3. Computer controlled cutting

Vinyl cutting....and else.

Third week, new assignment...and lots of tests

This past week we learn about parametric software, and how to use it for our own projects.

Also, we learn about vynil cutting tools and laser cutting tools.

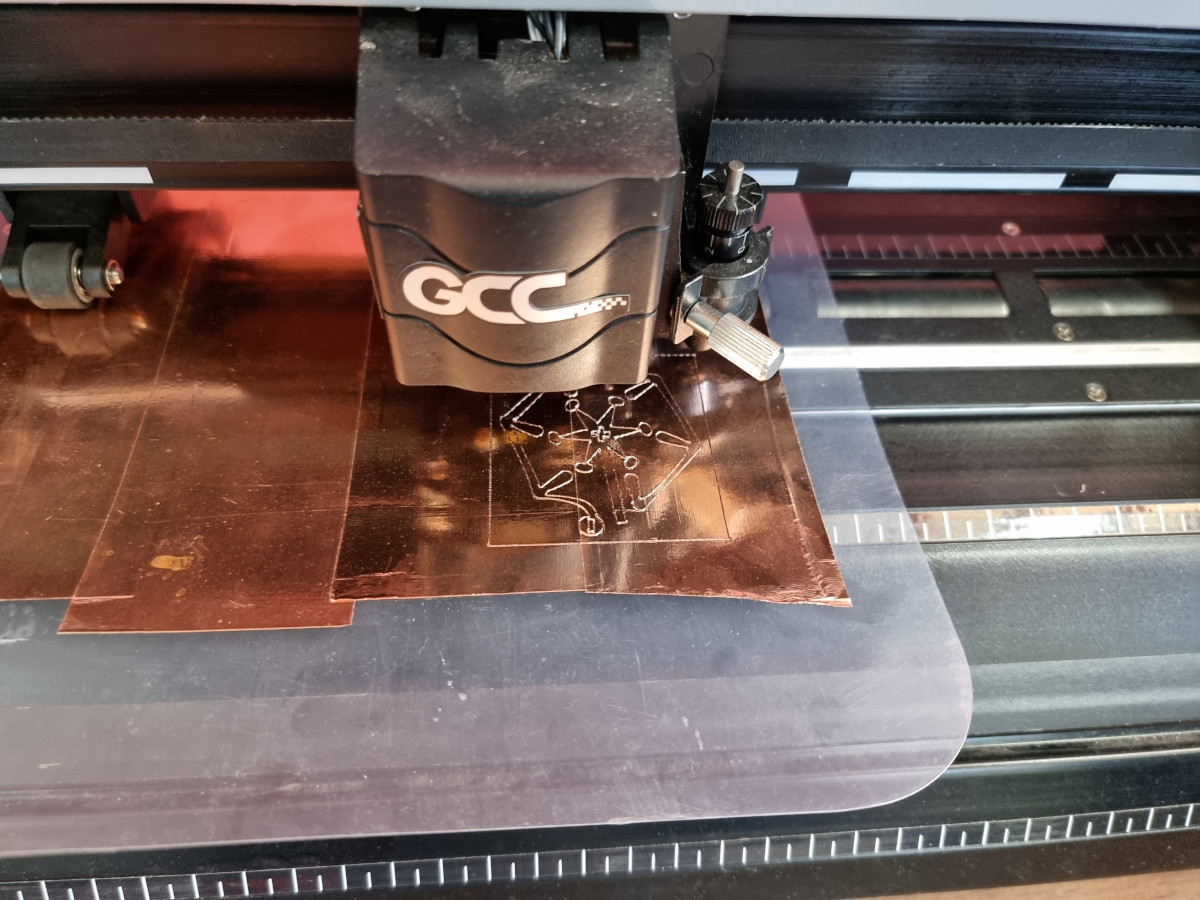

First, we try the vinyl cutting machine. Ours is a GCC PUMA IV 60 LX, easy to use machine.

Did some cutting test over vynil....and our instructor Silvia told us:"would you like to do something fun?"....obviusly we said:"oh yeah!!!"

She brought us some copper tape and we stick it over PET sheet, to give a better surface to cut over.

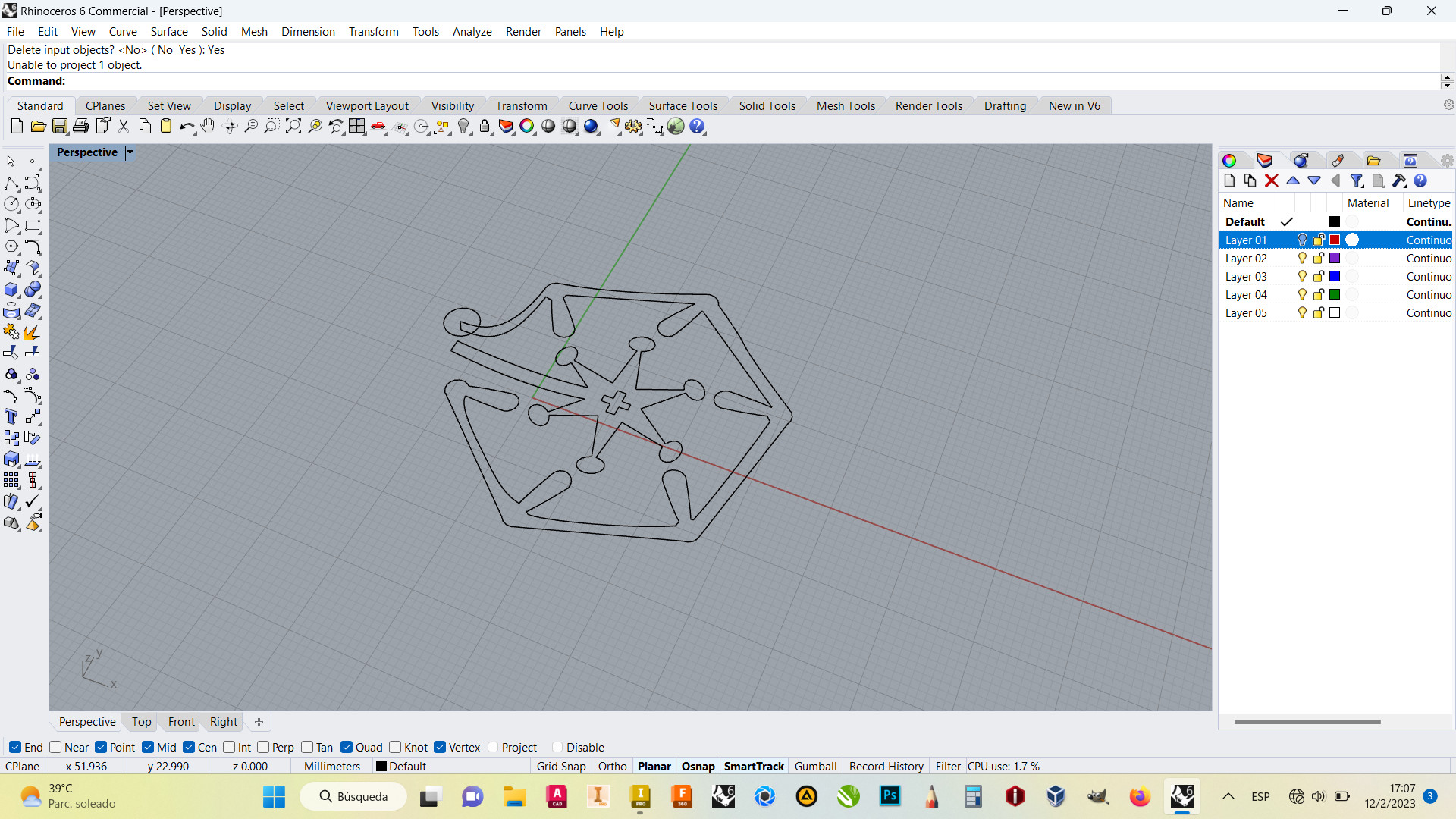

Next, we did some doodles of a circuit....and export to DXF, to cut.

I draw some lines to resemble the paths to cut, with at least 2mm of thickness. That is worth enough to not be peel off when cutting or cleaning the copper vynil.

.png)

The parameters settings for cutting Copper vynil are : cutting speed 12cm/s and cutting pressure 50 grams of pressure.

