Mohit Ahuja's Fabacademy 2021

Electronics Design

Group Assignment

This is the link to the group project for this week, where we checked the microcontroller circuit's properties using different test equipment:

Group Project

Individual Assignment

Using Kicad

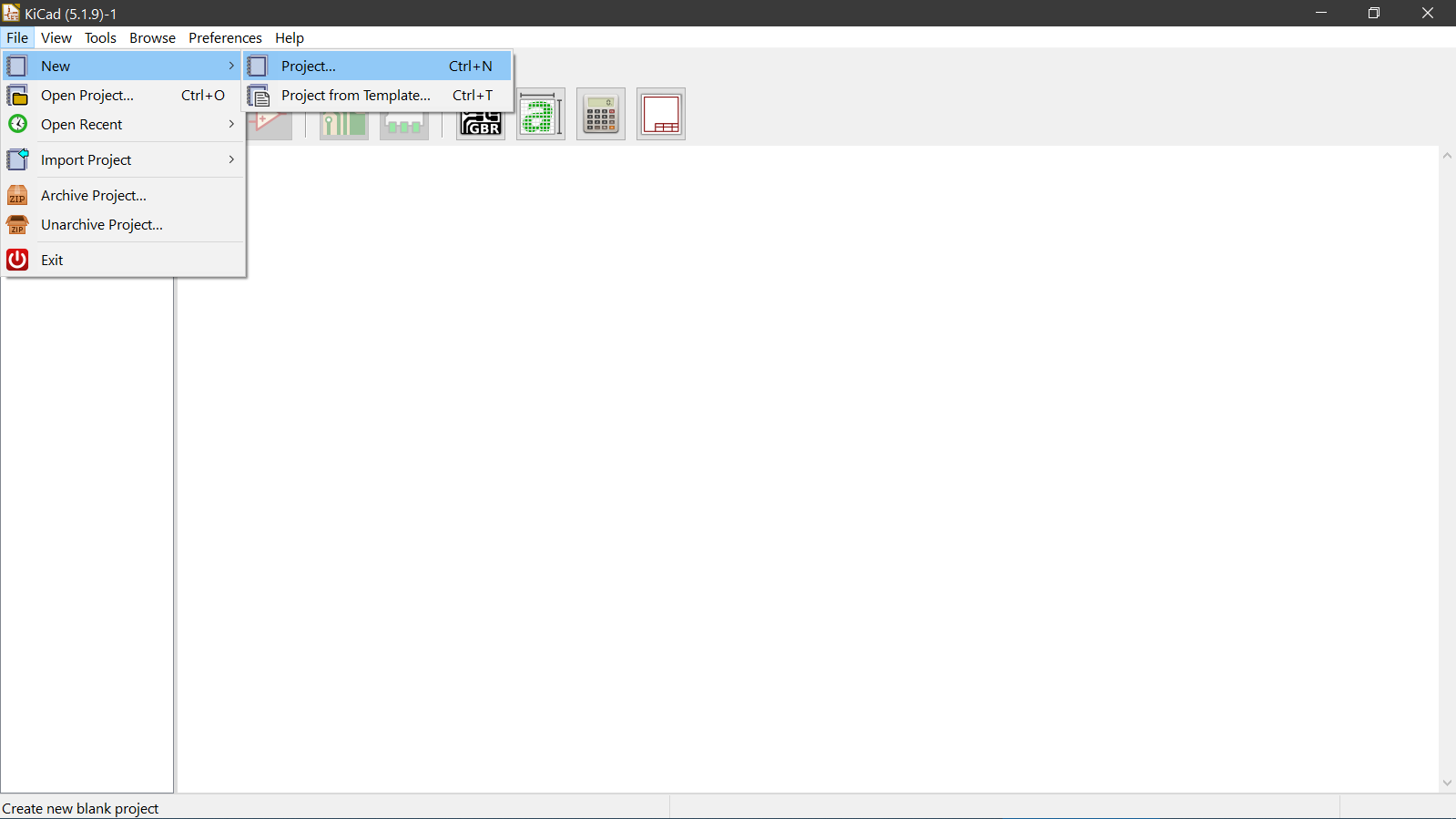

Starting a new project by going to File>New>Project

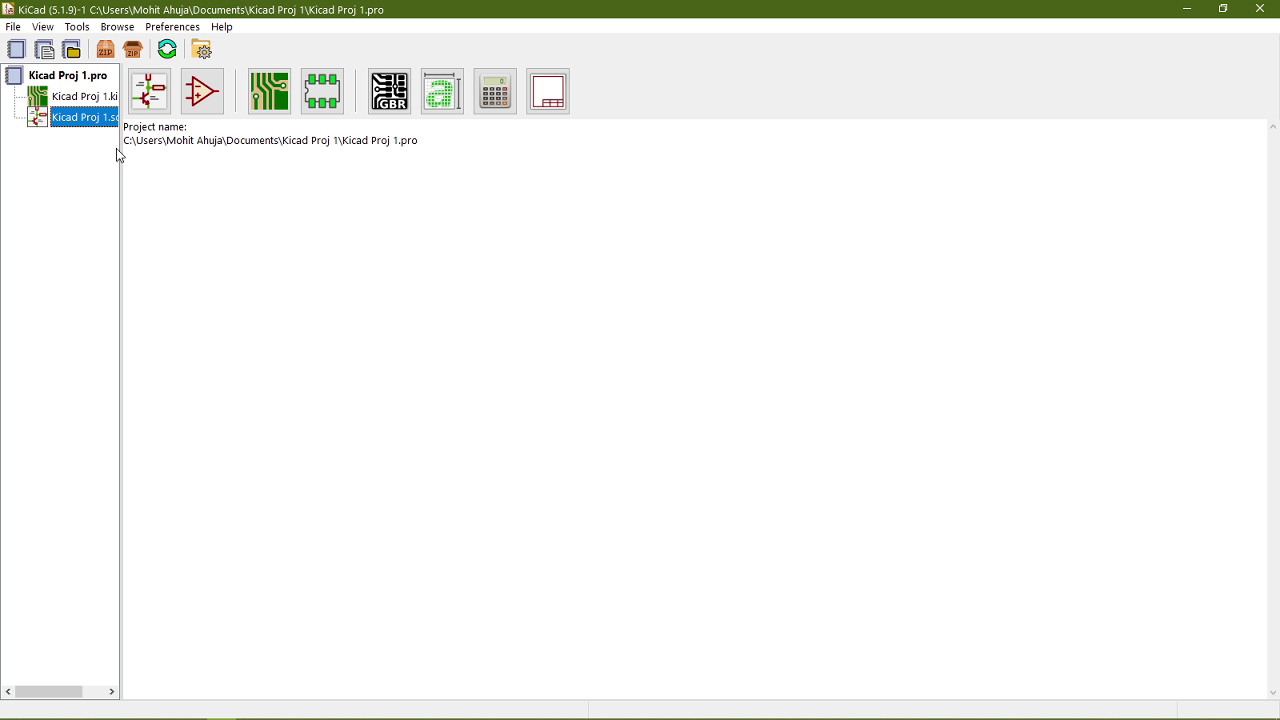

After entering the name of the project, this is the screen that I see:

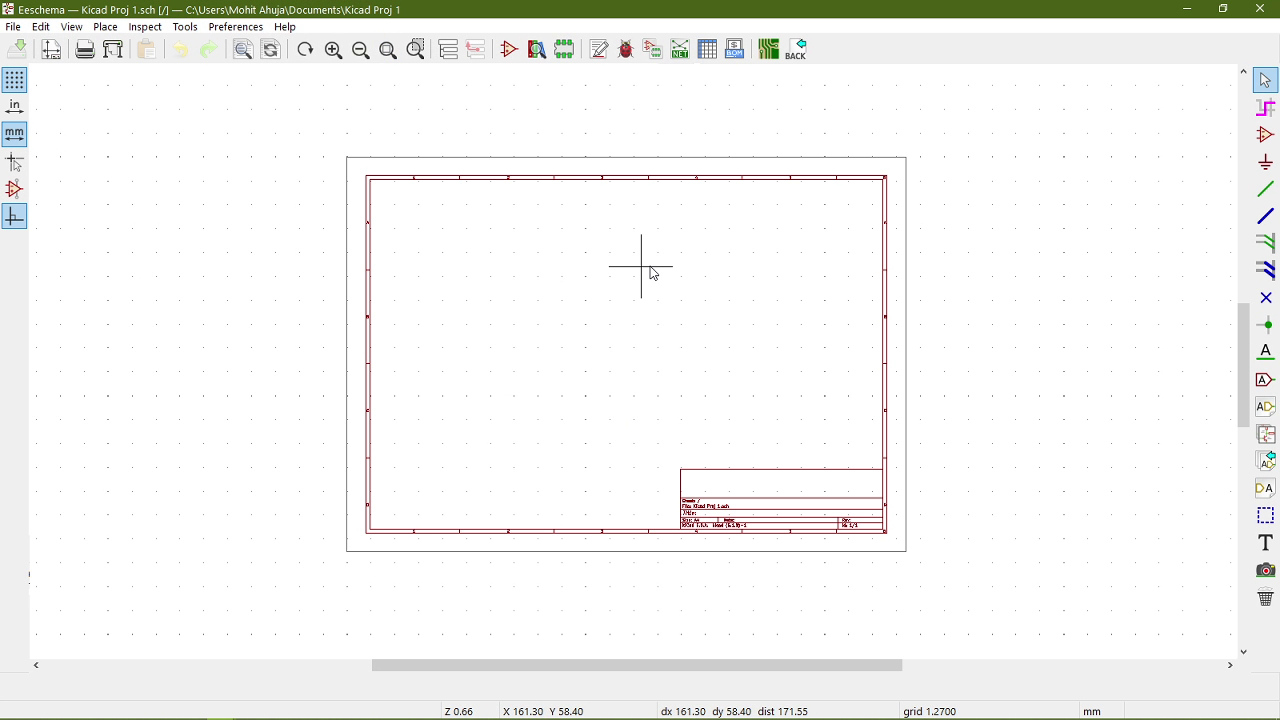

I opened the schematic file which is the file with the .sch extension and this screen popped up:

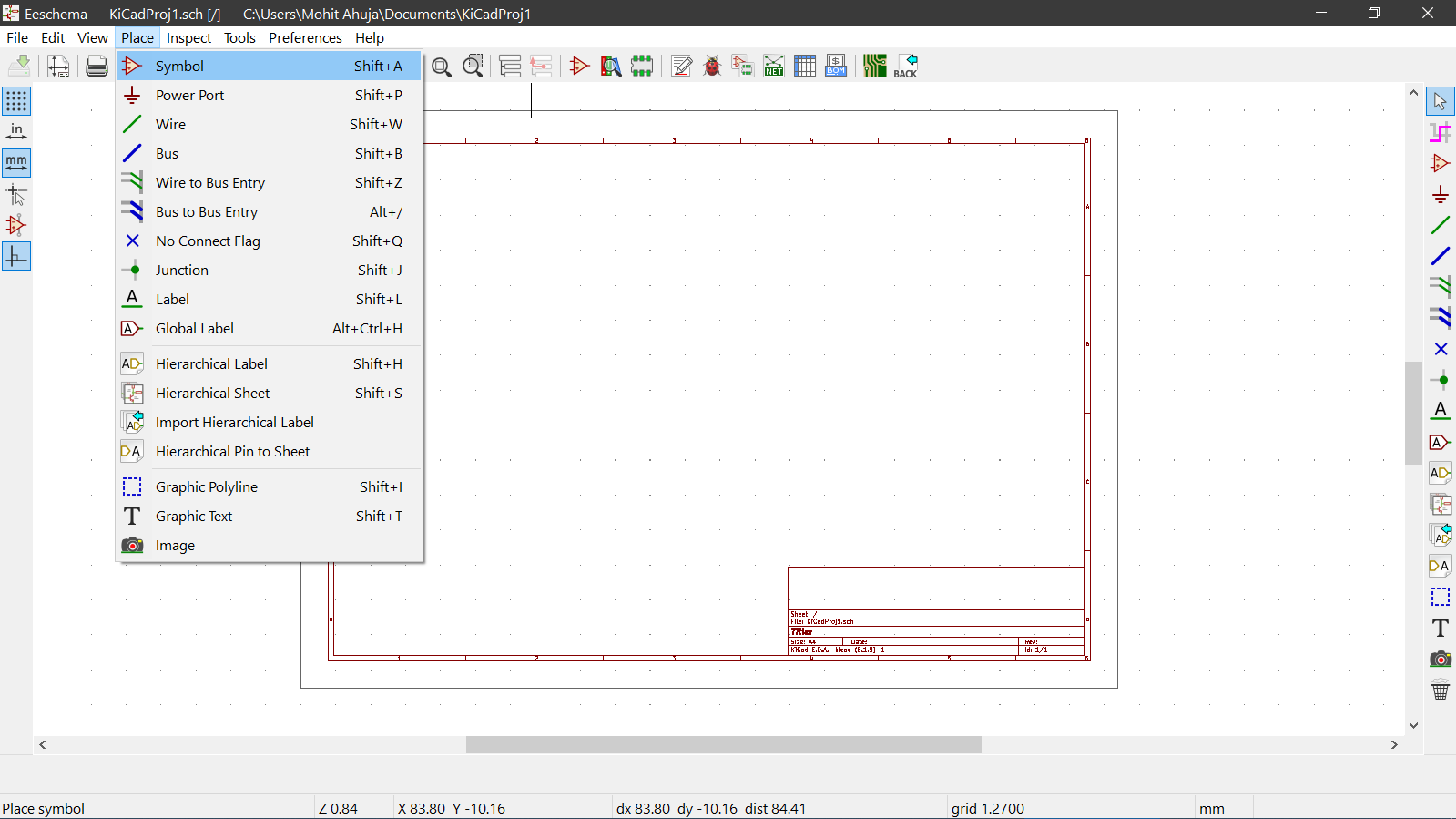

I then places the components using the Place>Symbol menu.

