12. moulding and casting

This week we started the ancient and yet very useful technic of moulding and casting.

We can model things in 3d, carve or print them, but if we need to make a high volume of parts it´s wiser to use a mould and cast material in it.

this is the way to produce more things, cheaper and faster.

The first thing we need to learn is how to mix the materials for the moulds and for the cast.

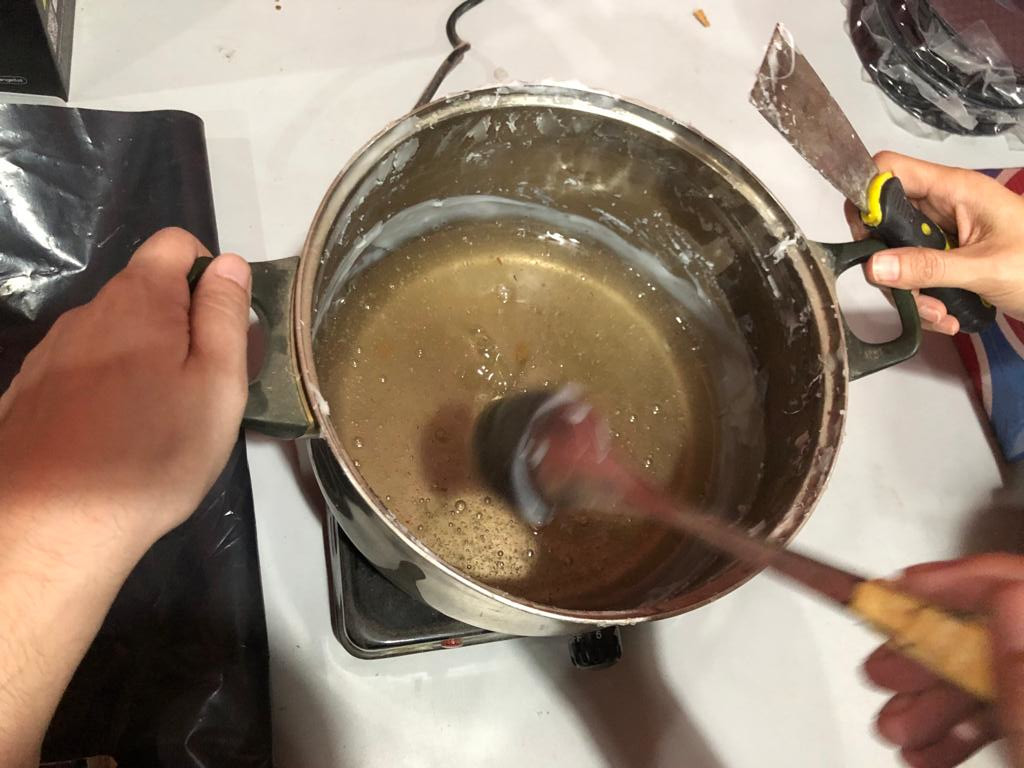

We used Epoxi resin to make the models (1:1 proportion mix), and rubber silicone to make moulds (1:1 proportion mix).

With the blend of the 2 materials, we have to mix them gently and slowly, because we don't want to make any bubbles that weaken the mould or the material for the final part.

