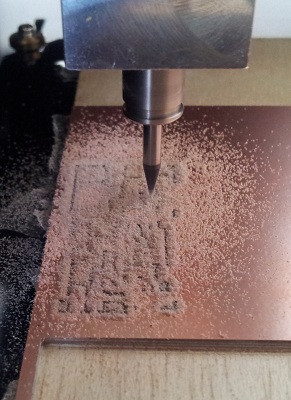

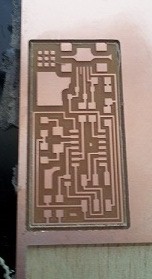

The first I

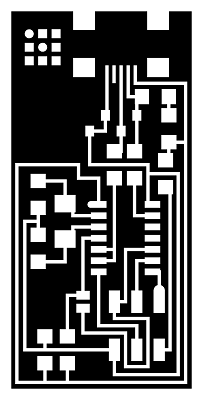

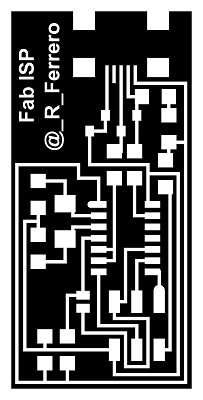

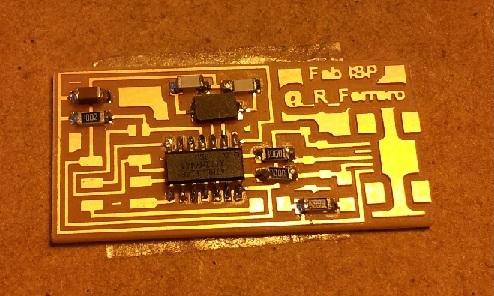

did this week was to edit the design of the circuit with Inkscape to add a

little customized text to the board.

After this

I used the Fab modules to configure the CAM details.

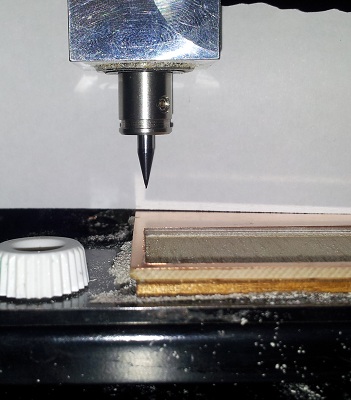

To set the

Z=0 without danger to damage the mill, what I make is to insert the mill more

than necessary on support and move the machine to the x=0 & y=0 that we set

on Fab modules. After this, when we have the mounting head paced on x=0 &

y=0, I down it near the board but not a lot and unscrew a bit the mill support,

and the mill will go down and adjust to the board, now I screw again the

support and the z=0 is set now.

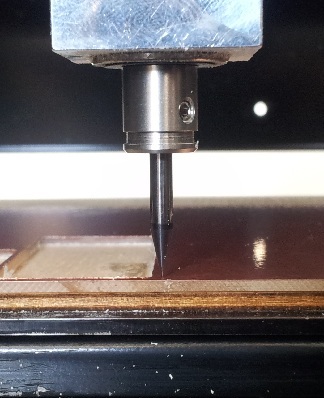

I used a 1/64 mill to make the circuit lay-out and a 1/32 one to cut the board.

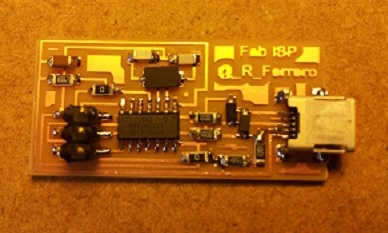

I start to solder the smaller components and form in to out of the board.

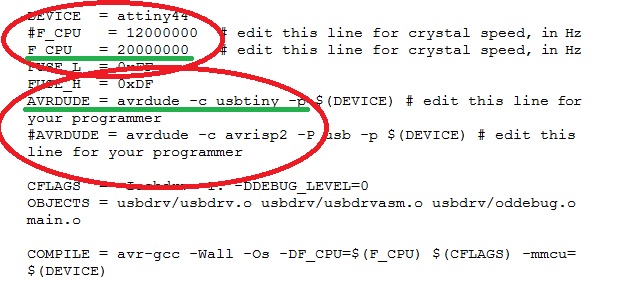

To program

my FabISP I used a MAC, after download and install all the necessary software

(avrdude and GCC) I edit the makefile file and look to the crystal speed and

programmer configuration.

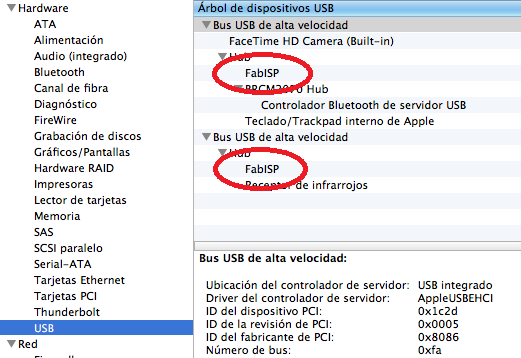

Now I power

my FabISP and connect it to another FabISP that was already programmed last

year.

Then I used

the next instructions to transfer the program to the new board.

make clean

make hex

sudo make

fuse

sudo make program

If everything is Ok, you must see your new FabISP (also the 1st one) on your system hardware menu.