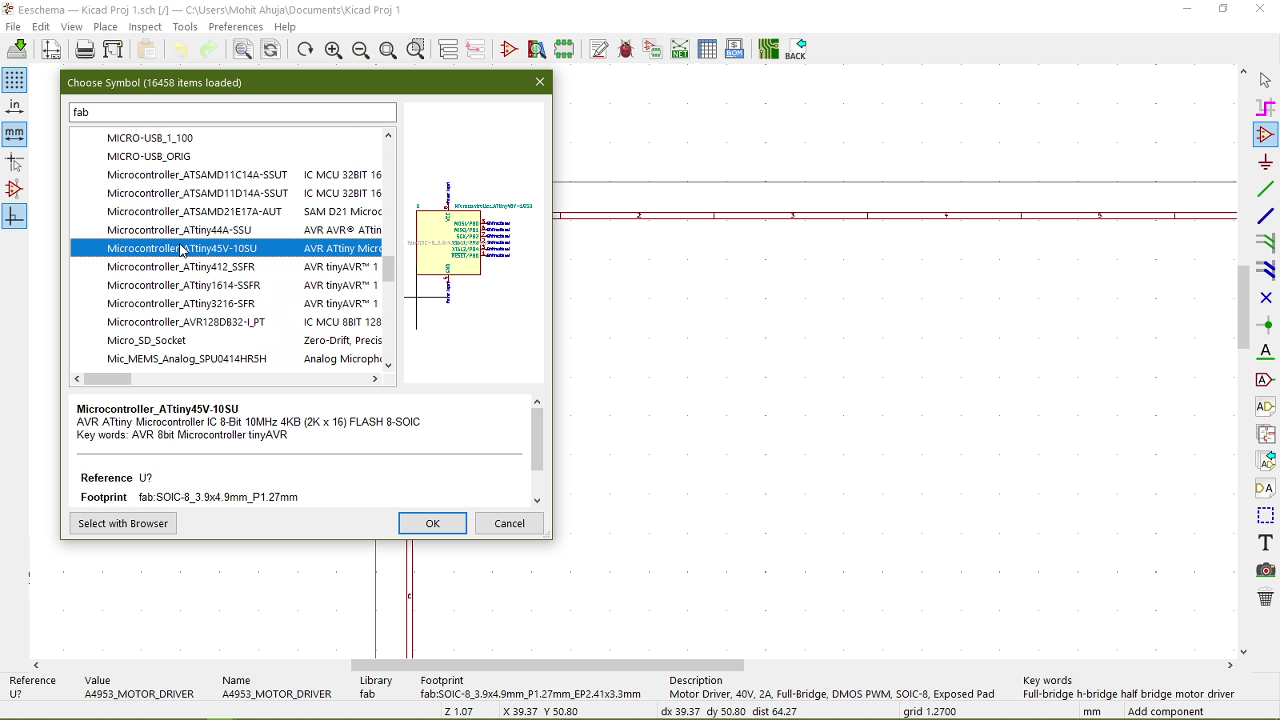

I selected the appropriate components one by one from the fab library of components

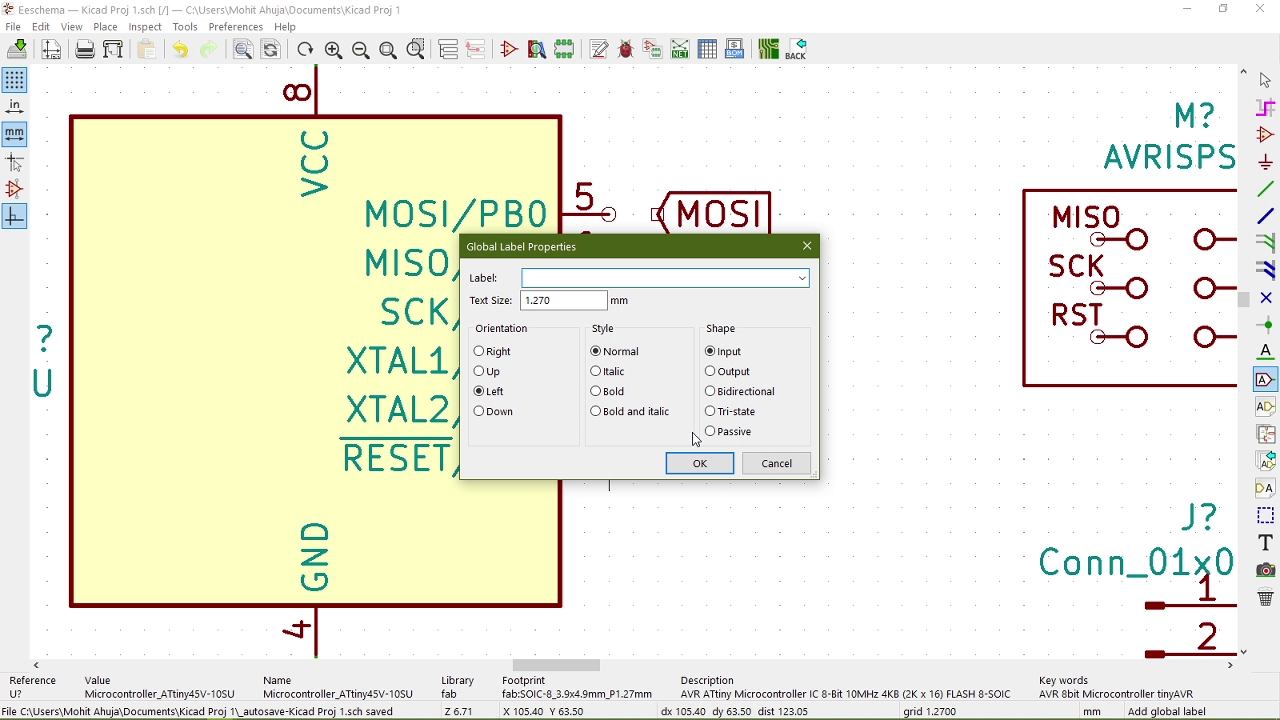

Then I started assigning labels to all the pins based on how I want to connect the components. I did that by going to Place>Global Label

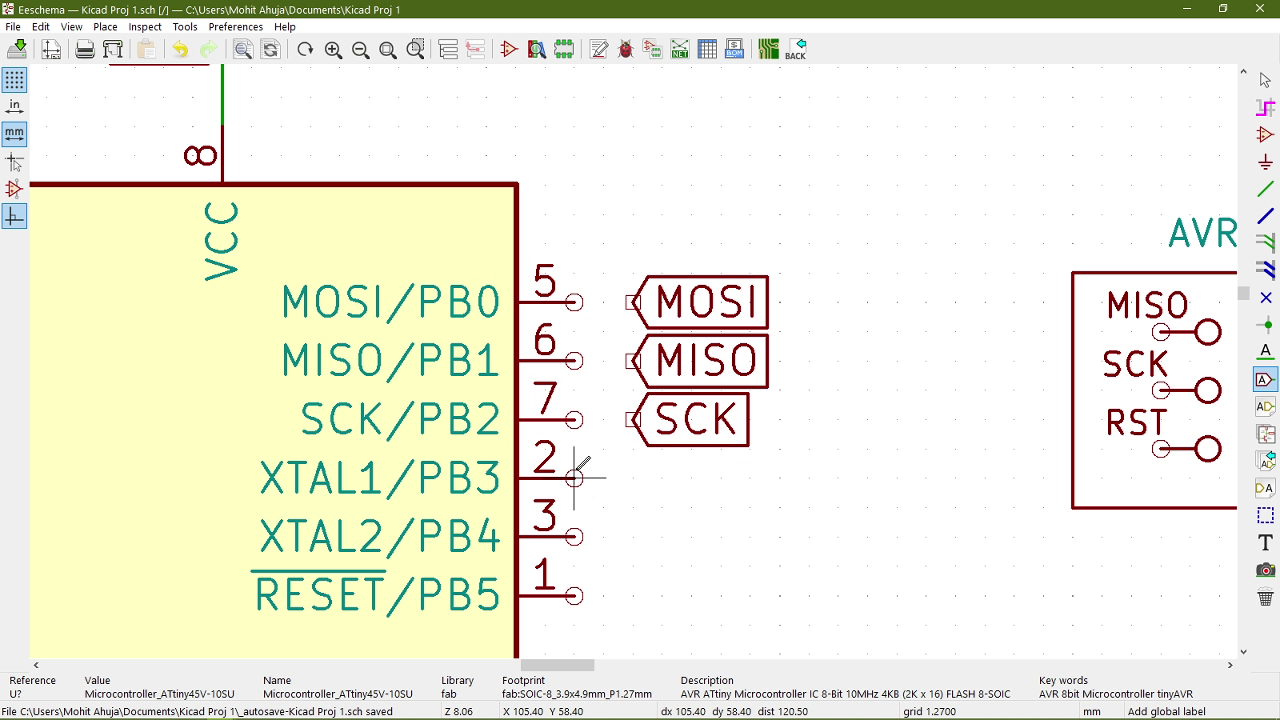

This is what it looked like after the labels were added:

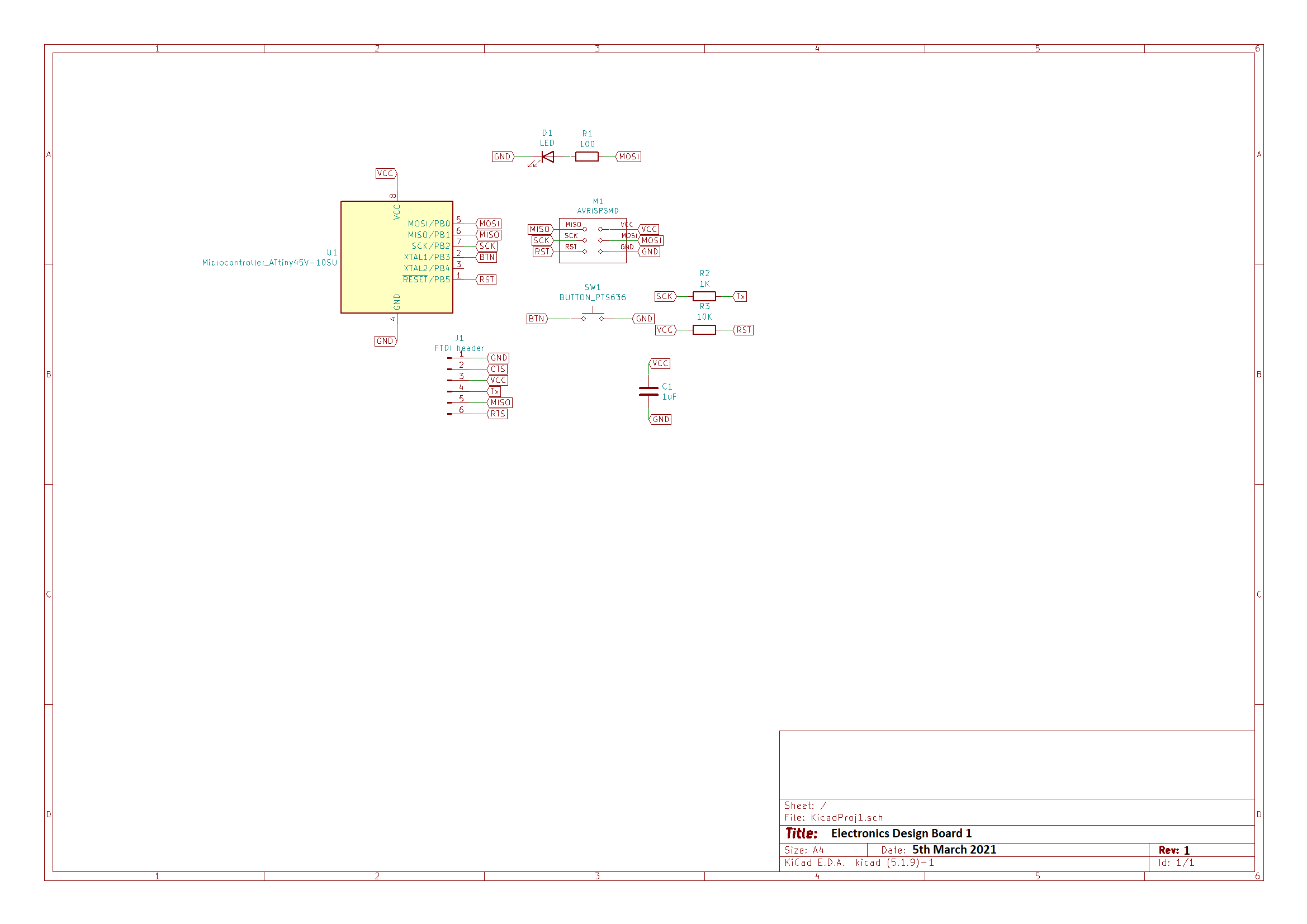

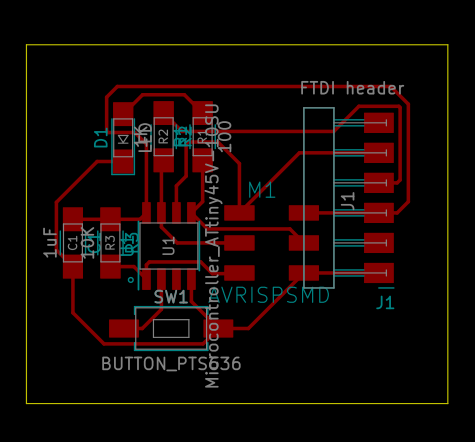

Then I connected everything appropriately, taking reference from Neil's Hello Echo World Board. This is the schematic after adding the LED and the button as required by the assignment:

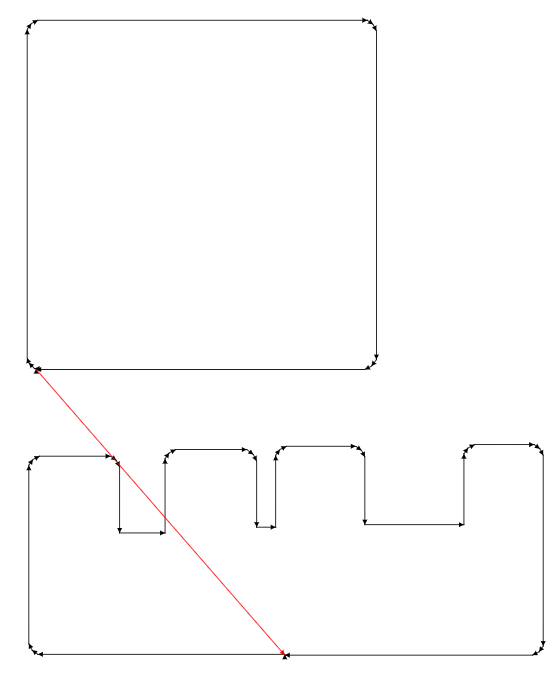

Designing the Traces

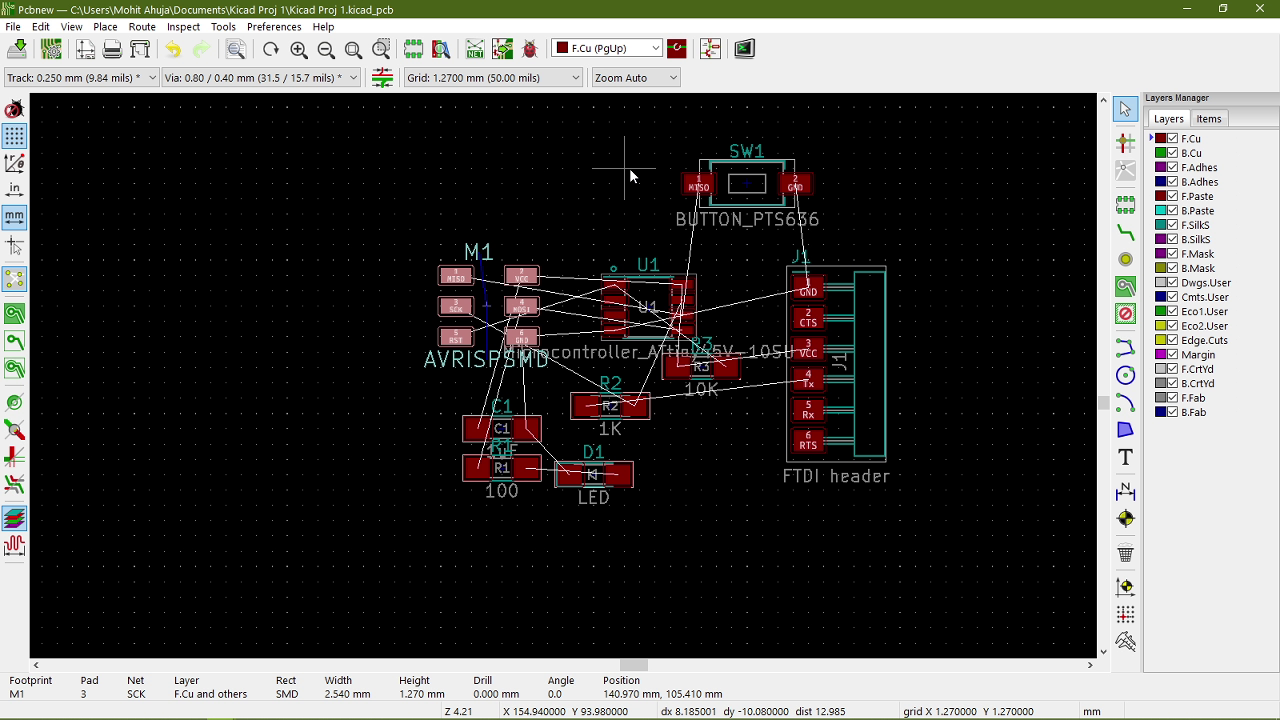

I first arranged the components in the configuration I wanted.