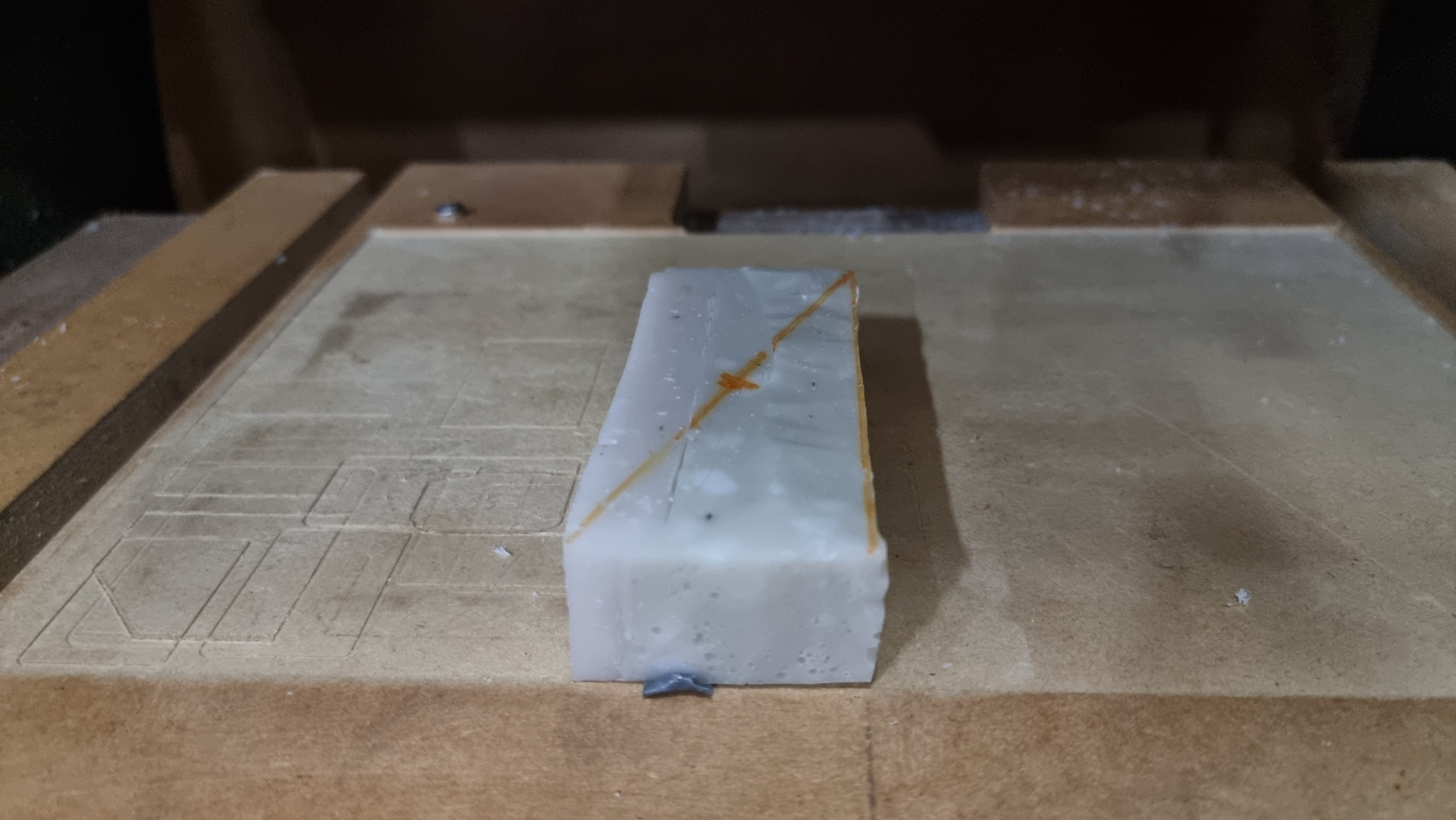

Also, we made and used some machinable wax (paraffin plus LDPE) to make moulds.

We put some paraffin in a pan, set the cook top to low heat and wait till it's melted...meanwhile we put some LDPE pellets, and mix all gently till it's homogenized.

