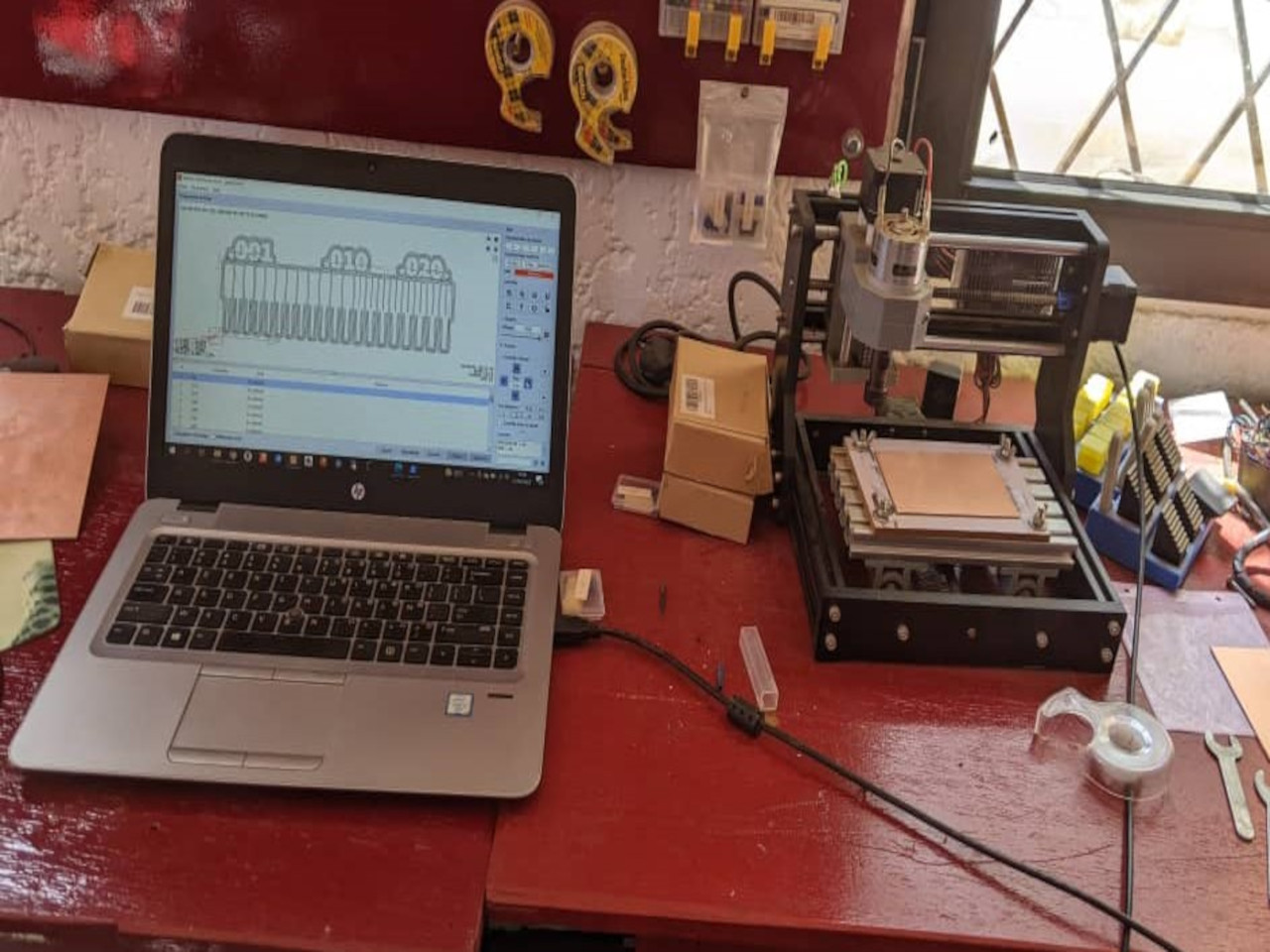

Operation setup

This setup shows the machine connected to a laptop via a usb cable. this will enable us to control and feed the machine via the laptop