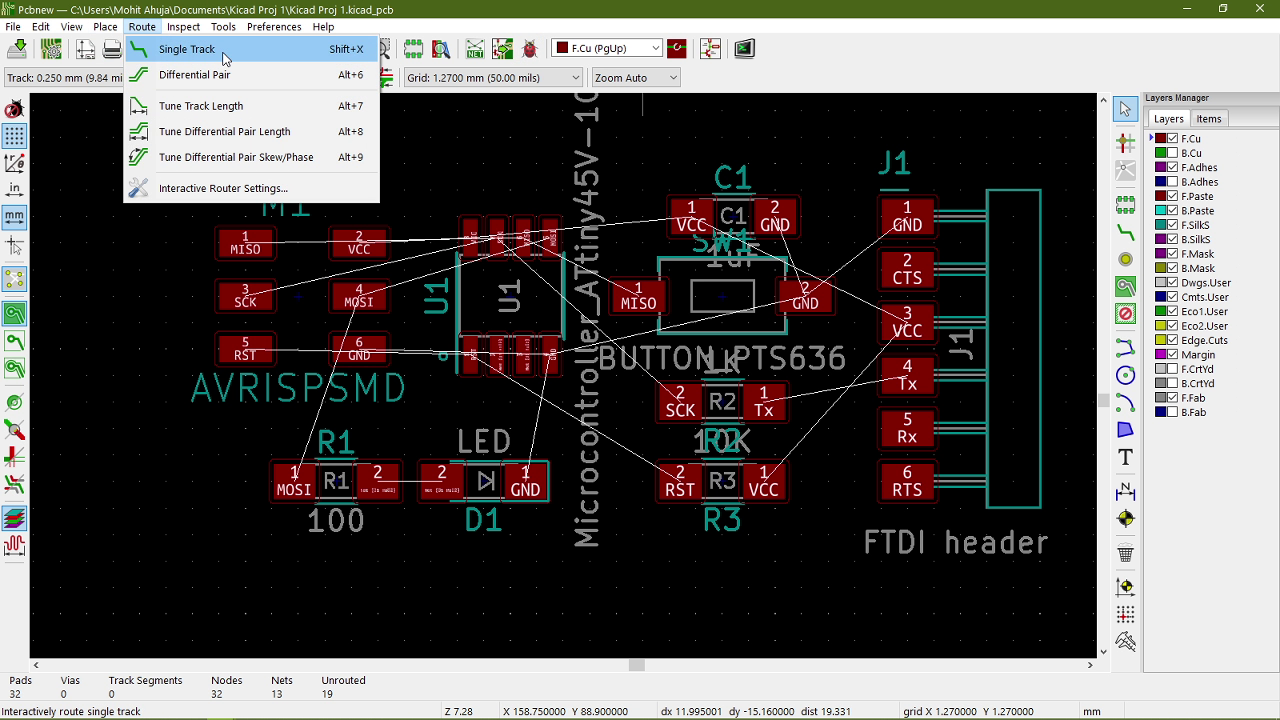

Then I started putting the traces down by using:

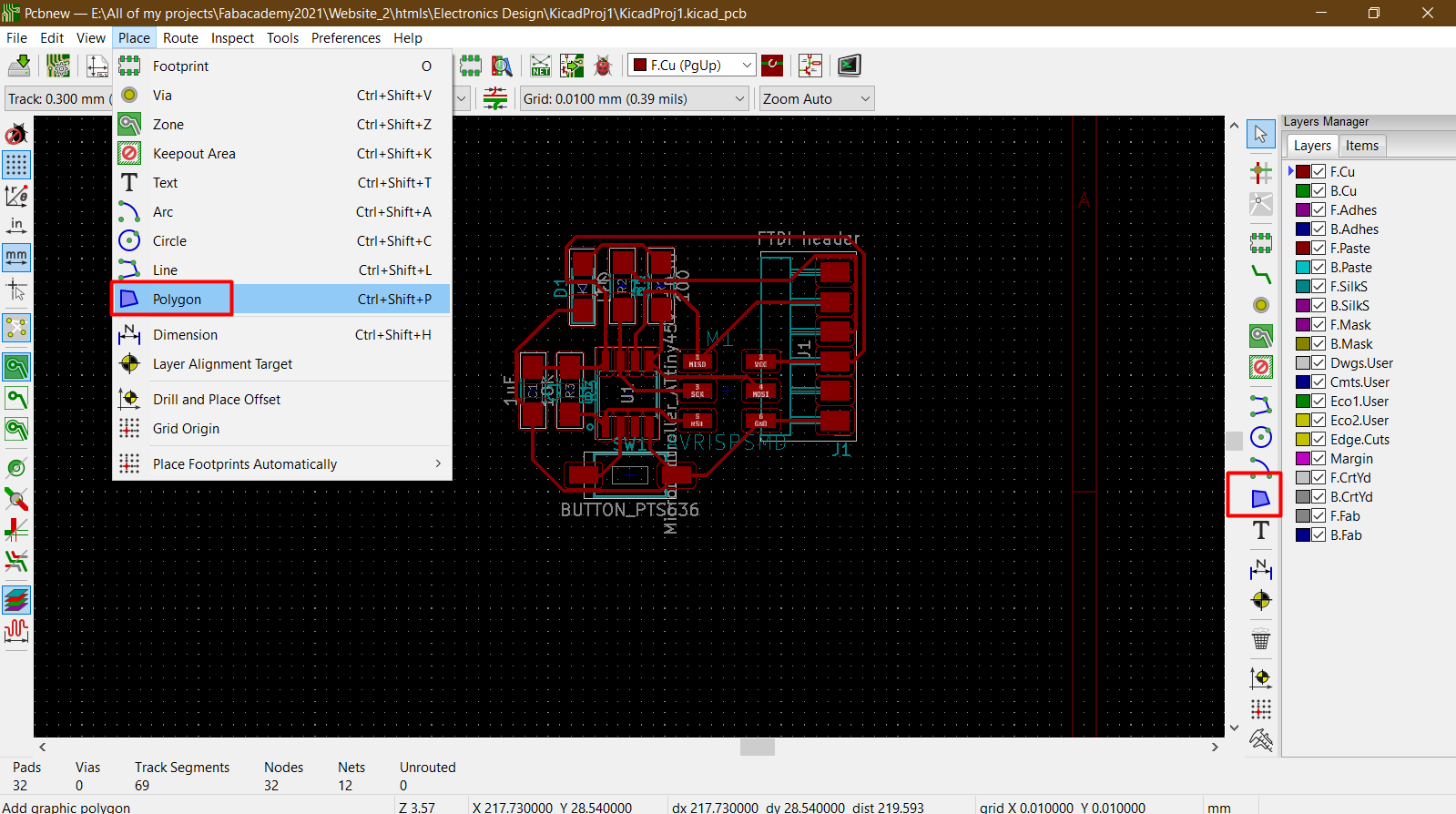

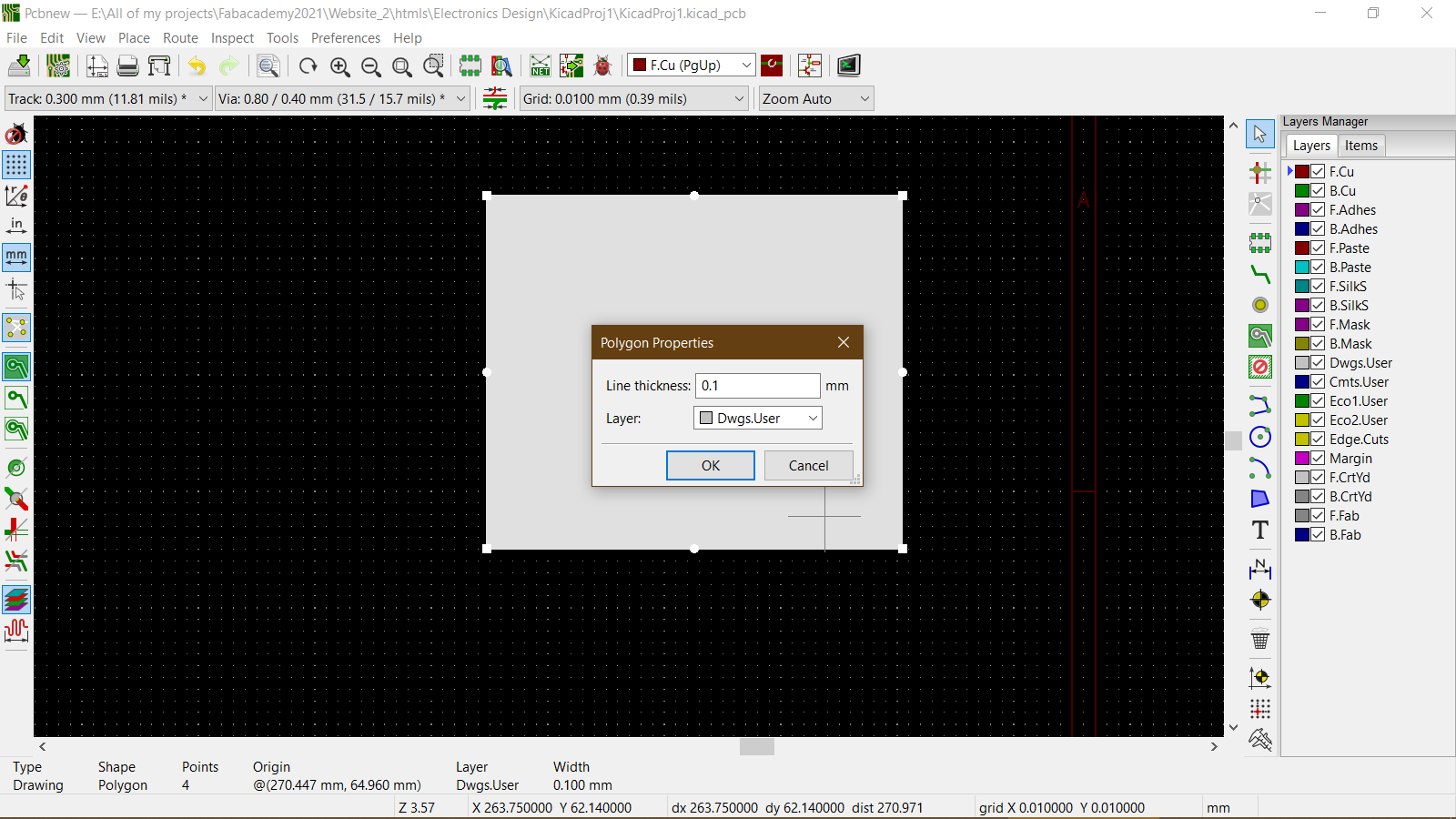

Then I made the outline of the board using:

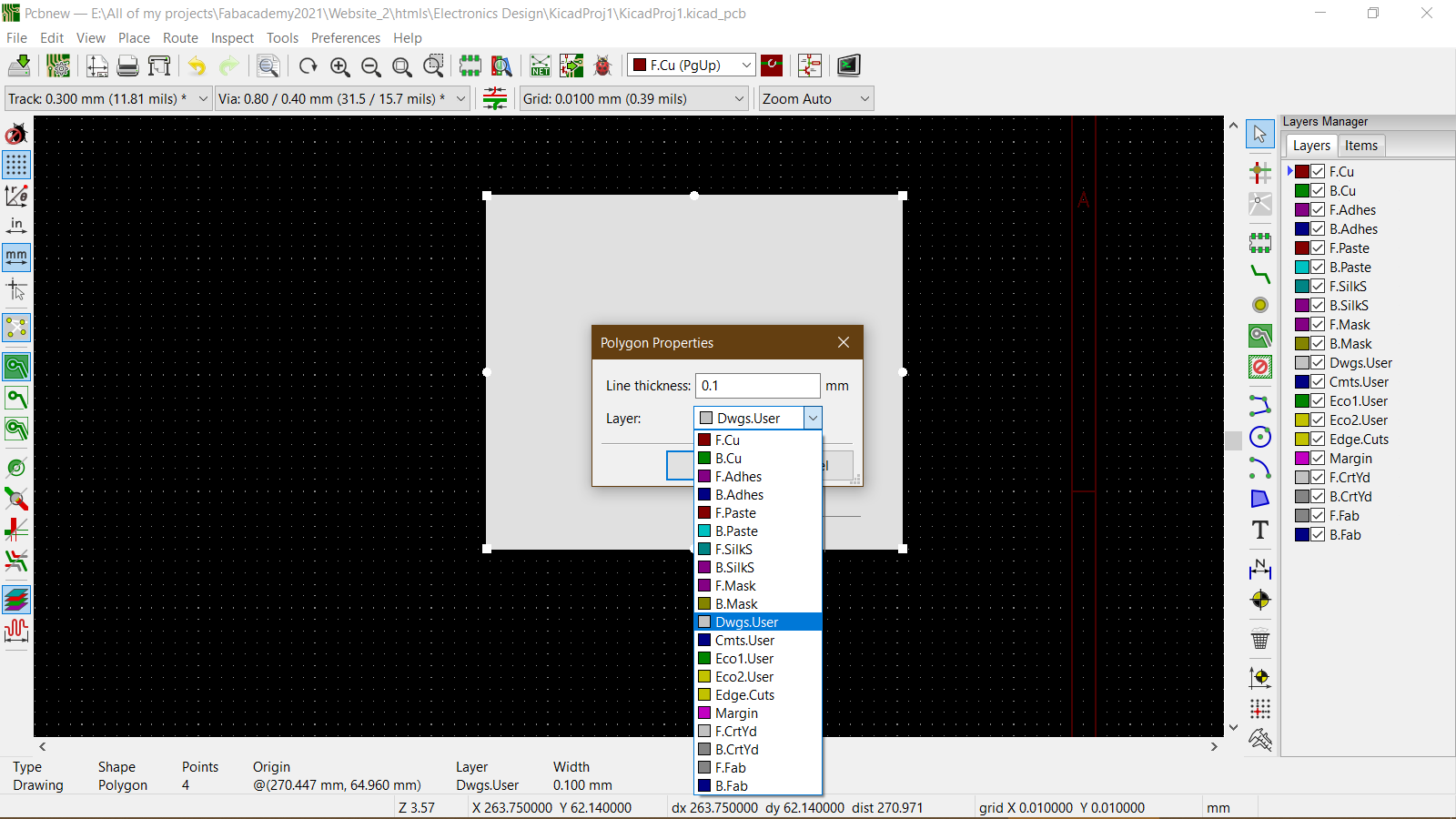

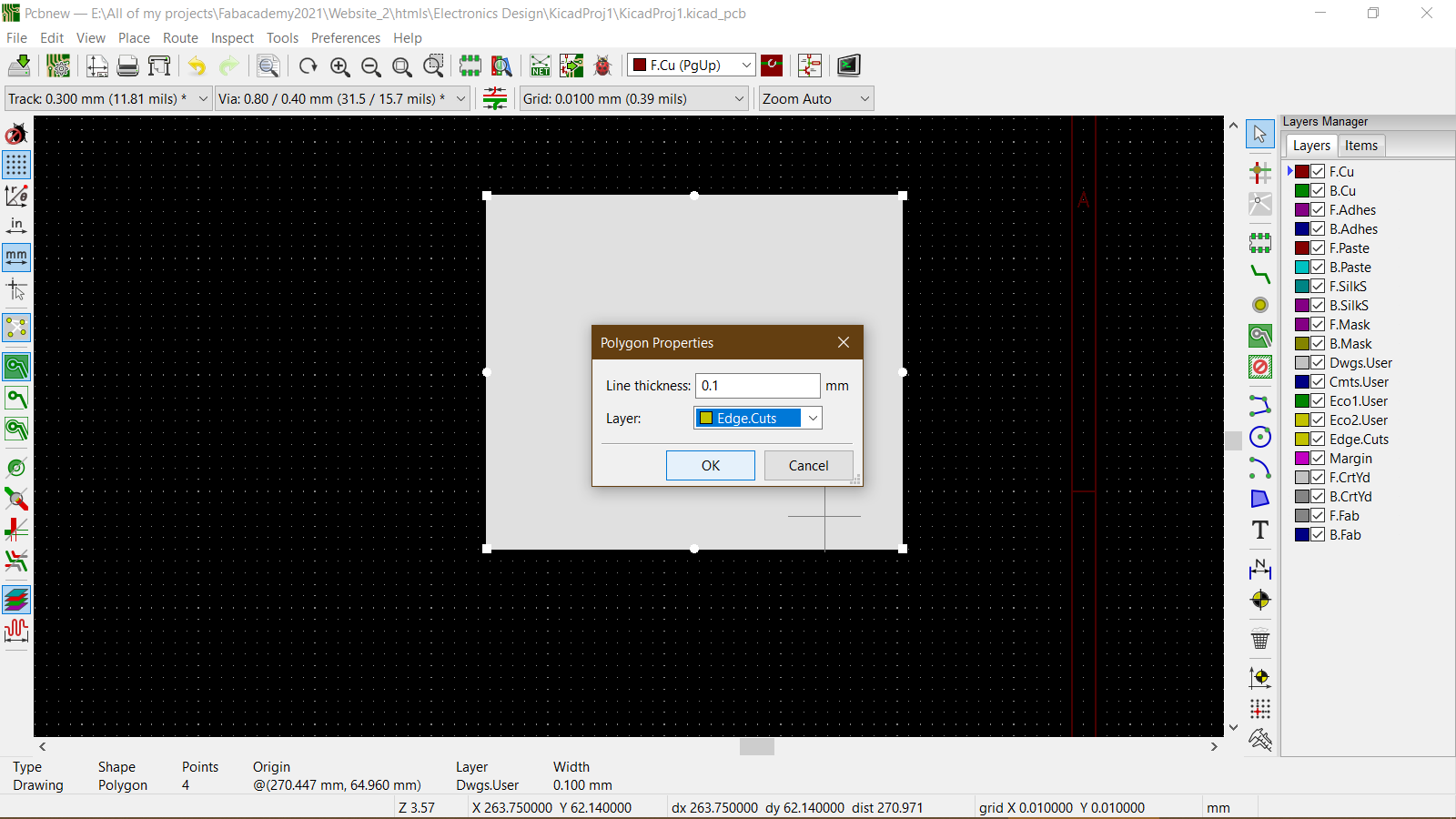

I changed the outline layer by double clicking on the polygon and then changing the layer:

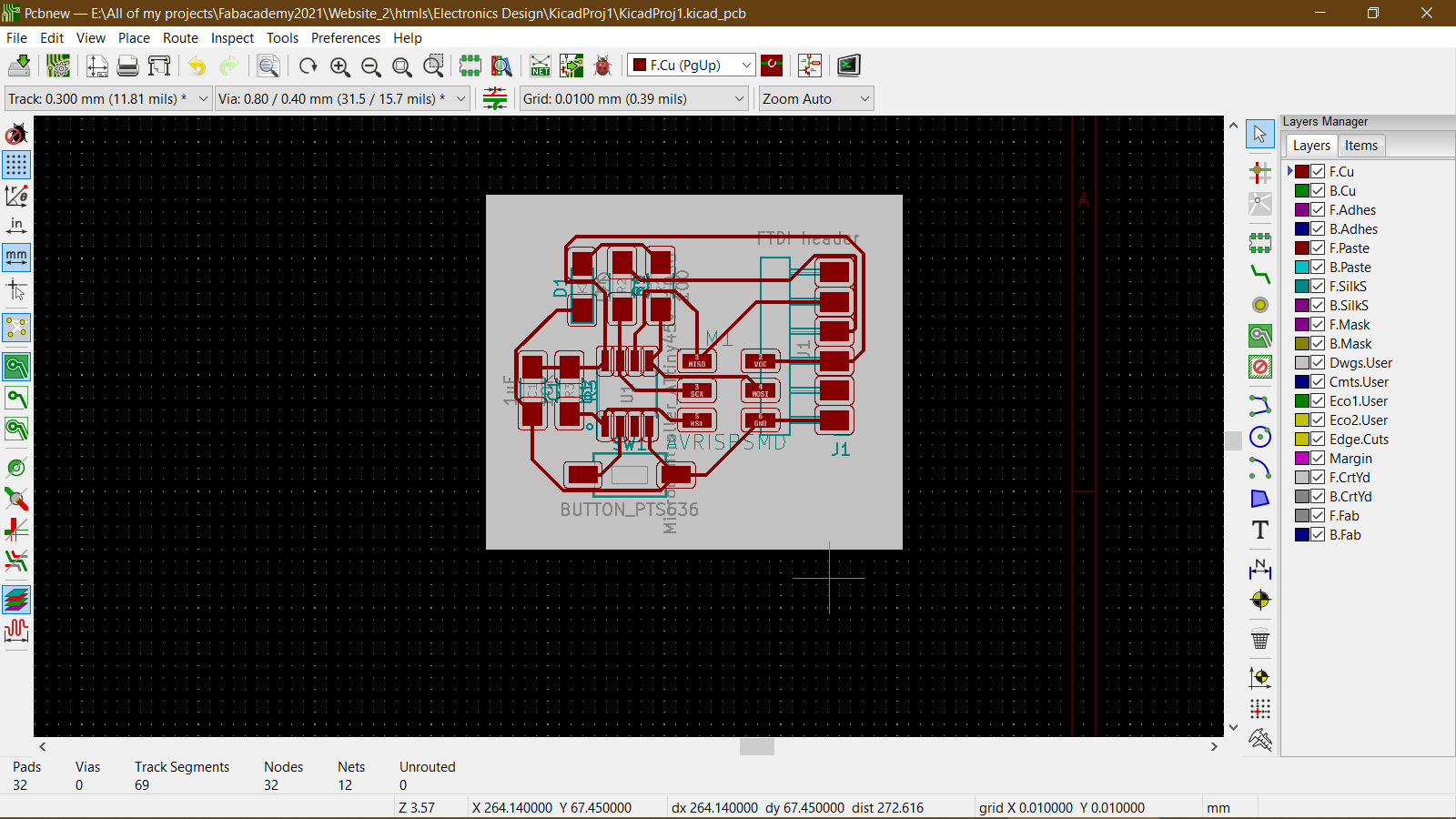

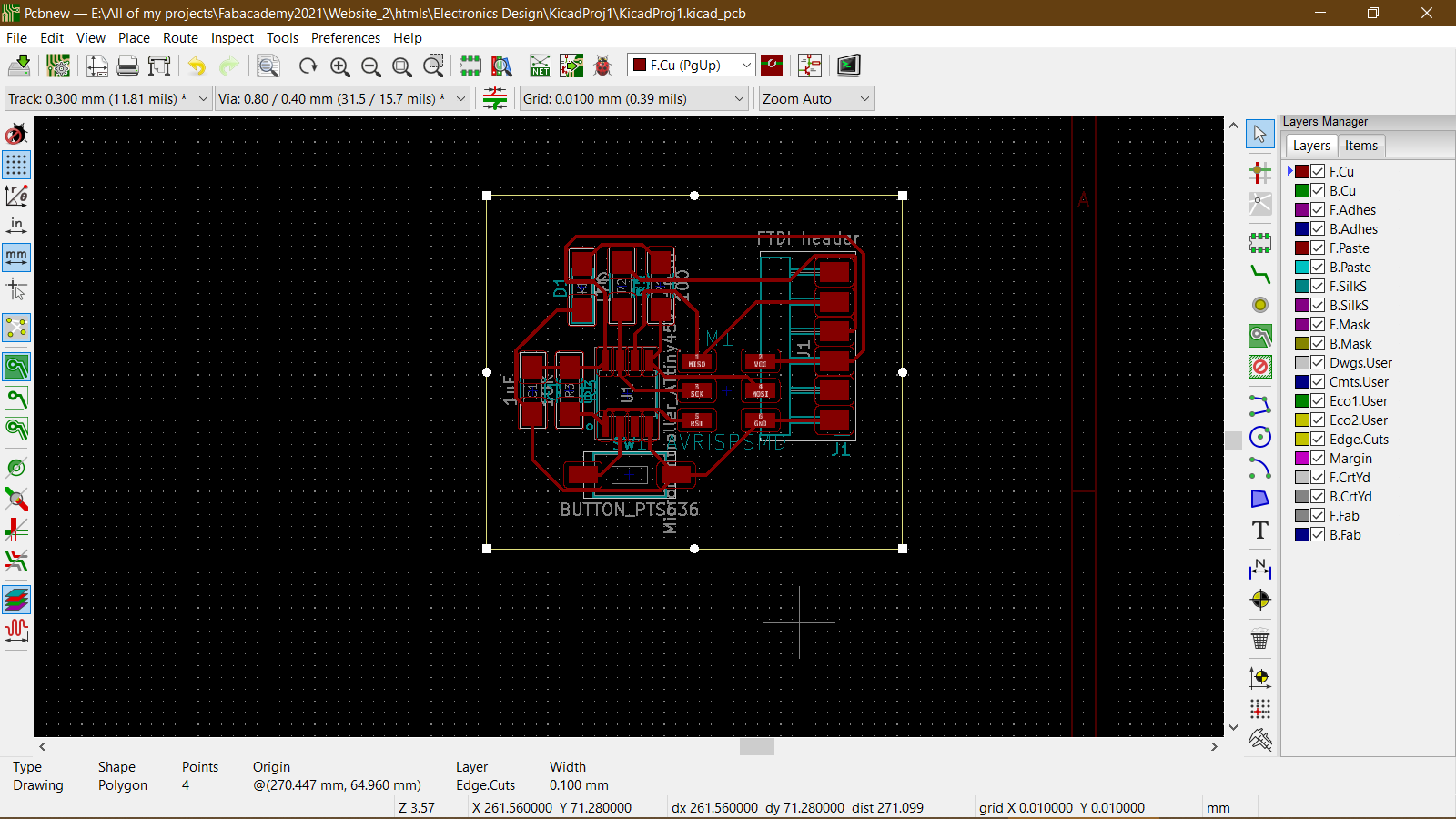

This was the final PCB design.