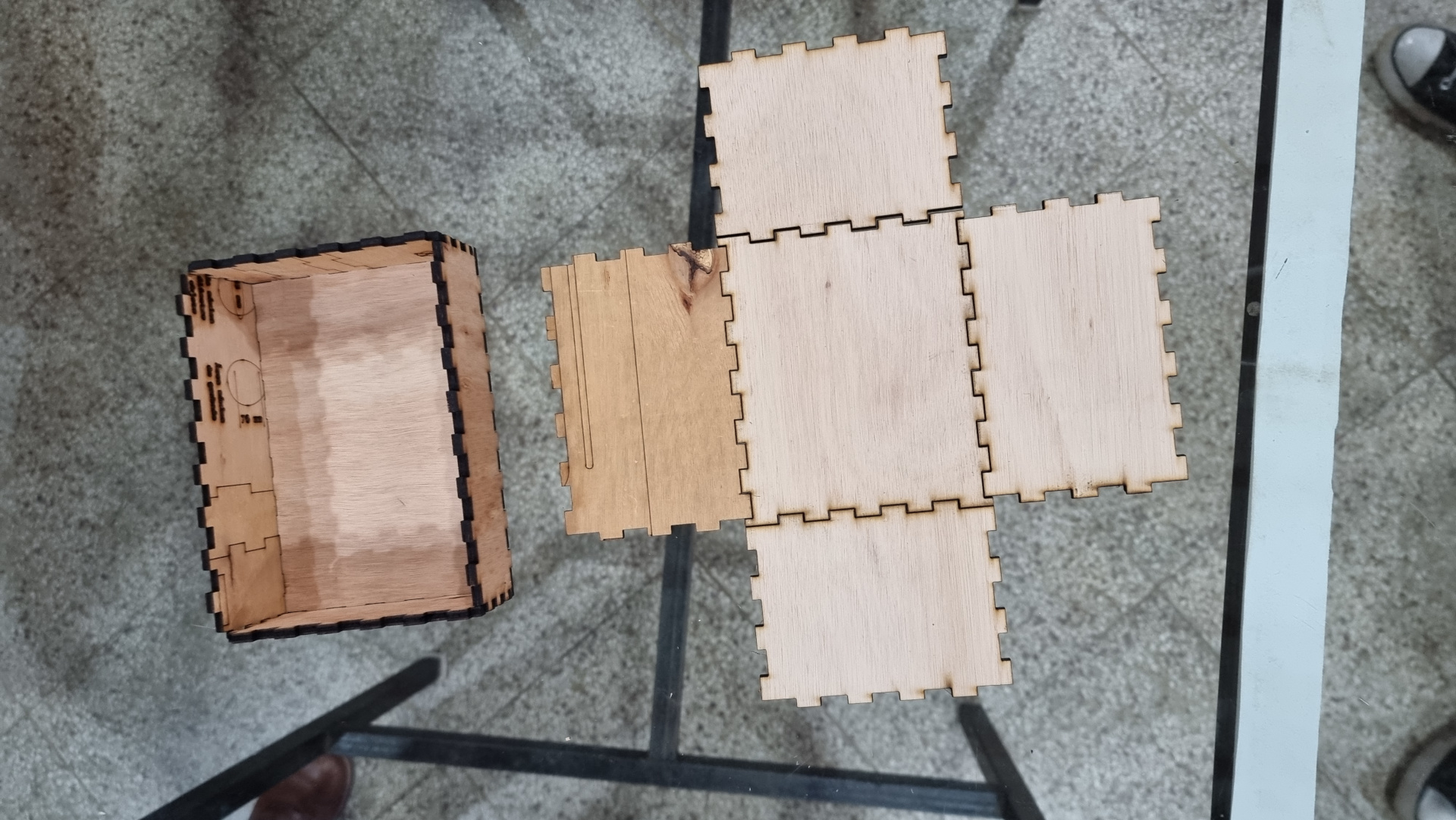

Meantime, we laser cut some cases to pour the paraffin + LDPE and let them cool.