.png)

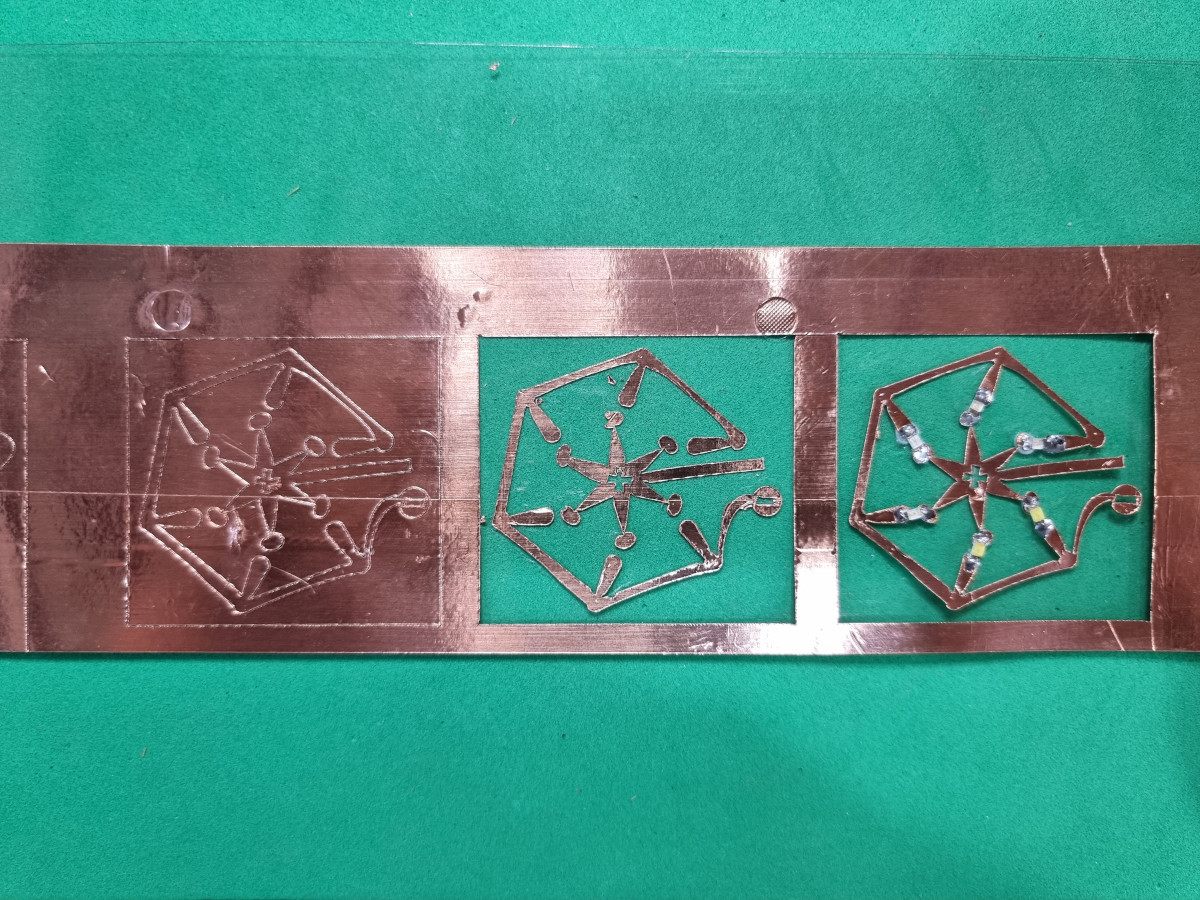

The peeling off the parts that are no longer needed was easy with the scalpel and the dental hook.

Having the circuits cut off, we procede to peel off the excess material to expose what we want to use.

The following step, soldering, 380 degrees, some flux applied and make those tiny diodes get hot.

Ok, this really was fun....but, it works? Let´s find out.

Laser cutting.

Third week was also a laser cutting week...and we must use parametrics tools to make a press fit kit to play with.

