The objective for this week was to propose a final project masterpiece that integrates the range of units covered. The project should incorporate:

- 2D and 3D design

- additive and subtractive fabrication processes

- electronics design and production

- microcontroller interfacing and programming

- system integration and packaging

- Where possible, you should make rather than buy the parts of your project. Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable.

The answers to the questions below will allow you to create your BOM (Bill Of Materials).

Learning outcomes

- Define the scope of a project

- Develop a project plan

- Describe what will it do?

- Describe who has done what beforehand?

- Describe What will you design?

- Describe what materials and components will be used?

- Describe where will they come from?

- Describe how much will they cost?

- Describe what parts and systems will be made?

- Describe what processes will be used?

- Describe what questions need to be answered?

- Describe how will it be evaluated?

Pelletier Electric Stove

The idea for the final project that I would like to construct throughout the FabAcademy is a powered stove similar to the PowerStove or the BioLite.

PowerStove

BioLite

55% of rural Africans across the continent have little to no access to electricity as they try to cook in the nighttime . The PowerStove will immediately provide electricity for these families with a short payback period compared to buying a conventional stove and small solar panel. PowerStove provides a solution much more elegant than cooking without the benefit of creating electricity and/or the complexity of having to buy additional equipment

The PowerStove is designed for user’s with no training required. Simply fill the stove with biopellets, ignite them and you’re ready to cook while powering your electronic device through the USB port.

This two in one solution replaces your conventional charcoal stove and comes with the added bonus of electric power. No need to buy a solar panel, this stove powers while you cook. A similar stove has proven successful in Nigeria with little to know user training necessary.

Define the scope of a project

Develop a project plan

What it will do

The Powered Stove converts heat from cooking into Direct Current Electricity using Thermoelectric Generators (TEGs). TEGs are thermo-electric component that take advante of the (Seebeck Effect)

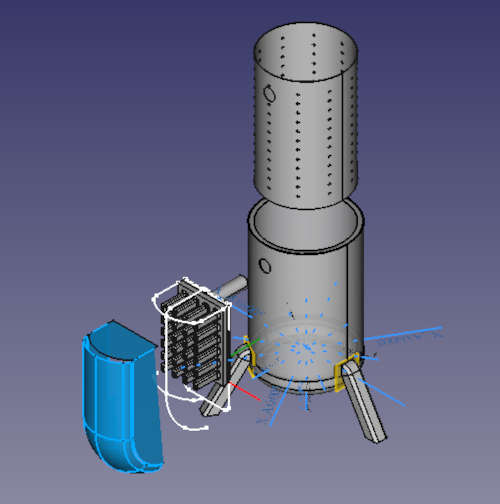

The electricity is used to power a USB terminal suitable to charge a phone. Critical to the Seebeck effect is the requirement of a thermal differential. As such, a heat sink and fan are required on one side of the TEG to appropriately cool the TEG. The photo below provides a general overview of what it does.

IoT Component

Furthermore, the concept for this stove will have an IoT component that will measure and display the power it is producing and how warm the plate is and will relay this information via a ESP-32 module to a telephone app.

Who has done what beforehand

To date a commercial product called the BioLite exists. Much of my design is based on that. Details can be found here at this Biolite Link

There is also very good description of their invention in the Biolite patent application and shown in the photo below.

There have also been pelletier module stoves that have been developed and are sold on Alibaba as per the following link and the photo below.

Lastly, a Fab Academy student Ferdinand Meier who made a trigeneration stove that could generate heat, cold and electricity from a woodfire. His project can be found at the following link. Below is a photo of his concept:

These resources will all be very great sources of imformation for future projects.

What I will design

For this project there are four main elements to be designed they are:

- The combustion chamber

- The power unit and electronics

- The cover

- The IoT user interface

My intention is to design all four of these elements.

Bill of Materials

In this section I will present the bill of materials for each of the four main elements. It has been asked that we answer the following questions:

- Describe where will they come from?

- Describe how much will they cost?

Below the bill of materials for each system is presented.

1. Combustion Chamber

| Part | Quantity | Source | Cost | Link |

|---|---|---|---|---|

| a | b | c | d | e |

| a | b | c | d | e |

2. Power Unit and Electronics

The electronics is made of two systems, a) the power systems which includes the pelletier modules, heat sink, fan, baterries, and charge controllers and b) the electronics which inclues the microcontroller system and design based on the Satscha kit, the input and output devices, the ESP 32 unit, and other electronic components.

