Final Project

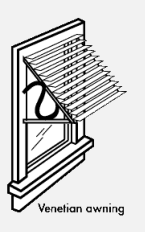

My project is a shade house with slats. In Seville, my city, the climate is very

hot in summer and the city has over 300 days of sunshine a year. Typically,

the buildings have textile folding canopy shades that do not maintain air

circulation (greenhouse effect) and manual handling (need to maneuver often

for optimal performance, by sunlight, rain).

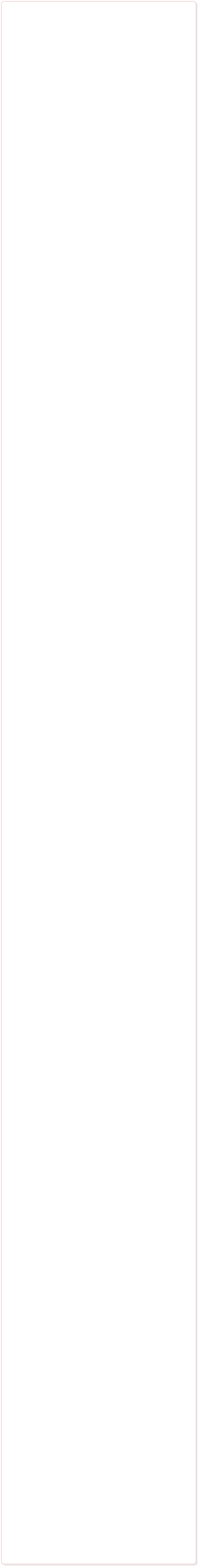

On a walk through the historic center of Seville exist an increase, from 2006

until today, of the outdoor tables of bars and restaurants. A few years ago the

use of outside for these premises was different: not used in peak hours

sunlight or in and out intermittently.

On a walk through the historic center of Seville exist an increase, from 2006

until today, of the outdoor tables of bars and restaurants. A few years ago the

use of outside for these premises was different: not used in peak hours

sunlight or in and out intermittently.

From Snuff Act, there is a new situation: external empowerment zones in a

longer stay (tables) for smokers. But there appears to have resulted in an

innovative response to ensure comfort in these spaces.

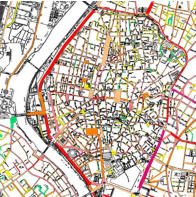

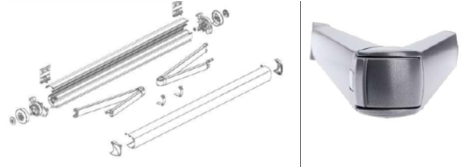

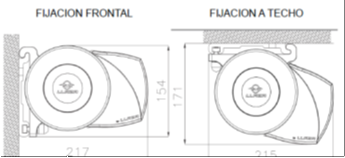

In the study area have seen little innovation or awnings are textiles are rigid

type (sliding as much). I have investigated in these cases, to know what

exists in the market through dynamometer control that automatically fold the

awning with high wind loads, etc.

From Snuff Act, there is a new situation: external empowerment zones in a

longer stay (tables) for smokers. But there appears to have resulted in an

innovative response to ensure comfort in these spaces.

In the study area have seen little innovation or awnings are textiles are rigid

type (sliding as much). I have investigated in these cases, to know what

exists in the market through dynamometer control that automatically fold the

awning with high wind loads, etc.

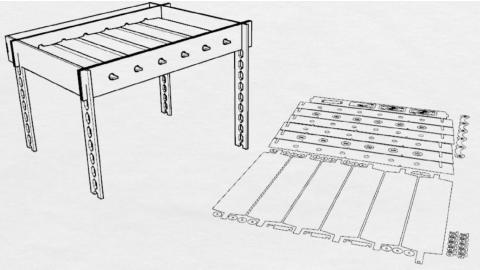

Therefore, my project is a scale model which enables the possibility of

creating a house of shadows for every need. My idea was more ambitious

and not be alone in this project, as I explain below.