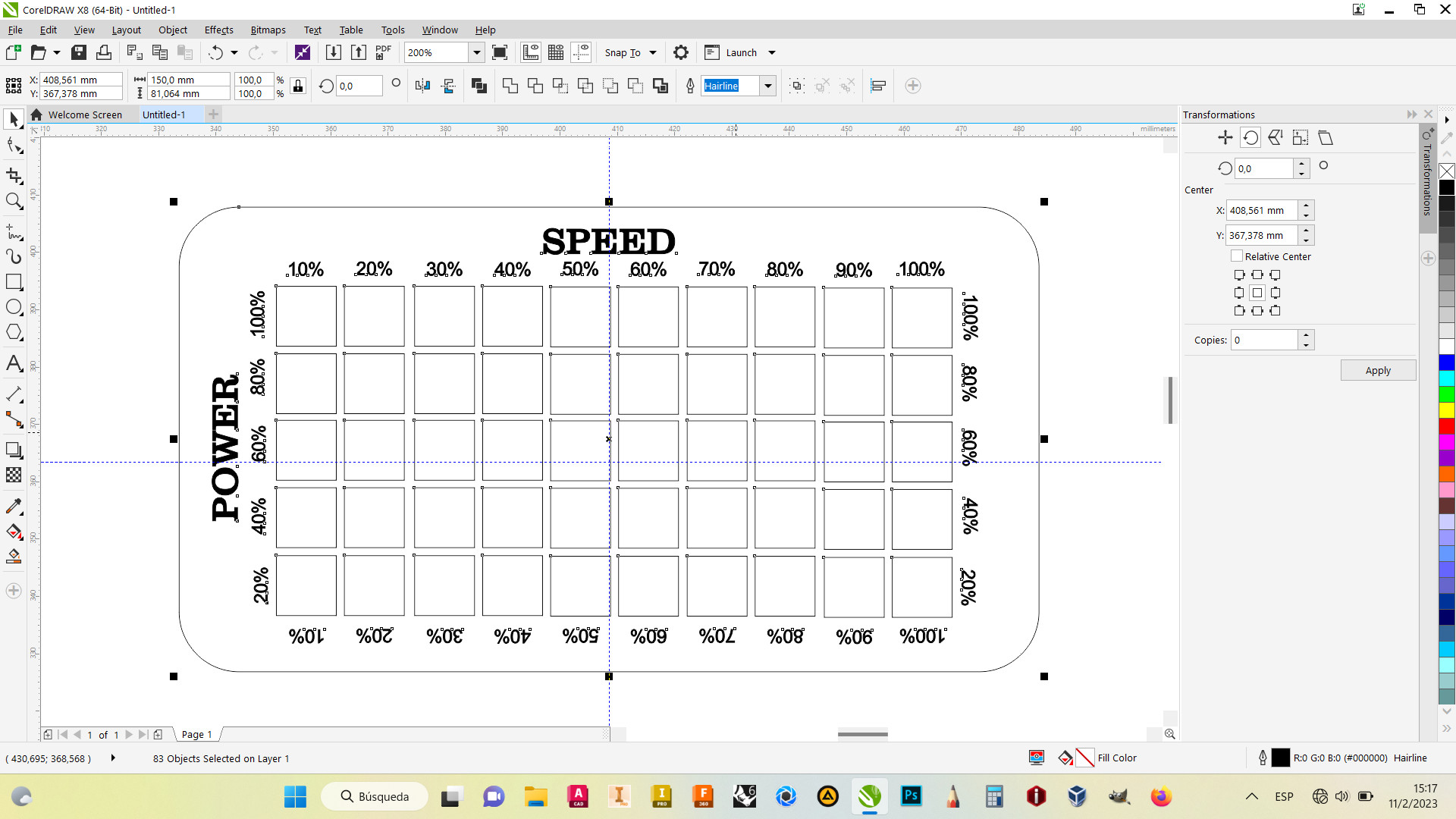

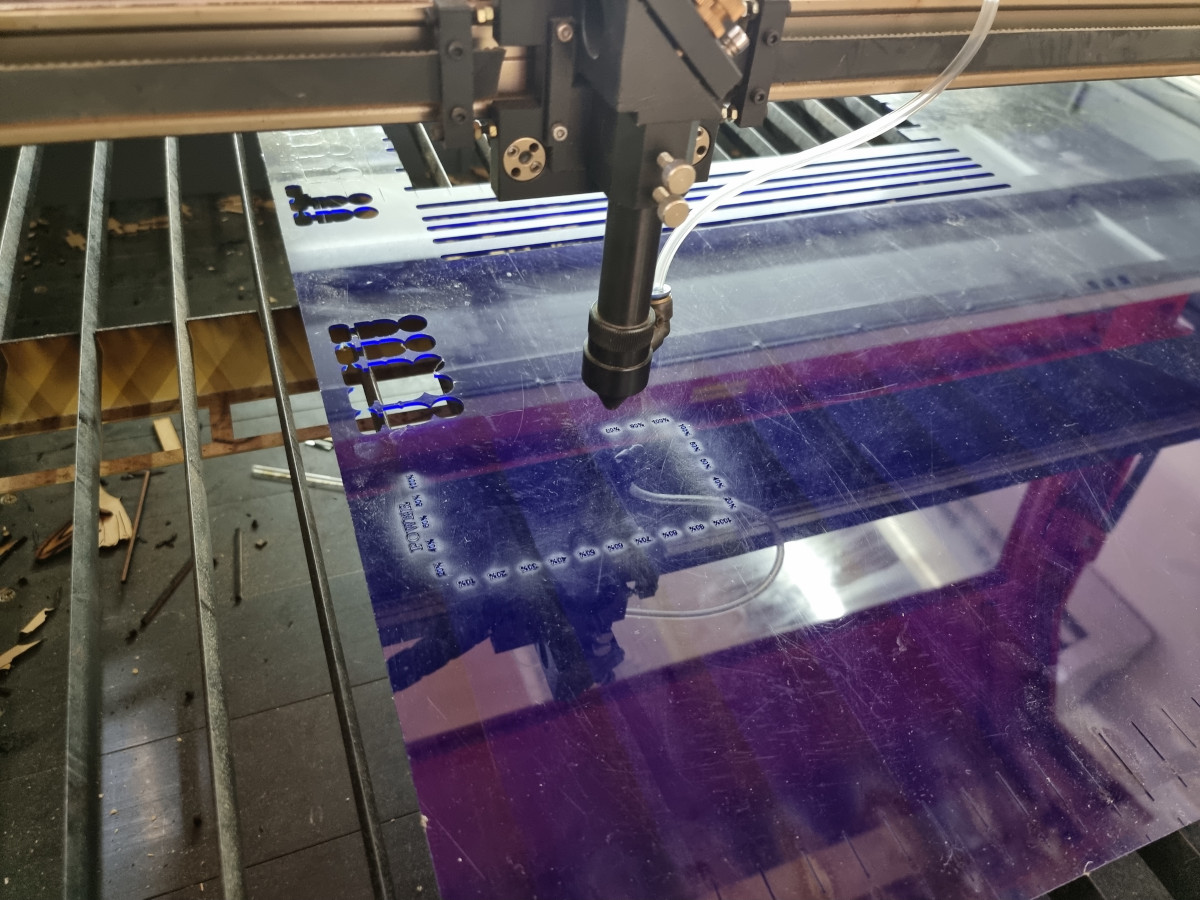

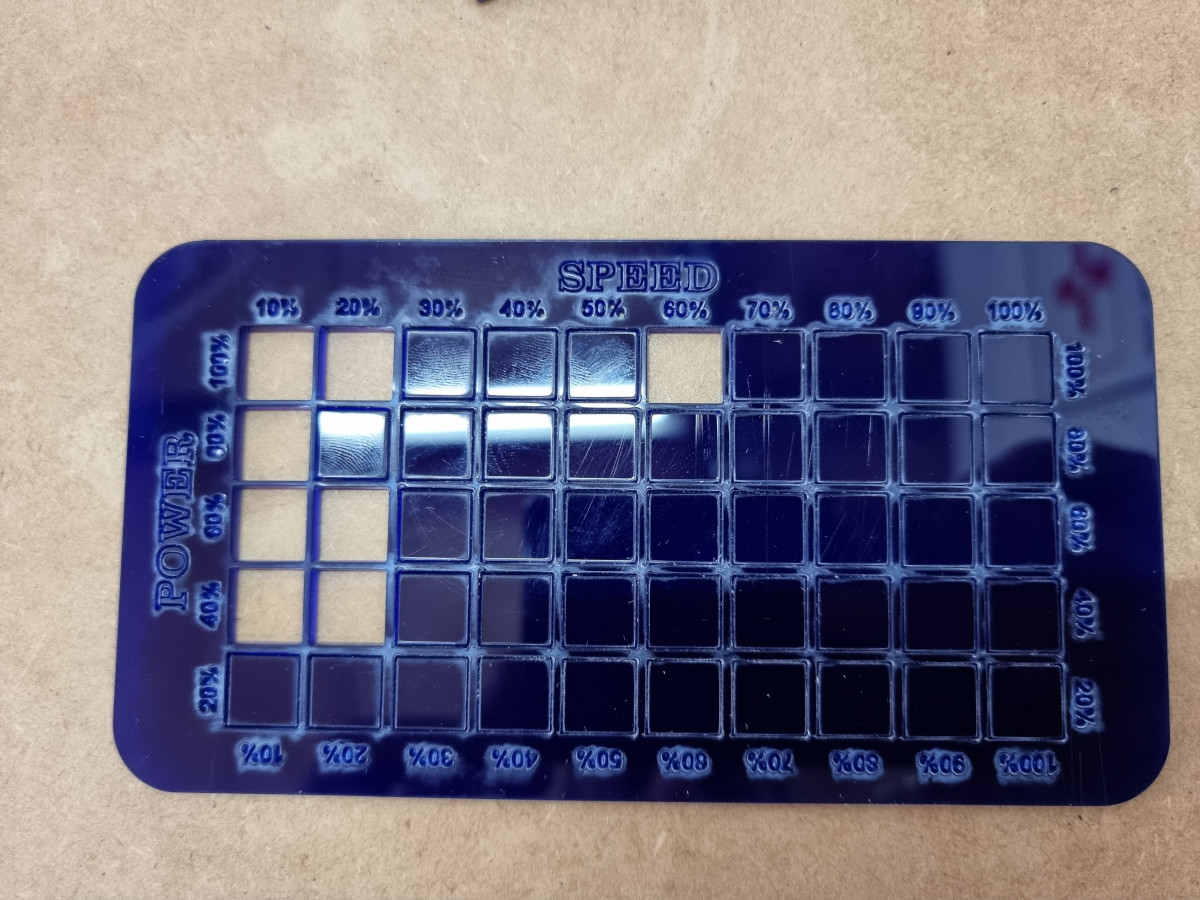

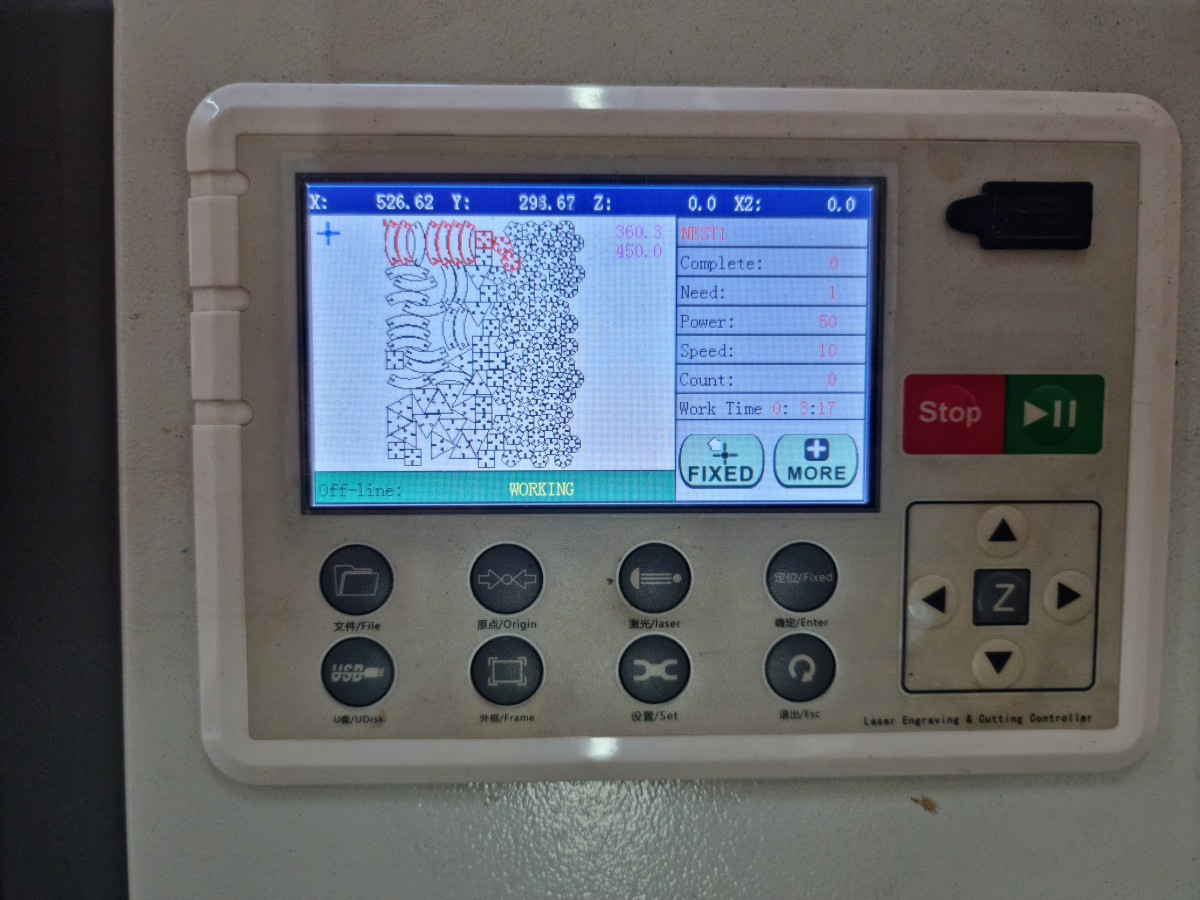

First, test the power and speed to make a good cut in different materials

Kerfing test

After our first tests, we discover that the laser bed was not as flat as we thought, and that´s why there are some places where it should cut and it doesn´t..and vice versa.

With that in mind, we check the bed and level it.

Now, our bed is fine to cut, let´s cut!!!!....we also had a fire incident because an obtruded air nozzle...that´s another story

Wait, first, we need a parametric press kit...

