This week I have made some composite helicopter blades

First of

all I demount the original blades from the helicopter.

My idea was

to use the original blades as mold to make some replacement blades to my

helicopter, unfortunately I usually break a lot of them :-(

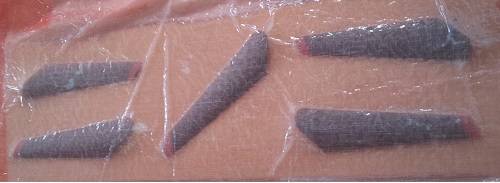

Here you

can see the original blades out of the rotor.

I decide

between two different materials for the composite, my first idea was to use a

“plastic” waterproof cloth (black one on the photo) to get more hard, but I

test it before and it’s difficult to fill it with the resin, so finally I use a

normal thing cloth (white one on the photo).

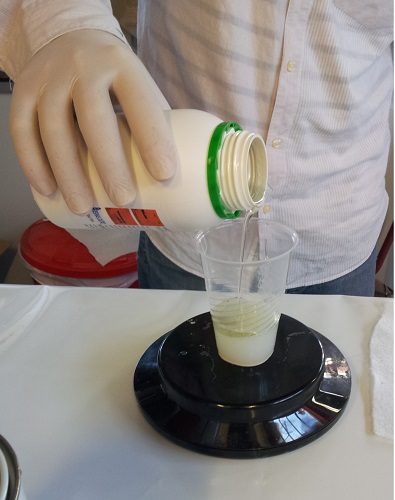

In the next

photo composition you can see all the process; I put the original blades over a

piece of wood and cover it with plastic to keep if save to the resin. Over this

plastic we put our cloth “painted” with the resin, and we cover it again with

plastic. Then, we cover all it again with the special foamy cloth, this cloth

its necessary to prevent the vacuum nozzle hole be blocked by plastic while

vacuuming.

Now it’s the moment to put all in a final bag (It’s important to close very well all the lateral holes) finally we put the vacuum nozzle on the final bag and connect the vacuum machine.

We must

keep the bag on vacuum for about 20 hours to get the resin dry on the right

form.

The two

finally photos of the compose are the result after the drying time.

rc helicopter - DIY blades from R.Ferrero on Vimeo.