Molding, Casting and Composites

|

I do quite some molding and casting in our lab... One of my favorite projects is to make chocolat molds with the modela. Pictures of that and an explanaition on how to do it below.

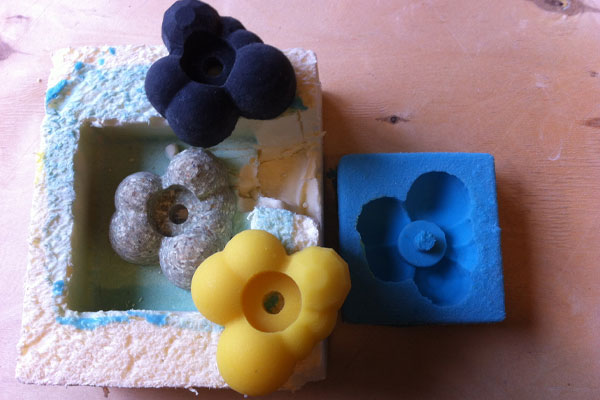

The picture on the left is a climbing hold I machined with the shopbot, to create a mold for casting some hard rubber pieces... I put the machined piece in a box, and poored the silicones directly on top. Pieces came out nice, but I'm not sure they are going to be great for actualy climbing, since they are kind of slippery... for future pieces I'd add some kind of rugged texture. For the mold I used Mold Star 16 which is cool stuff because it is ready to use after just 30 minutes. To use it, you mix the 2 components by volume, so I mostly poor water into the box with the piece I'd like to create a mold of, and then use the same volume of resin. |

|

|

|

You start by pooring part A into a cup (use gloves, and DON'T use latex gloves for they inhibit the cure of the stuff)

then add part B, and mix the two with a wooden stick. I ask everyone in the lab to keep their chopsticks if they get chinese, and we have not run out (so far). Since the working time of the 'fast' version is just 6 minutes, it's smart to set up a timer that counts down...

I mix 4 minutes or less for small quantities, and poor the mixture into the mold. Poor with a thin strand, to try and evade big bubbles in your mixture.

I created a vacuum chamber (pics below) that is really great for getting all the bubbles out of your molds. It's easy to build and really makes a difference...

For the final pieces I used Task 16 Urethane resin from Smooth on. Good stuff as well, because the 'fast' version only needs 90 minutes to solidify. I colored them with This colorant of which you really need to add just a tiny bit. Dipping your mixing stick into the color is enough. |

|

|

|

more text here on chocolat molding |

|

|

|

more new stuff on vacuum chamber |