Design Considerations

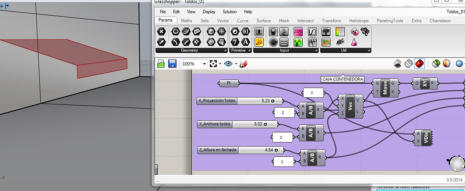

For the design I used Rhinoceros 3D. The possibility of using grasshoppers

is important. In my business idea argue that web design is a application in

which the client can with parametric design house design their own shadows

.

Therefore, my project is a scale model which enables the possibility of

creating a house of shadows for every need. My idea was more ambitious

and not be alone in this project, as I explain below.

Design Considerations

For the design I used Rhinoceros 3D. The possibility of using grasshoppers

is important. In my business idea argue that web design is a application in

which the client can with parametric design house design their own shadows

.

In this case, due to the simplicity of the prototype have not used, but is in the

business idea.

In this case, due to the simplicity of the prototype have not used, but is in the

business idea.

In my prototype, I wanted no screws or glue to the prototype is assembled

and disassembled. I've only used screws holding the motor and board.

In my prototype, I wanted no screws or glue to the prototype is assembled

and disassembled. I've only used screws holding the motor and board.

Final Model

Final Model

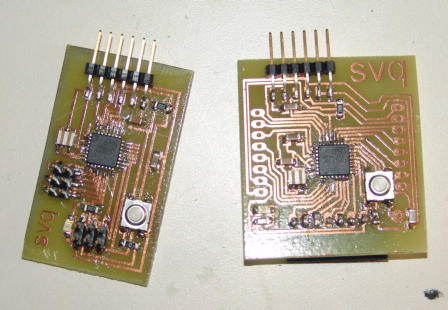

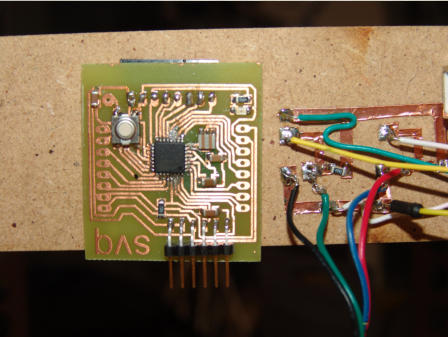

In my story on Fab Academy my main weakness is electronics. I knew

absolutely nothing about electronics for 6 months. But I have learned a little.

In my story on Fab Academy my main weakness is electronics. I knew

absolutely nothing about electronics for 6 months. But I have learned a little.

To my electronics I chose something very simple. A control system using two

light sensors and servo motor. While the first idea was more likely that he

could still go ahead.

I made some modifications to a code I got from the internet

#include <Servo.h>

Servo myservo;

int pos = 0; // Variable para almacenar la posición del servo.

int inputPhotoLeft = 1; // más fácil de leer, en lugar de sólo 1 ó 0

int inputPhotoRight = 0;

int Left = 0; // lecturas de los fotoresistores.

int Right = 0; // lecturas de los fotoresistores.

void setup()

{

myservo.attach(9); // Conecta el servo al pin 9

}

void loop()

{

// Lee los valores de los fotoresistores a las variables Izquierda y Derecha.

Left = analogRead(0);

Right = analogRead(1);

// Comprueba si el derecho es más grande que la izquierda, si es así mover a

derecha.

if (Left > (Right +20))

// 20 es la zona muerta, por lo que planteo se agitan de ida y vuelta.

{

if (pos < 90)

pos++;

myservo.write(pos);

}

// Comprueba si la izquierda es mayor que el derecho, si así trasladarse a la

izquierda.

if (Right > (Left +20))

// 20 es la zona muerta, por lo que planteo se agitan de ida y vuelta.

{

if (pos > 1)

pos -= 1;

myservo.write(pos);

}

// Añadido cierto retraso, aumentar o disminuir si quiere más o menos velocidad.

delay(25*-0);

}

In this video we can see the model.