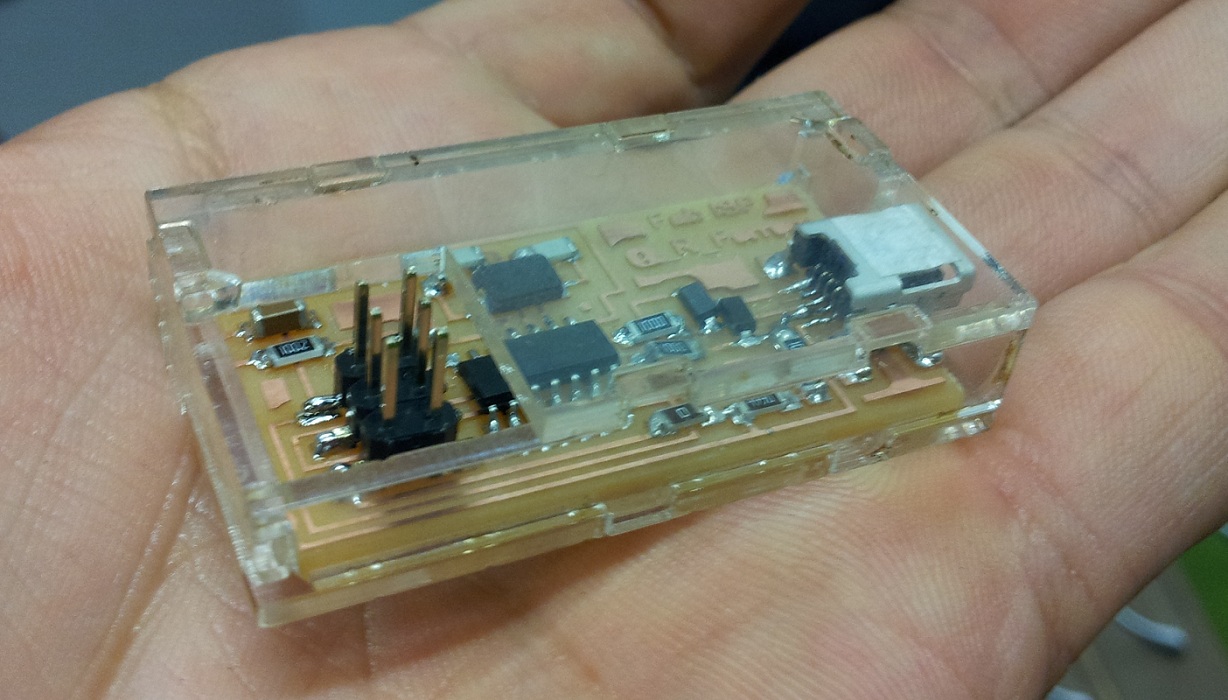

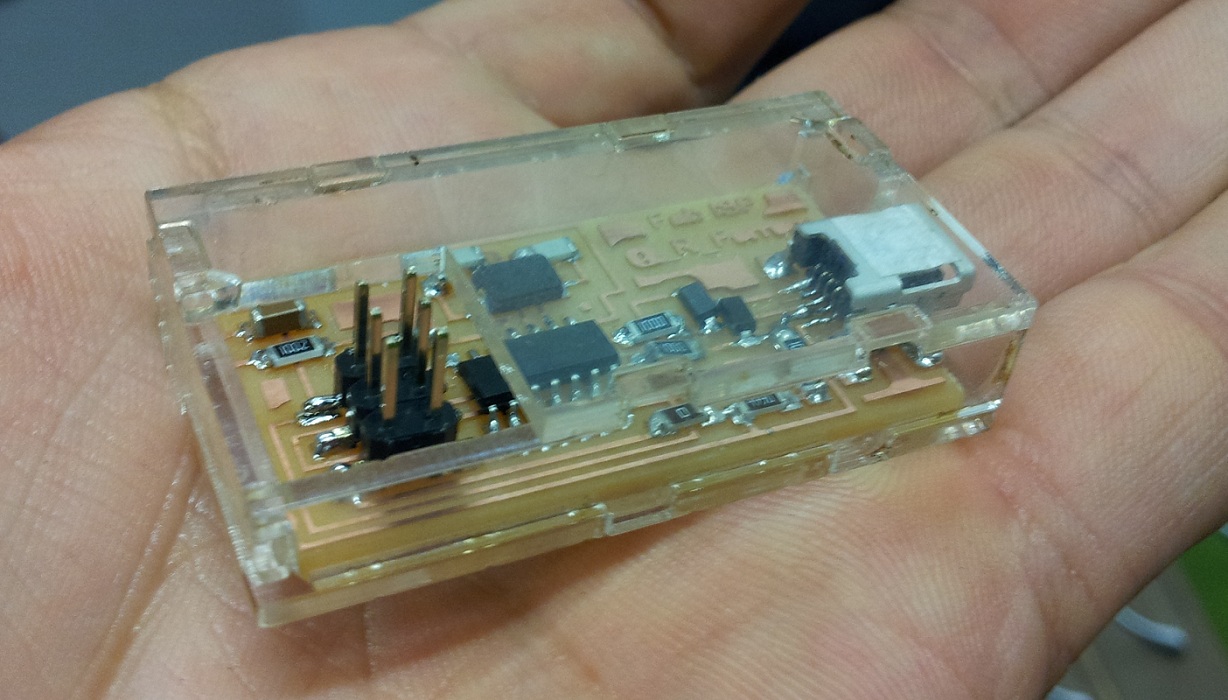

To finish I design a little box to the FabISP in Rhino and cut it on 2mm acrylic.

I hope you

like it.