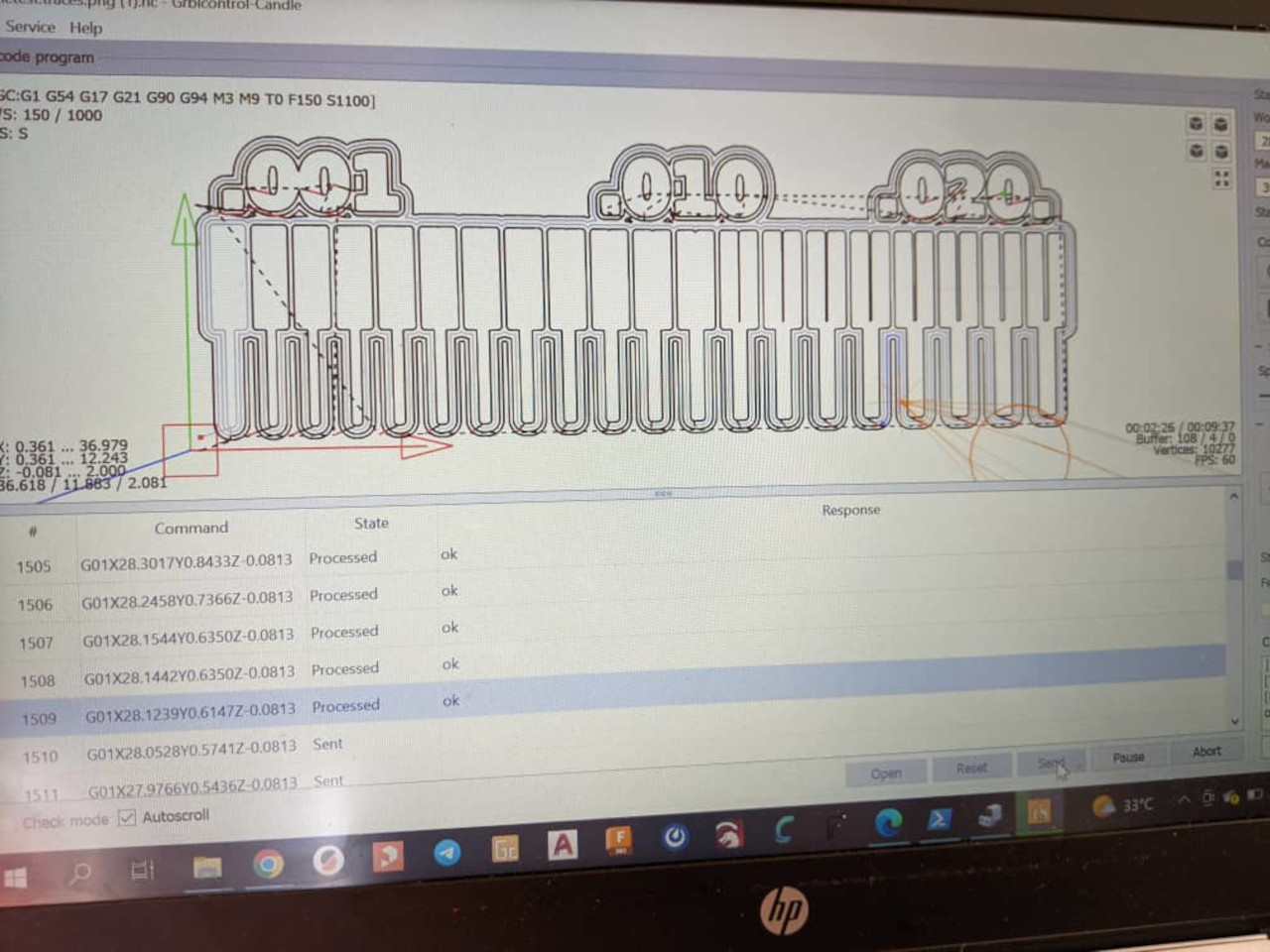

Toolpath and Milling

Universal G-code sender was used to send the G-Code to Pinnochio(the milling machine)