Final conclusions

I have the feeling that I have only begun to see the possibilities of my project.

This excites me, because I will continue after the Fab Academy to make

improvements, such as adding new controls moisture to protect from rain,

supporting solar panels or micro sprinklers to cool. I also thought that the

prototype can be adapted to the windows to keep intruders out and the sun

too.

To my electronics I chose something very simple. A control system using two

light sensors and servo motor. While the first idea was more likely that he

could still go ahead.

I made some modifications to a code I got from the internet

#include <Servo.h>

Servo myservo;

int pos = 0; // Variable para almacenar la posición del servo.

int inputPhotoLeft = 1; // más fácil de leer, en lugar de sólo 1 ó 0

int inputPhotoRight = 0;

int Left = 0; // lecturas de los fotoresistores.

int Right = 0; // lecturas de los fotoresistores.

void setup()

{

myservo.attach(9); // Conecta el servo al pin 9

}

void loop()

{

// Lee los valores de los fotoresistores a las variables Izquierda y Derecha.

Left = analogRead(0);

Right = analogRead(1);

// Comprueba si el derecho es más grande que la izquierda, si es así mover a

derecha.

if (Left > (Right +20))

// 20 es la zona muerta, por lo que planteo se agitan de ida y vuelta.

{

if (pos < 90)

pos++;

myservo.write(pos);

}

// Comprueba si la izquierda es mayor que el derecho, si así trasladarse a la

izquierda.

if (Right > (Left +20))

// 20 es la zona muerta, por lo que planteo se agitan de ida y vuelta.

{

if (pos > 1)

pos -= 1;

myservo.write(pos);

}

// Añadido cierto retraso, aumentar o disminuir si quiere más o menos velocidad.

delay(25*-0);

}

In this video we can see the model.

Final conclusions

I have the feeling that I have only begun to see the possibilities of my project.

This excites me, because I will continue after the Fab Academy to make

improvements, such as adding new controls moisture to protect from rain,

supporting solar panels or micro sprinklers to cool. I also thought that the

prototype can be adapted to the windows to keep intruders out and the sun

too.

Acknowledgements

To Fab Academy, I learned a lot. I was a machine operator Fab Lab sad, now

I have really wanted to participate in projects of my workplace.

For José Pérez de Lama, Juan Carlos Venegas and Jose Mailbox, for

helping teach me and bear with me.

To Aureliano Gomez, our craftsman guru, a person who is able to do

anything.

To all fellow Fab Academy who have helped us to continue to the end.

Thank you very much ....

Materials

- Table of MDF (1220x800x3 mm)

- 1 Servo

- 2x 490 Ohms resistors.

- 2x Photoresistors

- 1 arduino fabkit

-

References

How to make a light tracker using arduino & photoresistors!

Fab Academy at AS220

http://academy.cba.mit.edu/2013/schedule/index.html

Pérez de Lama’s web at Fab Academy 2013

Nuria Robles’ web at Fab Academy 2012

http://www.arduino.cc/

Acknowledgements

To Fab Academy, I learned a lot. I was a machine operator Fab Lab sad, now

I have really wanted to participate in projects of my workplace.

For José Pérez de Lama, Juan Carlos Venegas and Jose Mailbox, for

helping teach me and bear with me.

To Aureliano Gomez, our craftsman guru, a person who is able to do

anything.

To all fellow Fab Academy who have helped us to continue to the end.

Thank you very much ....

Materials

- Table of MDF (1220x800x3 mm)

- 1 Servo

- 2x 490 Ohms resistors.

- 2x Photoresistors

- 1 arduino fabkit

-

References

How to make a light tracker using arduino & photoresistors!

Fab Academy at AS220

http://academy.cba.mit.edu/2013/schedule/index.html

Pérez de Lama’s web at Fab Academy 2013

Nuria Robles’ web at Fab Academy 2012

http://www.arduino.cc/

On a walk through the historic center of Seville exist an increase, from 2006

until today, of the outdoor tables of bars and restaurants. A few years ago the

use of outside for these premises was different: not used in peak hours

sunlight or in and out intermittently.

