group assignment do your lab’s safety training test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machine

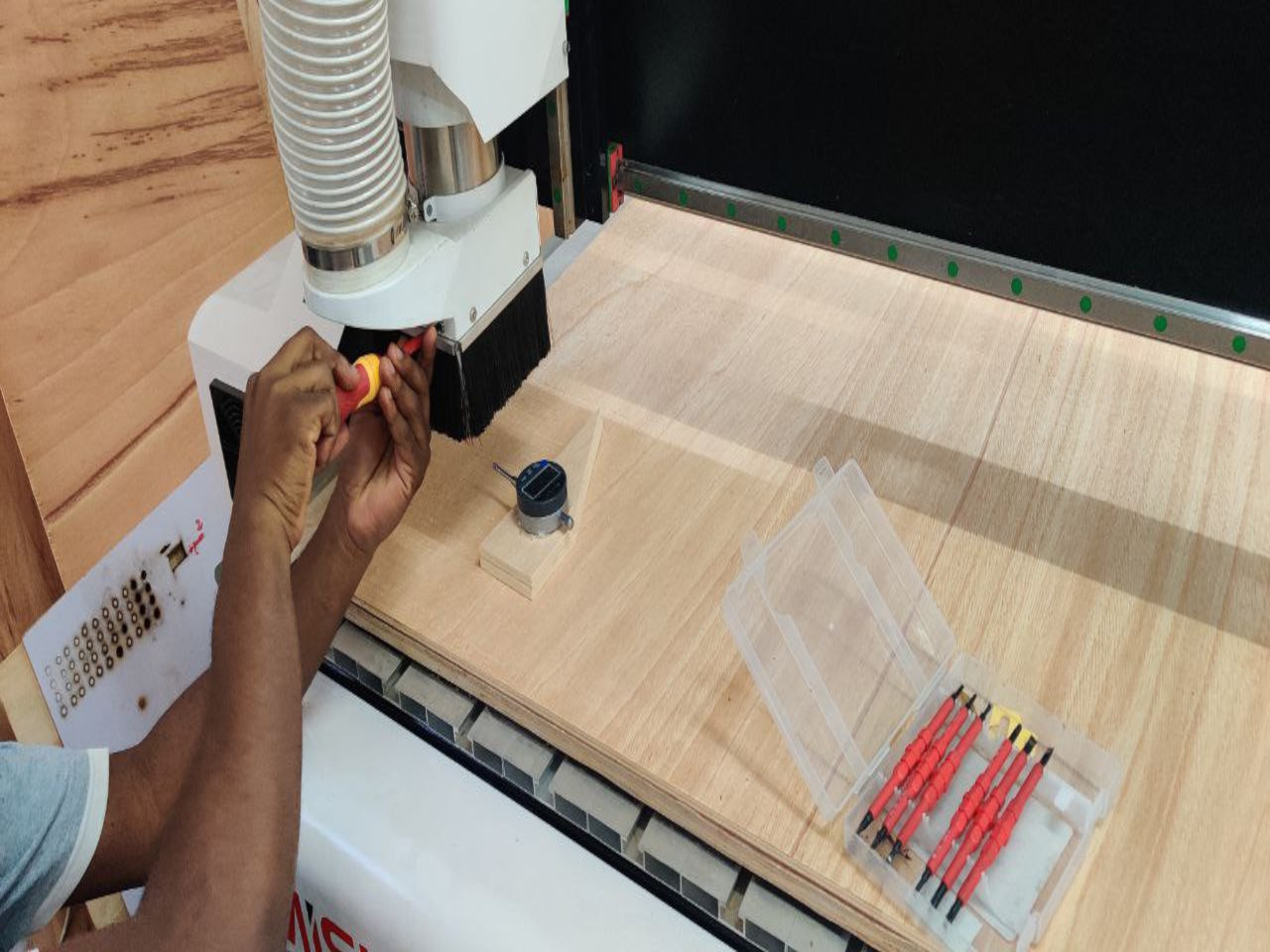

Runout

We performed the runout test on the Spindle to know the amount of runout error it had. CNC spindle runout refers to the amount of deviation or wobble in the rotation of the spindle. It affects the accuracy of machining operations, with higher runout leading to reduced precision. Minimizing runout is crucial for achieving precise cuts and maintaining consistent quality in CNC machining processes.