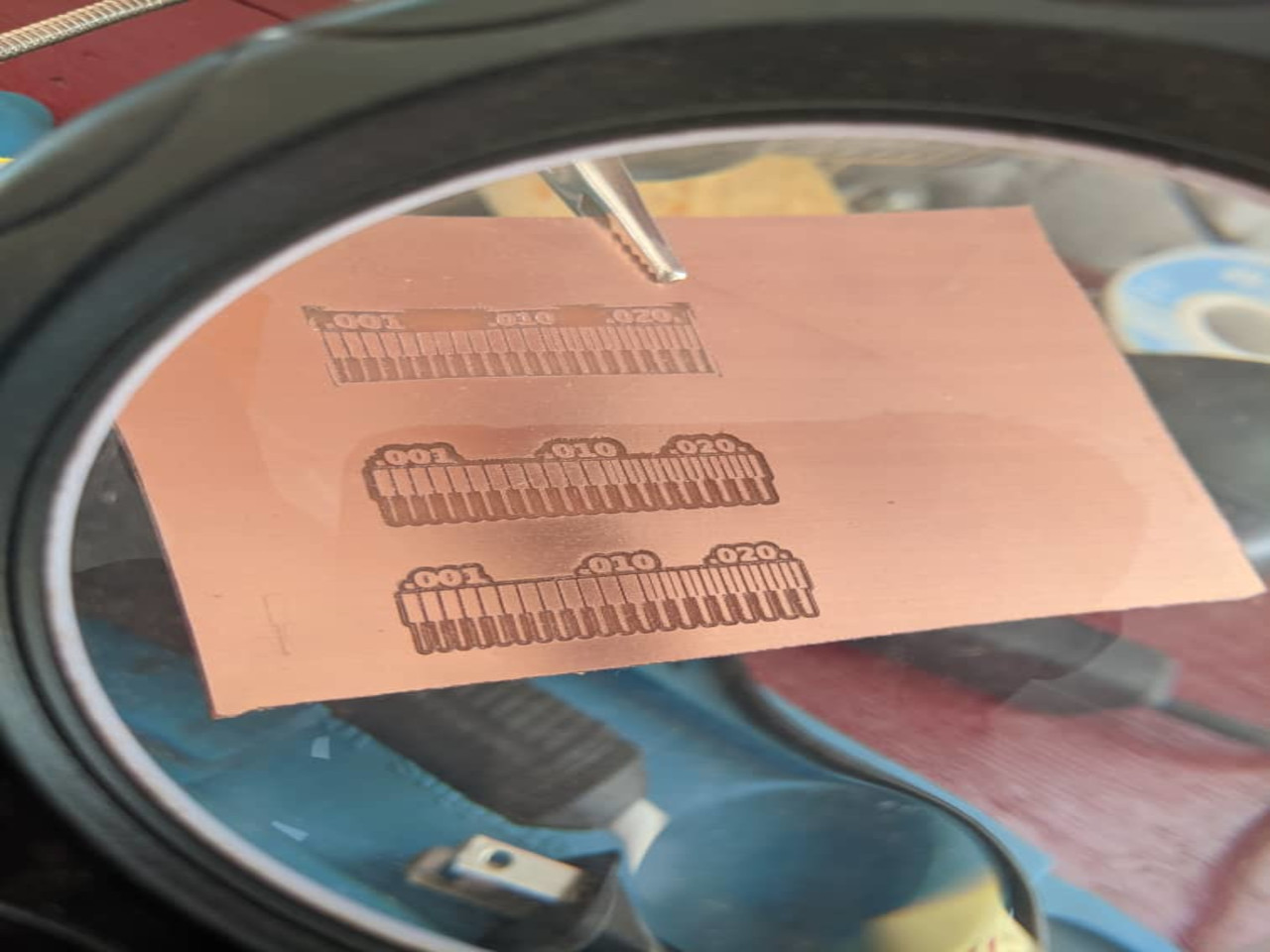

Zeroing Technique

We used the paper zeroing method to help in zeroing the bit(Z-travel). this is the process of using that technique, a piece of paper is placed on the copper piece and then the bit in the spindle is lowered until the tip of the bit touches the paper. the paper is then removed and the head is moved 0.08mm downwards to compensate for the thickness of the paper.