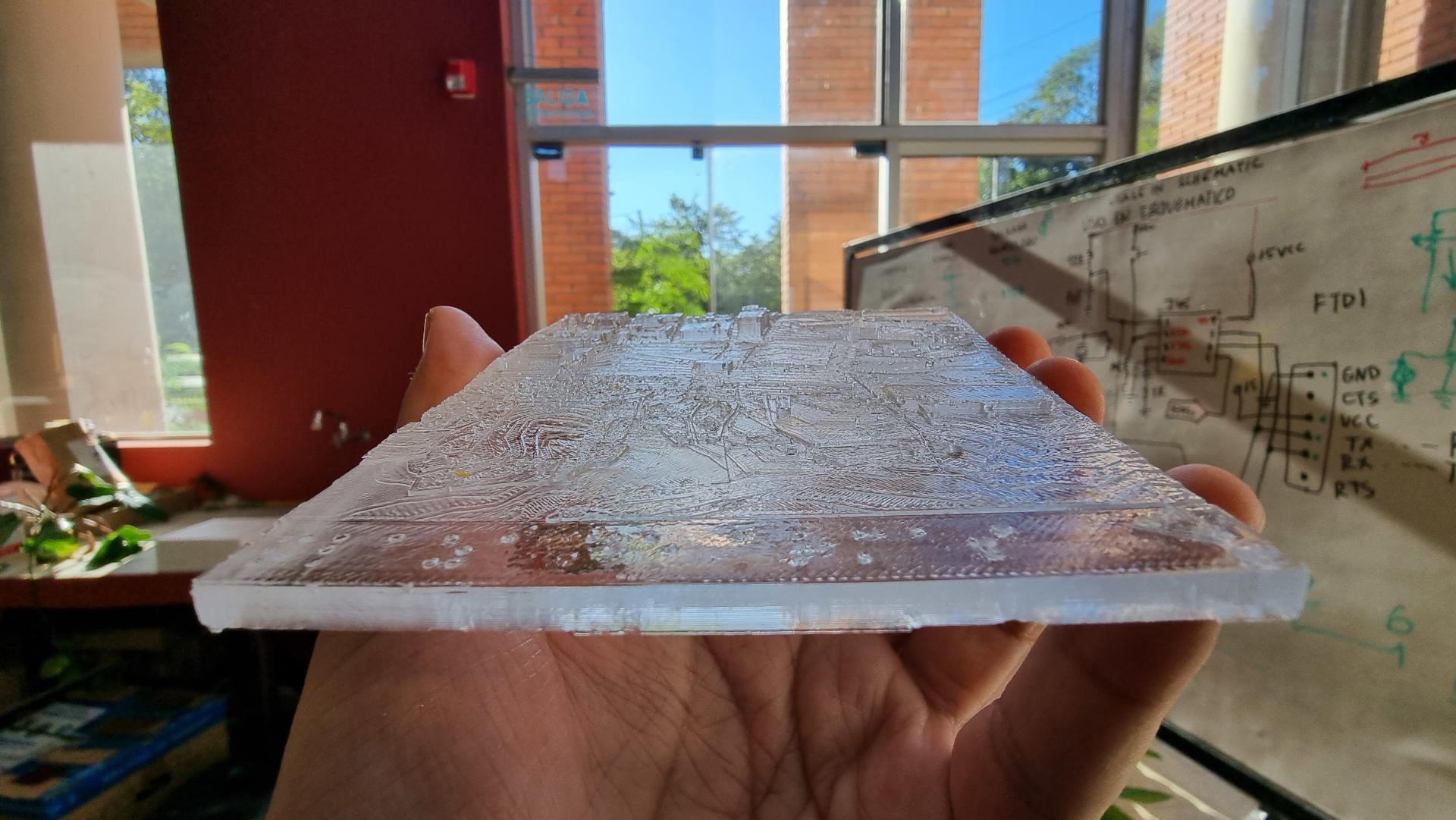

While paraffin were cooling down, with an empty box i made a silicone mould of 3d printed model of a Paraguayan neighbourhood.

After the silicone was cured, 24 hs later, i mix the components of the epoxi resin to made a transparent copy of the model.

And the result was amazing.