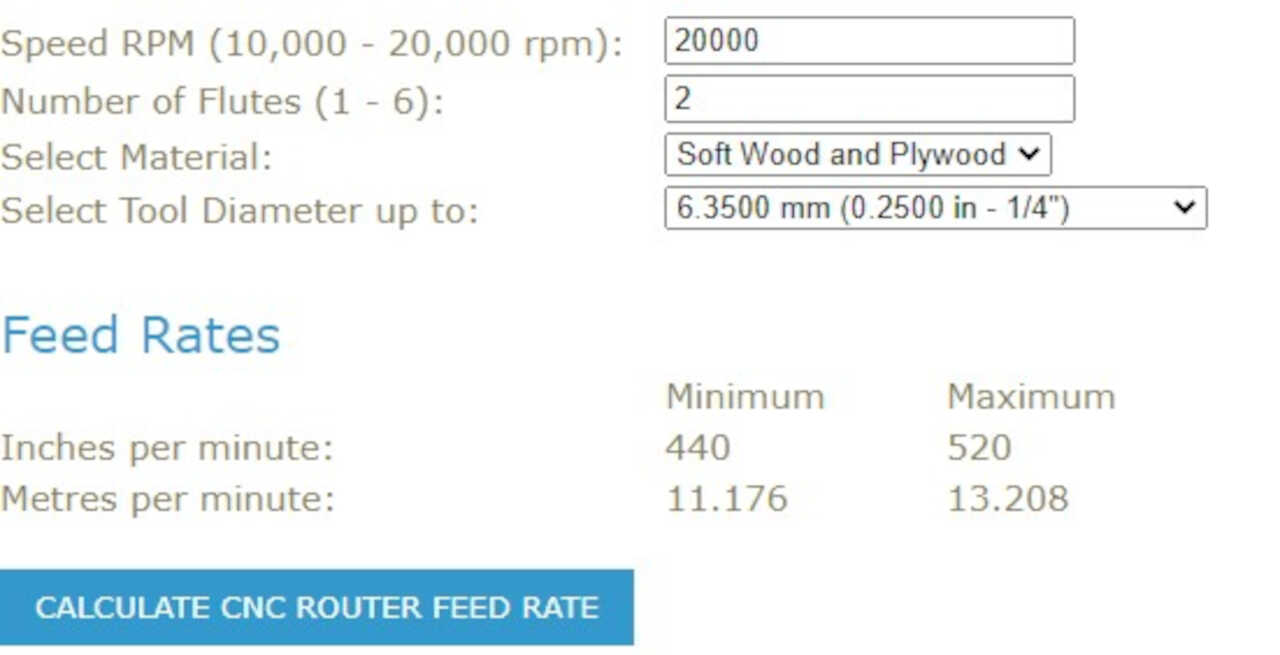

Speed and feed rate

Speeds and feeds are the cutting variables used in every milling operation and vary for each tool based on cutter diameter, operation, material, etc. reference. With large format CNC machining, the speed and feed can be calculated knowing the chip load. the number of flutes on the bit, and the spindle RPM.

An easier method to determine speed and feed is using an online calculator such as the one given at this link here. An image of the calculator is shown below.

In our group assignment, we calculated and test the speed and feed using the calculator above for plywood with a 1/4” bit and a spindle speed of 20000 RPM.