On a walk through the historic center of Seville exist an increase, from 2006

until today, of the outdoor tables of bars and restaurants. A few years ago the

use of outside for these premises was different: not used in peak hours

sunlight or in and out intermittently.

From Snuff Act, there is a new situation: external empowerment zones in a

longer stay (tables) for smokers. But there appears to have resulted in an

innovative response to ensure comfort in these spaces.

In the study area have seen little innovation or awnings are textiles are rigid

type (sliding as much). I have investigated in these cases, to know what

exists in the market through dynamometer control that automatically fold the

awning with high wind loads, etc.

From Snuff Act, there is a new situation: external empowerment zones in a

longer stay (tables) for smokers. But there appears to have resulted in an

innovative response to ensure comfort in these spaces.

In the study area have seen little innovation or awnings are textiles are rigid

type (sliding as much). I have investigated in these cases, to know what

exists in the market through dynamometer control that automatically fold the

awning with high wind loads, etc.

Therefore, my project is a scale model which enables the possibility of

creating a house of shadows for every need. My idea was more ambitious

and not be alone in this project, as I explain below.

Design Considerations

For the design I used Rhinoceros 3D. The possibility of using grasshoppers

is important. In my business idea argue that web design is a application in

which the client can with parametric design house design their own shadows

.

Therefore, my project is a scale model which enables the possibility of

creating a house of shadows for every need. My idea was more ambitious

and not be alone in this project, as I explain below.

Design Considerations

For the design I used Rhinoceros 3D. The possibility of using grasshoppers

is important. In my business idea argue that web design is a application in

which the client can with parametric design house design their own shadows

.

In this case, due to the simplicity of the prototype have not used, but is in the

business idea.

In this case, due to the simplicity of the prototype have not used, but is in the

business idea.

In my prototype, I wanted no screws or glue to the prototype is assembled

and disassembled. I've only used screws holding the motor and board.

In my prototype, I wanted no screws or glue to the prototype is assembled

and disassembled. I've only used screws holding the motor and board.

Final Model

Final Model

In my story on Fab Academy my main weakness is electronics. I knew

absolutely nothing about electronics for 6 months. But I have learned a little.

In my story on Fab Academy my main weakness is electronics. I knew

absolutely nothing about electronics for 6 months. But I have learned a little.

To my electronics I chose something very simple. A control system using two

light sensors and servo motor. While the first idea was more likely that he

could still go ahead.

I made some modifications to a code I got from the internet

#include <Servo.h>

Servo myservo;

int pos = 0; // Variable para almacenar la posición del servo.

int inputPhotoLeft = 1; // más fácil de leer, en lugar de sólo 1 ó 0

int inputPhotoRight = 0;

int Left = 0; // lecturas de los fotoresistores.

int Right = 0; // lecturas de los fotoresistores.

void setup()

{

myservo.attach(9); // Conecta el servo al pin 9

}

void loop()

{

// Lee los valores de los fotoresistores a las variables Izquierda y Derecha.

Left = analogRead(0);

Right = analogRead(1);

// Comprueba si el derecho es más grande que la izquierda, si es así mover a

derecha.

if (Left > (Right +20))

// 20 es la zona muerta, por lo que planteo se agitan de ida y vuelta.

{

if (pos < 90)

pos++;

myservo.write(pos);

}

// Comprueba si la izquierda es mayor que el derecho, si así trasladarse a la

izquierda.

if (Right > (Left +20))

// 20 es la zona muerta, por lo que planteo se agitan de ida y vuelta.

{

if (pos > 1)

pos -= 1;

myservo.write(pos);

}

// Añadido cierto retraso, aumentar o disminuir si quiere más o menos velocidad.

delay(25*-0);

}

In this video we can see the model.

Final conclusions

I have the feeling that I have only begun to see the possibilities of my project.

