Be part of my FabAcademy journey!

My name is Alberto González Espinosa (yeah, that's where Agonzalespi comes from, how creative, right?), I was born in Madrid, Spain, and I've been working on FabLabs for a year and a half. Now it's my time to bite the bullet and join the FabAcademy family for real. Should I be scared? Well, I am (a bit).

I work as the FabLab coordinator in FabLabUE, but in this amazing journey I'll be on board with Michael, Mauro, Lorena and Sergio, as remote students of FabLab León with Nuria, Adrián and Pablo.

If you want to know more about me, you can click here, but probably you're more interested in my assignments or my final project

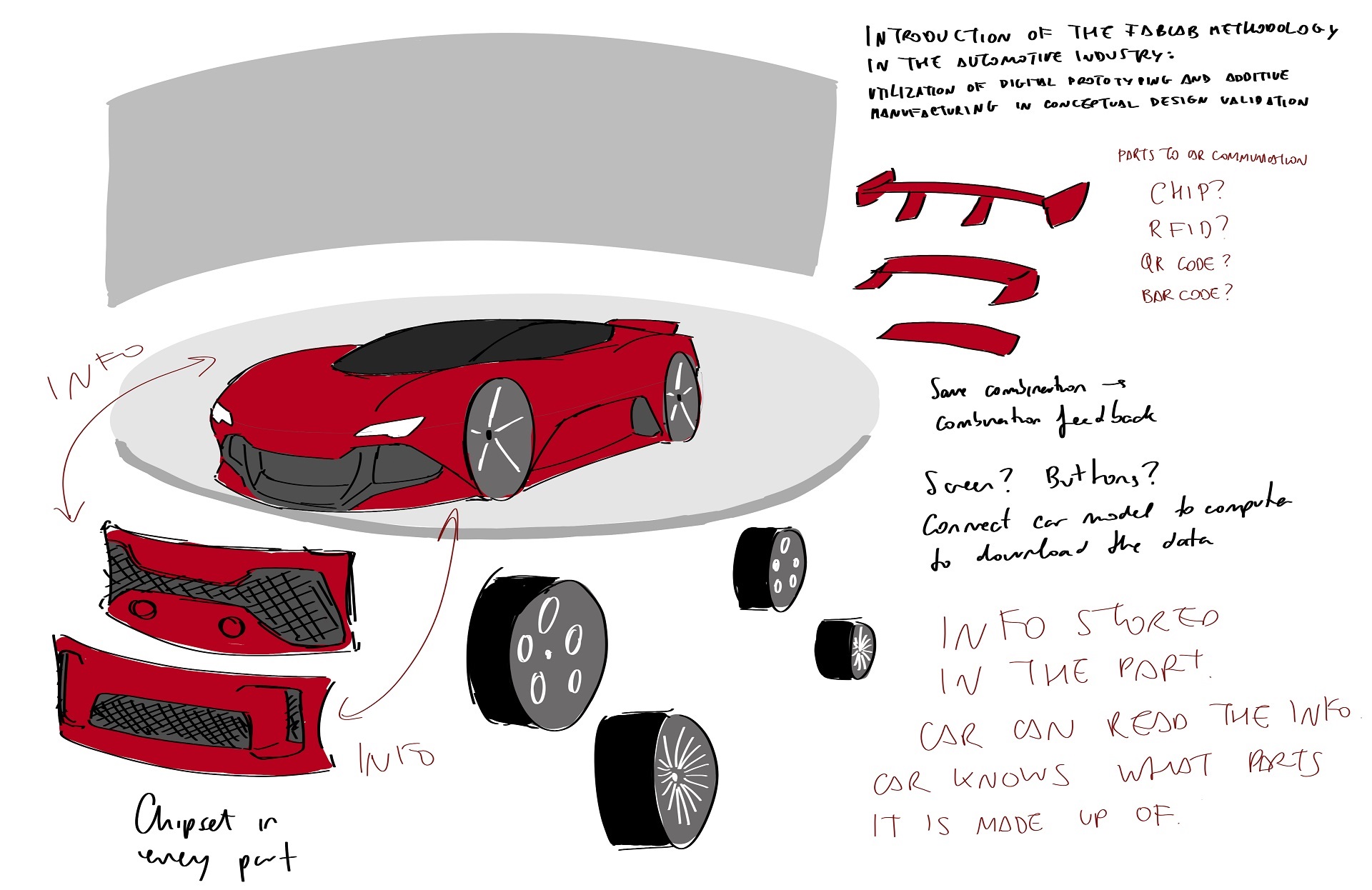

The original idea for my final project was to create a way to share information between interchangeable parts in an assembled model. It's like a lego, but the pieces can share information within each other and to the people around the assembled model. Let's see how far can we develop this idea.