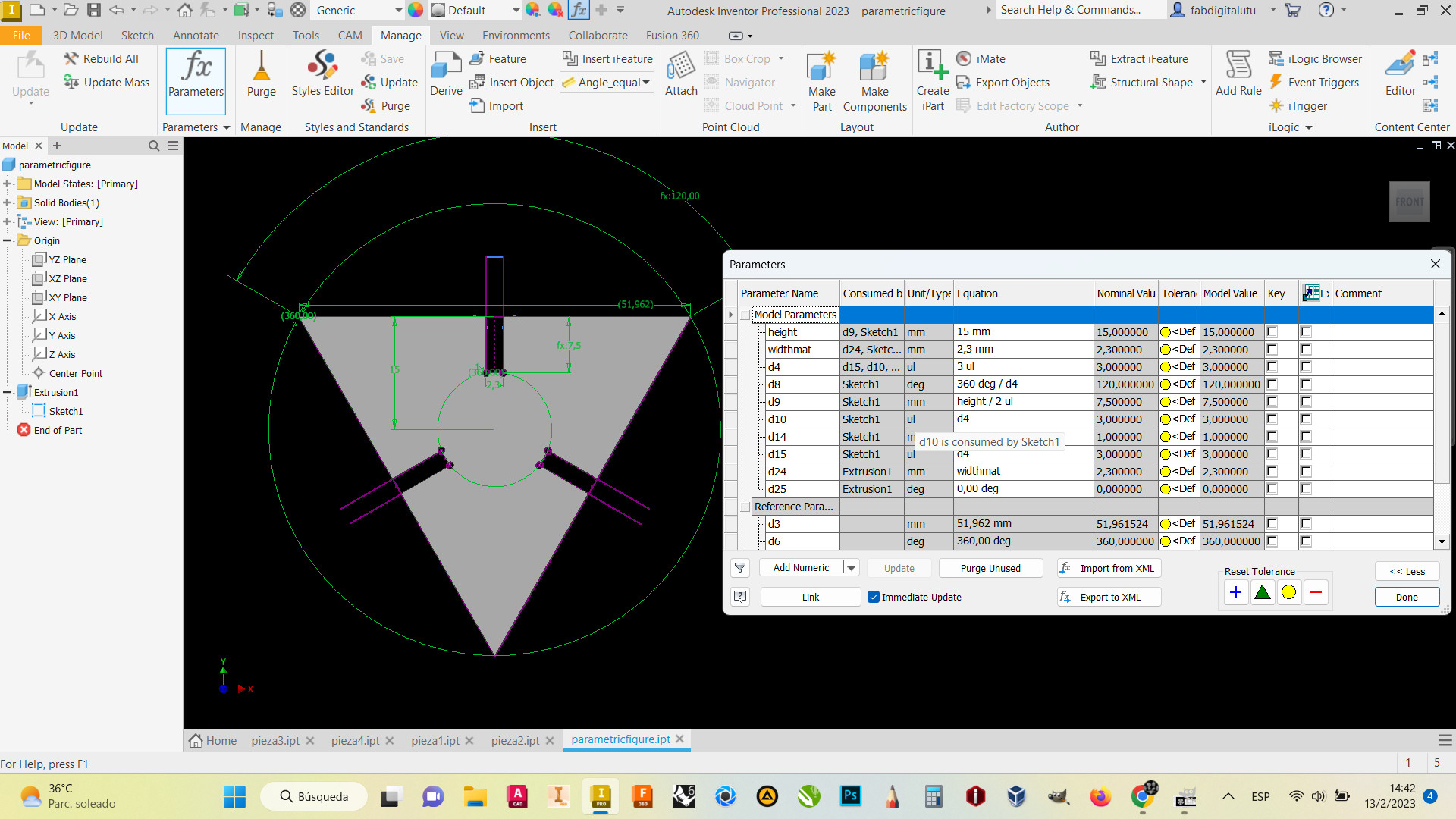

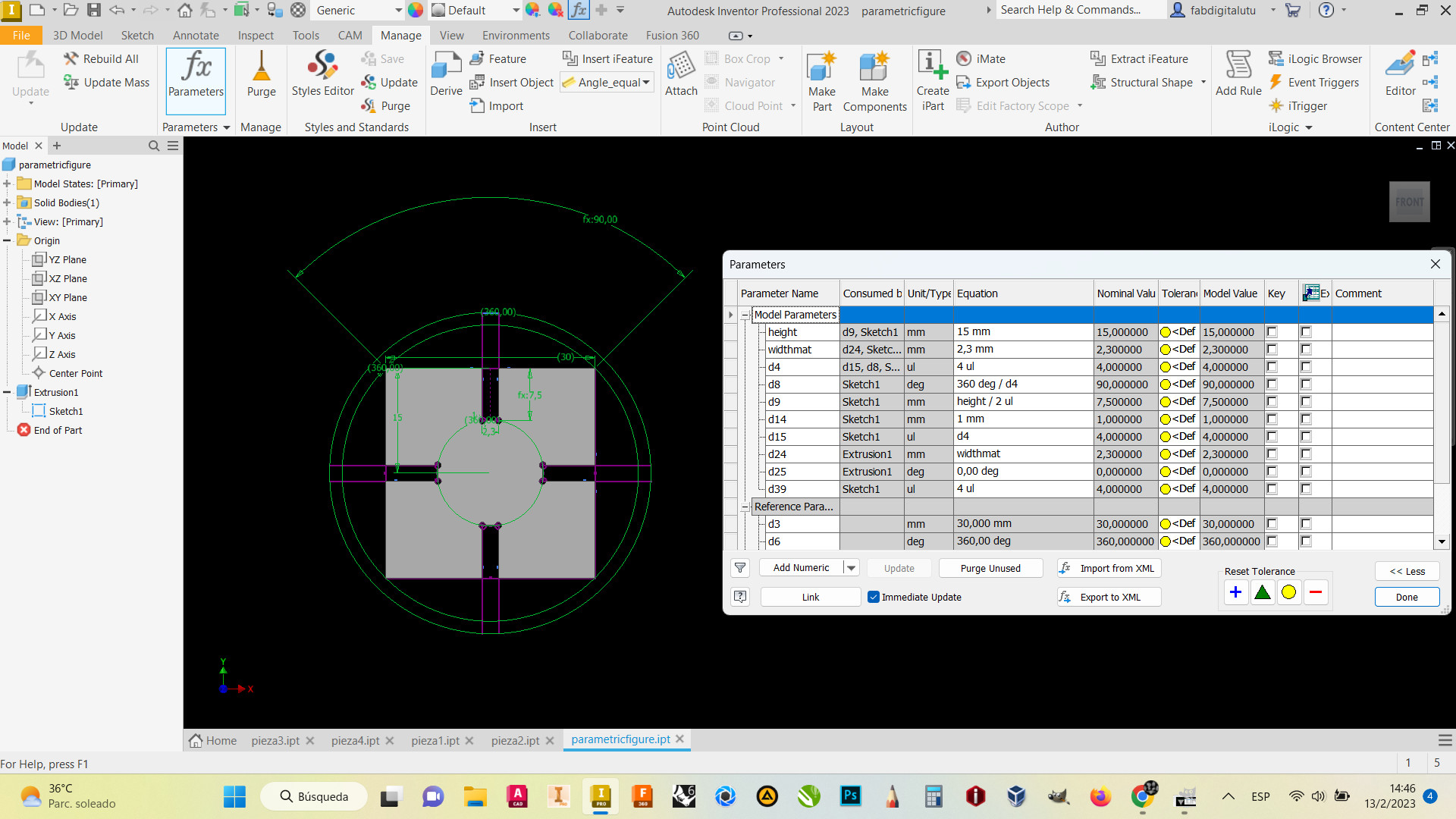

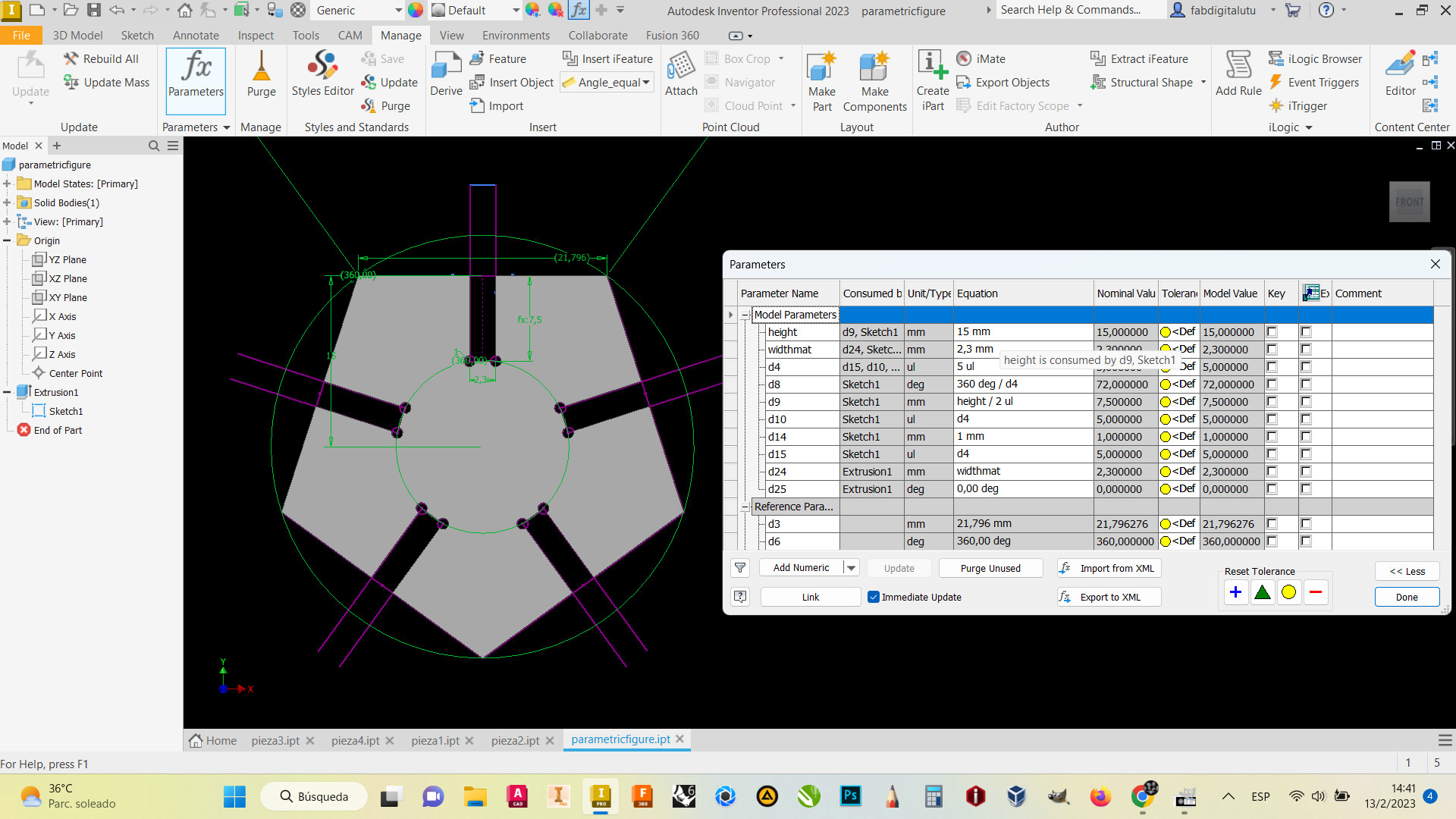

I drawn some sketches in Inventor, constrain them and here is the result.