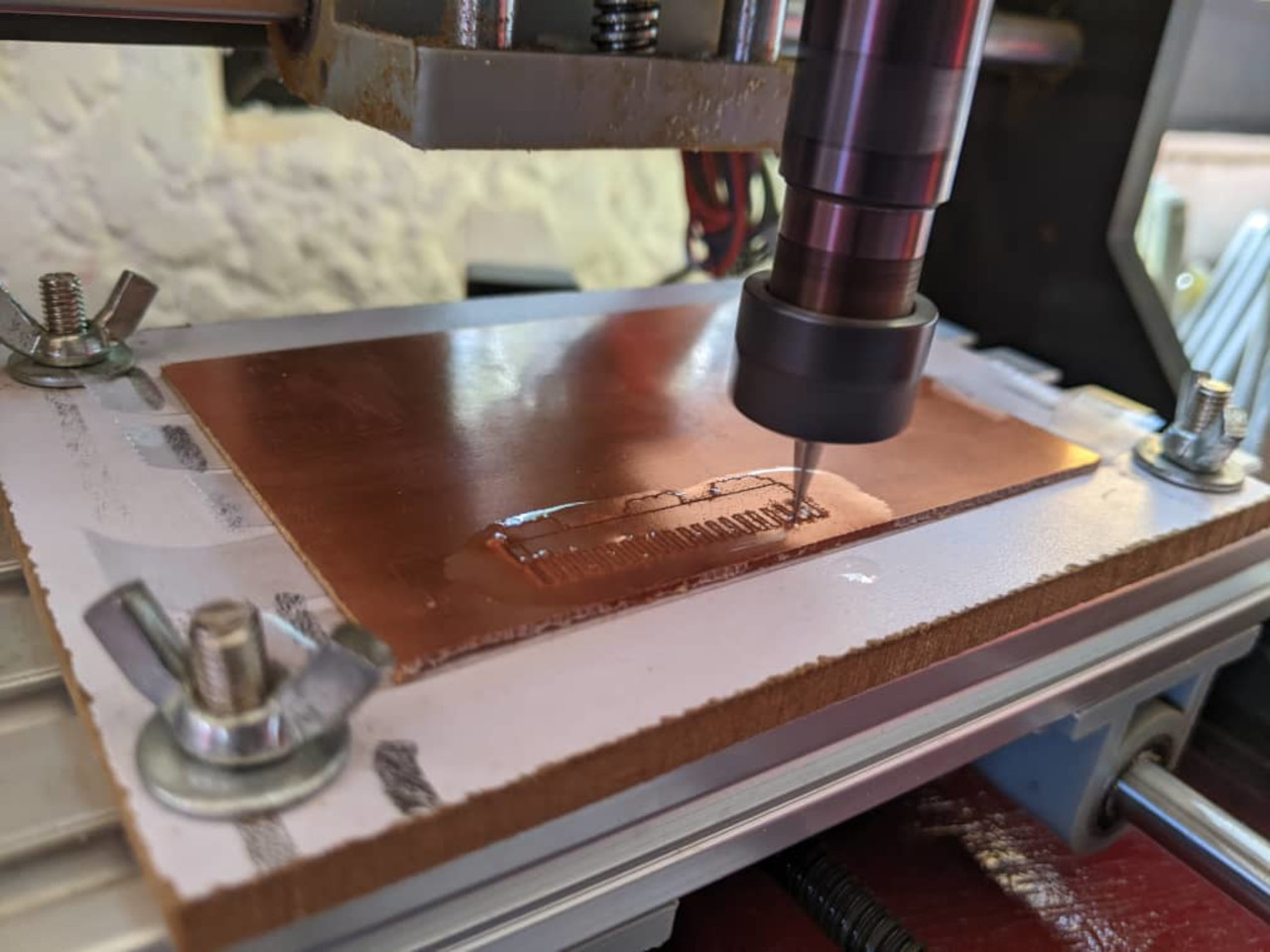

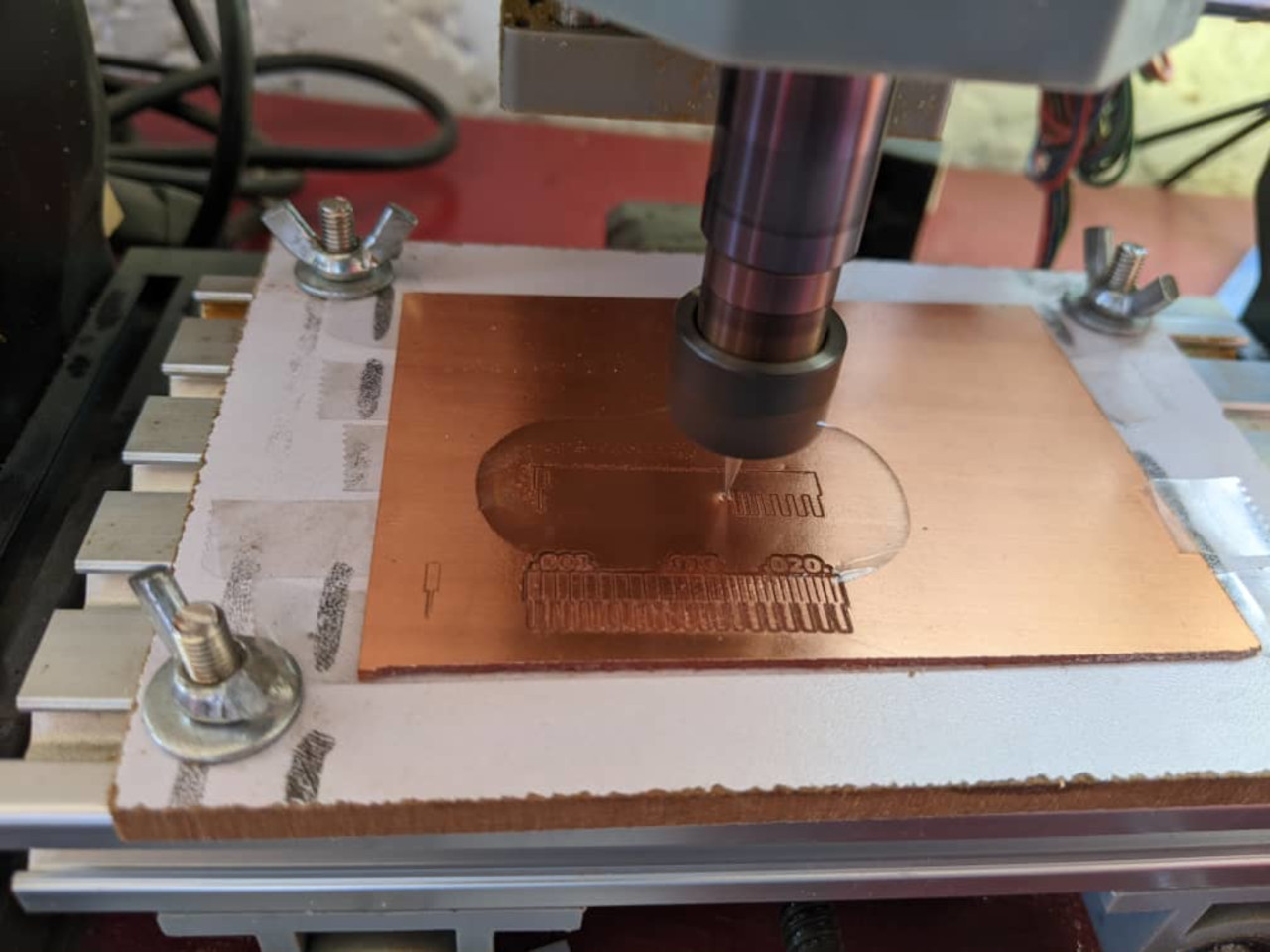

Milling Process

A film of oil(machine oil) was put on the copper face to have a cleaner cut.

| IDEAL SETTINGS FOR PCB V-BIT¶ | IDEAL SETTING FOR PCB END-MILL¶ |

|---|---|

| Bit type: V-bit | flat-end Mill |

| Bit size: Select 0.3 mm | 1 mm |

| cut depth: 0.1 | 0.5 |

| max depth: 0.1 | 1.5 |

| cut speed: 2.5 mm/s | 2.5 mm/s |

| Plunge speed: 2.5 mm/s | 2.5 mm/s |