Computer Controlled Machining

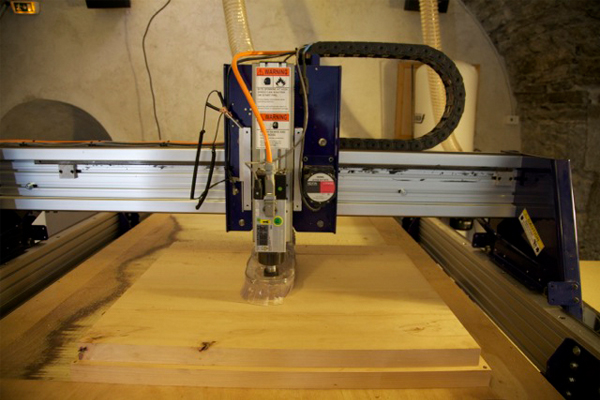

The Shopbot is, by far, my favorite machine in the lab. It let's you make houses,

press fit furniture, molds and 3d objects with very high precision.

On this page you'll find some of the things I made using this machine..

I'm by no means done and I keep learning, so if you want to know more about the projects i'm working on now,

drop me a line. |

|

Making Mountains | |

|

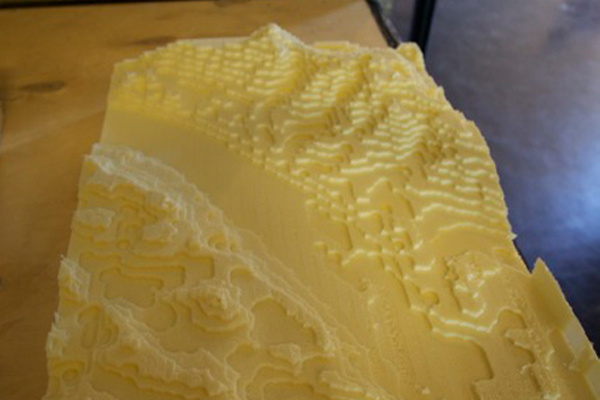

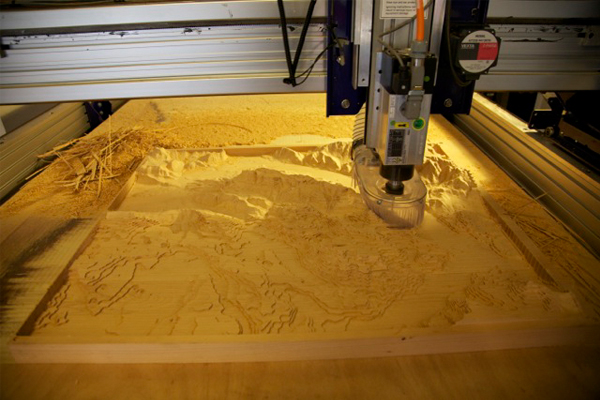

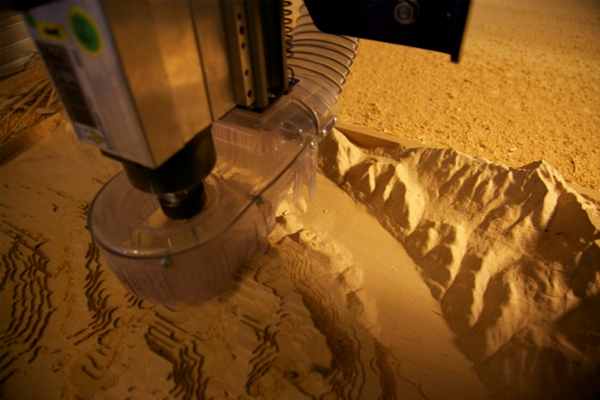

Our lab is situated on the side of a mountain, which is part of the

'Chartreuse' range. After I found I could get all the 3D data of the entire globe from the NASA,

I decided it would be cool to machine

the mountains in wood, to create a map of the mountain range in relief. First try (on the left) was done

in isolation foam, to cut down on machine time and see if all would go well.

|

|

Eventually we machined it in hardwood... machining took 32(!) hours, but the result is

quite stunning. |

|

|

Sit down and talk | |

|

Since we are in a Science Center, we participate at Ecsite each year (conferences for

science centers and musea).

The first year I went, we animated a session on Fab Labs, and the maker movement. I came up with the idea

to machine some seats for the participants with the shopbot

and bring them as construction kits so our speakers had to assemble them before starting the session. This

resulted in people not being able to hear

the first speaker (hammering away on these puppies made quite some noise) but it got us noticed, and we now

run a temporary Fab Lab every year at Ecsite. |

|

|

Sails away matey! | |

|

At one point, this guy walked into the lab with the broken rudder of his sailing boat.

His question was if we could help him make a new rudder, so he could repair his boat.

Of course I said yes. but he had to model it first.

He did, and returned a little under a month later with an STL and a big slab of wood. This made for a very cool flip part setup, where we had to machine both sides to obtain the final piece. Doing this is actually quite simple, as long as you fix your material well and measure everything precicely. We did a roughing pass with a 8mm flattip mill, and did a finishing pass with a 4mm ballnose, using a quite big stepover to cut down on machining time. In the end, it took us the better part of a day, but he had a new rudder. |

|

|

|

Eventually he ended up covering the rudder in fiber and epoxy, to make it even more

solid and protect it against the water.

in the picture on the left you see it mounted on this boat, that he keeps in the 'Lac du Bourget' a

beautiful lake not far from our lab. |

Robotically blended Yoghurt anyone? | |

|

We where contacted by an organisation called Feed'Art, for they were looking

for a space to hold a 'culinairy electronic evening'.

That obviously sparked our interest and we said YES! Let's do that. The event was called MIAM, and

consisted of diverse renowned chefs preparing small bites

that where surprising and innovative. With one of them, we decided to do something using the machines

in the lab in combination with food. The theme was 'gravity' so one of the

things we did was engrave the law of gravitation? on small apples with the laser. The shopbot,

we turned into a giant blender. |

|

|

The cool thing with this project (next to mixing yogurts with a large milling machine)

was that I got the hang of creating programs for the shopbot just by typing them,

so no grapical interface or toolpath creation in partworks, but just typing in a textpad. Below is the program I

created. The subroutines are for the movements in X and Y (the glasses where evenly spaced on the

workbed) and the mixing subroutine is where the shopbot plunges the mixer into the cups, turns on the spindle,

turns it of again and lifts the head. The whole program is simply a repetition of thoses 3 steps.

If you'd like the file to study it more closely, Get it here and enjoy |

|