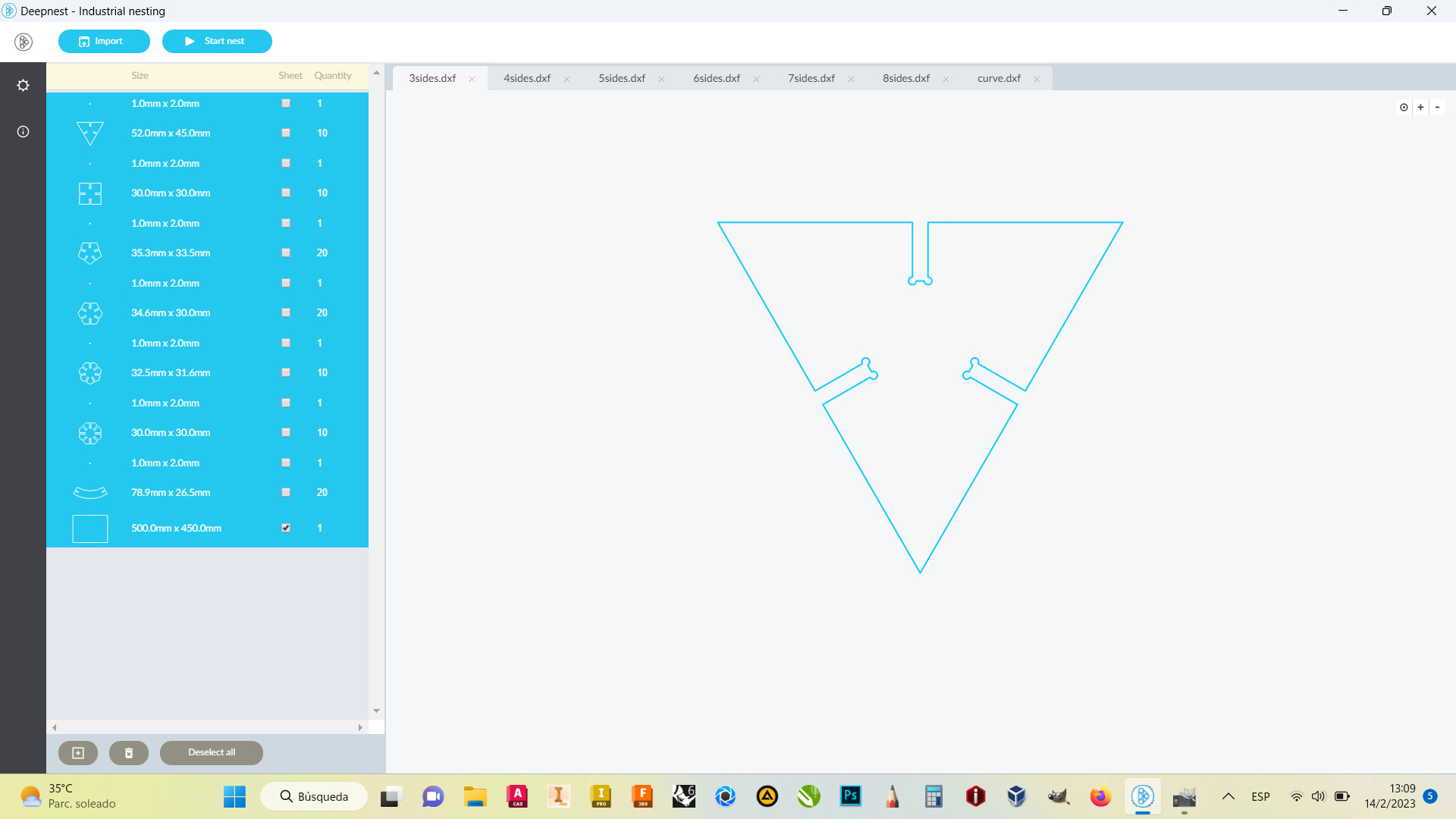

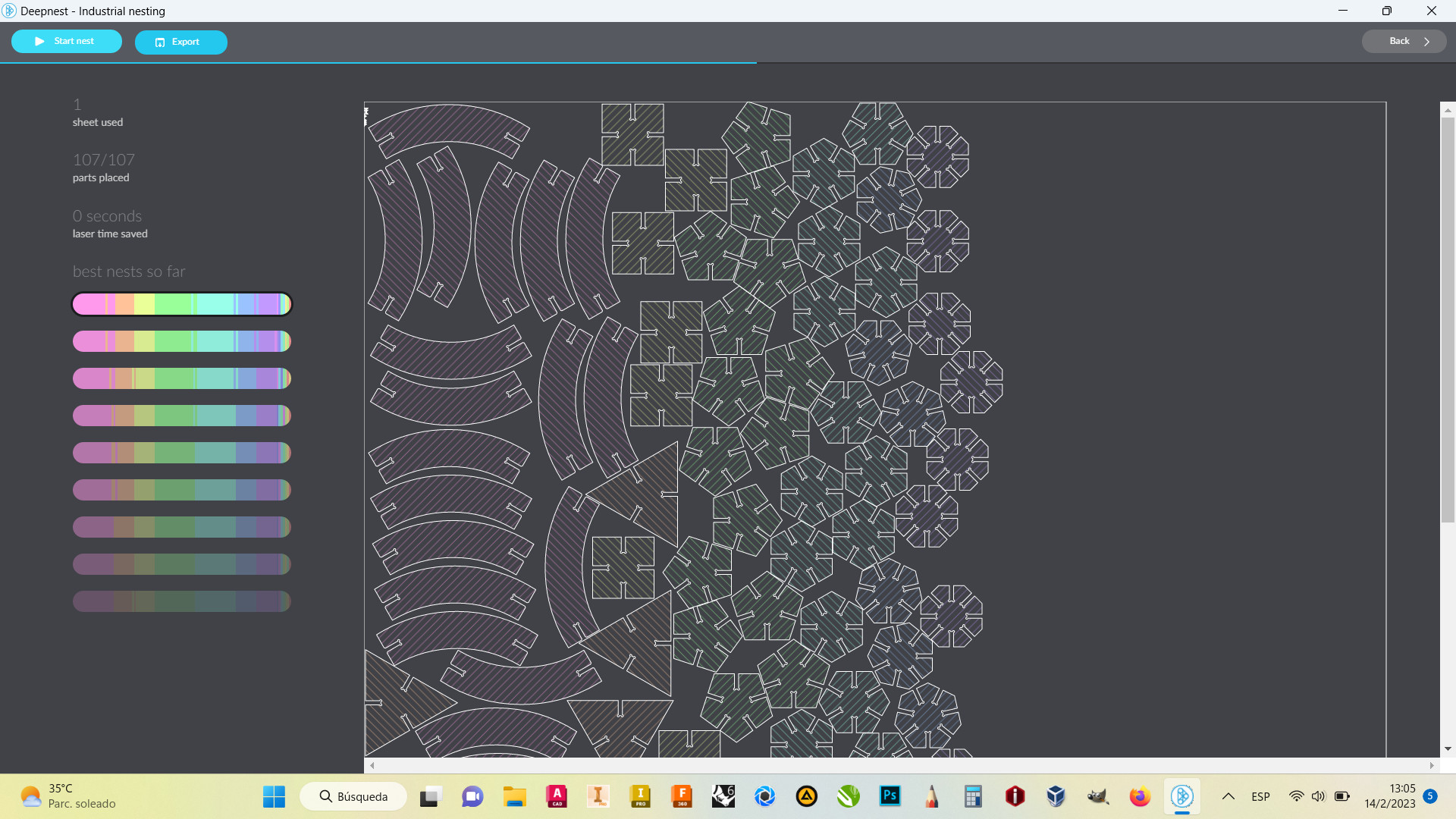

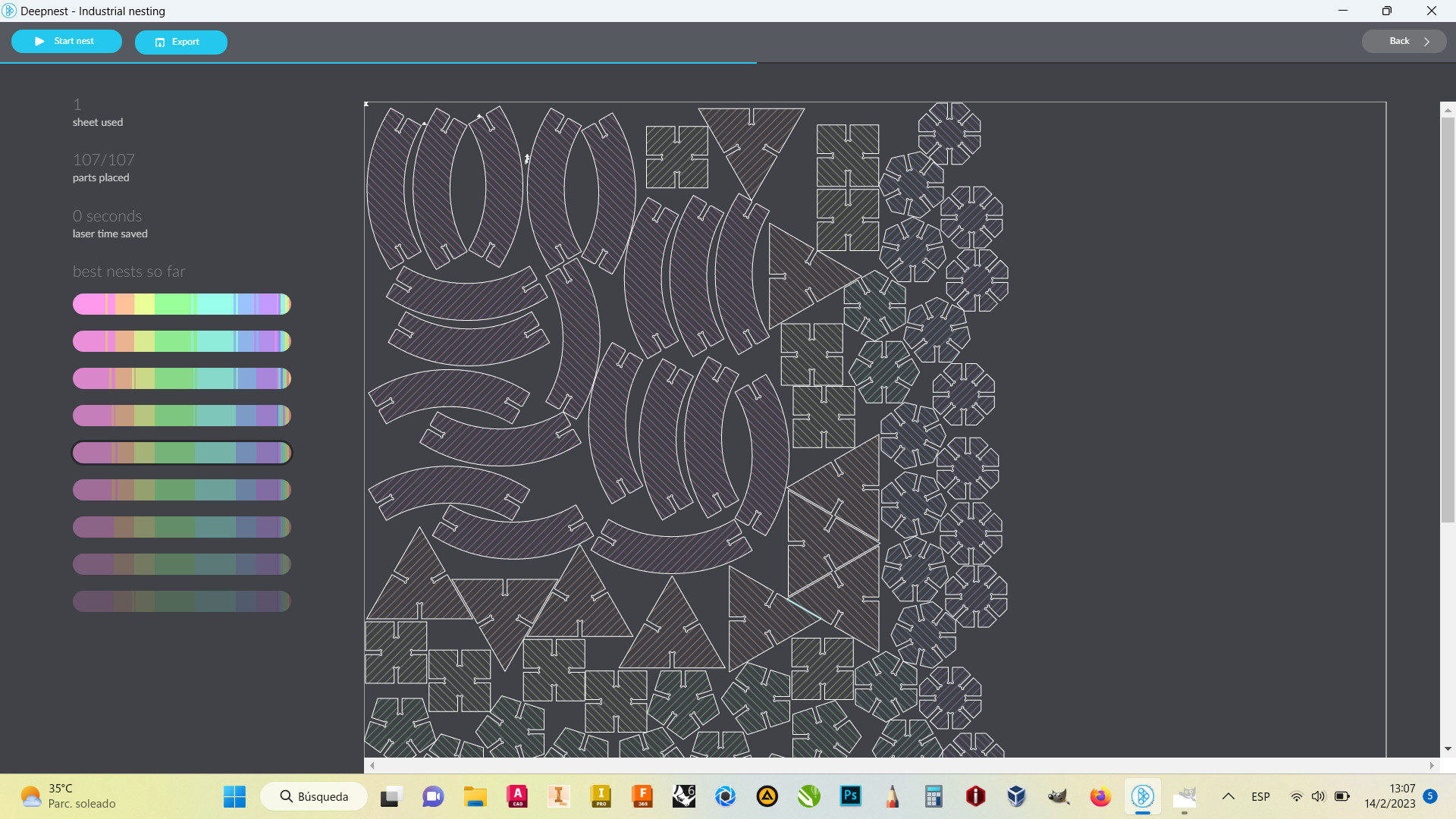

