Genmitsu PROVerXL 4030¶

About¶

Specification¶

| Title | Spec |

|---|---|

| Working area | 400 x 300 x 110mm |

| Control Board Compatibility | GRBL 1.1h |

| Spindle | 300W 6A, 12,000 RPM |

| Max speed | 2000mm/min |

| Accuracy | 0.1 mm |

| Overall Machine Size | 641 x 755.5 x 580mm |

| Machine Weight | 26kg |

| Collet (in package) | 1/8” Shank |

Test¶

Design: Fusion360¶

Export: Shaper Utilities¶

Download: SVG

CAM: Mods¶

Attention

See Adjust MODS’ g-code for this machine first (below)

- read SVG

- select SVG file -> 30x30_40x40mm.svg

- convert SVG image

- ** Check ** image size: 39.980 x 39.980 (mm)

- set PCB defaults

- mill outline (1/32) -> Click to set

- mill raster 2D

- calculate -> Click to make path -> Download .nc file

- view -> Click to see Path

Download: SVG image.nc

G-gode sender: gSender¶

Set up Software¶

Note

Do not install if you have the current macOS Mojave 10.14 or later. macOS Mojave 10.14 (released in October 2018) includes a CH34x driver by Apple. If both Apple’s and the OEM driver are installed, they will create conflicting non-functional serial ports.

- Install CH340 Driver

- Download setting file gSender-settings-Genmitsu PROVerXL-4030.json.zip

- Gear icon(right top) -> Clock to open Setting

- General -> Settings -> Import Settingds

- Import Setting gSender-settings-Genmitsu PROVerXL-4030.json

- Connect PROVerXL 4030 and power ON

- Connect to Machine -> Unrecognized devices -> /dev/tty.wchusbserial1440

Set up Machine¶

- Click to Run Homing

Danger

Machine Move to home position (right up)

Make sure you are SAFE ! Work area is clear!!

- Jog Control

- Home (Machine origin)

- X: 0 (Right)

- Y: 0 (Back)

- X: 0 (Up)

- Jog

- X: “ X- ” to move Left

- Y: “ Y- ” to move Forword

- Z: “ Z- ” to move Down

- Keyboard short cut

- X: shift + right/left

- Y: shift + up/down

- Z: shift + pageup/pagedown

- Home (Machine origin)

- Tool setting

- Use 2 Wrenches

- No.13 : hold top

- No.17 : loose/tight Collet holder

- Use 2 Wrenches

- Move to Material

- Use Jog control to your material(left-down)

- Z-touch

- Use paper to touch the tool on the paper surface

- move one more -0.1mm down to reach the material surface

- Work ZERO

- Click Zero All to Work origin (X0,Y0,Z0)

- Click Zero All to Work origin (X0,Y0,Z0)

Load File¶

- Click Load File and open SVG image.nc

Start milling¶

- Click Start Job to run

Milled¶

From this result, 30mm design

| 30x30mm | X | Y |

|---|---|---|

| SVG | 29.52 | 29.57 |

| PNG | 29.50 | 29.55 |

| Ave | 29.51 | 29.56 |

| 30/Ave | 1.016605 | 1.014885 |

Adjust G-code Parameters¶

- Open Console (right-down)

Type and Enter

$$

This is default settings

client $$

$0=10 (Step pulse time, μs)

$1=255 (Step idle delay, ms)

$2=0 (Step pulse invert, mask)

$3=0 (Step direction invert, mask)

$4=0 (Invert step enable pin, boolean)

$5=0 (Invert limit pins, boolean)

$6=0 (Invert probe pin, boolean)

$10=3 (Status report options, mask)

$11=0.010 (Junction deviation, mm)

$12=0.002 (Arc tolerance, mm)

$13=0 (Report in inches, boolean)

$20=0 (Soft limits enable, boolean)

$21=1 (Hard limits enable, boolean)

$22=1 (Homing cycle enable, boolean)

$23=0 (Homing direction invert, mask)

$24=25.000 (Homing locate feed rate, mm/min)

$25=500.000 (Homing search seek rate, mm/min)

$26=250 (Homing switch debounce delay, ms)

$27=3.000 (Homing switch pull-off distance, mm)

$30=10000 (Maximum spindle speed, rpm)

$31=0 (Minimum spindle speed, rpm)

$32=0 (Laser-mode enabled as spindle, boolean)

$100=160.000 (X-axis travel resolution, step/mm)

$101=160.000 (Y-axis travel resolution, step/mm)

$102=160.000 (Z-axis travel resolution, step/mm)

$110=2000.000 (X-axis maximum rate, mm/min)

$111=2000.000 (Y-axis maximum rate, mm/min)

$112=2000.000 (Z-axis maximum rate, mm/min)

$120=300.000 (X-axis acceleration, mm/sec^2)

$121=300.000 (Y-axis acceleration, mm/sec^2)

$122=300.000 (Z-axis acceleration, mm/sec^2)

$130=420.000 (X-axis maximum travel, mm)

$131=310.000 (Y-axis maximum travel, mm)

$132=110.000 (Z-axis maximum travel, mm)

ok

Look at these three parameters

$100=160.000 (X-axis travel resolution, step/mm)

$101=160.000 (Y-axis travel resolution, step/mm)

$102=160.000 (Z-axis travel resolution, step/mm)

X and Y axis¶

I need to change these numbers

| 30x30mm | X | Y |

|---|---|---|

| SVG | 29.52 | 29.57 |

| PNG | 29.50 | 29.55 |

| Ave | 29.51 | 29.56 |

| 30/Ave | 1.016605 | 1.014885 |

| travel resolution160.000*30/Ave[step/mm] | 162.657 | 162.382 |

To set numbers, simply type and enter, one by one

$100=162.657

$101=162.382

To check to be saved

client $$

.