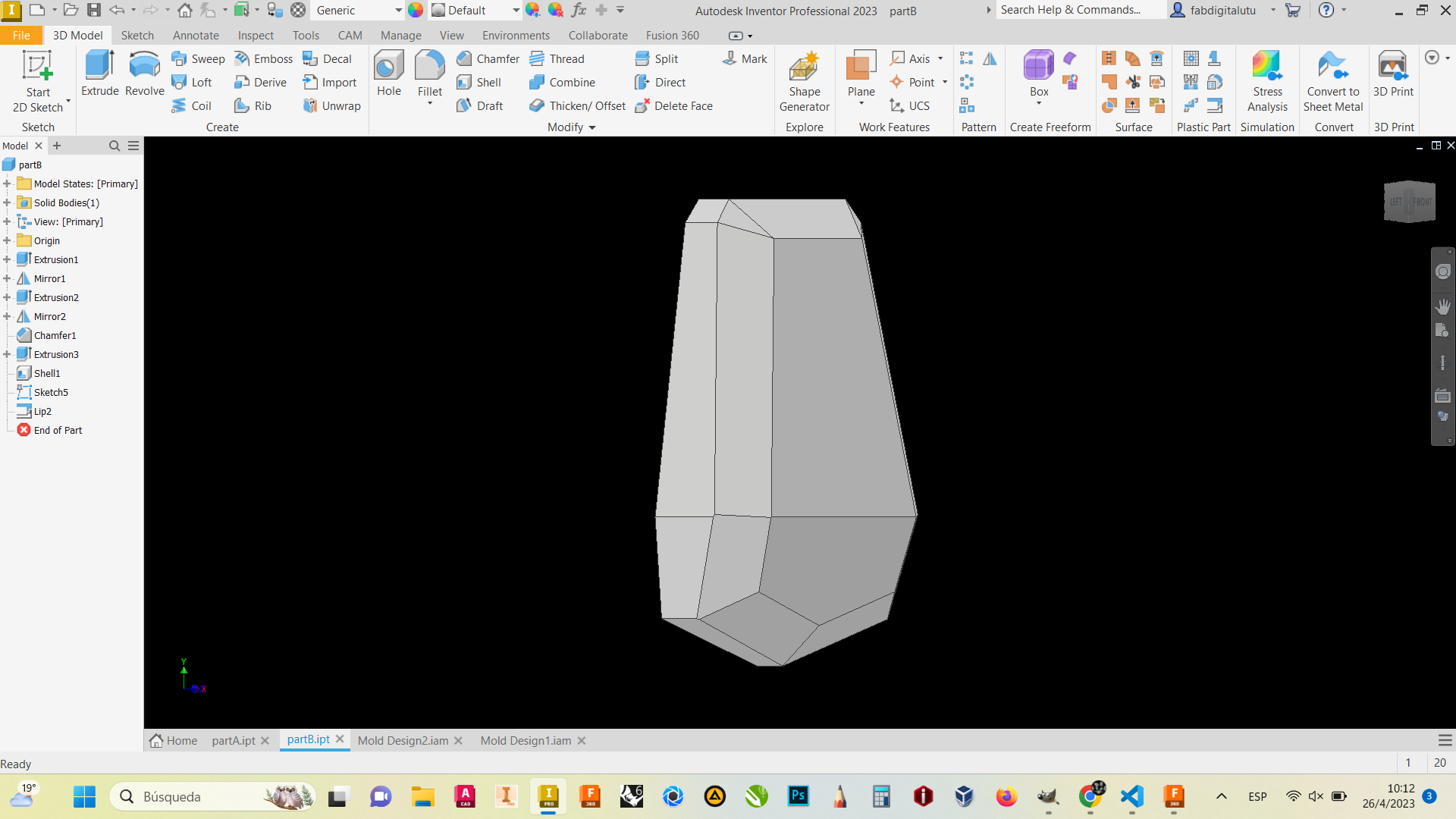

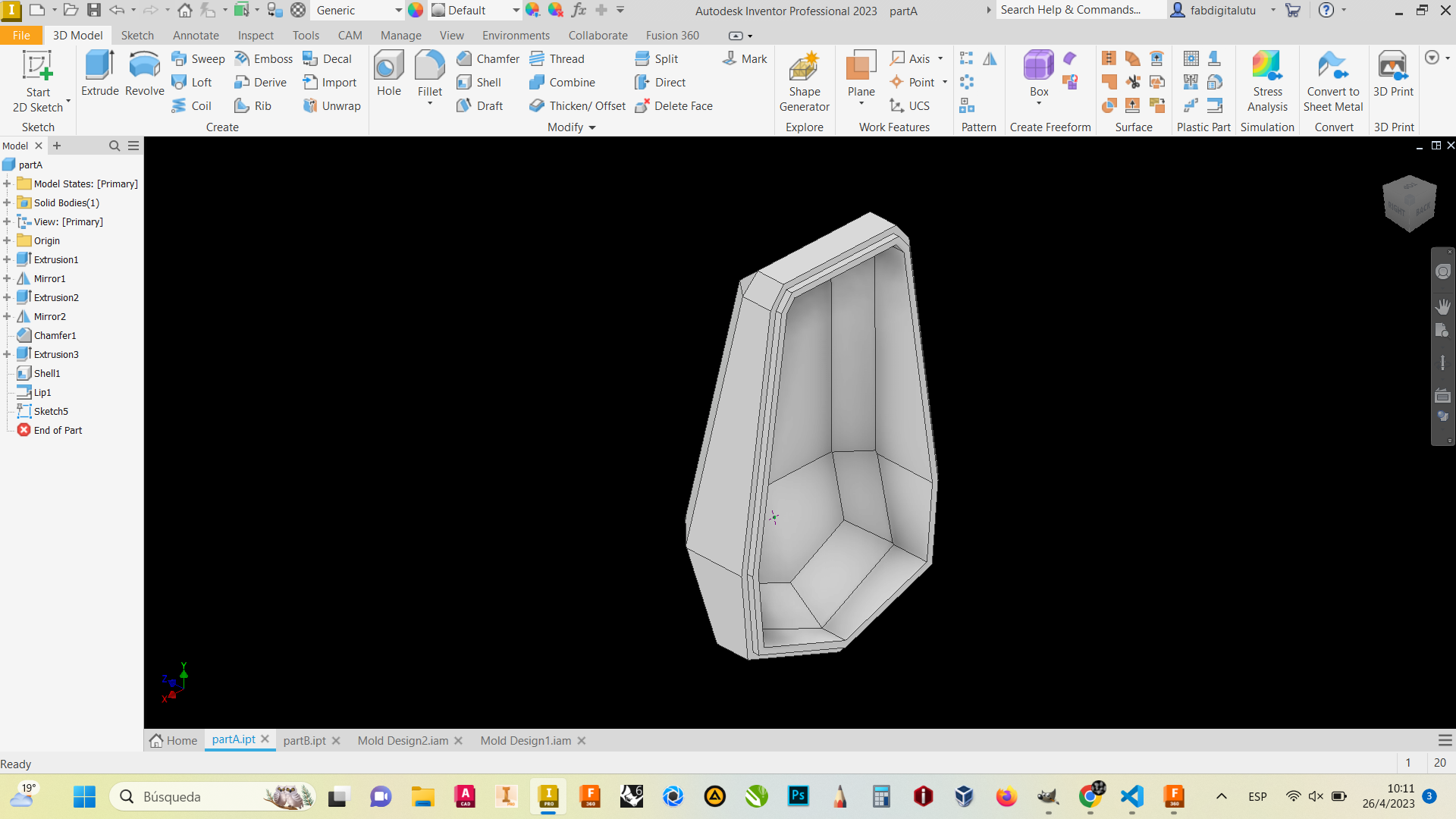

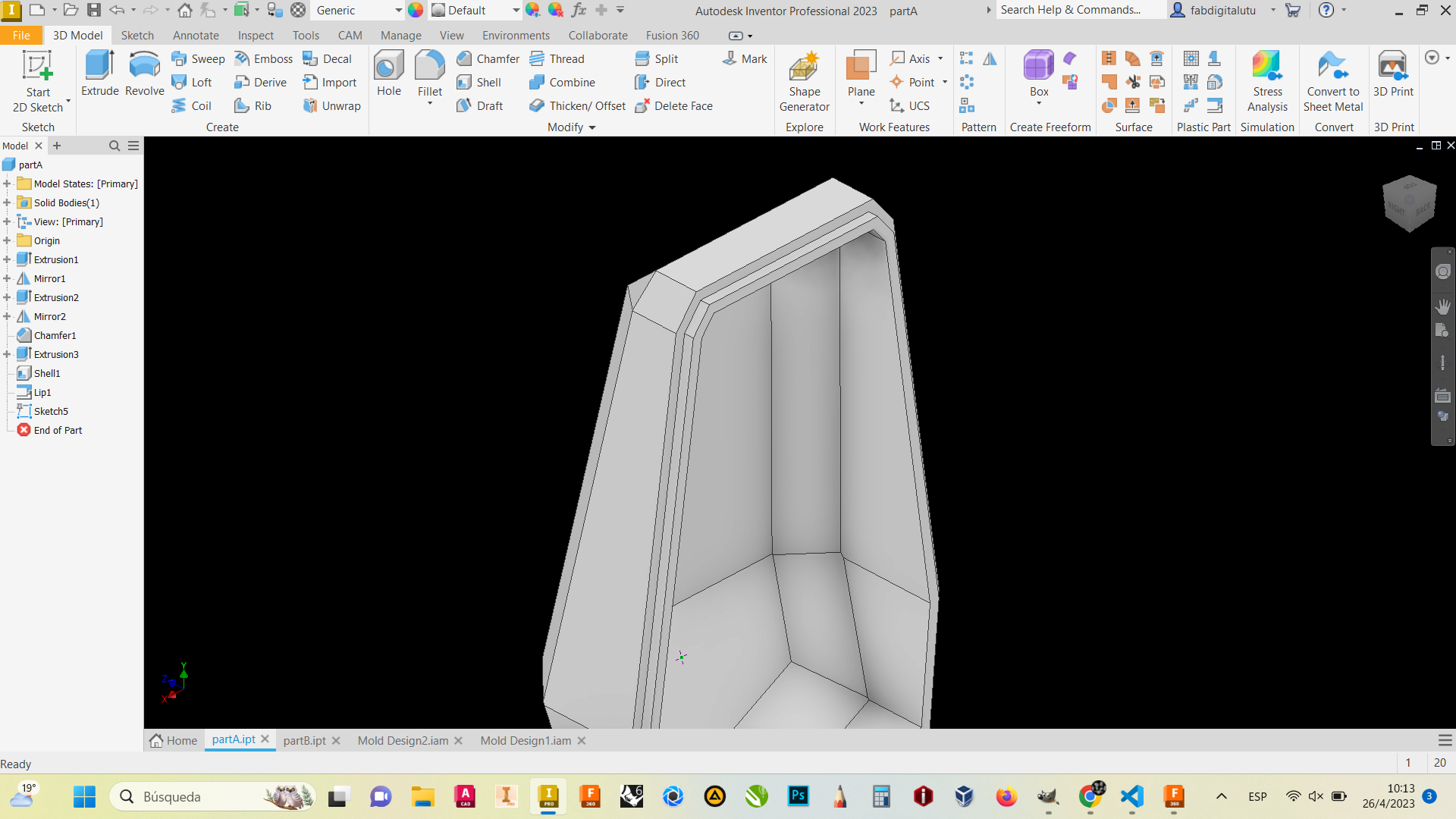

Ok, after we learned the basics, we need to make models of our final project parts, to be castable.

I started to model the submergible capsule, the part which is going to be in water, to heat it.

Also, design the lips for connect the 2 cases with the tools for plastic that have Inventor.

