WEEK 9 Mechanical design, Machine design

Group Assignment

compare the performance and development workflows for other architectures

This week’s group Assignment is written in here

Individual Assignment

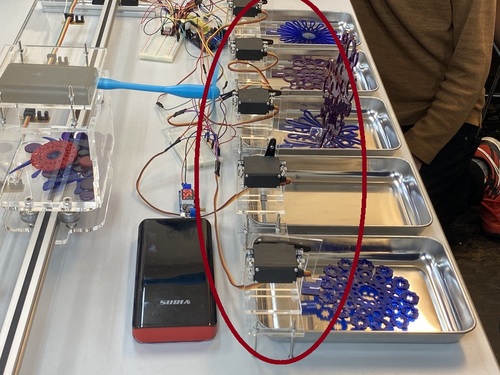

For the group project, I was in charge of designing.I made the movable bubble wands, entire base for the bubble wands and soap dishes and acrylic box to set the movable fan. The second role was making the video.

Our Idea

Before the local session on Saturday, we had several meetings to talk about the idea of our machine. We found the idea of making machine that blows bubbles automatically might be interesting because…

1.it’s the hybrid of soft/flexible object (=bubble) and hard/solid object (=machine)

2.the concept is so simple and easy to understand

3.we assume the presentation video with the image of flying bubbles in the sky will be beautiful.

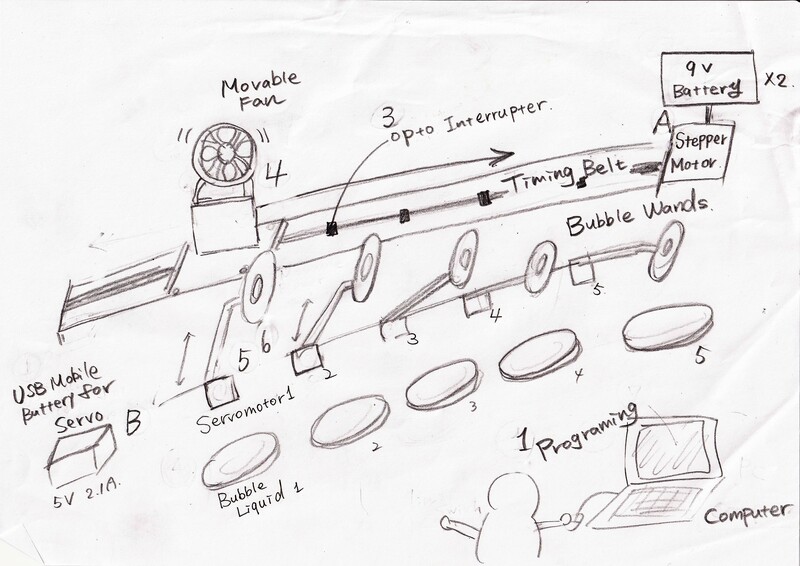

Basic Construction

◆PREPARING

A. Turn on the button to start stepper motor

B. Turn on the button to start servo motors

◆HOW THE MACHINE WORKS

1.Turn on start switch to run the program

2.The base of movable fan moves by stepper motor

3.Detect the place of the base by opto interrupter

4.Stop the stepper motor

5.Turn up the bubble wand by servo motor

6.Turn down the bubble wand by servo after pausing for 5 seconds

7.After Repeating 2-6 for four more times, the stepper mortor will be stopped.

Experimenting of Blowing Bubbles

Honestly, this was one of the fun parts of the week for me. I purely enjoyed making bubbles on the rooftop of the building our fablab is in, and learned the basic structure of it. It helped us to understand the structure of blowing bubbles and the shape of bubbles.

Designing, Laser Cutting, and Assembling

I was in charge of designing and making 5 bubble wands and fixed base for them, and acrylic box to fix the movable fan.