.

$100=162.657 (X-axis travel resolution, step/mm)

$101=162.382 (Y-axis travel resolution, step/mm)

$102=160.000 (Z-axis travel resolution, step/mm)

.

| SVG 30x30mm | X | Y |

|---|---|---|

| Test_1travel resolution[step/mm] | 162.657 | 162.382 |

| Result_1[mm] | 30.03 | 30.05 |

| Test_2 | 162.495 | 162.119 |

| Result_2 | 29.91 | 29.99 |

| Test_3 | 162.984 | 162.173 |

| Result_3 | 30.00 | 30.00-29.99 |

This is the setting from Test_3

$100=162.984 (X-axis travel resolution, step/mm)

$101=162.173 (Y-axis travel resolution, step/mm)

$102=160.000 (Z-axis travel resolution, step/mm)

Z axis¶

| Height Gauge | Value | Diff |

|---|---|---|

| Before | 7.60 | 0 |

| After 10mm down | 6.61 | -9.99 |

This is the setting from Test (no change)

$102=160.000 (Z-axis travel resolution, step/mm)

Surfacing¶

Tool¶

- 3/4” = 19.05mm

- Change Collet to 3/4”

Click Surfacing (Top-Center)

- Dimensions: size of a spoiled board

- Router Bit Diameter 19 mm

-

Start Position

- left-down

-

Genetate G-code -> Run on Main Visualizer

- Click Start job to start surfacing

Attention

This is very DUSTY process!!

Adjust MODS’ g-code for this machine¶

Compare G-code form png and from SVG

Note

PNG’s G04 P1 or SVG’s G04 P1000 need to be commented out for this machine, otherwise machine will stop on this line.

Attention

T1M06 may be also need to be commented out. This happened when wchusbserial1440 did not appear in the device list to connect. Possibly CH340 driver may not be installed successfully.

| 30x30_40x40mm_96dpi.png.nc | SVG image.nc | Meanig |

|---|---|---|

| % | % | % Signals start |

| G17 | G17 | G17 Select X-Y plane |

| G21 | G21 | G21 Metric units |

| G40 | G40 | G40 Cancel cutter compensation |

| G49 | G49 | G49 Cancel cutter |

| G54 | G54 | G54 Set Datum |

| G80 | G80 | G80 Cancel cycles |

| G90 | G90 | G90 Absolute programming |

| G94 | G94 | G94 Per minute feed |

| T1M06 | T1M06 | T1 Tool Number, M06 Tool Change |

| F150.0000 | F150.0000 | F Defines feed rate |

| S11000 | S11000 | S Defines speed |

| G00Z2.0000 | G00Z2.0000 | G00 Positioning at rapid travel Z2.0000 |

| M03 | M03 | M03 Spindle on clockwise |

| G04 P1 | G04 P1000 | G04 Dwell P[ms] |

| G00Z2.0000 | G00Z2.0000 | |

| G00X5.3263Y4.7937Z2.0000 | G00X5.0324Y4.8037Z2.0000 | |

| G01Z-0.7989 F150.0000 | G01Z-0.7117 F150.0000 | |

| F150.0000 | F150.0000 | |

| G01X5.3263Y5.0600Z-0.7989 | G01X5.0324Y4.8291Z-0.7117 | |

| G01X4.7937Y5.5926Z-0.7989 | G01X4.9816Y4.8291Z-0.7117 | |

| G01X4.7937Y34.6208Z-0.7989 | G01X4.8545Y4.9561Z-0.7117 | |

| G01X5.8589Y35.1534Z-0.7989 | G01X4.8037Y5.1086Z-0.7117 | |

| G01X34.6208Y35.1534Z-0.7989 | G01X4.8037Y34.9472Z-0.7117 | |

| G01X35.1534Y34.0882Z-0.7989 | G01X4.9561Y35.1251Z-0.7117 | |

| G01X35.1534Y5.3263Z-0.7989 | G01X5.1086Y35.1759Z-0.7117 | |

| G01X34.0882Y4.7937Z-0.7989 | G01X34.9472Y35.1759Z-0.7117 | |

| G01X5.3263Y4.7937Z-0.7989 | G01X35.1251Y35.0235Z-0.7117 | |

| G00Z2.0000 | G01X35.1759Y34.8710Z-0.7117 | |

| G1X0Y0Z0 | G01X35.1759Y5.0324Z-0.7117 | |

| M05 | G01X35.0235Y4.8545Z-0.7117 | |

| M30 | G01X34.8710Y4.8037Z-0.7117 | |

| % | G01X5.0324Y4.8037Z-0.7117 | |

| G00Z2.0000 | ||

| M05 | M05 Spindle Stop | |

| M30 | M30 Program end, return to start | |

| % |

Ref. G-gode, M-code, T1M06, G04, G54, %

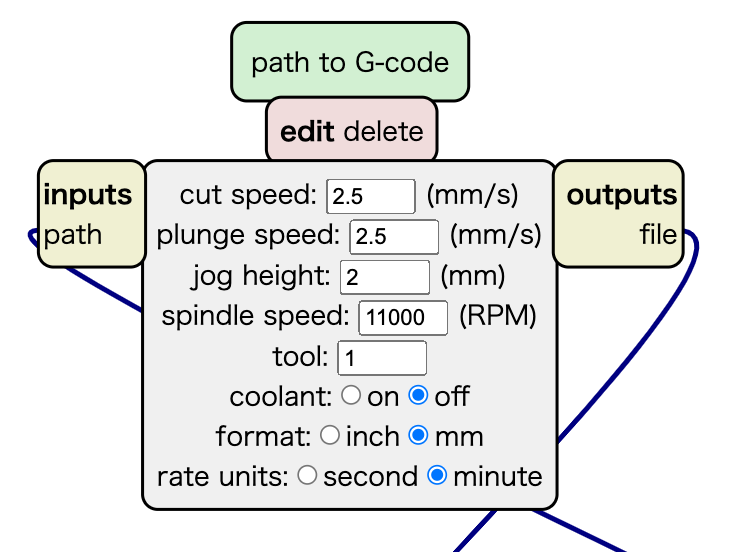

Edit path to G-code module¶

Comment out G04 P1000 and

//

// local functions

//

function make_path() {

var dx = 25.4*mod.width/mod.dpi

var cut_speed = parseFloat(mod.cutspeed.value)

var plunge_speed = parseFloat(mod.plungespeed.value)

var jog_height = parseFloat(mod.jogheight.value)

var nx = mod.width

var scale = dx/(nx-1)

var in_mm_scale = 1

if (mod.formatInch.checked) {

dx /= 25.4

scale /= 25.4

cut_speed /= 25.4

plunge_speed /= 25.4

jog_height /= 25.4

}

if (mod.unitMinutes.checked) {

cut_speed *= 60

plunge_speed *= 60

}

var spindle_speed = parseFloat(mod.spindlespeed.value)

var tool = parseInt(mod.tool.value)

str = "%\n" // tape start

str += "G17\n" // xy plane

if (mod.formatInch.checked)

str += "G20\n" // inches

if (mod.formatMm.checked)

str += "G21\n" // mm

str += "G40\n" // cancel tool radius compensation

str += "G49\n" // cancel tool length compensation

str += "G54\n" // coordinate system 1

str += "G80\n" // cancel canned cycles

str += "G90\n" // absolute coordinates

str += "G94\n" // feed/minute units

//str += "T"+tool+"M06\n" // tool selection, tool change..................comment out

str += "F"+cut_speed.toFixed(4)+"\n" // feed rate

str += "S"+spindle_speed+"\n" // spindle speed

if (mod.coolanton.checked)

str += "M08\n" // coolant on

str += "G00Z"+jog_height.toFixed(4)+"\n" // move up before starting spindle

str += "M03\n" // spindle on clockwise

//str += "G04 P1000\n" // give spindle 1 second to spin up................comment out

//str += "G04 P1\n" // give spindle 1 Millisecond to spin up..............comment out

save local program¶

Download local program¶

| mill_2D_PCB | PNG | SVG |

|---|---|---|

| html | png.html | svg.html |

| txt | png.txt | svg.txt |

open local program¶

- html

- Double Click mill_2D_PCB_svg.html (work in local PC)

- text

- Open mods (MIT server)

- left click -> program -> open local program -> mill_2D_PCB_svg.txt -> open

line Test¶

1/64¶

V-bit¶

- Cutting Edge Diameter 0.2mm

- 30 Degrees

| Depth of Cut | Width of Cut |

|---|---|

| 0.1 | 0.25359 |

| 0.2 | 0.30718 |

| 0.3 | 0.36077 |

Ref. calculator width-of-cut of a “V” shaped cutting tool

Depth = 0.2mm

Adjust G-code Parameters 2022/4/25¶

Design, g-code, milling¶

Test_0¶

$$

...

$100=162.984 (X-axis travel resolution, step/mm)

$101=162.173 (Y-axis travel resolution, step/mm)

Tests and Result¶

| test_0 | test_1 | test_2 | |

|---|---|---|---|

| X-axis(L-R) | |||

| $100 | 162.984 | 161.290 | 161.403 |

| length | 101.05 | 99.93 | 100.02 ok |

| Y-axis(Up-Dw) | |||

| $101 | 162.173 | 161.174 | 161.126 |

| length | 100.62 | 100.03 | 100.01 ok |

Parameters from test_2 are good to use

$$

...

$100=161.403 (X-axis travel resolution, step/mm)

$101=161.126 (Y-axis travel resolution, step/mm)