Alignment

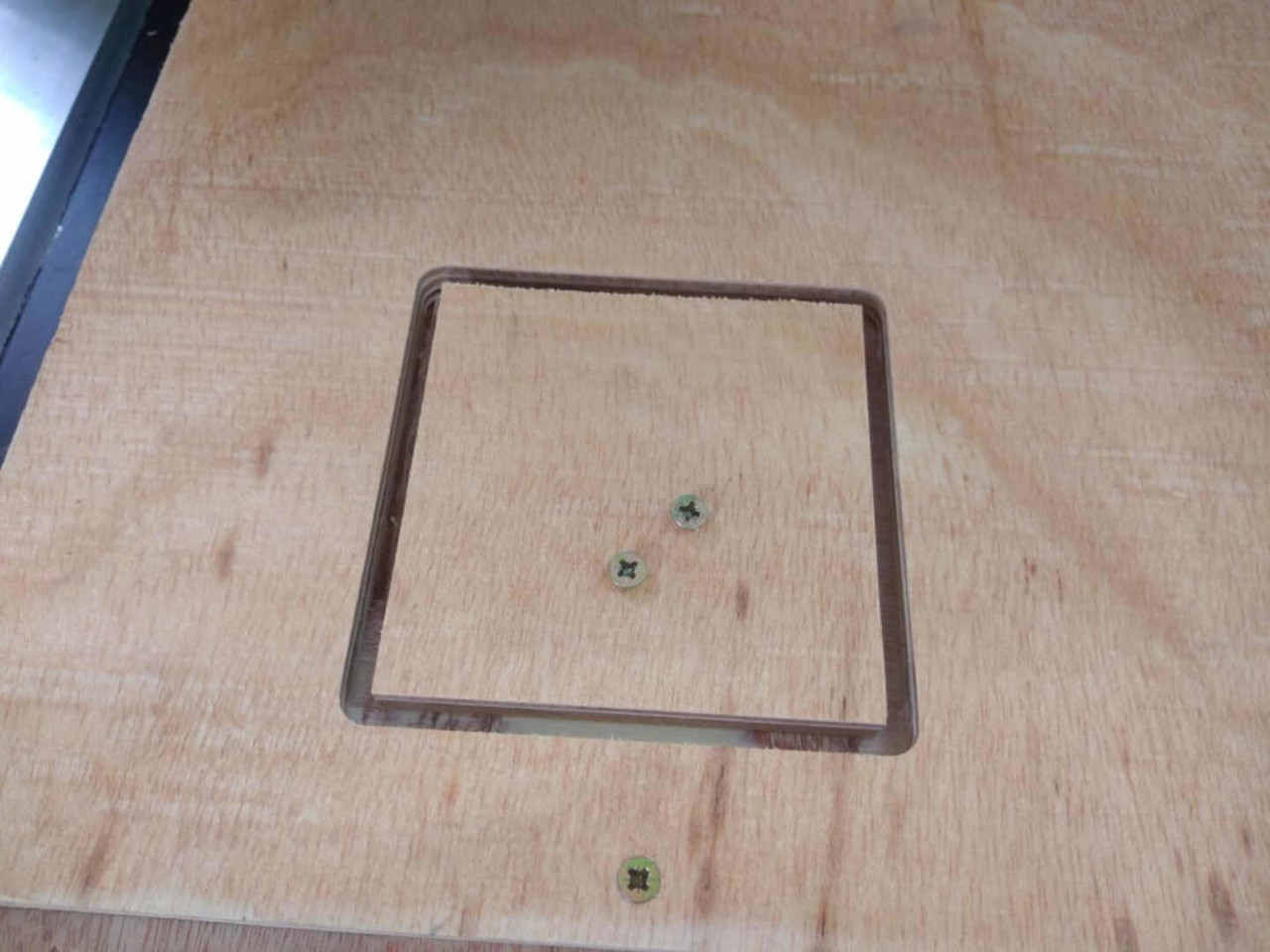

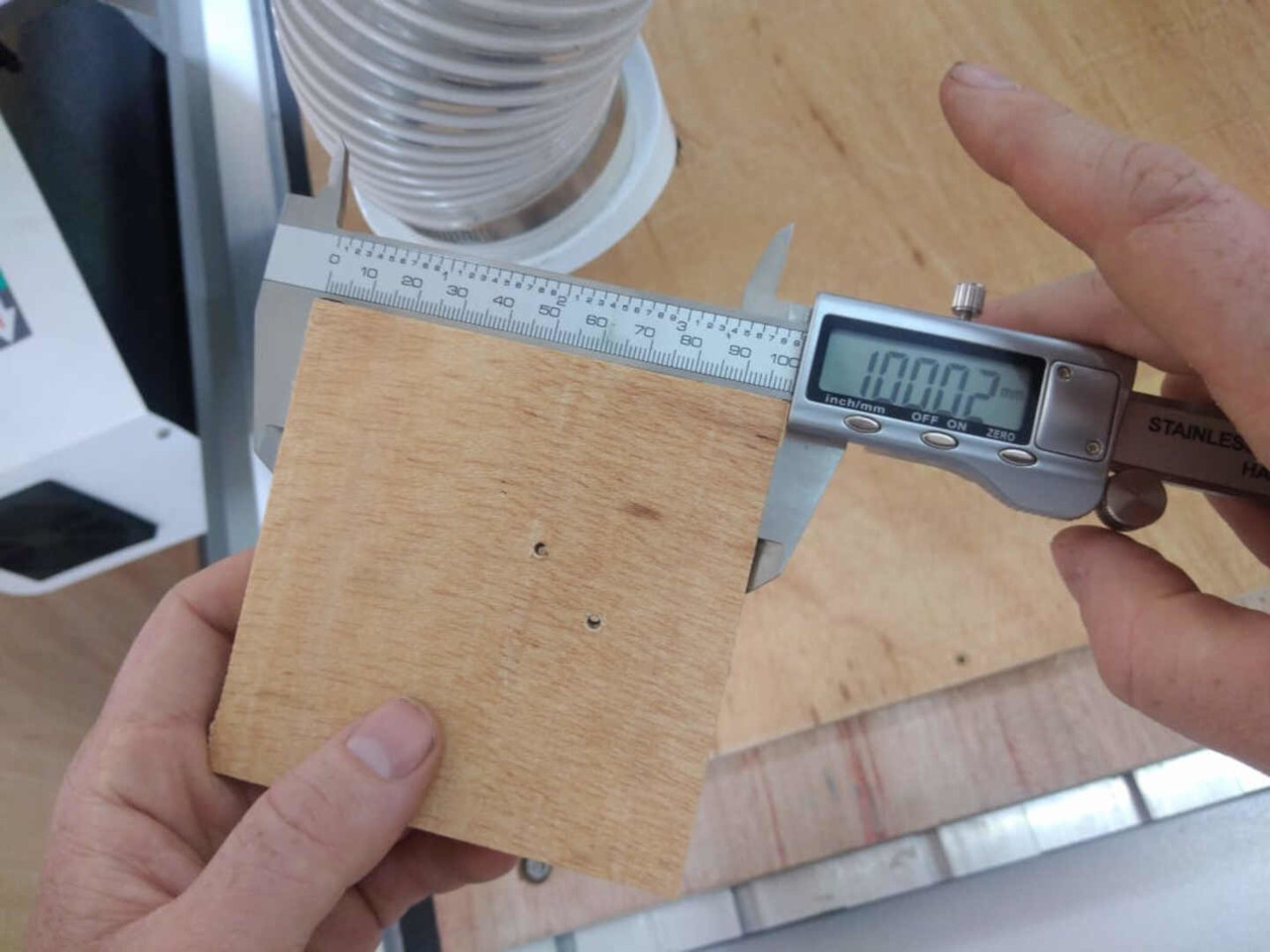

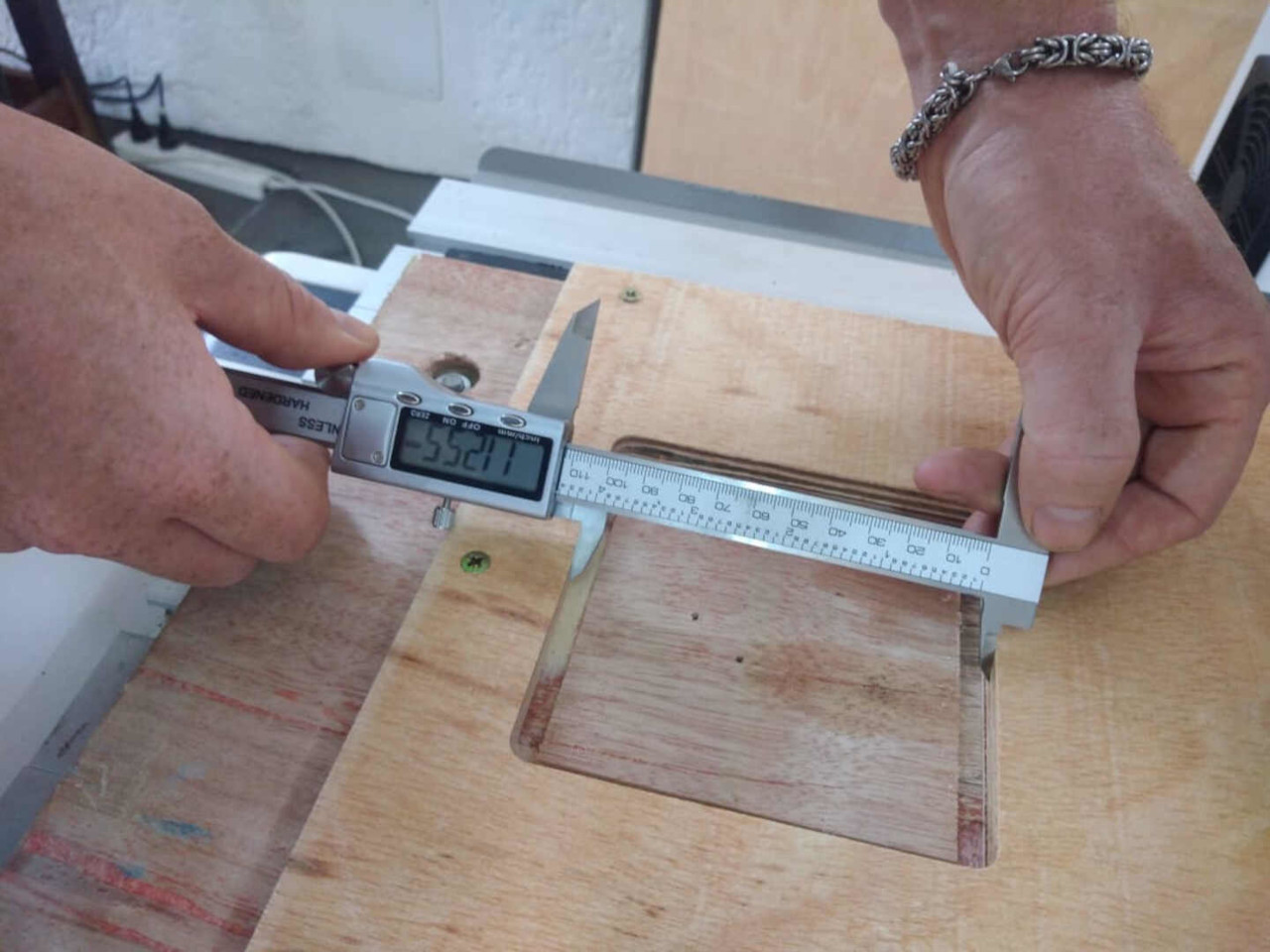

As part of our group task, we had to run the alignment test on our CNC machine to check how aligned our rails are. These rails are resposible for the X-Y-Z-axis movements on our CNC machine. if the machine fails this test, it would result in missalignment of right angled milling. So to run this test, we simply designed a square plate (100mm X 100mm and 141.4213mm across the diagonals) in freecad and milled it out on the machine.