Kicad Project files

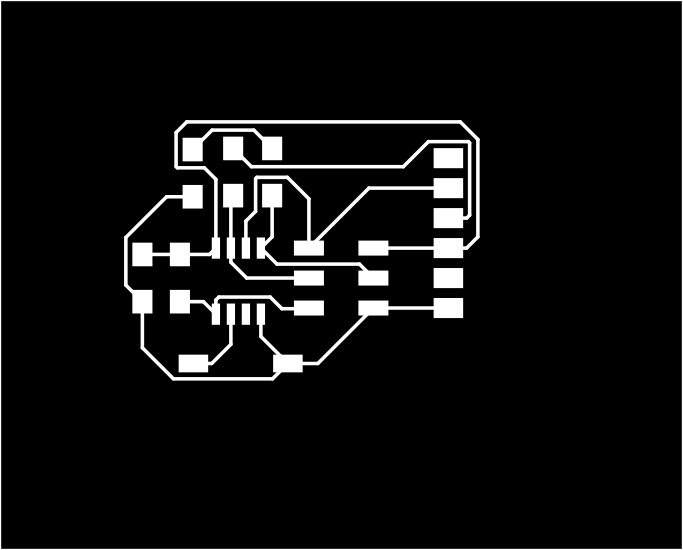

SVG Traces File for the PCB

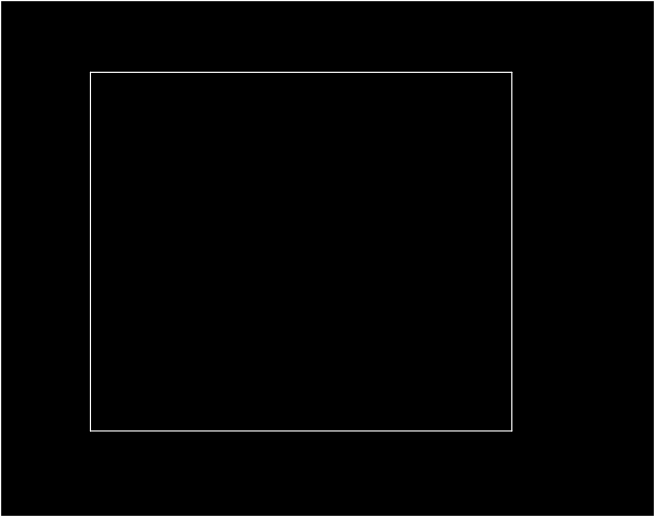

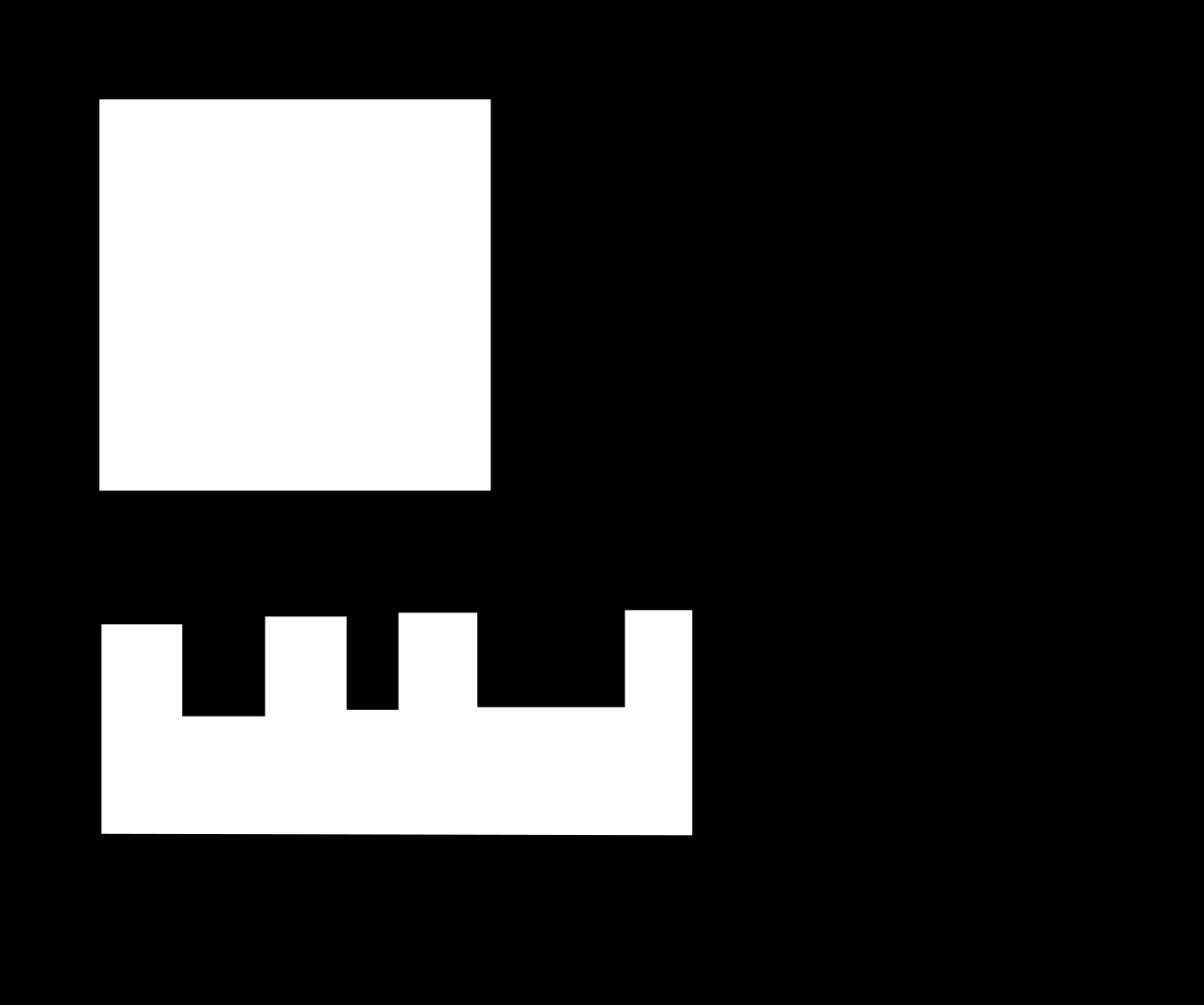

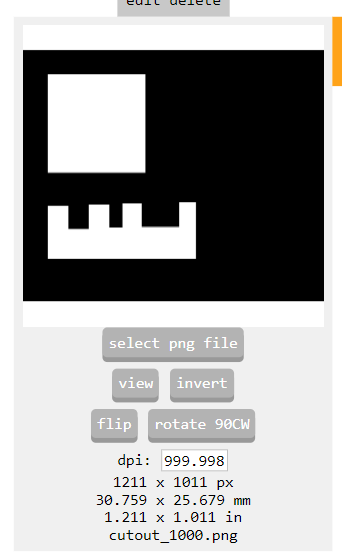

SVG Cutout File for the PCB

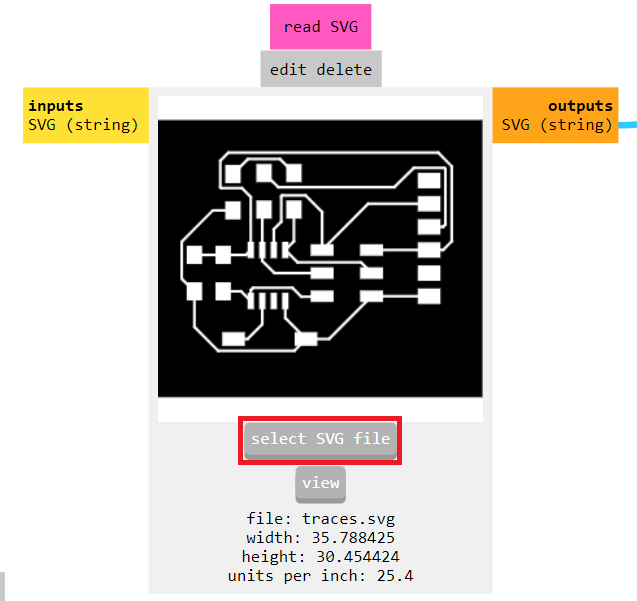

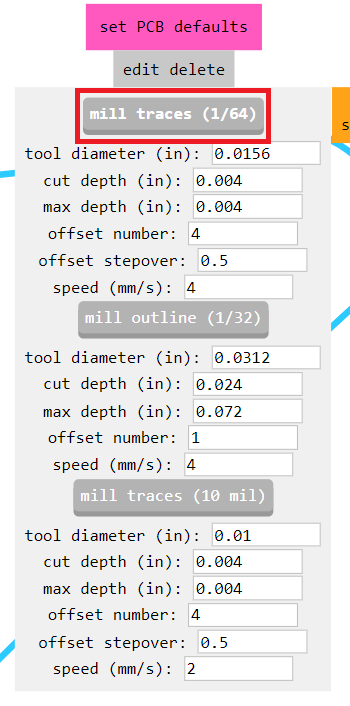

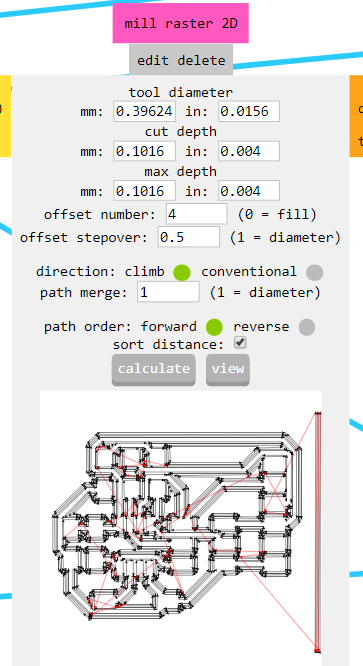

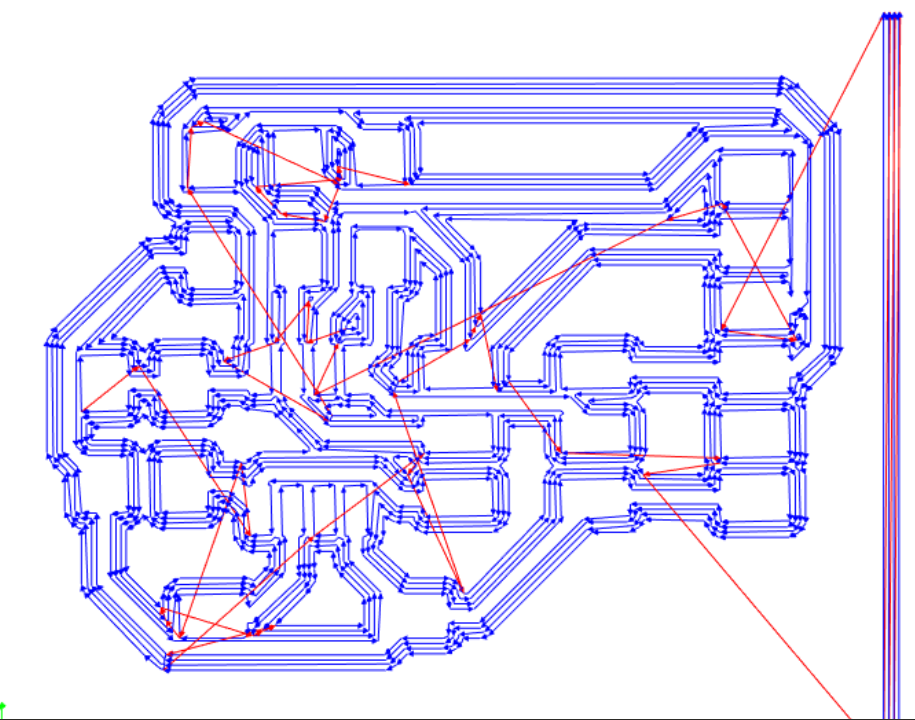

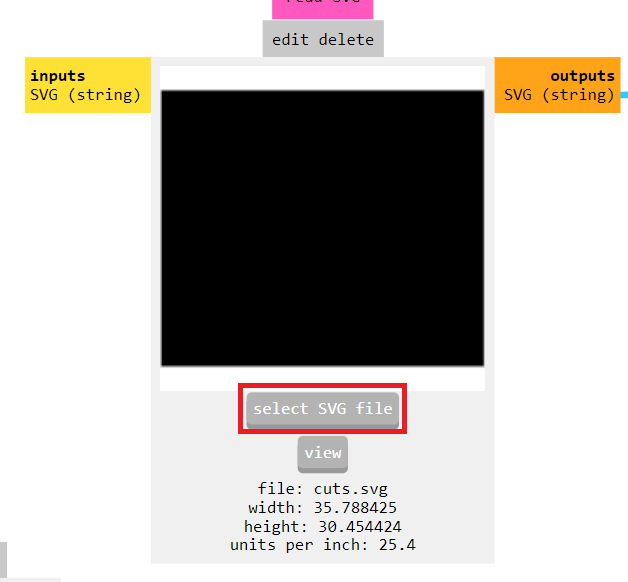

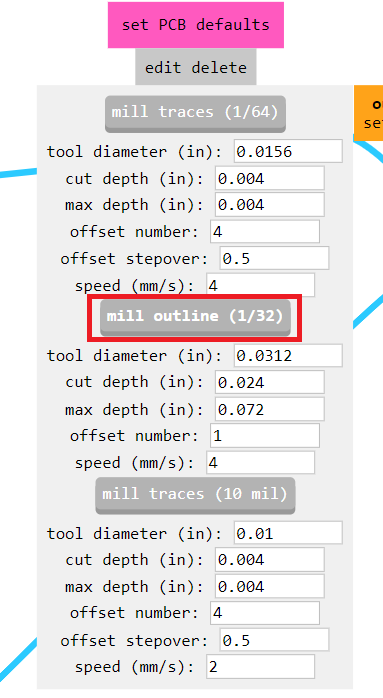

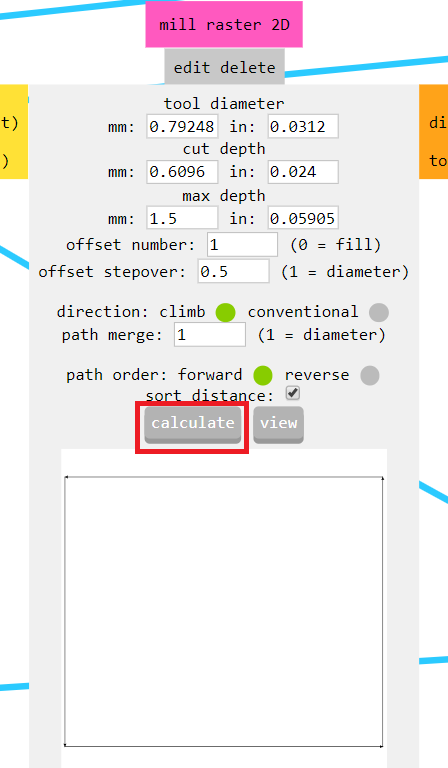

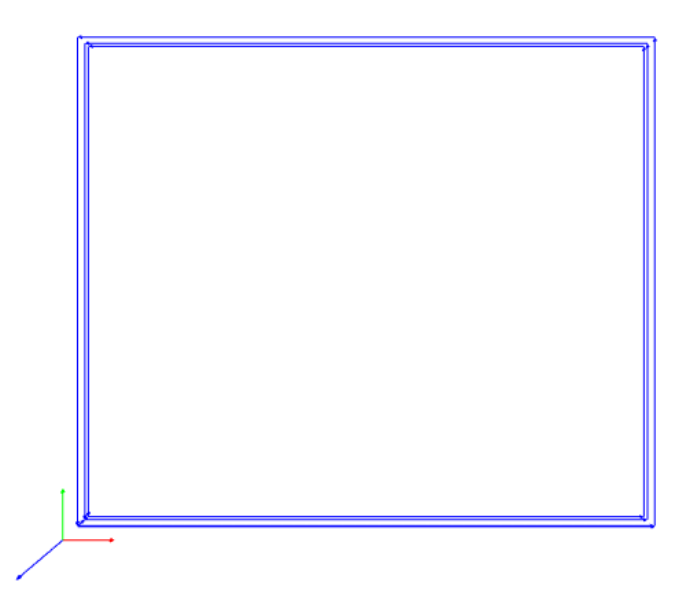

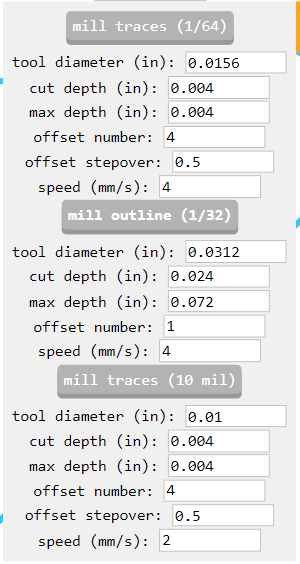

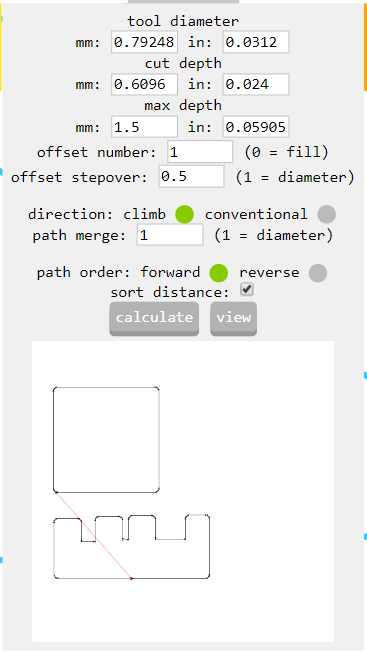

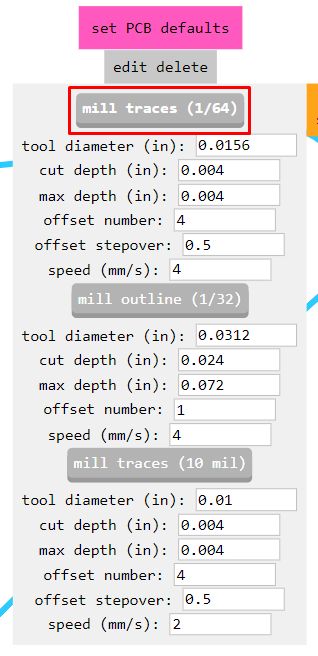

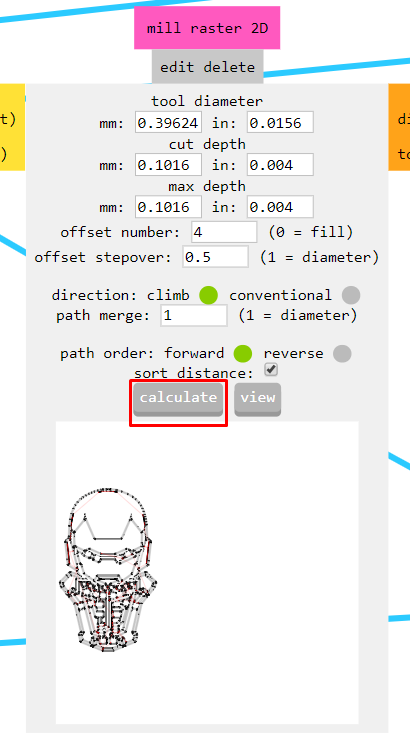

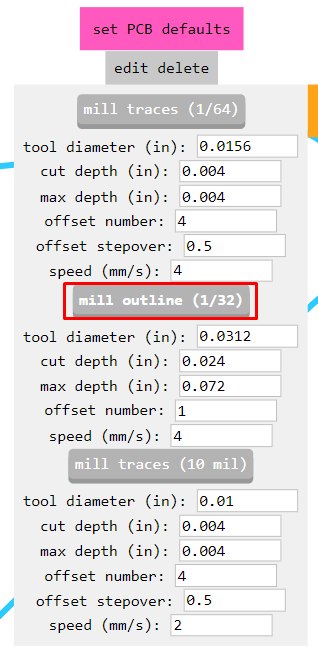

Milling the circuit using mods

Traces

Cutout

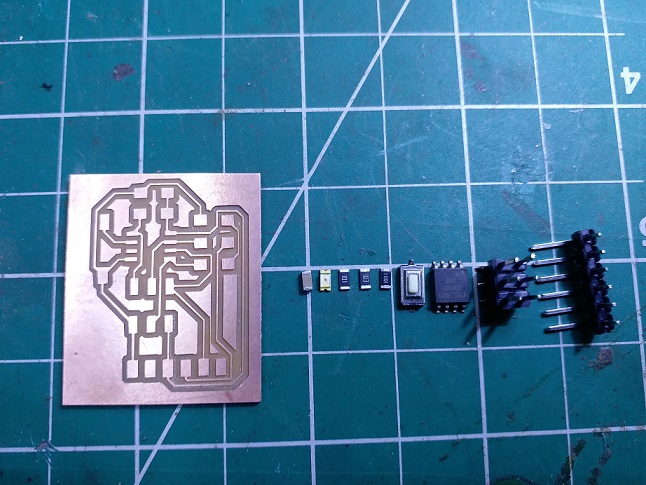

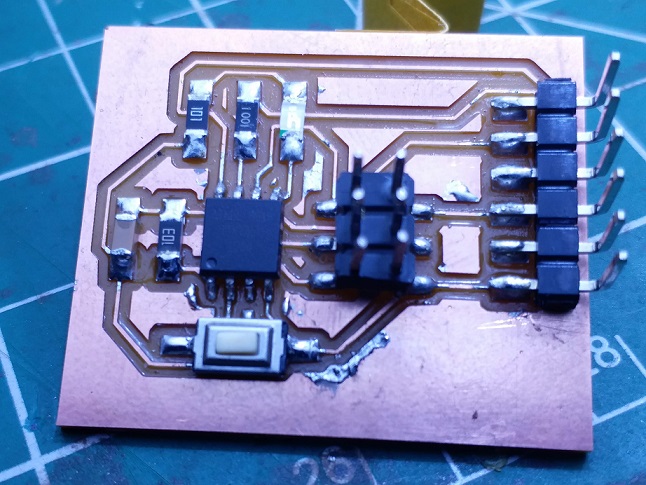

Soldering

Programming:

Blink Sketch

/*

Blink

Turns an LED on for one second, then off for one second, repeatedly.

Most Arduinos have an on-board LED you can control. On the UNO, MEGA and ZERO

it is attached to digital pin 13, on MKR1000 on pin 6. LED_BUILTIN is set to

the correct LED pin independent of which board is used.

If you want to know what pin the on-board LED is connected to on your Arduino

model, check the Technical Specs of your board at:

https://www.arduino.cc/en/Main/Products

modified 8 May 2014

by Scott Fitzgerald

modified 2 Sep 2016

by Arturo Guadalupi

modified 8 Sep 2016

by Colby Newman

This example code is in the public domain.

http://www.arduino.cc/en/Tutorial/Blink

*/

int LED = 0;

int del = 1000;

// the setup function runs once when you press reset or power the board

void setup() {

// initialize digital pin LED_BUILTIN as an output.

pinMode(LED, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(LED, HIGH); // turn the LED on (HIGH is the voltage level)

delay(del); // wait for a second

digitalWrite(LED, LOW); // turn the LED off by making the voltage LOW

delay(del); // wait for a second

}

Blink sketch file

Output:

Serial Communication using SoftwareSerial

/*

Software serial multple serial test

Receives from the hardware serial, sends to software serial.

Receives from software serial, sends to hardware serial.

The circuit:

RX is digital pin 2 (connect to TX of other device)

TX is digital pin 1 (connect to RX of other device)

Note:

Not all pins on the Mega and Mega 2560 support change interrupts,

so only the following can be used for RX:

10, 11, 12, 13, 50, 51, 52, 53, 62, 63, 64, 65, 66, 67, 68, 69

Not all pins on the Leonardo and Micro support change interrupts,

so only the following can be used for RX:

8, 9, 10, 11, 14 (MISO), 15 (SCK), 16 (MOSI).

created back in the mists of time

modified 25 May 2012

by Tom Igoe

based on Mikal Hart's example

This example code is in the public domain.

*/

#include <SoftwareSerial.h>

SoftwareSerial mySerial(2, 1); // RX, TX

void setup() {

mySerial.begin(4800);

}

void loop() { // run over and over

mySerial.println("Hello, world?");

} Software Serial sketch file

Output

Making the Iron Man board.

References:

Ironman:https://twitter.com/adrianpontohart/status/786543326451294209/photo/1

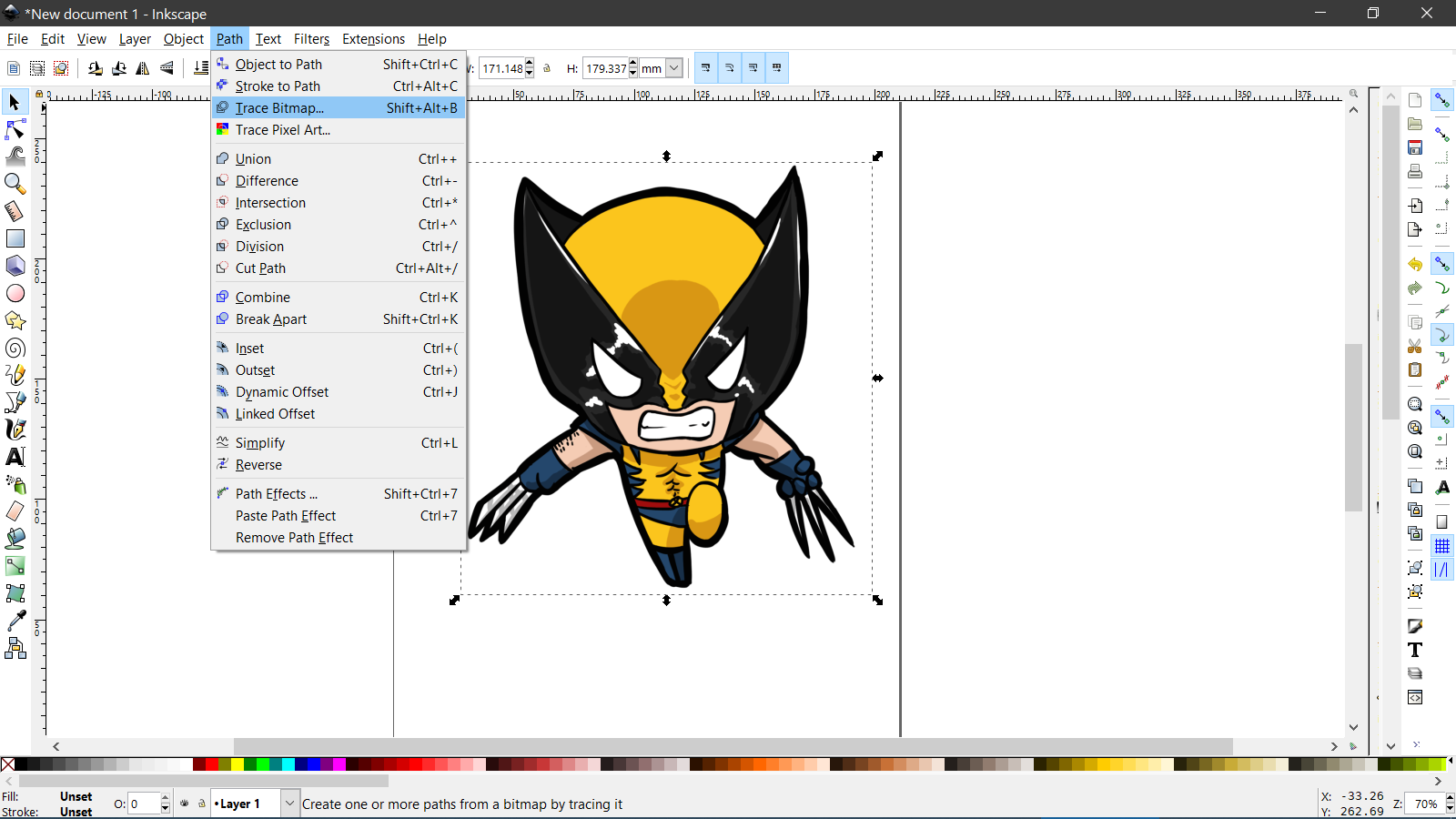

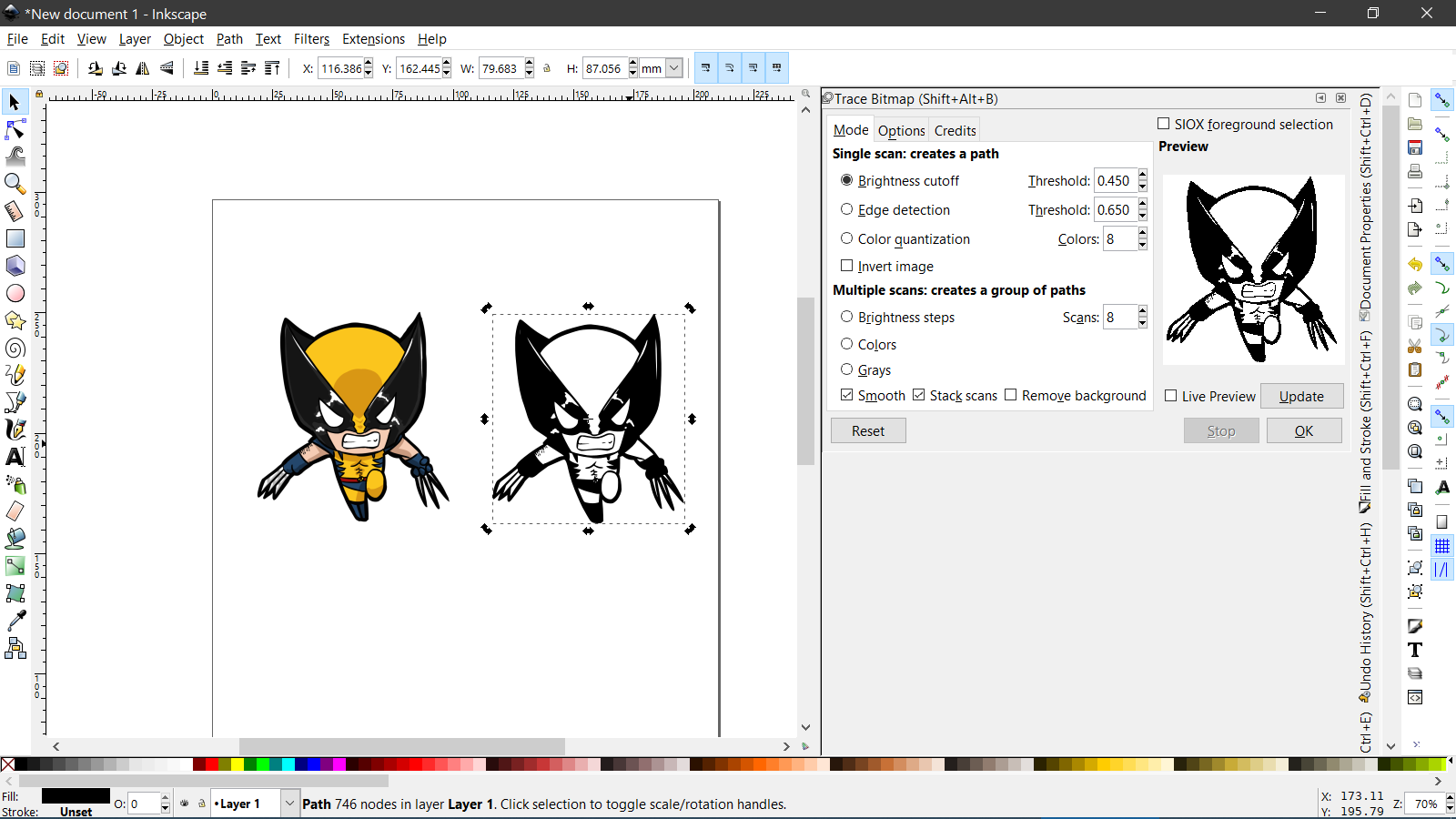

Using Inkscape

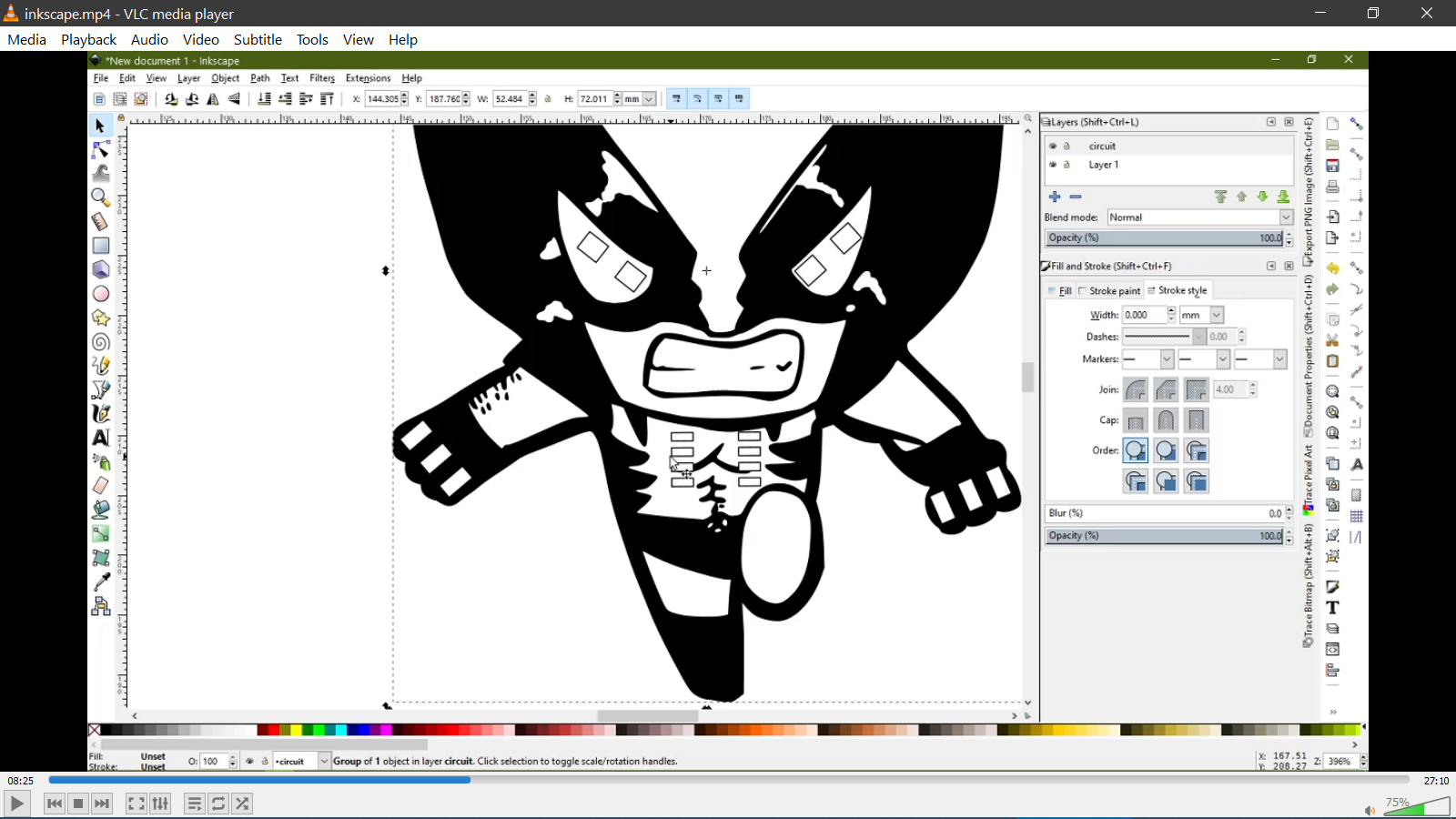

Tracing Bitmap

Initial Idea

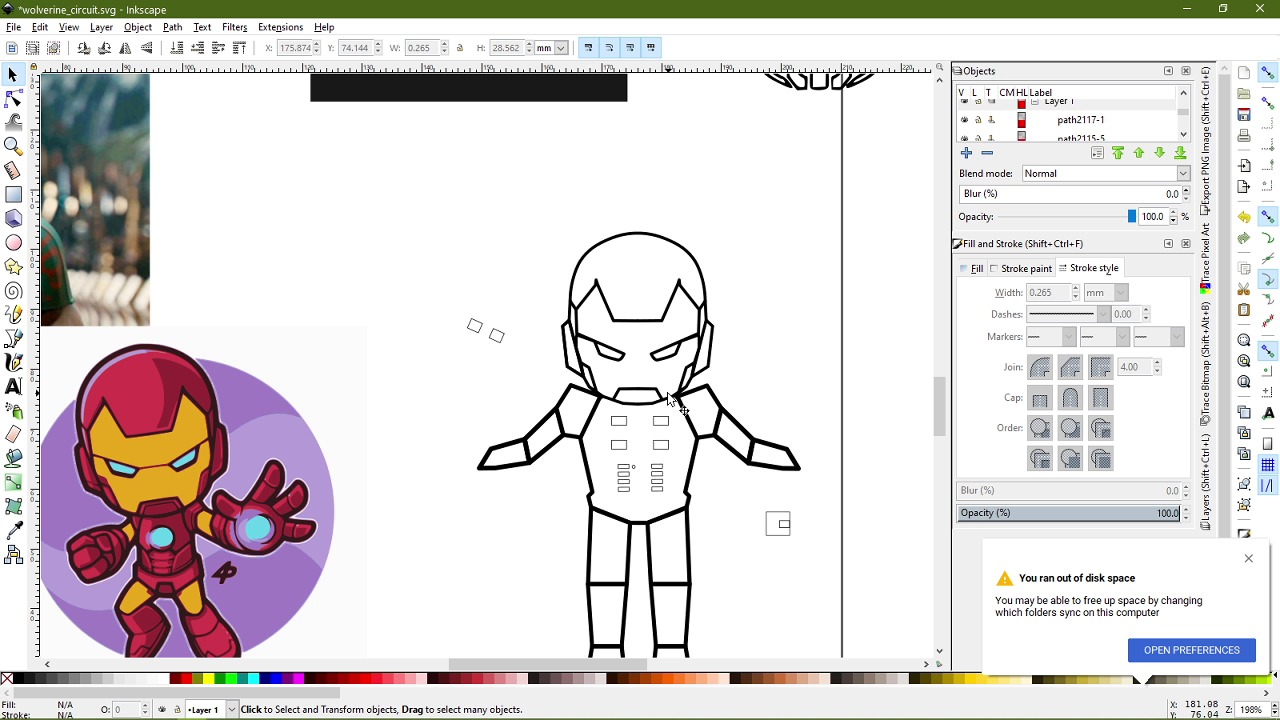

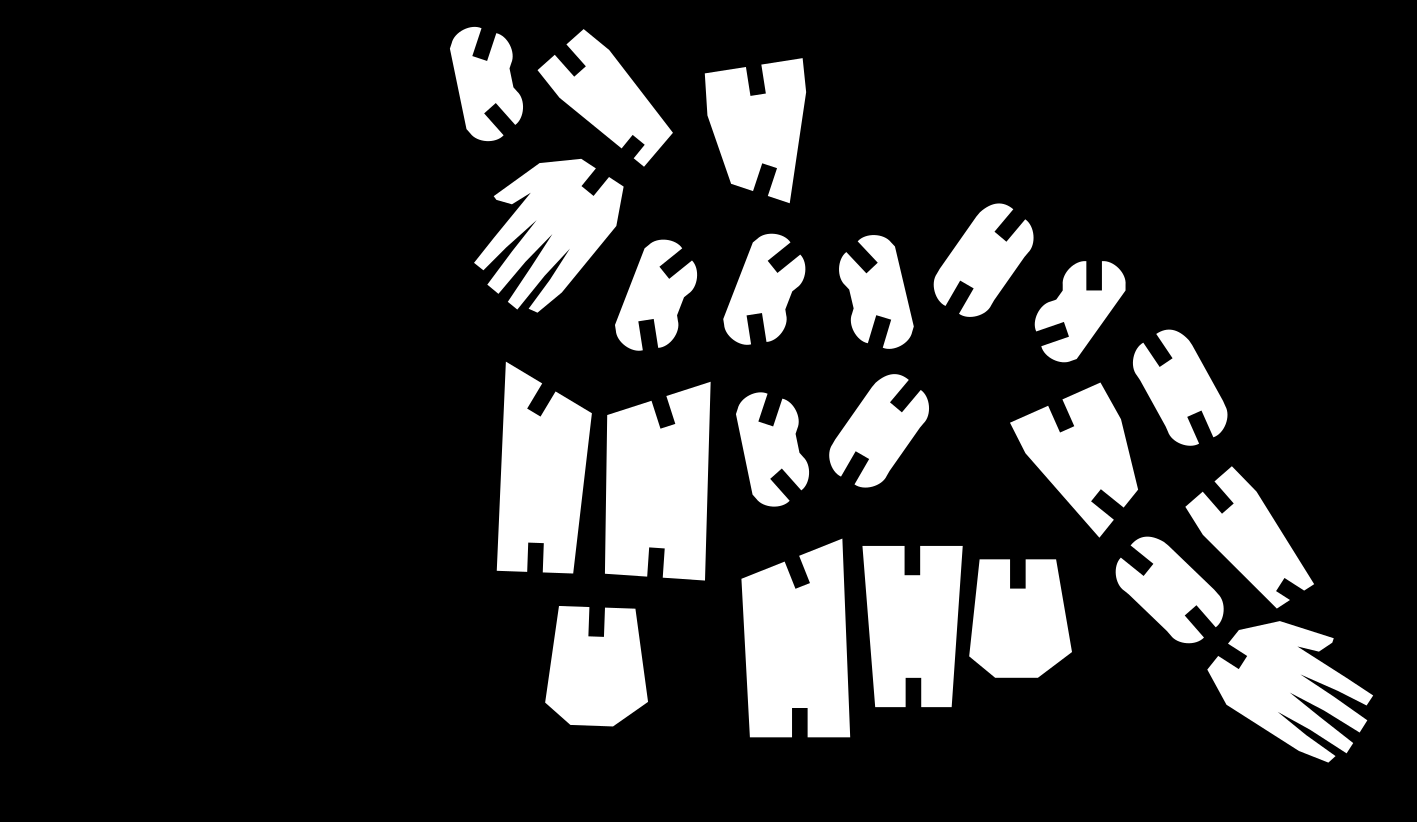

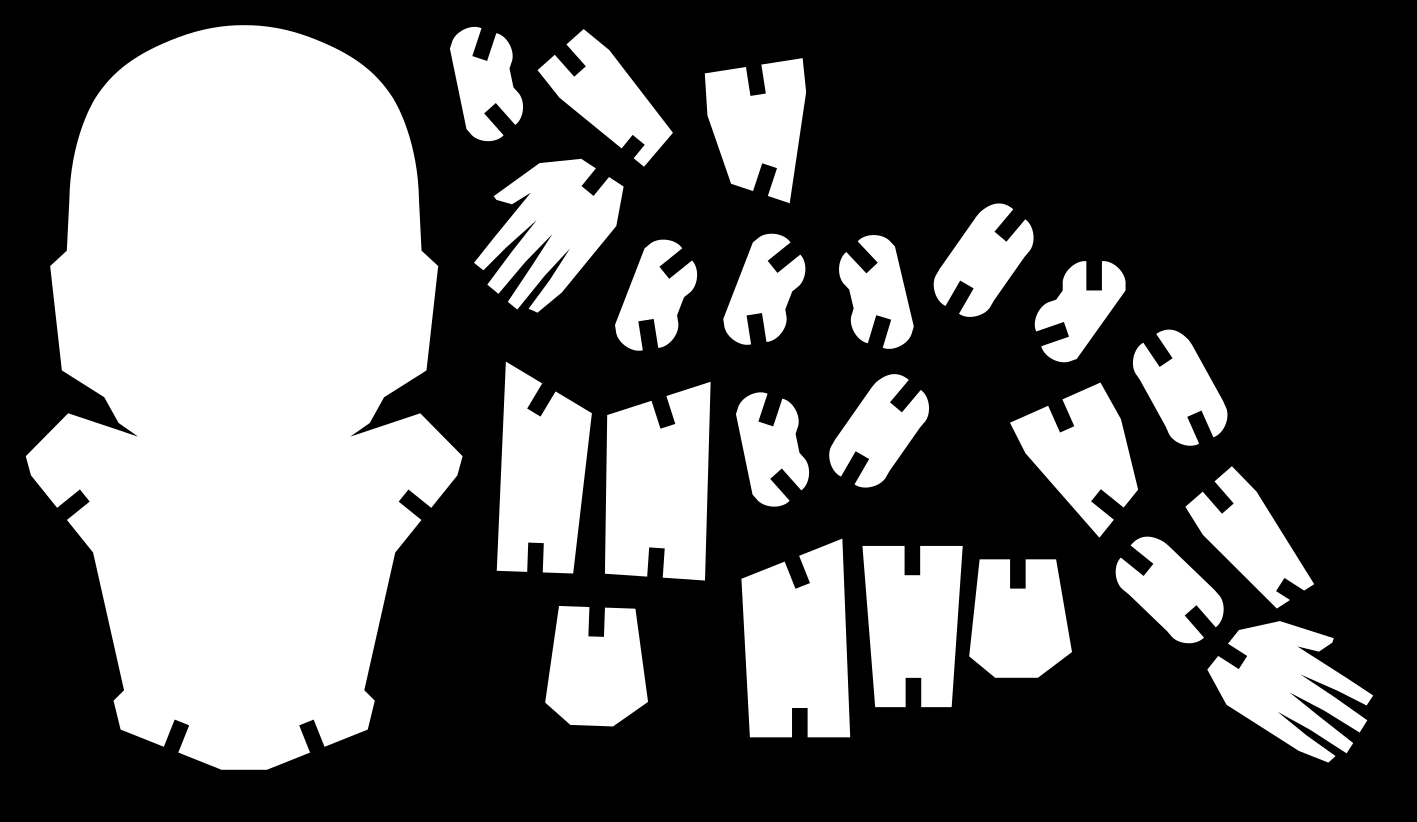