a) Power Unit

| Description | Part | Quantity | Source | Cost | Link |

|---|---|---|---|---|---|

| 5V Fan | b | c | d | e | |

| TEGs | b | c | d | e | |

| Batteries | b | c | d | e |

b) Electronics

| Description | Part | Package | Quantity | Source | Cost | Link |

|---|---|---|---|---|---|---|

| Microcontroller | ATMEGA328P-AU | TOFP-32 | 1 | Digikey | ??? | ??? |

| 16 MHz crystal | MCRSD16000F183000RR | SMD 11.4 x 4.77 | 1 | Digikey | ??? | ??? |

| Green LED | MCL-S250GC | 1206 | 1 | Digikey | ??? | ??? |

| Blue LED | MCL-S250BL | 1206 | 1 | Digikey | ??? | ??? |

| Switch | B3SN-3112P | 6 x 6 x3.1 mm | 1 | Digikey | ??? | ??? |

| 10K Resistor | ERJ8GEYJ103V | 1206 | 4 | Digikey | ??? | ??? |

| 4.99 K Resistor | 311-4.99KFRCT | 1206 | 3 | Digikey | ??? | ??? |

| 499 Resistor | 311-499FRCT-ND | 1206 | 2 | Digikey | ??? | ??? |

| 0 Ohm Resistor | 311-0.0ERCT-ND | 1206 | 6 | Digikey | ??? | ??? |

| 22 pF capacitor | MC1206N220J500CT | 1206 | 2 | Digikey | ??? | ??? |

| 10 uF capacitor | MC1206X106K250CT | 1206 | 1 | Digikey | ??? | ??? |

| 1 uF capacitor | MC1206F105Z500CT | 1206 | 1 | Digikey | ??? | ??? |

| 100 nF capacitor | MC1206B104K500CT | 1206 | 2 | Digikey | ??? | ??? |

| 40 V 2A Schottky diode | 478-SD1206T040S2R0CT | 1206 | 4 | Digikey | ??? | ??? |

| 20V 4.7A P-channel MOSFET | TSM500P02CXRFGCT-N2 | SOT23 | 3 | Digikey | ??? | ??? |

| N.O. Temperature Switch | ??? | ??? | 1 | Amazon | ??? | ??? |

| Toggle Switch | ??? | ??? | 1 | Amazon | ??? | ??? |

| ESP-32 module | ??? | ??? | 1 | Amazon | ??? | ??? |

| 25 V Volt Sensor | ??? | ??? | 1 | Amazon | ??? | ??? |

| +/- 5A Current Sensor | ??? | ??? | 1 | Amazon | ??? | ??? |

| Temperature Sensor | ??? | ??? | 1 | Amazon | ??? | ??? |

| 5V USB Outlet | ??? | ??? | 2 | Amazon | ??? | ??? |

| 5V 1A LiON Charge Controller | ??? | ??? | 3 | Amazon | ??? | ??? |

| LED Digital Display | ??? | ??? | 2 | Amazon | ??? | ??? |

| LED light bar | ??? | ??? | 1 | Amazon | ??? | ??? |

| 4x1 Female through Pin | ??? | ??? | 4 | Amazon | ??? | ??? |

| 7x1 Female through pin | ??? | ??? | 1 | Amazon | ??? | ??? |

| 2x1 JCT through pin | ??? | ??? | 7 | Amazon | ??? | ??? |

| 3x1 JCT through pin | ??? | ??? | 1 | Amazon | ??? | ??? |

| Male through pin kit | ??? | ??? | 1 | Amazon | ??? | ??? |

3. The cover

The cover consists of the epoxy cover that was made using rotary casting methods described in the 12 - Moulding and Casting assignment. There is also an element that is 3D printed which contains the heatsink enclosure.

| Part | Amount | Source | Cost | Link |

|---|---|---|---|---|

| a | b | c | d | e |

| a | b | c | d | e |

Parts and systems

As mentioned the systems described are as follows:

- The combustion chamber

- The power unit and electronics

- The cover

- The IoT user interface

In the following subsections I will provide the details on the parts and how they will be made.

1. The combustion chamber

2. The power unit and electronics

3. The cover

4. The IoT user interface

Processes used

The processes to be used will be borken down by system as follows.

1. The combustion chamber

The combustion chamber is comprised of the inner chamber, outer chamber, bottom, legs, and mounting plates. The processes will be described as follows:

- Inner chamber: 2D design, sheet metal cutting with large format CNC, riveting

- Outer chamber: 2D design, sheet metal cutting with large format CNC, riveting

- Mounting plate: 2D design, sheet metal cutting with large format CNC, bending with the press

- Bottom: 3D design, sheetmetal cutting with large format CNC, forming/drawing

- Legs: TBD

2. The power unit and electronics

The powering unit and electronics comprises of the power system which includes the pelletier modules as well as the electronic system such as the circuit board. The processes used to produce and assemble each are discussed below:

- Pelletier modules and heat sinks: these were sourced and glued to the mounting plate using thermal paste and the connections were made using soldering techniques

- Circuit Board: PCB design, milling using a small CNC of a copper PCB board, soldering

- Battery holder: 3D design and additive manufacturing through 3D-printing

3. The cover

The cover consists of two elements, the cover, and the heatsink enclosure:

- The cover: designed using 3D modeling and made using rotary casting techniques covered in the Moulding and Casting Assignment

- Heat sink enclusore: designed using 3D modeling and manufcatured using additive manufacturing (3D printing)

4. The IoT user interface

The IoT interface was all done completely using programing on the Arduino IDE and Processing IDE

Questions that need answering

- Describe what questions need to be answered?

How it will be evaluated

- Describe how will it be evaluated?

The project will be considered a success if the Stove is able to produce electricity, charge the batteries, and output results to the app.