Assignments

Scanning and printing / 3D scan and 3D print an object

My poor son For this practice I wanted to print a child's head in the 3D printer. Actually, at first after watching Neil's class, I realized there are many new ways to do

Actually, at first after watching Neil's class, I realized there are many new ways to do this. But I had to choose what was important to get the practice done correctly and in

this. But I had to choose what was important to get the practice done correctly and in time.

The tests we had done some time ago with the Kinect and Firefly had needed a lot of

time.

The tests we had done some time ago with the Kinect and Firefly had needed a lot of cleaning of the generated solids, and even if I initially wanted to use it I couldn't afford

cleaning of the generated solids, and even if I initially wanted to use it I couldn't afford spending most of the assignments time cleaning the stl files.

I had never gotten before a 3D model from photographic images, and was curious to see

spending most of the assignments time cleaning the stl files.

I had never gotten before a 3D model from photographic images, and was curious to see if I was going to be able to get it now. At the beginning I didn't want to believe that I

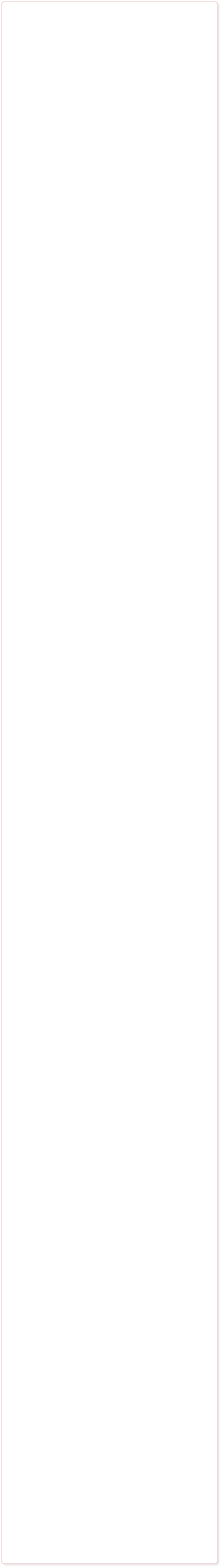

if I was going to be able to get it now. At the beginning I didn't want to believe that I many checkpoints were needed, and I made some tests with small objects and no

many checkpoints were needed, and I made some tests with small objects and no checkpoints, but the results were poor.

checkpoints, but the results were poor.

Then I also tried with my son Darius, who has been my assistant and has suffered my

Then I also tried with my son Darius, who has been my assistant and has suffered my experiments with him. At first I didn't understand that it was the camera that had to be

experiments with him. At first I didn't understand that it was the camera that had to be moved around the model, so I made my son turn around while I photographed him. My

moved around the model, so I made my son turn around while I photographed him. My son was annoyed and I did not get anything good from the experience.

son was annoyed and I did not get anything good from the experience.

Then I also tried with my son Darius, who has been my assistant and has suffered my

Then I also tried with my son Darius, who has been my assistant and has suffered my experiments with him. At first I didn't understand that it was the camera that had to be

experiments with him. At first I didn't understand that it was the camera that had to be moved around the model, so I made my son turn around while I photographed him. My

moved around the model, so I made my son turn around while I photographed him. My son was annoyed and I did not get anything good from the experience.

son was annoyed and I did not get anything good from the experience.

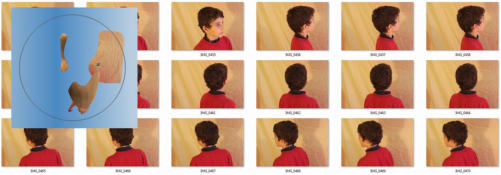

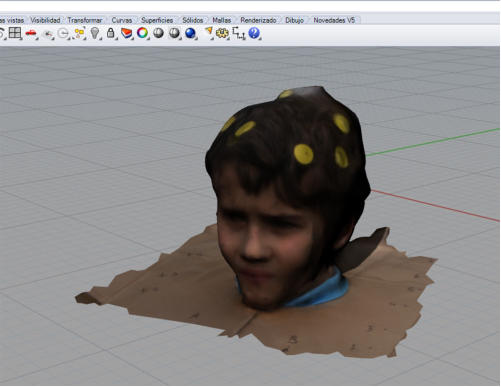

My son thought that I would tire him as much as the first time he helped me, and I knew I

My son thought that I would tire him as much as the first time he helped me, and I knew I would have little time before he would flee.. So, I marked his hair with yellow stickers

would have little time before he would flee.. So, I marked his hair with yellow stickers and painted his face with carnival makeup to have more control of the elements. This

and painted his face with carnival makeup to have more control of the elements. This time I did not want to fail because I had many chores to do in the weekend.

time I did not want to fail because I had many chores to do in the weekend. I made about 90 pictures, I signed up in 123DC and started with the latests photographs.

I made about 90 pictures, I signed up in 123DC and started with the latests photographs. The result has been spectacular. It is not perfect but I have been very satisfied.

The result has been spectacular. It is not perfect but I have been very satisfied.