On this page however, I want to give a little bit of background of what I want my final project to work for. I don't know where will I end, but here's the dream: This idea is aiming for modernising the early stages in Concept Car Prototyping.

First of all, we have to discuss what are we actually going to be working on. What is Concept Car Prototyping? And why reforming a process that has been unchanged for almost 80 years?

When we are talking about Concept Cars, we are talking about the first steps in the development of a new car model. Concept cars are a tool that designers use to show to the managers of a company, the automotive media and possibly a group of potential clients what the upcoming regular production cars are going to look like and what kind of design trends the Brand is going to follow. So what are the basic stages a new car project goes through, in order to evolve from an idea of the designer to a production model?

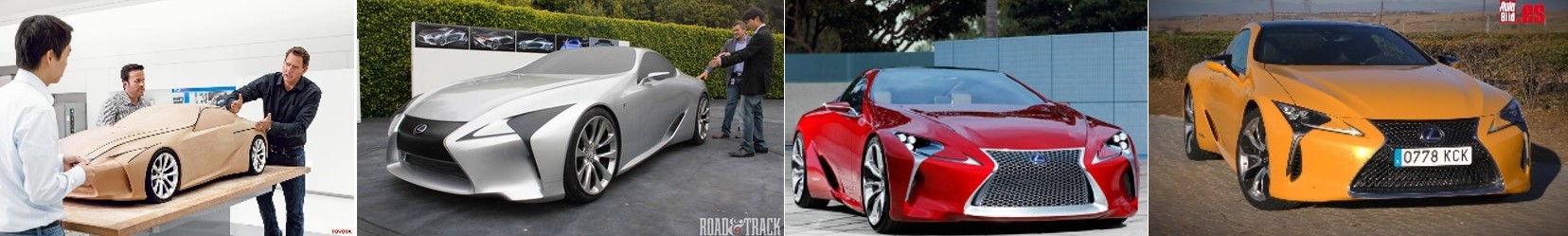

Lexus LC Design Process: 1:5 clay model (one of many), 1:1 clay model (one of two or three), Concept Car (unique), 2012, Production Car (regular production), 2016

Lexus LC Design Process: 1:5 clay model (one of many), 1:1 clay model (one of two or three), Concept Car (unique), 2012, Production Car (regular production), 2016

When a new car project is on the horizon, hidden away in the deepest and most secret rooms of the design centres, a meeting is held in which the designers and the top managers of the brand envision and discuss ideas for the new models. That meeting is called ‘the briefing’. In the early stages, the designers of the brand’s team are organized in small groups and each of them shows their vision of the original idea, presenting a reduced-scale clay model car.

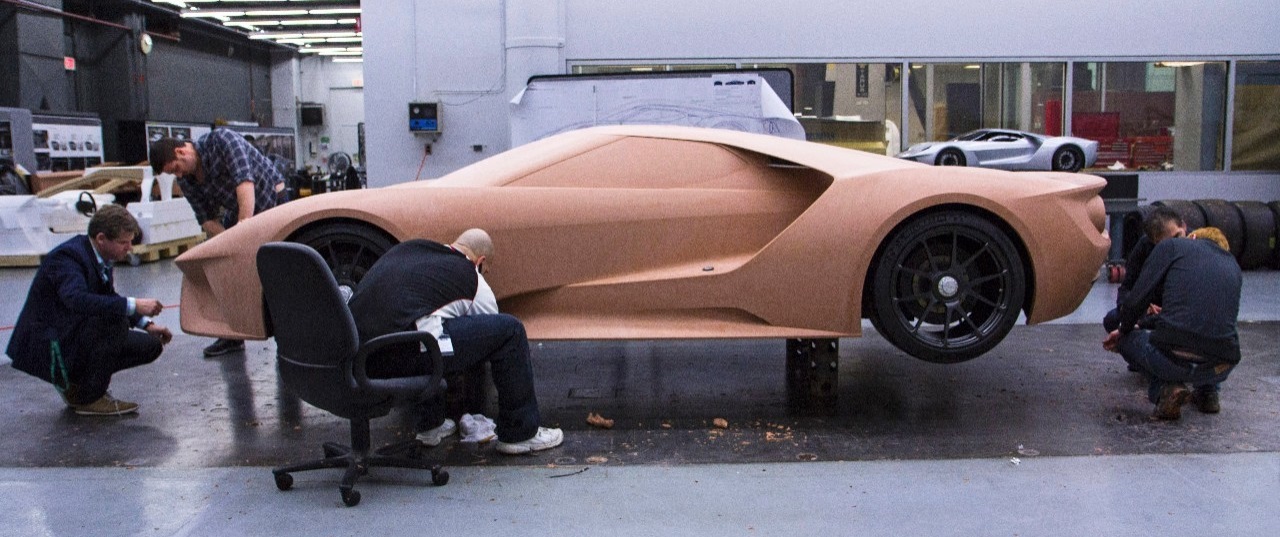

Ford GT design process (1:5 clay models). Source: Detroit Free Press and Formtrends

Ford GT design process (1:5 clay models). Source: Detroit Free Press and Formtrends

Several 1:5 scale models are made in order to develop the full potential of the idea and the design team, together with the managers of the brand, usually chooses up to three potential directions to go. After that, rough 3D models are created and the different full-size clay models are produced using a multi-axis milling machine .

