|

|

It

was interesting to hear

discussions regarding resins and

reinforcements relative to making composite

items. I have been working

with reinforced glass fibers

using polyester resin for a number of years when

rebuilding my boat. Respirators and protective

clothing are important to

maintain one's

health as they work in these

environments. I personally would

not use epoxy resin without a

respirator and good

ventilation. Part of the

danger of using the

resin is that it does not

smell.

The health

effects of

using and

inhaling epoxy

resin still

results in respiratory

issues.

|

|

I

am going to struggle when trying to make a reinforced

composite that will help repair this lawnmower grill. The

grill has a lot of depth do it so I will need to figure

out how to make a mold that is this deep.

I am considering making a male plug instead of a

female mold. That would help me maintain inside

tolerances. However, I would need to make sure the

bagging system was created a smooth enough surface in

order to avoid having to do an inordinate amount of

sanding.

|

|

I was concerned about tolerances on

the lawnmower grill. I started

drawing a mold in Inventor but decided to try a scan

one more time using 123D Catch. I read that you needed at least 20 photos to make the stitching work,

In the past I hadn't used that many photos.

This time I took 54

photos. I need to work on the

image but details on the reverse side of the

grill were captured.

I am not sure if I will

end up

doing a drawing or if I

will get the

scanning to mold

process figured out.

|

|

|

I have decided to do a number of test

strips. In boats they use balsa

core to increase stiffness and to provide some rigidity to the hull. In this

application I need to build up a housing that

is about 1/8 inch thick. Experience

has taught me that using

individual layers of cloth adds weight and

can be expensive if using

glass fibers. I also know that mat

is used between layers of cloth to increase bonding between

layers. So, I chose a number of layers to

experiment with. From left to

right they are: 1 layer of bamboo

batting (used in quilts); 1 layer of gray felt; 1 layer of

brown woven wool; 4 layers

of muslin; 4 layers of white

linen; 1

layer of wool sandwiched

between 2 layers of

green cotton; 1 layer of

bamboo batting

sandwiched between 2

layers

of cotton; 1 layer of

gray wool sandwiched

between 2 layers

of linen on each

side; 1 layer of

bamboo batting sadwiched

between

2 layers of

linen

on each side.

|

|

|

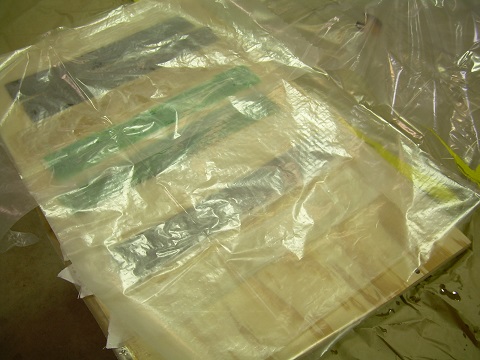

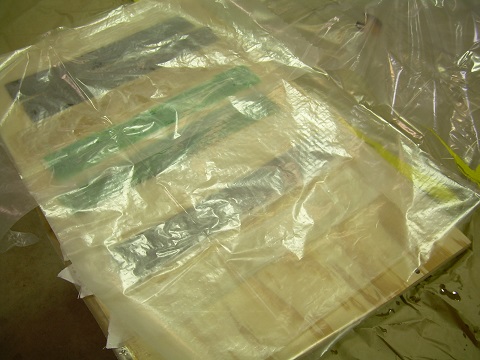

My mold

was a simple piece of plywood. I needed something flat to mold to and to get the basic

process down. I bagged the whole piece of plywood

in case there were voids in the wood.

|

|

|

I cut

the three necessary layers or vacuum bagging.

I used wax paper as

the release. It works on polyester resin and I assume it will work

on epoxy as well.

The bleeder fabric and

breather fabric are cut to size as well.

|

|

In order

to model best practices I have donned the

safety gear I use when

working with resins. This includes the

respirator and vinyl gloves.

|

|

I use

a cheap bristle brush (chip

brush) to work with resin. I find that it is

easier to pull resin through the

fibers by laying down a coat of

resin, laying the

reinforcement over the resin, and using the

brush to pull the resin through successive layers of

fibers.

|

|

You can

tell where more resin

needs to be added by observing how

"wet" the reinforcement layer

looks. The white parts of this strip need more

attention.

|

|

After

all of the test strips are laid up the wax paper release layer is

placed over the epoxied strips.

|

|

The bleeder fabric layer is added.

|

|

The breather layer of fabric is

added.

|

|

The mold is placed in the vacuum bag. Air is sucked out of the bag and

pressure is left on the mold while the resin cures.

|

|

The next morning I checked the samples.

Note that the wax paper did the

job.

|

|

Most

of the samples look good. I took them on a bandsaw

to cut the ends off of the test

strips. For the most part they

look good. In an attempt to get the perfect

composite (using the right proportion

of resin to cloth) I skimped on the

resin. There are some voids particularly

in the felt and bamboo

batting samples.

I will need to attend to this in

the final product.

|

|

Almost all of the samples are

flexible to some degree. A

single layer of woven wool material is shown here. The

best composite I found was 2 layers

of linen, a core of bamboo batting, followed by 2 more layers of linen. This

composite is about the correct thickness that I need, holds it shape with some give, and will be easy enough to

work with.

|

|

|