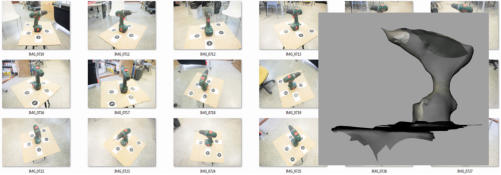

The second test I made was not so good, but I was able to start using the control points

The second test I made was not so good, but I was able to start using the control points with which I had marked Darius. Without worrying much I used more than the four

with which I had marked Darius. Without worrying much I used more than the four control points recommended by the program. I didn't like the result much.

control points recommended by the program. I didn't like the result much.

I returned then to to my first test, and I placed control points following the program's

I returned then to to my first test, and I placed control points following the program's instructions, and got a model that was very similar to the final result. When I thought that

instructions, and got a model that was very similar to the final result. When I thought that the model was correct and had it cleaned up, I exported it as an OBJ file (dario5.obj).

the model was correct and had it cleaned up, I exported it as an OBJ file (dario5.obj).

To prepare the STL file I used Rhinoceros (dario5.3dm); I closed the holes and saved the

To prepare the STL file I used Rhinoceros (dario5.3dm); I closed the holes and saved the result as STL (dario5.stl).

result as STL (dario5.stl).

The printer I have used is a Makerbot Replicator. It is a printer with two injection heads,

The printer I have used is a Makerbot Replicator. It is a printer with two injection heads, with the following specifications:

with the following specifications:

MECHANICAL

MECHANICAL Dimensions: 320 x 467 x 381 mm | 12.6 x 18.4 x 15 in

Dimensions: 320 x 467 x 381 mm | 12.6 x 18.4 x 15 in Weight: 32 lbs

Linear ball bearings

Precision shafts 8 mm land

In add-on, snap front carriage assemblies

ELECTRONIC

Weight: 32 lbs

Linear ball bearings

Precision shafts 8 mm land

In add-on, snap front carriage assemblies

ELECTRONIC MakerBot motherboard MightyBoard unique piece

MakerBot motherboard MightyBoard unique piece 5 axes, 1/16 micro-stepping motor control

4x20 character LCD display and multi-directional control pad

5 axes, 1/16 micro-stepping motor control

4x20 character LCD display and multi-directional control pad Piezo Buzzer

Piezo Buzzer Software-controllable RGB LED lighting

Software-controllable RGB LED lighting Universal power supply: 100-240V, 50/60Hz, 4.0A (input), and IEC standard socket cord

Universal power supply: 100-240V, 50/60Hz, 4.0A (input), and IEC standard socket cord SOFTWARE: REPLICATORG ™

SOFTWARE: REPLICATORG ™ Compatibility: Linux, OSX and Windows

Compatibility: Linux, OSX and Windows Printing from SD card or USB

Printing from SD card or USB Input file type: STL, Gcode

Input file type: STL, Gcode Approximately 5 liters

Approximately 5 liters Choose Layer thickness 0.2-0.3 mm with stock nozzle

Choose Layer thickness 0.2-0.3 mm with stock nozzle The nozzle diameter of 0.4 mm

The nozzle diameter of 0.4 mm Accelerating 40 mm / s

Accelerating 40 mm / s Flow Approximately 24 cc / hr

Flow Approximately 24 cc / hr Maximum recommended extruder temperature 230 C

Heated Build Platform 120 C Maximum

Maximum recommended extruder temperature 230 C

Heated Build Platform 120 C Maximum 2.5 micron precision in positioning the Z axis

11.micron in XY

2.5 micron precision in positioning the Z axis

11.micron in XY MATERIALS

MATERIALS Works with ABS, PLA and other materials

Works with ABS, PLA and other materials Filament diameter: 1.75 mm

The printer software is simple to use REPLICATORG. The process is very sensitive to

Filament diameter: 1.75 mm

The printer software is simple to use REPLICATORG. The process is very sensitive to cold and if the printer is not carefully calibrated models do not print well. Heat is

cold and if the printer is not carefully calibrated models do not print well. Heat is important; these weeks in Sevilla temperatures are low. To keep the machine warm, we

important; these weeks in Sevilla temperatures are low. To keep the machine warm, we have had to cover the it with a plastic bag, which has been very successful.

have had to cover the it with a plastic bag, which has been very successful. The model was printed in 25 minutes and has a height of 3 cm. The result appears in the

The model was printed in 25 minutes and has a height of 3 cm. The result appears in the images, and I, who am the father of Darius, can ensure that the model looks like him.

images, and I, who am the father of Darius, can ensure that the model looks like him. The result of this is very interesting for my final project, as a suitable exercise to design

The result of this is very interesting for my final project, as a suitable exercise to design for children between 13 and 15 years old.

for children between 13 and 15 years old. Please note:

•

Checkpoints in the elements

•

Many photographs

Please note:

•

Checkpoints in the elements

•

Many photographs •

Beware of the elements around the model. The board I used on Darius' neck had

•

Beware of the elements around the model. The board I used on Darius' neck had too much information; it shouldn't have had the rear flaps.

too much information; it shouldn't have had the rear flaps. •

Optimum conditions for the printer.

•

Optimum conditions for the printer.

Juan Carlos Pérez Juidias. Fab Lab Escuela Técnica Superior de Arquitectura de la Universidad de Sevilla