This excites me, because I will continue after the Fab Academy to make

improvements, such as adding new controls moisture to protect from rain,

supporting solar panels or micro sprinklers to cool. I also thought that the

prototype can be adapted to the windows to keep intruders out and the sun

too.

To my electronics I chose something very simple. A control system using two

light sensors and servo motor. While the first idea was more likely that he

could still go ahead.

I made some modifications to a code I got from the internet

#include <Servo.h>

Servo myservo;

int pos = 0; // Variable para almacenar la posición del servo.

int inputPhotoLeft = 1; // más fácil de leer, en lugar de sólo 1 ó 0

int inputPhotoRight = 0;

int Left = 0; // lecturas de los fotoresistores.

int Right = 0; // lecturas de los fotoresistores.

void setup()

{

myservo.attach(9); // Conecta el servo al pin 9

}

void loop()

{

// Lee los valores de los fotoresistores a las variables Izquierda y Derecha.

Left = analogRead(0);

Right = analogRead(1);

// Comprueba si el derecho es más grande que la izquierda, si es así mover a

derecha.

if (Left > (Right +20))

// 20 es la zona muerta, por lo que planteo se agitan de ida y vuelta.

{

if (pos < 90)

pos++;

myservo.write(pos);

}

// Comprueba si la izquierda es mayor que el derecho, si así trasladarse a la

izquierda.

if (Right > (Left +20))

// 20 es la zona muerta, por lo que planteo se agitan de ida y vuelta.

{

if (pos > 1)

pos -= 1;

myservo.write(pos);

}

// Añadido cierto retraso, aumentar o disminuir si quiere más o menos velocidad.

delay(25*-0);

}

In this video we can see the model.

Final conclusions

I have the feeling that I have only begun to see the possibilities of my project.

This excites me, because I will continue after the Fab Academy to make

improvements, such as adding new controls moisture to protect from rain,

supporting solar panels or micro sprinklers to cool. I also thought that the

prototype can be adapted to the windows to keep intruders out and the sun

too.

Acknowledgements

To Fab Academy, I learned a lot. I was a machine operator Fab Lab sad, now

I have really wanted to participate in projects of my workplace.

For José Pérez de Lama, Juan Carlos Venegas and Jose Mailbox, for

helping teach me and bear with me.

To Aureliano Gomez, our craftsman guru, a person who is able to do

anything.

To all fellow Fab Academy who have helped us to continue to the end.

Thank you very much ....

Materials

- Table of MDF (1220x800x3 mm)

- 1 Servo

- 2x 490 Ohms resistors.

- 2x Photoresistors

- 1 arduino fabkit

-

References

How to make a light tracker using arduino & photoresistors!

Fab Academy at AS220

http://academy.cba.mit.edu/2013/schedule/index.html

Pérez de Lama’s web at Fab Academy 2013

Nuria Robles’ web at Fab Academy 2012

http://www.arduino.cc/

Acknowledgements

To Fab Academy, I learned a lot. I was a machine operator Fab Lab sad, now

I have really wanted to participate in projects of my workplace.

For José Pérez de Lama, Juan Carlos Venegas and Jose Mailbox, for

helping teach me and bear with me.

To Aureliano Gomez, our craftsman guru, a person who is able to do

anything.

To all fellow Fab Academy who have helped us to continue to the end.

Thank you very much ....

Materials

- Table of MDF (1220x800x3 mm)

- 1 Servo

- 2x 490 Ohms resistors.

- 2x Photoresistors

- 1 arduino fabkit

-

References

How to make a light tracker using arduino & photoresistors!

Fab Academy at AS220

http://academy.cba.mit.edu/2013/schedule/index.html

Pérez de Lama’s web at Fab Academy 2013

Nuria Robles’ web at Fab Academy 2012

http://www.arduino.cc/

Juan Carlos Pérez Juidias. Fab Lab Escuela Técnica Superior de Arquitectura de la Universidad de Sevilla