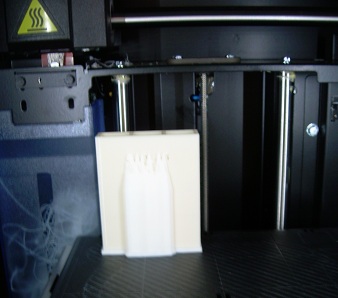

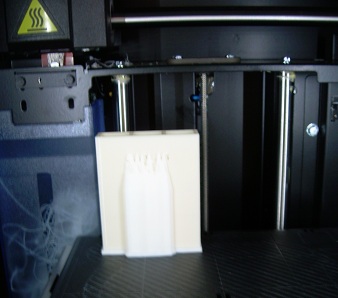

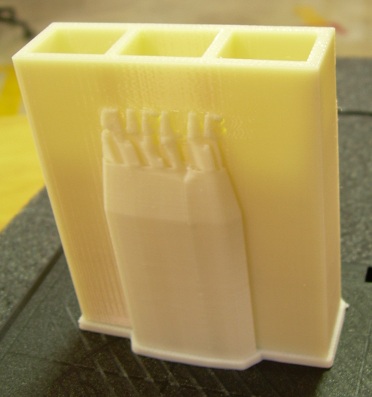

The

model took 5 hours to print which is longer than what I had anticipated. I would make

the walls of the box thinner next time to save on material and print time. |

|

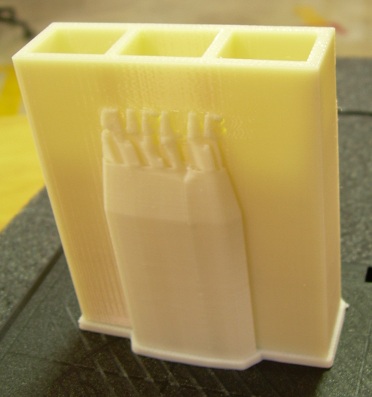

Lessons

learned when printing included:

- When using the shell command the

embossed text shells as well causing protrusions

inside the box.

- Two holes in the back and the embossing in

the front required extra support

material. I knew there would be

some but I was not

anticipating this much extra material.

- The extra material

required about 2

hours for removal.

Overall the printing

process was straight forward.

|

|

Abu, Mike, Scott and I worked to

get the Next Engine

scanner up

and running. It

took 2 hours to load the

software for the

scanner. The scanner would twitch but not

actually work to scan an object. We finally figured

out that the software did not run on

Windows

8.

When loaded onto a

machine

running Windows 7

it took less

than 5

minutes to

load

the software

and get the

scanner to

work.

|

|

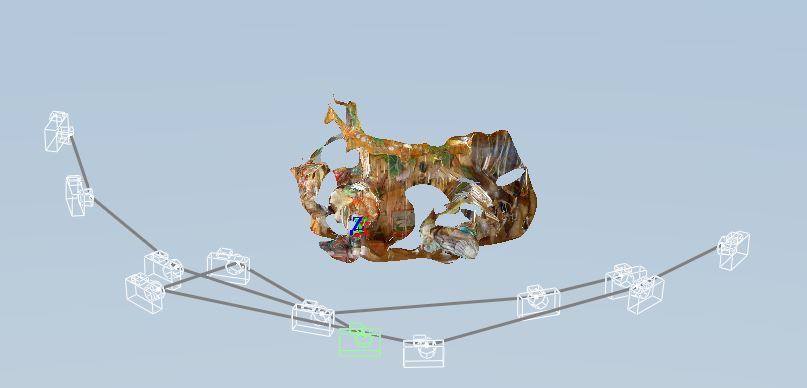

My 3D XActo holder is about to become a digitized

box. I chose to do 12 scans after

watching Mike do 8 scans and having to

spend a lot of time piecing his model back together. 12 scans

may be a little excessive given the flat geometry of the box but hopefully increased scan time saves time in

the long run.

|

|

My scanned model was centered fairly well and scanned

with few flaws. Items learned from this scan included:

