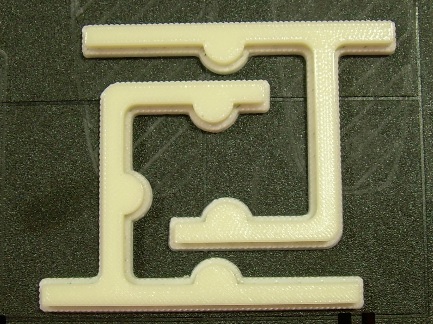

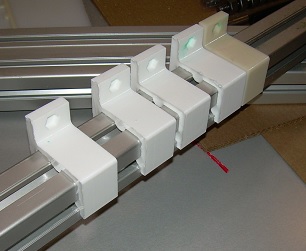

I followed his advise and the technique worked. We will need to drill the through holes for the bolts separately. This should be an easy enough task as I left recesses for drilling locations as part of the molding process.

The parts can be removed from the mold after about 20 minutes but it takes longer for them to reach full strength and rigidity.

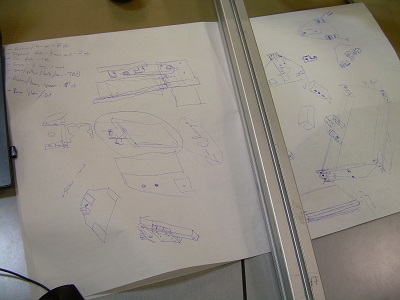

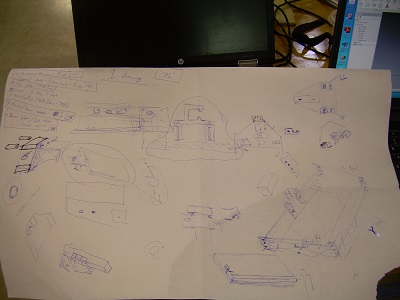

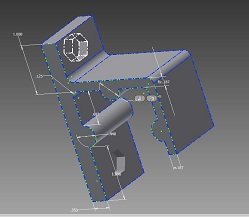

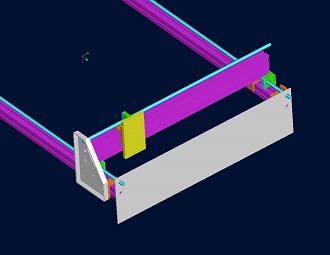

Mike is working on drawing and redrawing components. He is verifying that the machine will work on ProE. He deleted the spacers for the bearings. There wasn't enough room for the nuts that go with the screws, so he moved the screws above the rails. An alternative option is to put the 'long screws' on the outside of the 'side plates'.

Things that Mike identifies as

needing attention includes:

1. Needs a name.

2. Need to know which pulleys/belt is going to be

used. The motor mounting patterns need to be sized

correctly.

3. Need to know which motor is going to be used.

Need dimensions of mounting hole pattern and boss by

shaft end if there is one. Datasheet dimensions

seem incorrect.

4. With a little bit more info, I will cut / form the

side plates and end plates.

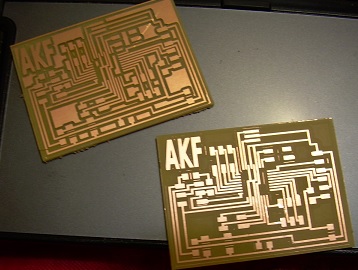

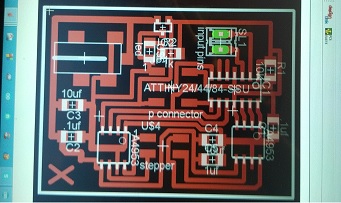

We are also trying to figure out the electronic system. We can fall back on Arduino or a computer with LinuxCNC or go all the way back to windows using Mach3.

//STEPPER MOTOR DRIVING PROGRAM

//MOTOR 4209L-03-01

//INPUT pin definition

//for step

int stepForward = PB0;

//for direction

int stepBackward = PB1;

//OUTPUT pin definition

int stepperPins[] = {PA0,PA1,PA3,PA4};

//initialize the constant

int znum = 1;

void setup(){

//OUTPUT pin setting

for(int i=0;i < 4;i++){

pinMode(stepperPins[i], OUTPUT);

}

//INPUT pin setting

pinMode(stepForward,INPUT);

pinMode(stepBackward,INPUT);

}

void loop(){

if(digitalRead(stepForward) == HIGH){

switch(znum){

case 1:

//STEP4

digitalWrite(stepperPins[0], LOW);

digitalWrite(stepperPins[1], HIGH);

digitalWrite(stepperPins[2], HIGH);

digitalWrite(stepperPins[3], LOW);

znum = 2;

break;

case 2:

//STEP3

digitalWrite(stepperPins[0], LOW);

digitalWrite(stepperPins[1], HIGH);

digitalWrite(stepperPins[2], LOW);

digitalWrite(stepperPins[3], HIGH);

znum = 3;

break;

case 3:

//STEP2

digitalWrite(stepperPins[0], HIGH);

digitalWrite(stepperPins[1], LOW);

digitalWrite(stepperPins[2], LOW);

digitalWrite(stepperPins[3], HIGH);

znum = 4;

break;

case 4:

//STEP1

digitalWrite(stepperPins[0], HIGH);

digitalWrite(stepperPins[1], LOW);

digitalWrite(stepperPins[2], HIGH);

digitalWrite(stepperPins[3], LOW);

znum = 1;

break;

}

}

if(digitalRead(stepBackward) == HIGH){

switch(znum){

case 1:

//STEP1

digitalWrite(stepperPins[0], HIGH);

digitalWrite(stepperPins[1], LOW);

digitalWrite(stepperPins[2], HIGH);

digitalWrite(stepperPins[3], LOW);

znum = 2;

break;

case 2:

//STEP2

digitalWrite(stepperPins[0], HIGH);

digitalWrite(stepperPins[1], LOW);

digitalWrite(stepperPins[2], LOW);

digitalWrite(stepperPins[3], HIGH);

znum = 3;

break;

case 3:

//STEP3

digitalWrite(stepperPins[0], LOW);

digitalWrite(stepperPins[1], HIGH);

digitalWrite(stepperPins[2], LOW);

digitalWrite(stepperPins[3], HIGH);

znum = 4;

break;

case 4:

Stepper control program is as follows:

/* Stepper Bipolar

*/

int motorPins[] = {PA0, PA1, PA3, PA4}; // pin numbers in order of 13,12,10,9

int frontPin = digitalRead(PB0); //

int backPin = digitalRead(PB1); //

int count = 0;

int count2 = 0;

int delayTime = 500;

void setup() {

pinMode(frontPin, INPUT);

pinMode(backPin, INPUT);

for (count = 0; count < 4; count++) {

pinMode(motorPins[count], OUTPUT);

}

}

void moveForward() {

if ((count2 == 0) || (count2 == 1)) {

count2 = 16;

}

count2>>=1;

for (count = 3; count >= 0; count--) {

digitalWrite(motorPins[count], count2>>count&0x01);

}

delay(delayTime);

}

void moveBackward() {

if ((count2 == 0) || (count2 == 1)) {

count2 = 16;

}

count2>>=1;

for (count = 3; count >= 0; count--) {

digitalWrite(motorPins[3 - count], count2>>count&0x01);

}

delay(delayTime);

}

void loop() {

if (frontPin == HIGH)

moveForward();

else {

delayTime = 1024;

}

if (backPin == HIGH)

moveBackward();

else {

delayTime = 1024;

}

}