| Milling | Parameters |

|---|---|

| Spindle speed | 20,000rpm |

| XY feed rate | 200mm/s |

| Z feed rate | 5mm/s |

the square was fixtured using screws

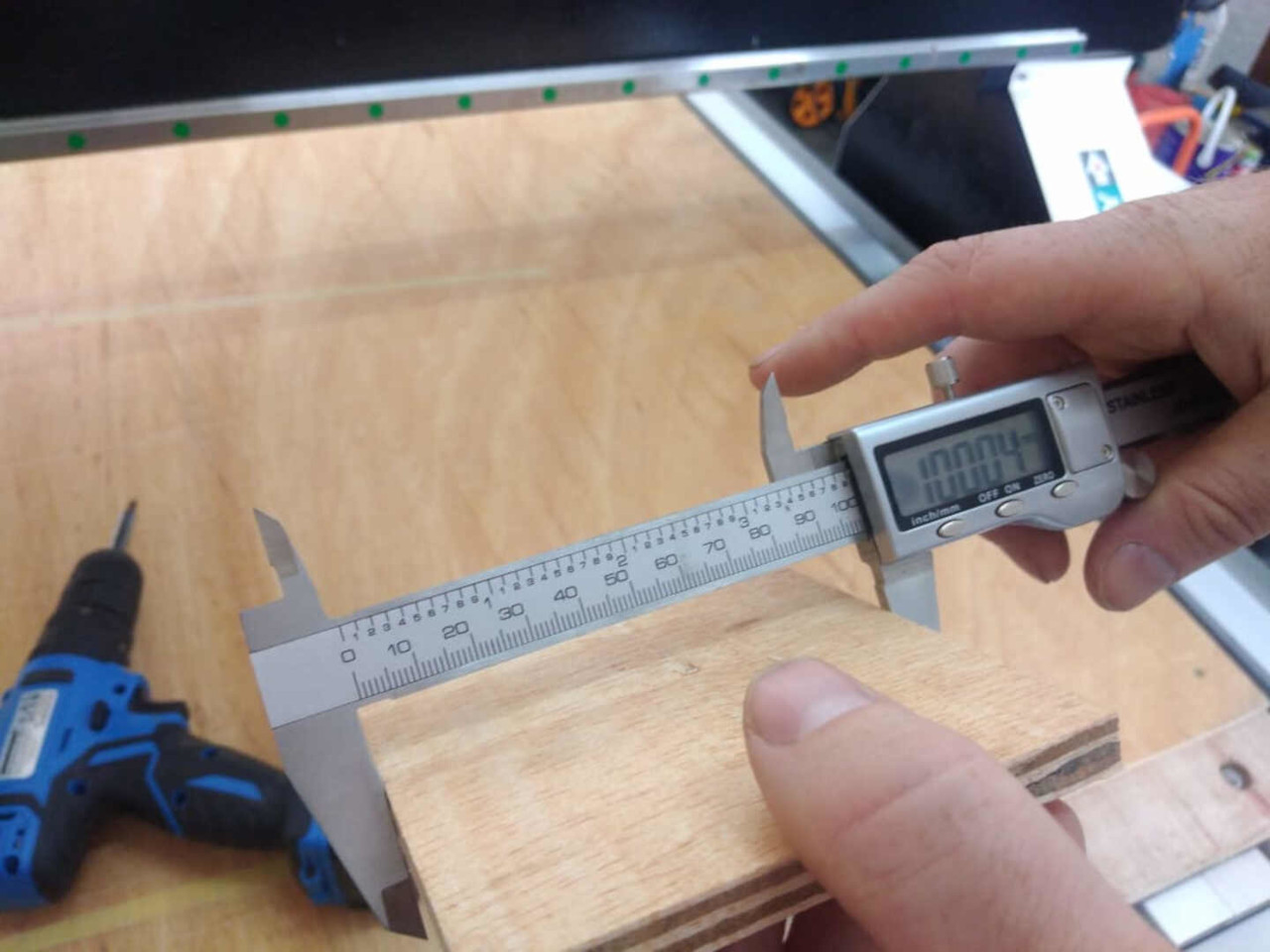

The sides of the square were measured to make sure it was the same or closest to the specified dimensisons in the software

the square cutouts was measured to have the dimensions as well

Safety

For the safety training, we were required to put on safety personal protective equipment like:

Safety glasses to protect our eyes Ear plugs to block loud noises leather gloves to prevent splinters when handling the wood pieces. make sure the blower and water pump were working to avoid any fire hazards.