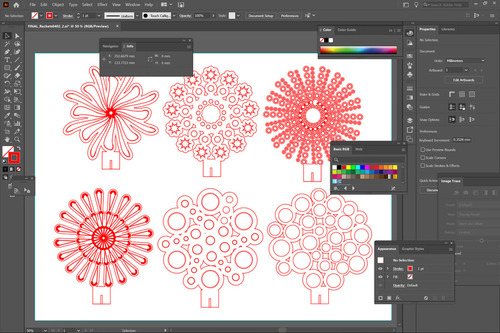

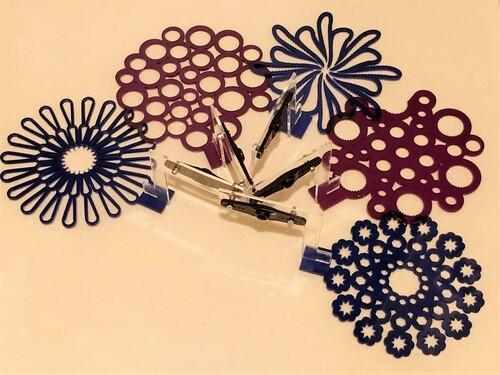

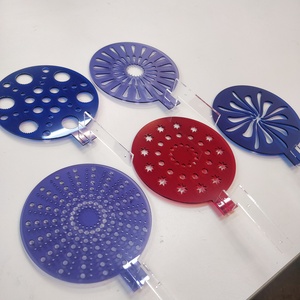

◆Bubble Wands

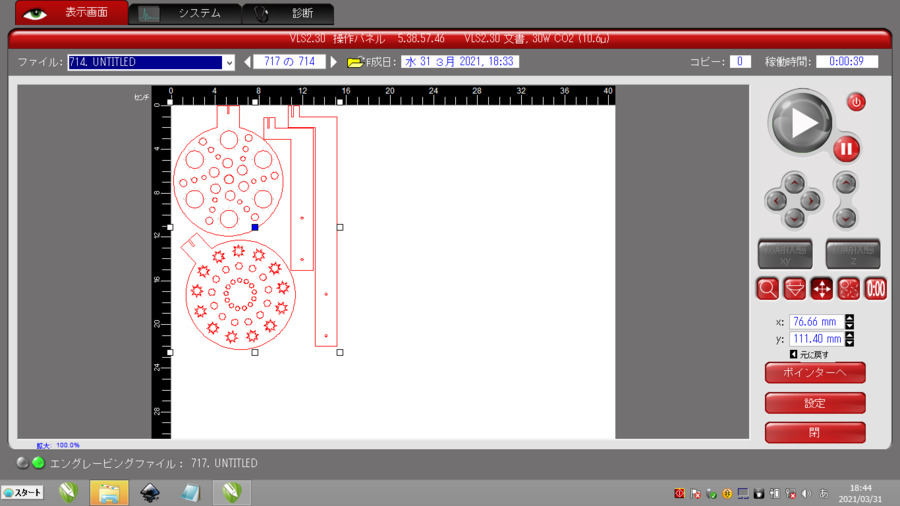

This is the final vector data of five bubble wands and outcome. The material is 2mm acrylic board.

Problem1 Joints and Kerf

The bubble wands consists of the handle part and top plate part. For the joints, I made a little slit to insert to the other part. This was the time to make the most of what I have learned before, “kerf”.

Surprisingly each 2mm acrylic board has slight difference in their thickness… so same kerf wasn’t work for all of them. Due to the limited time I have, I filed the slits to make the joints fit well.

Problem2 Shape of the Wands

I was inspired by the shapes of fireworks so made this design. Through the experiment of blowing the bubbles with these wands, I realized that if the areas of acrylic boards of the bubble wand are too much, the soap liquid drop on the surface and it didn’t fly away well. To make the bubbles flying away well, we needed high power of wind such as the circulator.

Problem3 Broken parts during the assembly.

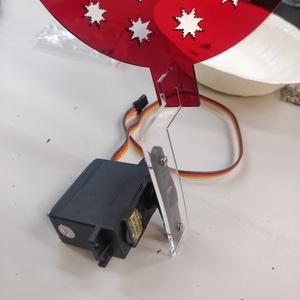

As I learned the characteristics of appropriate shapes for the bubble wands, the final model became very fragile and thin shapes. So that I had to be very careful when I assembled all the parts such as the handles, plates, and servo motors.

For the base to set the movable fan To fix the movable fan, I decided to make acrylic box. I enjoyed the designing step for this.

◆Entire base for the bubble wands and soap dishes

For the base to fix the 5 servomotors to move the bubble wands, I used 2mm acrylic board. I used 35 screws and 55nuts to assemble it, so it took much more time than I imagined!!

◆Acrylic box to set the movable fan

To fix the movable fan, I decided to make acrylic box. I enjoyed the designing step for this. I needed to make its heights same as the heights of the middle point of bubble wands. To figure out the correct heights, my instructor supported me a lot.

Problem4 Scale Confusion

I needed to make its heights same as the heights of the middle point of bubble wandss. Each part has different heights and they were piled, I had to be careful to figure out the correct heights for what I was trying to make. The collaboration with movable fan team Shinobu-san was important and my instructor supported me a lot.

Problem5 Position Displacement

I made the holes on the bottom face of the acrylic box to fit with the screws of the linear base of movable fan. But something wrong was my first design and I need to fix the design.

Making the Video

Making the video took more time than I thought...To make the file size smaller than 10MB, I fully used fffpeg.

The link from Fab Academy was very useful!

Thoughts

- Machine building assgignmnet was intense and super busy but very informative and practical. I learned much about mechanism ,acturations and automations.

This week help me to deepen the idea for my final project.

- I should always be careful for positioning and measurement at the first stage cafefully, otherwise they affects the entire structure of machine and fixing the problem will take enoumous time.

Files

Bubble Wands Vector data

SVG

ai

Acrylic Box Vector data

SVG

ai