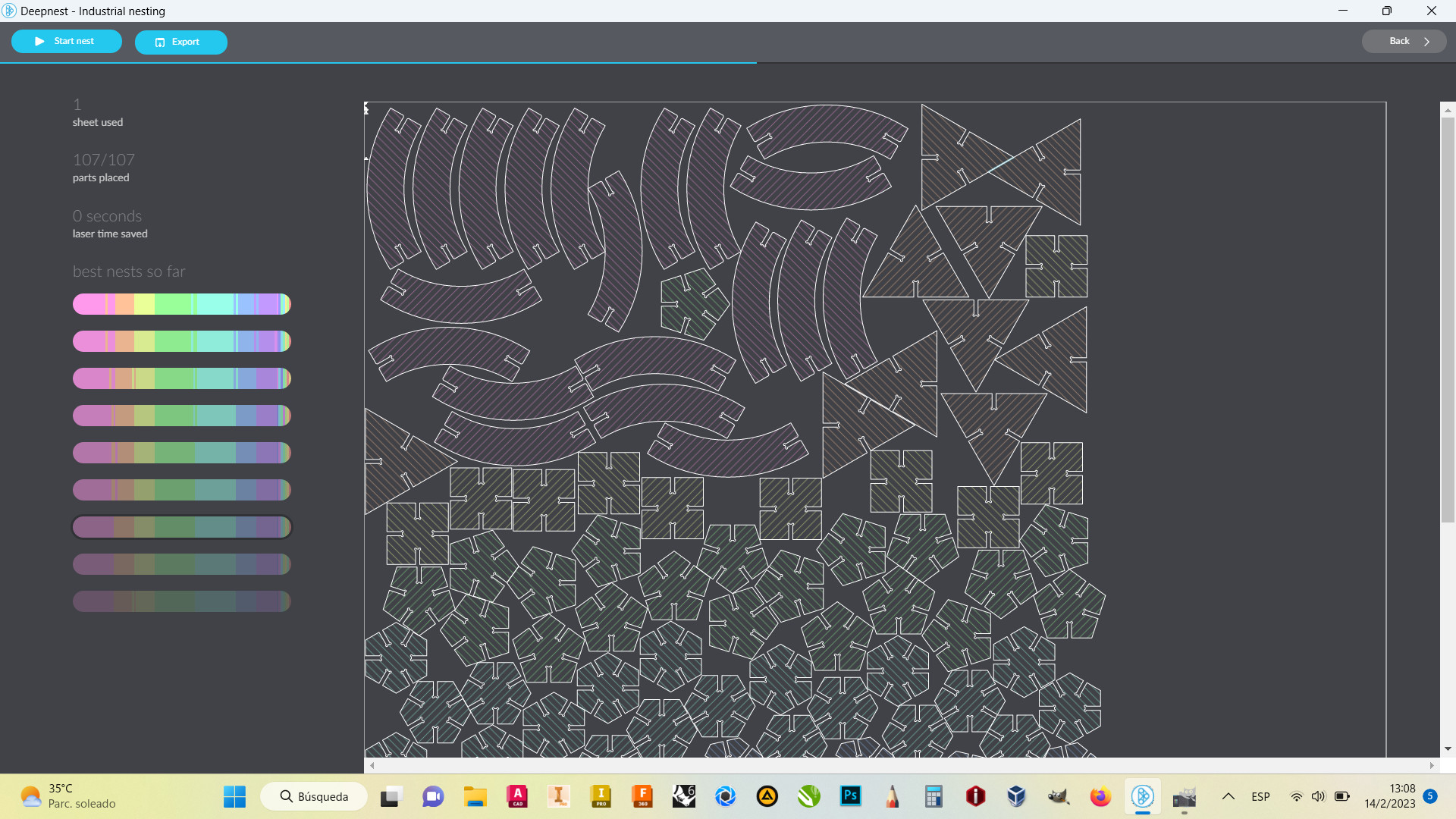

Parametric design...check....nesting....