The whole design team then works on the different 1:1 clay models, adding and removing material until the whole team is happy with one of the results. That will be the version of the car that moves on to the Concept Car stage.

A new full-size model is created using metal and composite materials. At this stage, the model is equipped with a working interior and usually with a running drivetrain, suspension system and brakes. Most importantly, the model already has the technological features that will make the car stand out among the hard competition on the automotive market.

The whole design team then works on the different 1:1 clay models, adding and removing material until the whole team is happy with one of the results. That will be the version of the car that moves on to the Concept Car stage.

A new full-size model is created using metal and composite materials. At this stage, the model is equipped with a working interior and usually with a running drivetrain, suspension system and brakes. Most importantly, the model already has the technological features that will make the car stand out among the hard competition on the automotive market.

If the car is approved by the managers of the company, it is then presented in an auto show, where the automotive media have a chance to give a feedback. Assuming that the results are positive and they decide to take the concept to production, the car is completely redesigned.

All of the parts are CAD-modelled again, adapting the shapes and functionalities of the concept car to the ‘big numbers’, because designing the components of a concept car and designing those of a real series production model are two entirely different things.

If the car is approved by the managers of the company, it is then presented in an auto show, where the automotive media have a chance to give a feedback. Assuming that the results are positive and they decide to take the concept to production, the car is completely redesigned.

All of the parts are CAD-modelled again, adapting the shapes and functionalities of the concept car to the ‘big numbers’, because designing the components of a concept car and designing those of a real series production model are two entirely different things.

This “Small clay models – Big clay models – Concept Car – Production car” approach has been the industry standard for the last 70 years, since Harley Earl ‘invented’ this system when working in General Motors. Not much has changed ever since, except for the addition of multi-axis milling machines to help the designers create the ‘rough clay shapes’ that they work on.

And I’m not here to prove them wrong. The big clay models are used for some reasons.

“Why clay?” laughs Joe Dehner, Head of Ram Truck and Mopar Design for Fiat Chrysler, “I asked the same question when I got here 28 years ago, yet here we are doing the same thing. I explain it as using an erasable pencil versus permanent ink, and clay lets you go back and make changes.”

Lloyd VandenBrink, modelling manager at Ford Truck Studio in Dearborn, Michigan, is a big believer, as well. “Clay has two characteristics that make it good for use. It’s easy to change — you just add it, or take it away. It allows you to be creative and come up with something quickly. 3D printing, on the other hand, is just that — printing.”

“Secondly, it’s a great collaborative tool,” he continues. “Everyone can get around it, brainstorming three-dimensionally.” (from BBC Autos)

However, Clay has huge disadvantages. For instance, it is not possible to create clay removable parts that can be interchanged between several different models. I personally believe that it would be very interesting to allow designers to share parts between different models, especially in the early 1:5 small model phase. Here is where the FabLab tools can help.

Those 1:5 scale cars are actually very ‘Fabbable’. With modern 3D printing machines and easier to use 3D CAD software, the idea of a ‘big scale Lego car’ does not seem very crazy, does it?

Those 1:5 scale cars are actually very ‘Fabbable’. With modern 3D printing machines and easier to use 3D CAD software, the idea of a ‘big scale Lego car’ does not seem very crazy, does it?

And what if the interchangeable parts could store information in them? For instance, who was the designer, what was the inspiration, the date of the designing, … The main core of the car would be able to read that data and know what combination of parts are forming it.

That could be one of the tools that car design companies give their teams, not to replace clay modelling but as an additional tool during the co-creation process in the early stages of the design. That data could be paired with the feedback of the design team on each specific combination.

It would definitely be a change, but an extremely useful one, I believe. It would be a powerful tool that could potentially improve the collaboration in the team that works on a Project.

This is only a dream, of course. An idea coming from a young, ‘just graduated’ car designer and engineer who ended up working in two different FabLabs rather than in a car company and decided to apply the potential that the Lab has to offer to his dream job. Car designing with modern tools in a simultaneous and collaborative design and engineering environment. Is it just a crazy utopia?

Anyway, What is FabAcademy for? We are here to express ourselves through what we create.

Anyway, What is FabAcademy for? We are here to express ourselves through what we create.

Well, this is me. Welcome to my FabAcademy Project.