MOLDING & CASTING

During this

week, i have created a Tetris pieces ice tray.

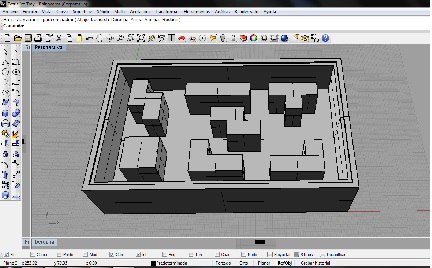

I designed it with Rhino and export the file as binary STL.

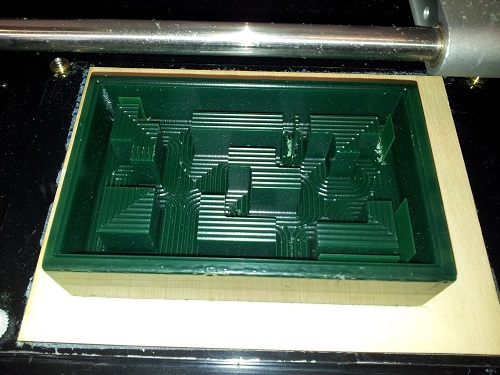

Then I configured de milling settings on the Modela, first of all I made a rough mill with a 3mm tool to pull out the most part of the material I need to mill for the machinable wax block.

After this I configure the milling settings for a final mill, also with 3mm tool, but in this case with more overlap to get a smooth finish.

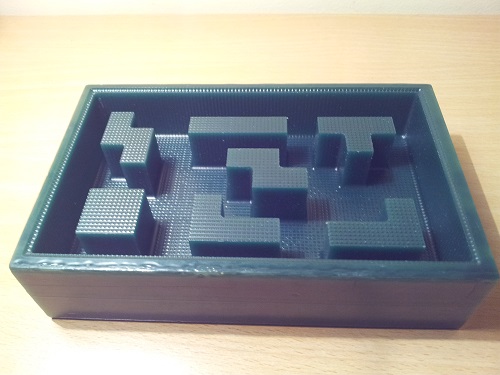

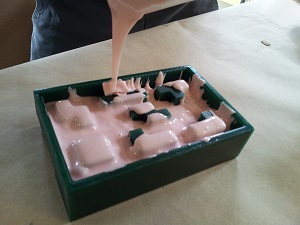

When I have our negative wax mold ready, I

calculated the volume of the mold, to mix only the necessary quantity of

silicone.

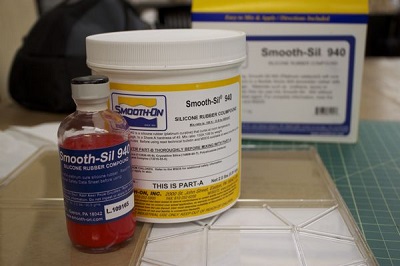

I used food grade silicone, in this case, Smooth-Sil 940.

Then, I mix very well the two parts of silicone, following the product instructions.

When we have our silicon really well mixed, we start to tip it out on the wax negative mold slowly and trying to put it all over the negative mold holes.

Then when we have the silicone on the negative mold, itīs very important to shake it, we do this to take all the air bubbles out of the silicone.

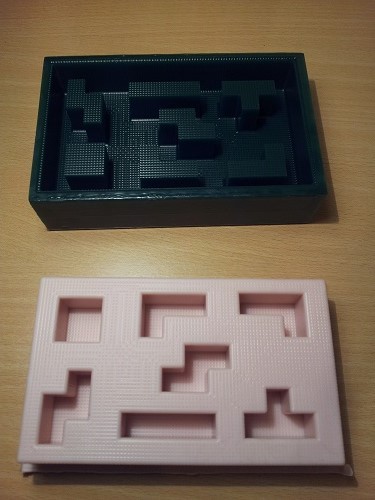

The product specifications tell us that we need to wait around 24 hours before to demold the silicone from the wax. Well… after 24 hours, this is the result.

Now we have our Tetris food grade silicone Ice tray mold ready to be filled of water and placed into the freezer.

After a couple of hours, we have our Tetris ices ready to be used.

The STL file of

the negative wax mold is available to be downloaded here.

Greetings

from Leon, and have a nice week!