- Scanned objects

need to be centered

- Black

backgrounds are used to prevent background clutter

- Holders keep objects from vibrating as they are rotated

|

|

The

problem with proprietary

software - specific to a particular machine - is that retrieving files is difficult once the computer,

hardware and software are gone. I

tried exporting files from the scanning

computer to my USB

sticks. Only one or

two images were

saved. The original files are

attached to the

computer hooked to the scanner and are now

inaccessible. I went on to trim

the excess

appendages off of my model

after the scan was complete.

|

|

I attempted to make my own 3D printing setup in addition to working with a

purchased scanner. I used a lazy susan bearing and

hung the bottom platform off of the bottom

of the bearing. The center platform is held

stationary on a pillar that is attached

to a base resting on a table.

It was important to find the center of a square

before cutting the corners to make a circle. By making squares, finding

centers, then trimming boards to circles, the center point through all of

the pieces was maintained to

some degree of accuracy.

I looked at links online and

at the commercial printer. and saw

that there had marked concentric circles to indicate

center. I have rings to help align

objects. I included saw kerfs around the edge of the plywood circle

in 15 degree increments

to help determine camera angles.

In

addition to using scrap plywood from home

I had $8.19 in 1/2" x 2' x 4'

plywood; 1- 6" metal lazy

susan bearing; about

$8.00 in a cheap camera

tripod; and $ about 4.00

in bolts and

washers. The

action is smooth

enough. It is easy

enough to align. I used a

Nikon CoolPix L4 for

taking

pictures.

|

|

I tried taking 9 shots and importing them into Autodesk 123D Catch.

The upload went fine. The photos were compiled but

there was an error at the 77%

mark. I think there are several

problem that I will

continue to work on. They are:

- Inconsistent

exposure among photos

- Unlike the purchased scanner that uses a

black background the Autodesk software wants a

detailed background to help stitch photos together.

I need to remove

the white background -- maybe.

|

|

I wanted to make sure that the

error message I was getting was not due

to the scanned object being too similar to the

background. I took pictures of a bass bird/paper clip to be

sure. The same error appeared. I

tried taking photos using a paper plate on a

kitchen table and the error still appeared.

|

|

In both

cases 123D Catch indicated that the photos were uploaded.

During the create

capture I received:

Process Error:

An unknown error occurred during the upload

process. Please check your connectin and try again

later.

I can try the process at

a different time during the day. I am pretty sure my home

made image capturing device will

work. I

think I will need to visit the tutorials and spend more

time troubleshooting the issue. I

would also like to try using the Kinnect

sensor when time permits.

February 26:

I tried using 123D

catch from school and came up with the same

error. I then tried the

"email" response instead of the "wait" selection. The

email message indicates

that

"The application was

unable to create your

capture because not

enough of your images

could be stitched

together". It

refers me to the 123D

Catch site and the video

tutorials. I will

review them as I believe my

exposures aren't

consistent enough and

that there is not

enough background information

to allow the

stitching to

occur.

|

I took the

opportunity to photograph an indoor carousel on a recent

excursion. So far it is working to stitch the photos

of the carousel together using 123D catch. It

is taking a bit of time. I am afraid if I quit then

I will lose my work. We'll see what happens.

|

|

|

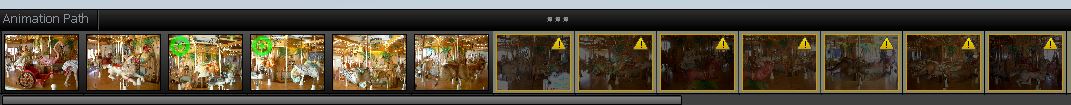

The photos I am

stitching together have more and more green arrows

indicating completion but the stitch looks much the same

as when I started. The first picture is the stitch

at the beginning of the process. The second shot

shows the stitch with photos halfway stitched. I

wish I would have taken more photos. There is too

little overlap in some of the photos to get good reference

points. I think I will also need to move more

dynamically between photos when I am stitching in order to

get the 3D effect.

|