After that, in inventor enviroment, i used the moulding plug in to generate the parts in STL

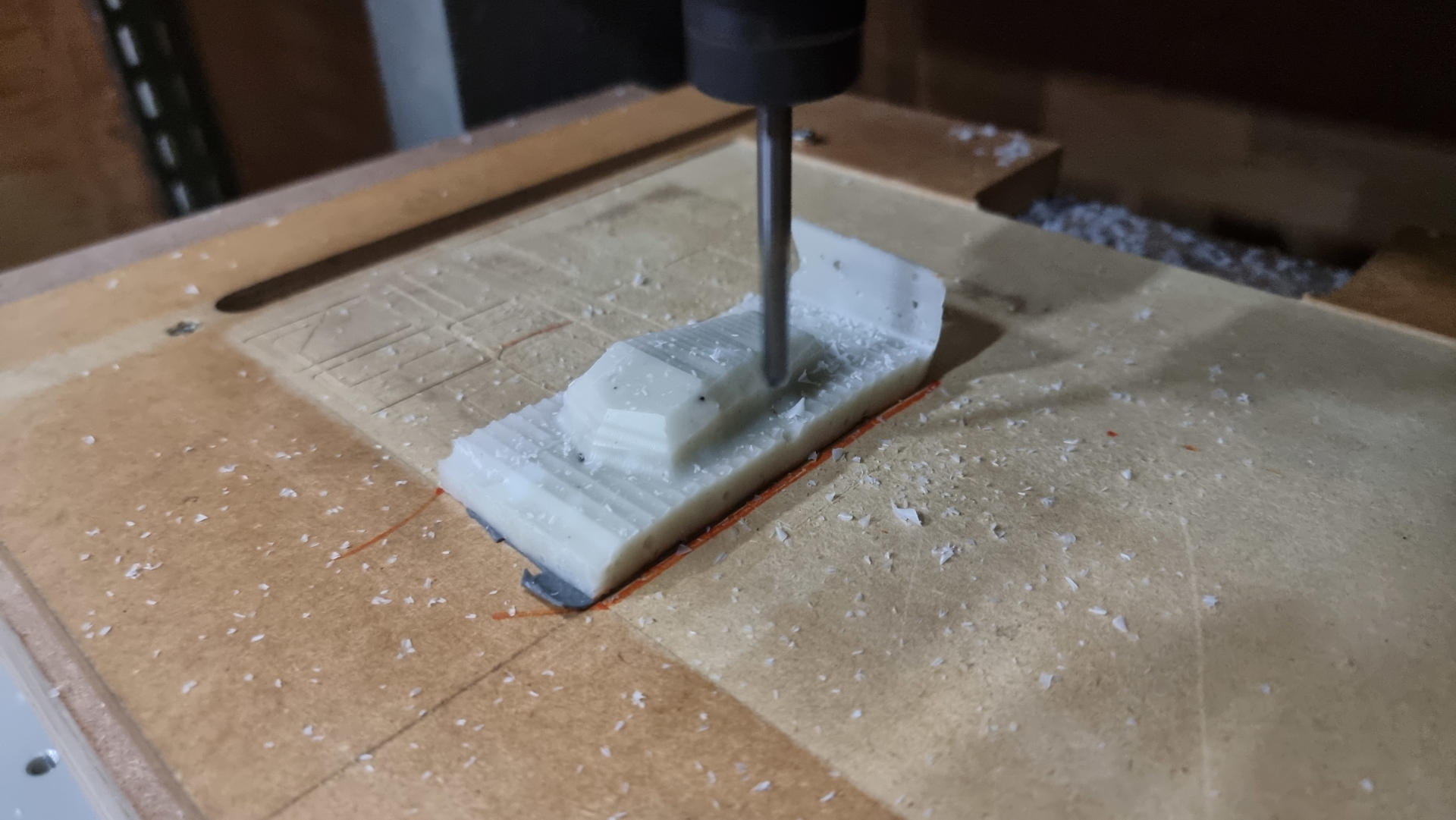

STL files ready, paraffin ready, time to mill it.

For this precision milling, i used the Roland MDX540 and the software for milling 3d models SRP Player.

Same procedure for the 2 parts of the mould, and voile!.

Mix more epoxi resin....and magic happened.

what i have learnt?

First, how to make high quality moulds for production models.

Second, how to mill a 3d model in machinable wax (paraffin + LDPE).

Third, how to get a mould from a 3d model in Inventor Moulding plug in.

Mould file Mould B file Link to group assignment