Nesting....check....laser cut....ready to burn

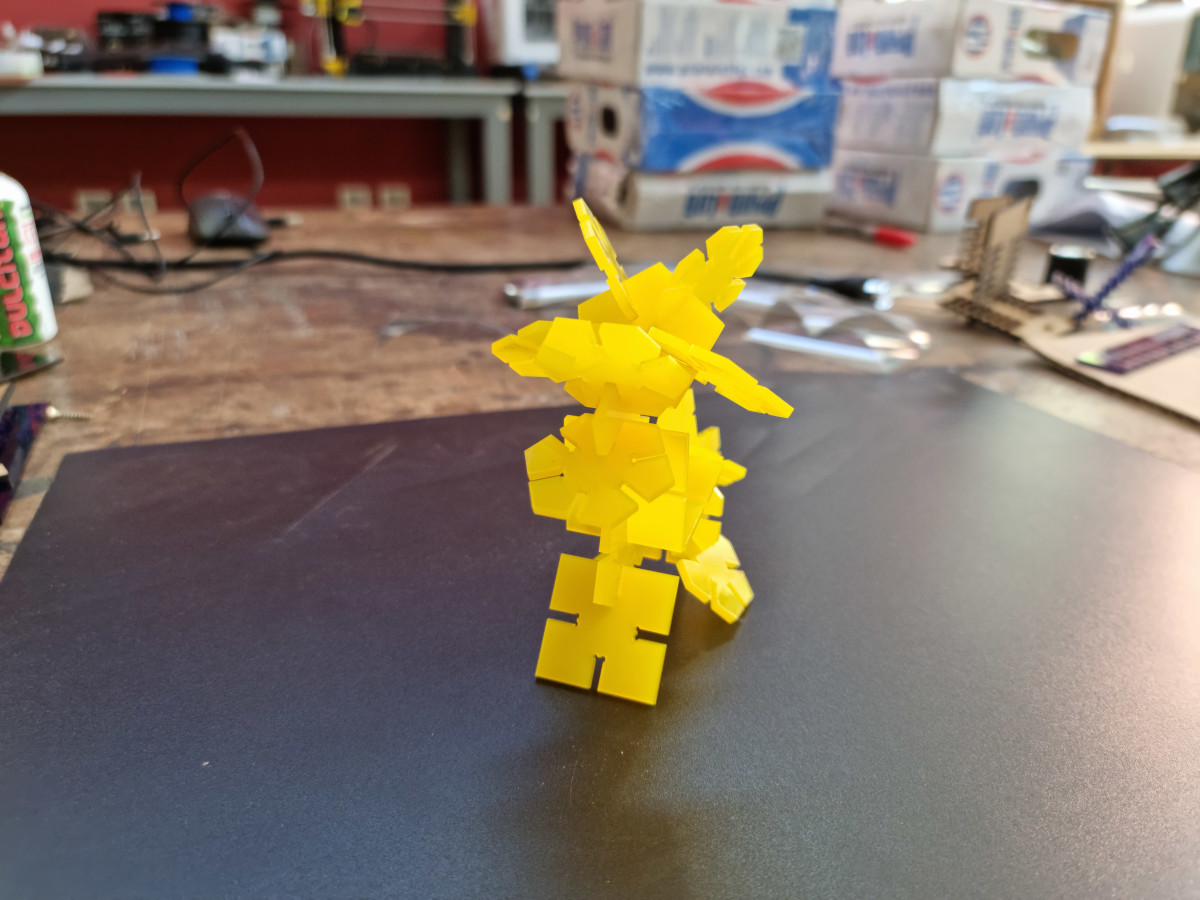

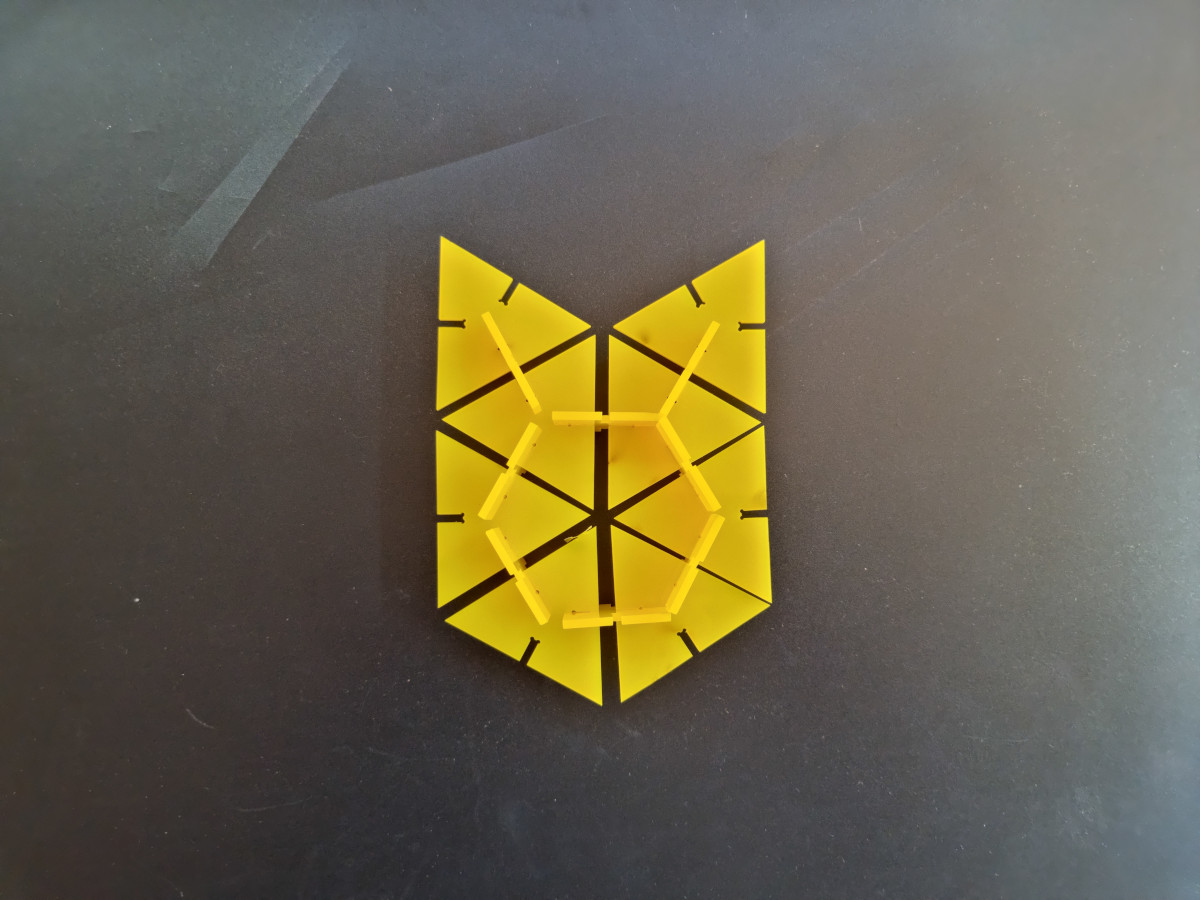

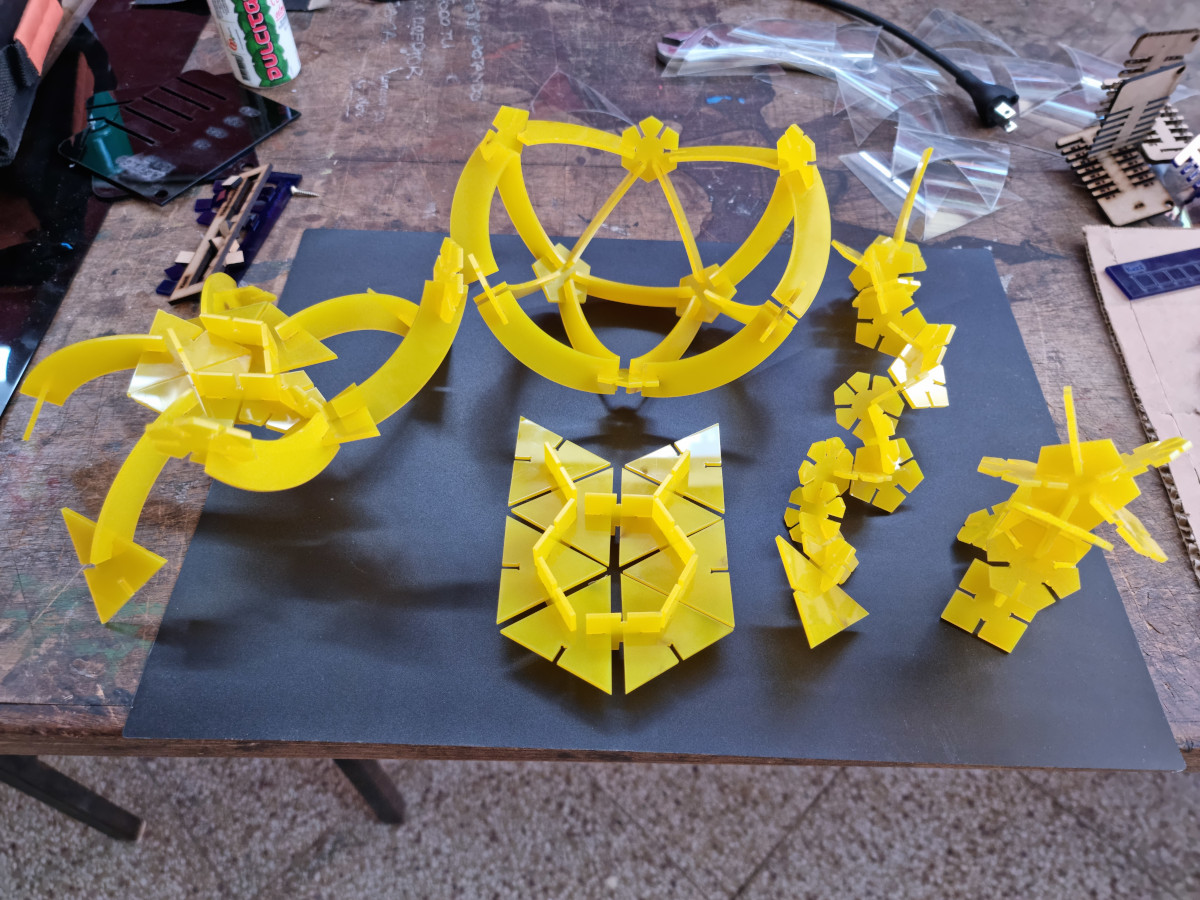

And the result of all this cutting....