Changing the idea to iron man with slotted parts due to inspiration from childhood toys found within cheetos packets:

Making Iron Man using the reference image linked previously:

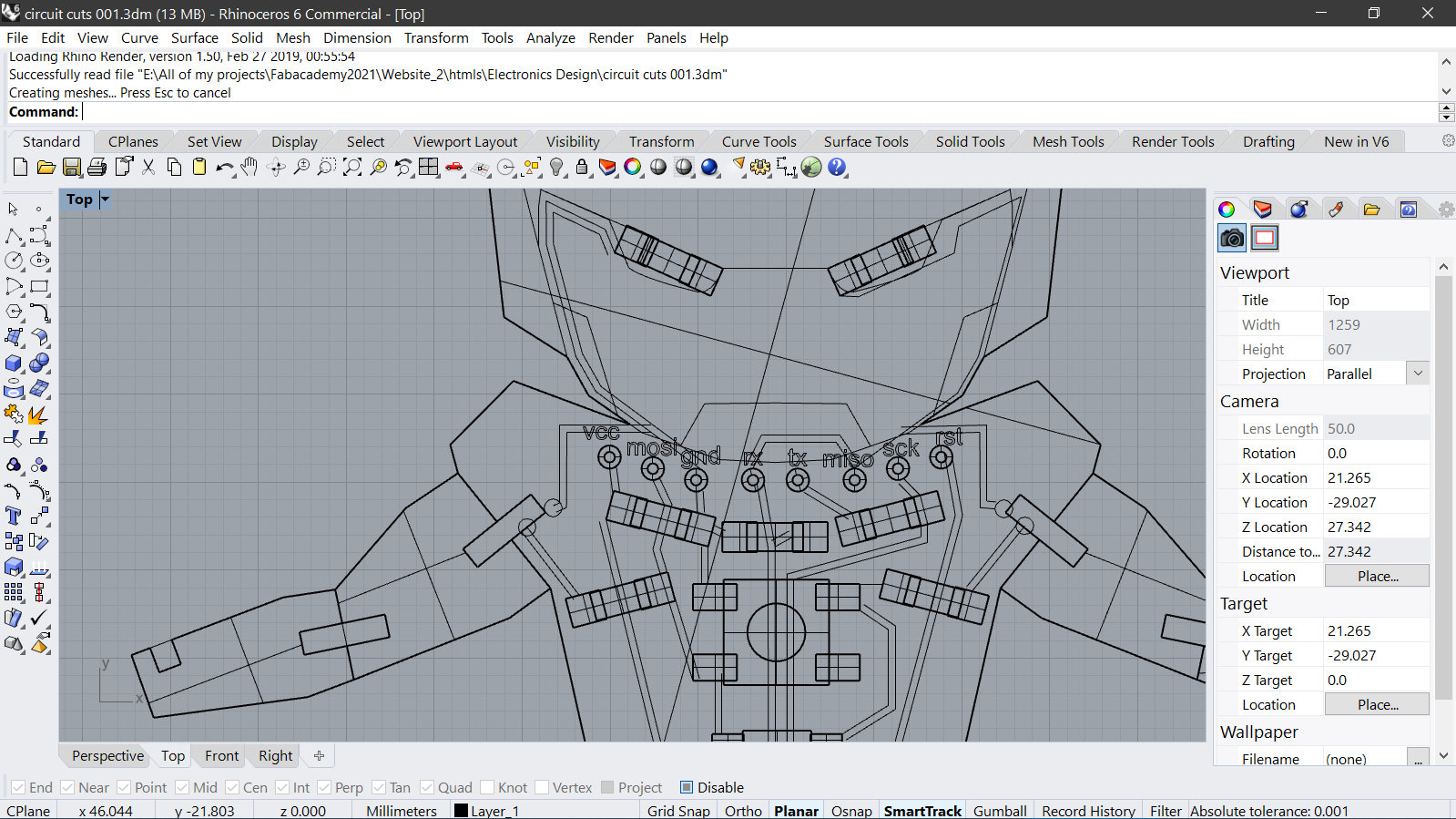

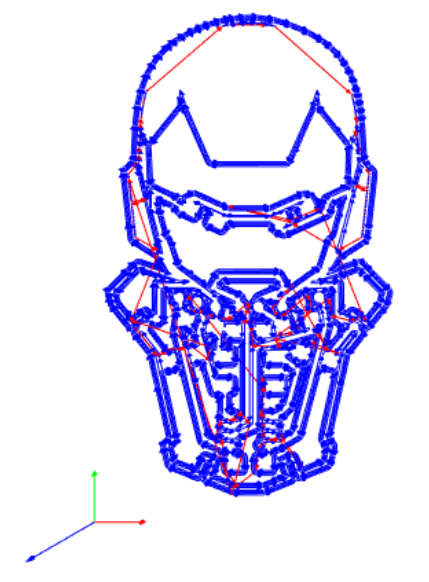

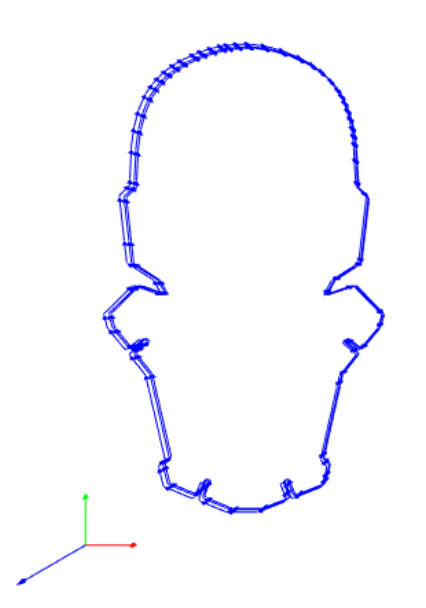

Using Rhino to create a vector file.