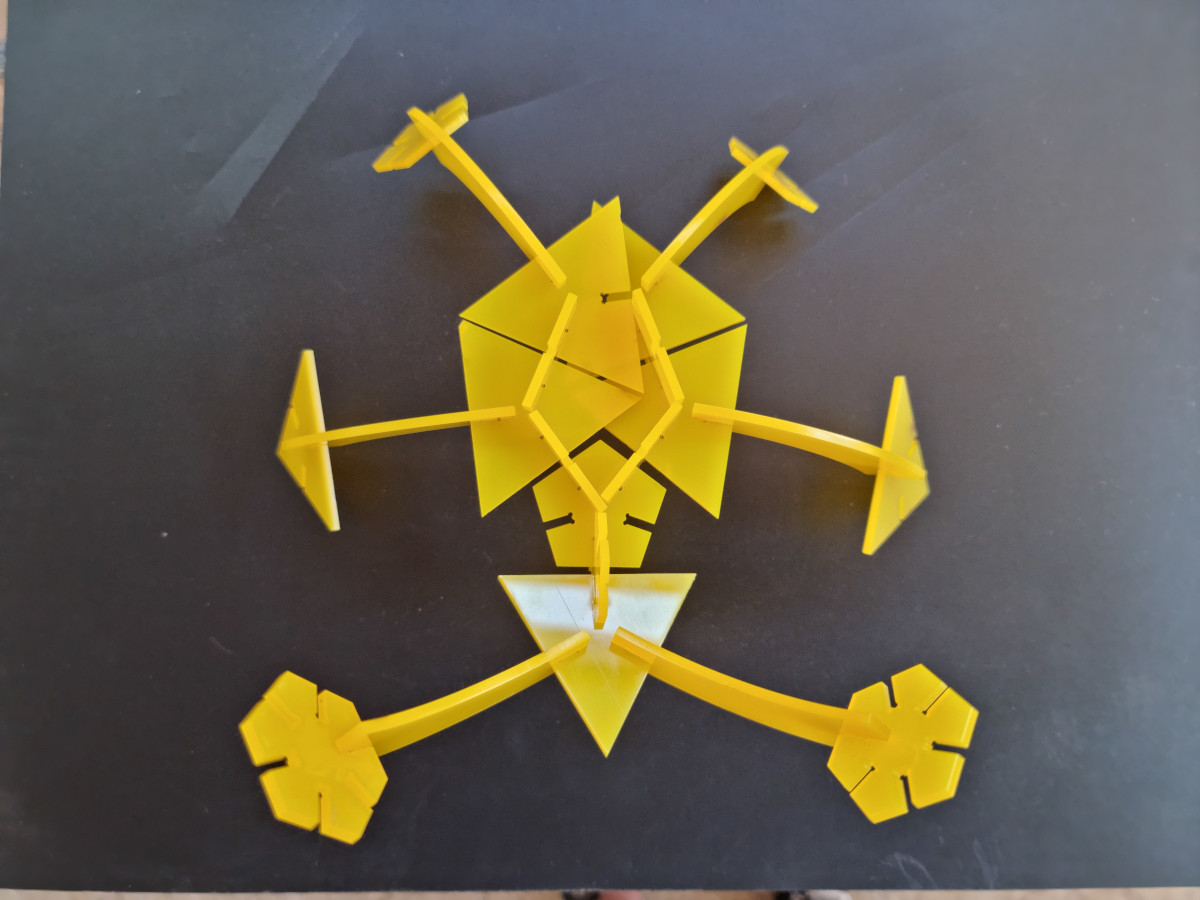

The Poodle

Don Gato

The crab

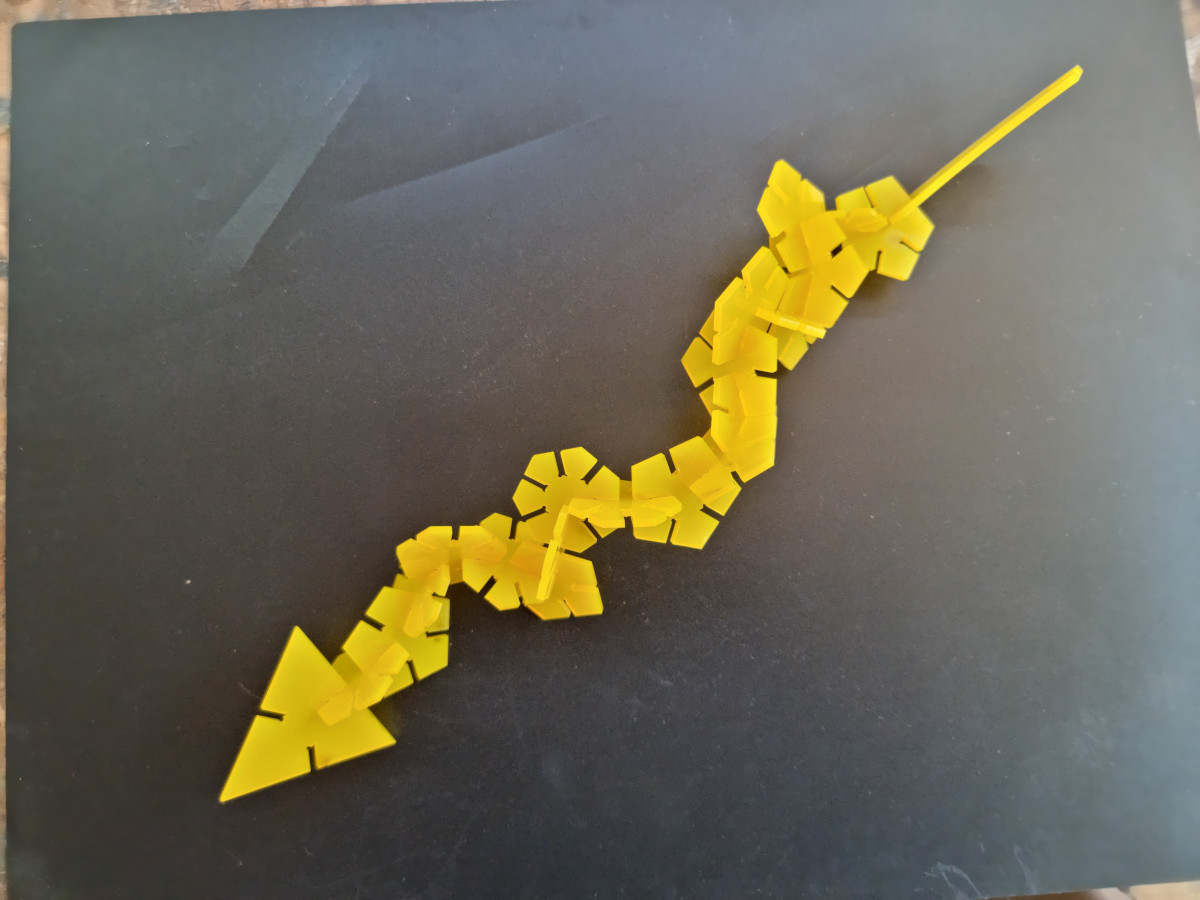

Snake

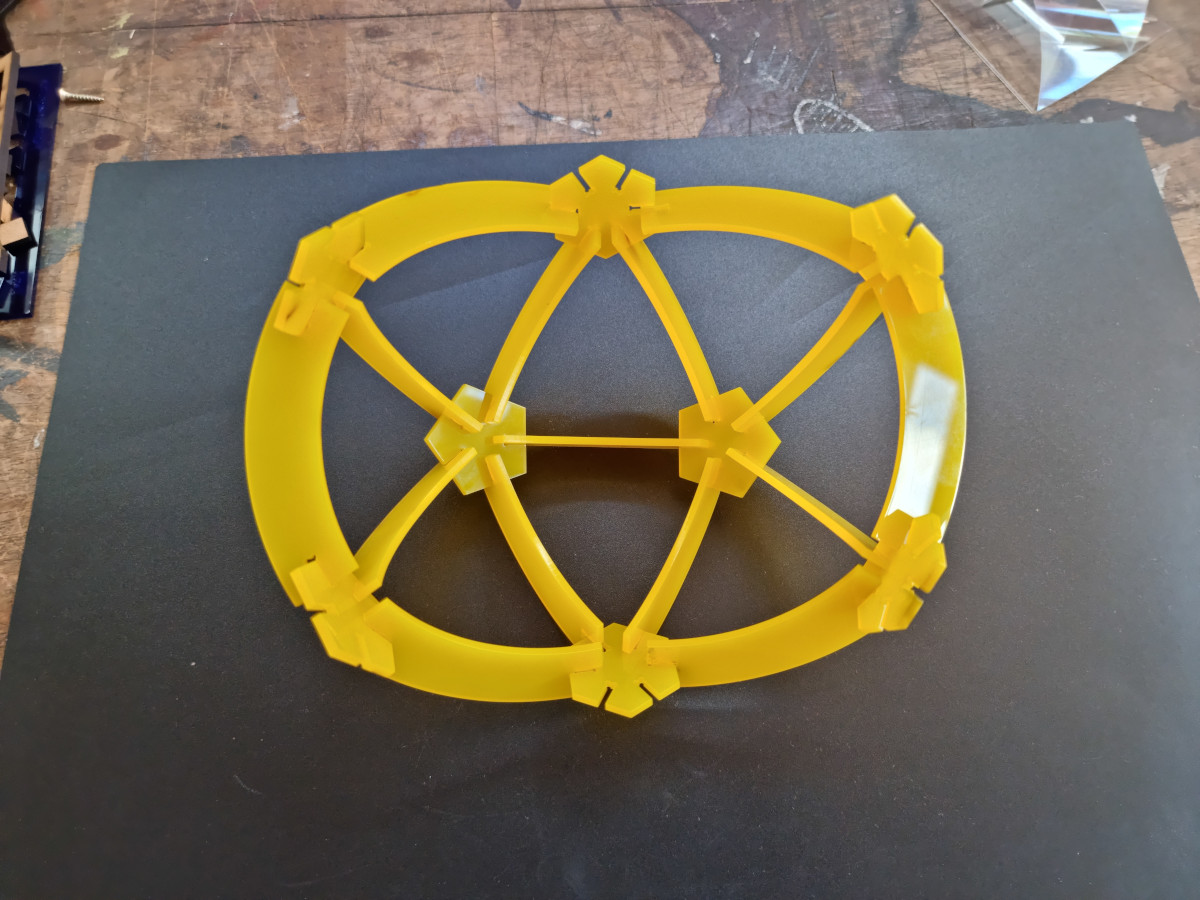

Da swing

Some of the objects you can build...free your mind and creat nice things.

To see more about our machines and the whole test we did...follow this link

Files

Download zip file [249kb] Link to group assignment