Pinout of the board:

Original Rhino file of the Circuit

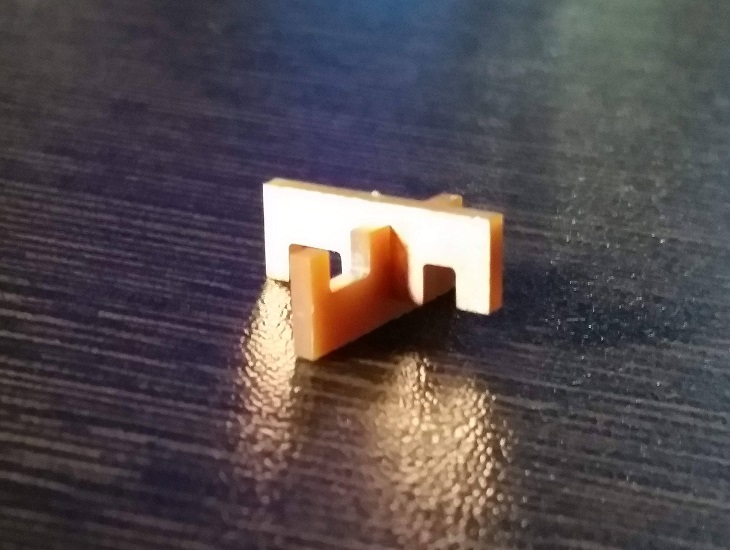

Designing parts to check the properties of the interlocking slots design.

Download the slot test file.

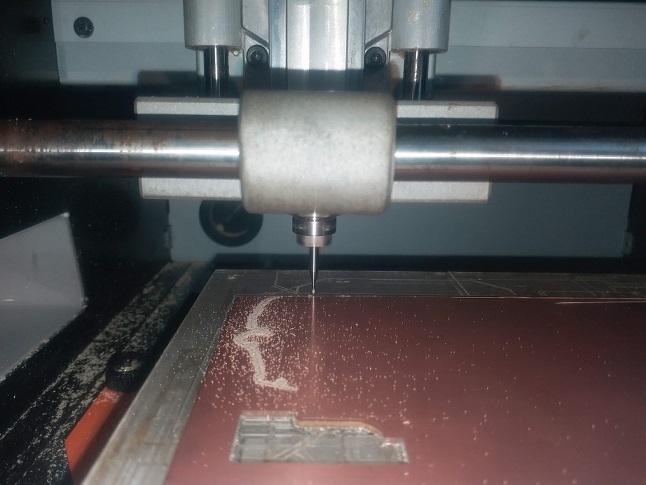

Milling:

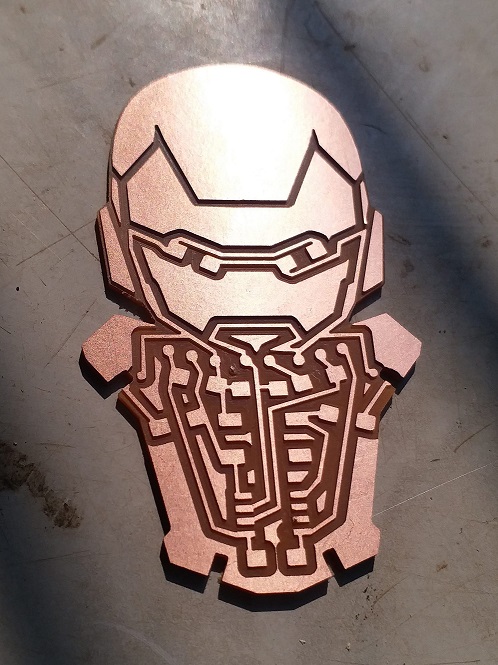

Result:

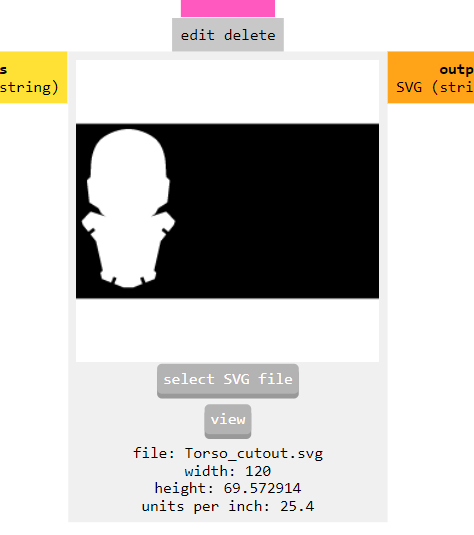

After I verified the width of slots needed to make the interlocking parts, I exported the outlines of the circuit from Rhino into PDF files and imported them into Inkscape:

PDF file of the torso

PDF file of the rest of the parts

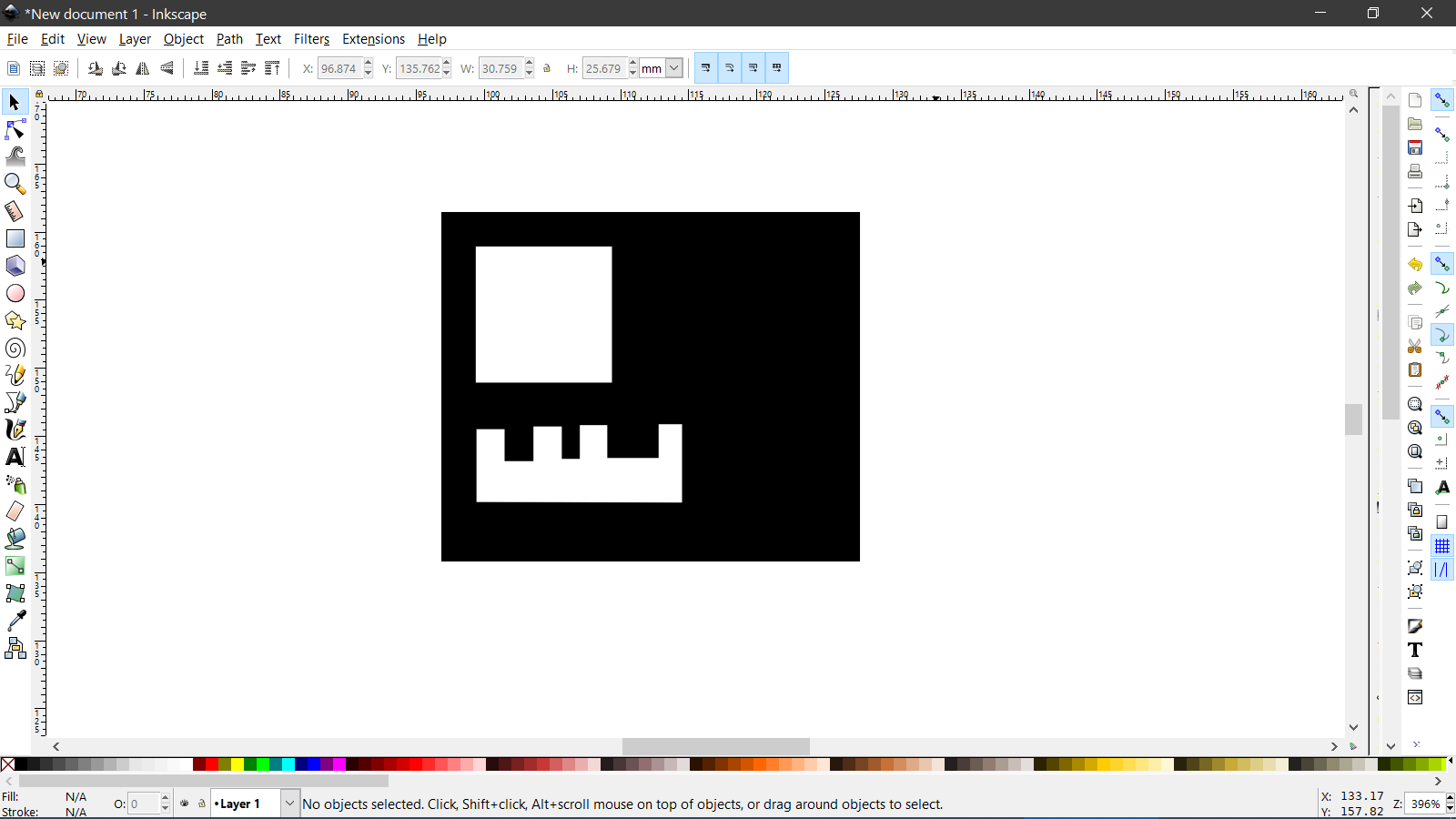

After importing the PDF file, I created the files for the milling:

Torso files:

SVG file for Torso Traces

SVG file for Torso Cutout

SVG file of the traces for the rest of the parts

SVG file of the cutouts of the rest of the parts

I am also including the combined version of the torso and the rest of the parts:

SVG files of the cutouts of all the parts

SVG file of the traces of all the parts

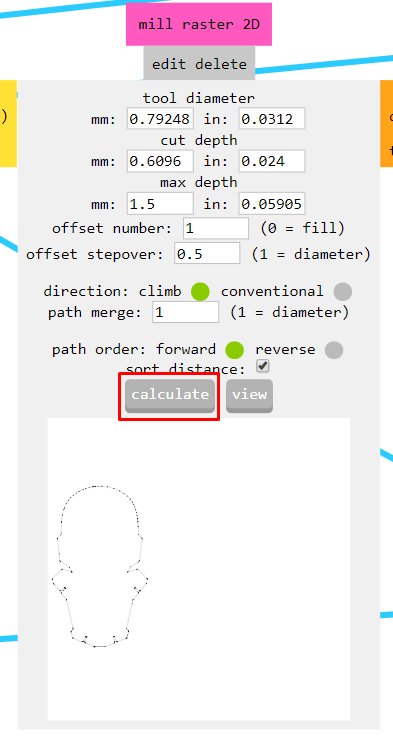

Milling the parts for the Ironman board:

Traces

Cutout

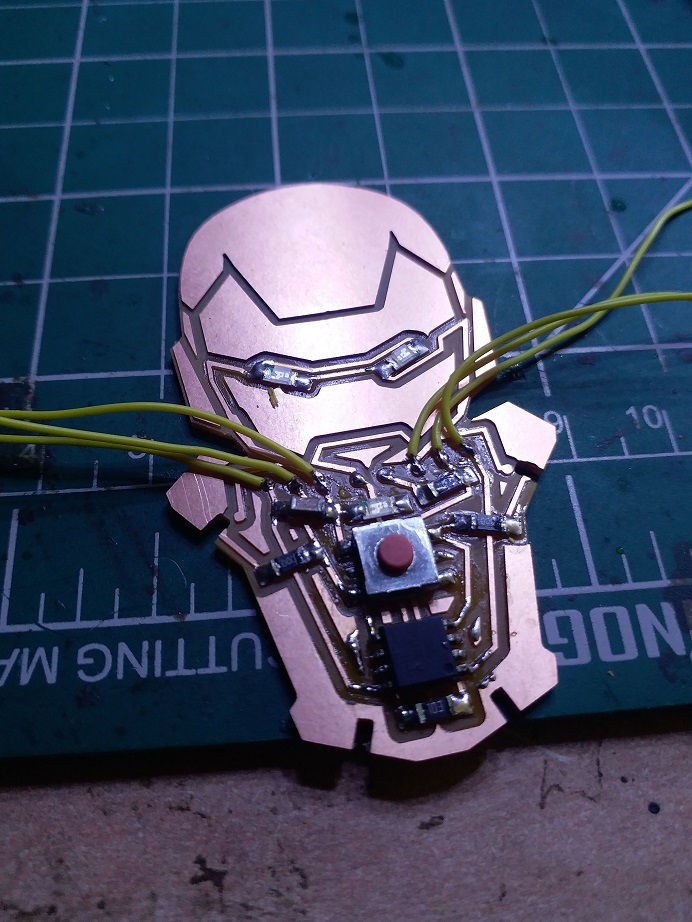

Soldering:

Programming:

I modified the code in the Arduino IDE File>Examples>Basics>Fade

/*

Fade

This example shows how to fade an LED on pin 9 using the analogWrite()

function.

The analogWrite() function uses PWM, so if you want to change the pin you're

using, be sure to use another PWM capable pin. On most Arduino, the PWM pins

are identified with a "~" sign, like ~3, ~5, ~6, ~9, ~10 and ~11.

This example code is in the public domain.

https://www.arduino.cc/en/Tutorial/BuiltInExamples/Fade

*/

int led = 1; // the PWM pin the LED is attached to

int brightness = 0; // how bright the LED is

int fadeAmount = 1; // how many points to fade the LED by

// the setup routine runs once when you press reset:

void setup() {

// declare pin 9 to be an output:

pinMode(led, OUTPUT);

}

// the loop routine runs over and over again forever:

void loop() {

// set the brightness of pin 9:

analogWrite(led, brightness);

// change the brightness for next time through the loop:

brightness = brightness + fadeAmount;

// reverse the direction of the fading at the ends of the fade:

if (brightness <= 0 || brightness >= 150) {

fadeAmount = -fadeAmount;

}

// wait for 30 milliseconds to see the dimming effect

delay(30);

}

Fading LEDs sketch

Output: