Electronics Production

Assignment Requirements:

- Characterize the design rules for your PCB production process: document feeds, speeds, plunge rate, depth of cut (traces and outline) and tooling.

- Document your work (in a group or individually)

- Make an in-circuit programmer by milling and stuffing the PCB, test it, then optionally try other PCB fabrication process.

Learning Outcomes:

Introduction:

For the group assignment, we fabricated the resolution test (traces & outline) on 3 CNC milling machines. First on Roland Modela MDX-20, Second on a chinese CNC milling machine and third on MonoFab SRM-20. Each macine has its resolution results.

For the individual assignment I decided to make Ali's FabOptimus ISP, I chose the Design Files (R_pullup=1K+0.5K).

Steps in General:

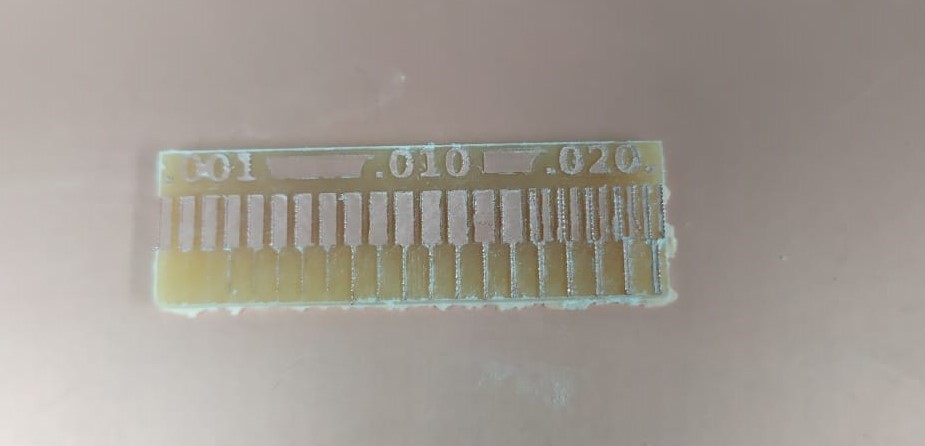

- Step(1): Fabricating the resoultion test on a Chinese CNC milling machine

- Step(2): Fabricating Ali's FabOptimus ISP on MonoFab SRM-20

- Step(3): Stuffing and soldering the PCB

- Step(4): Programing and testing

Steps in Details:

Step(1): Fabricating the resoultion test on a Chinese CNC milling machine

- I downloaded the traces and outline images as .png files.

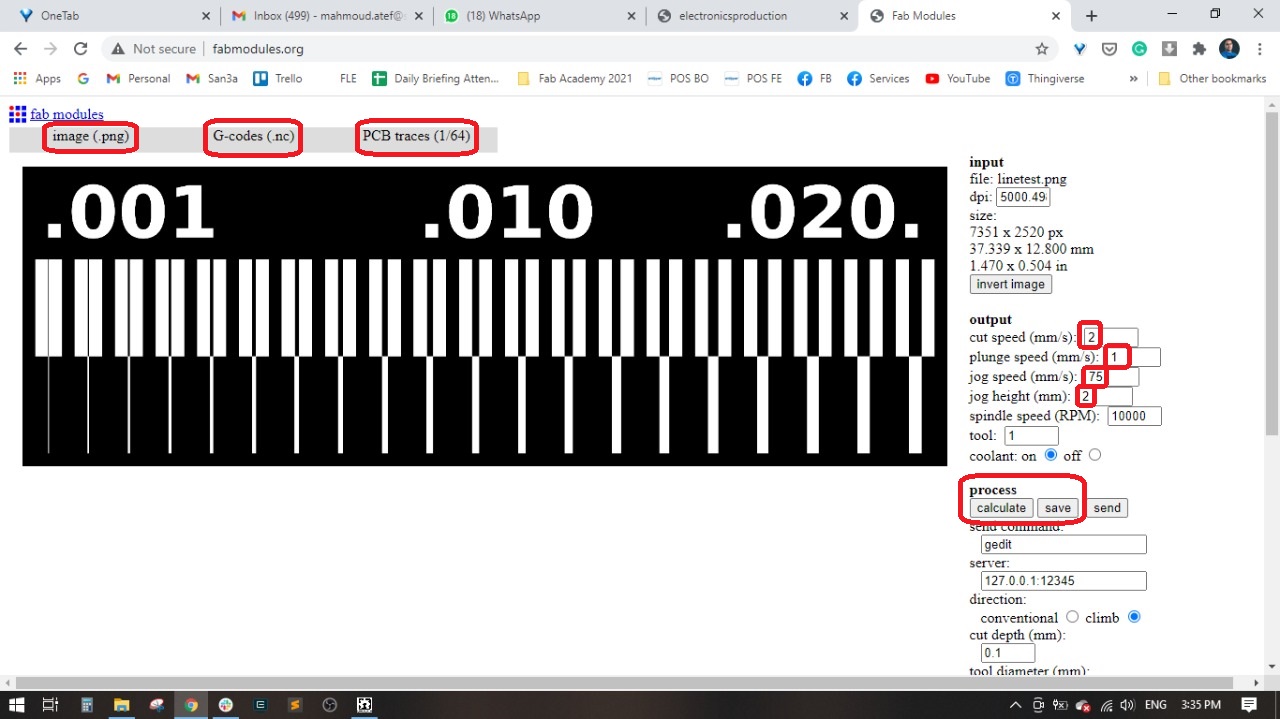

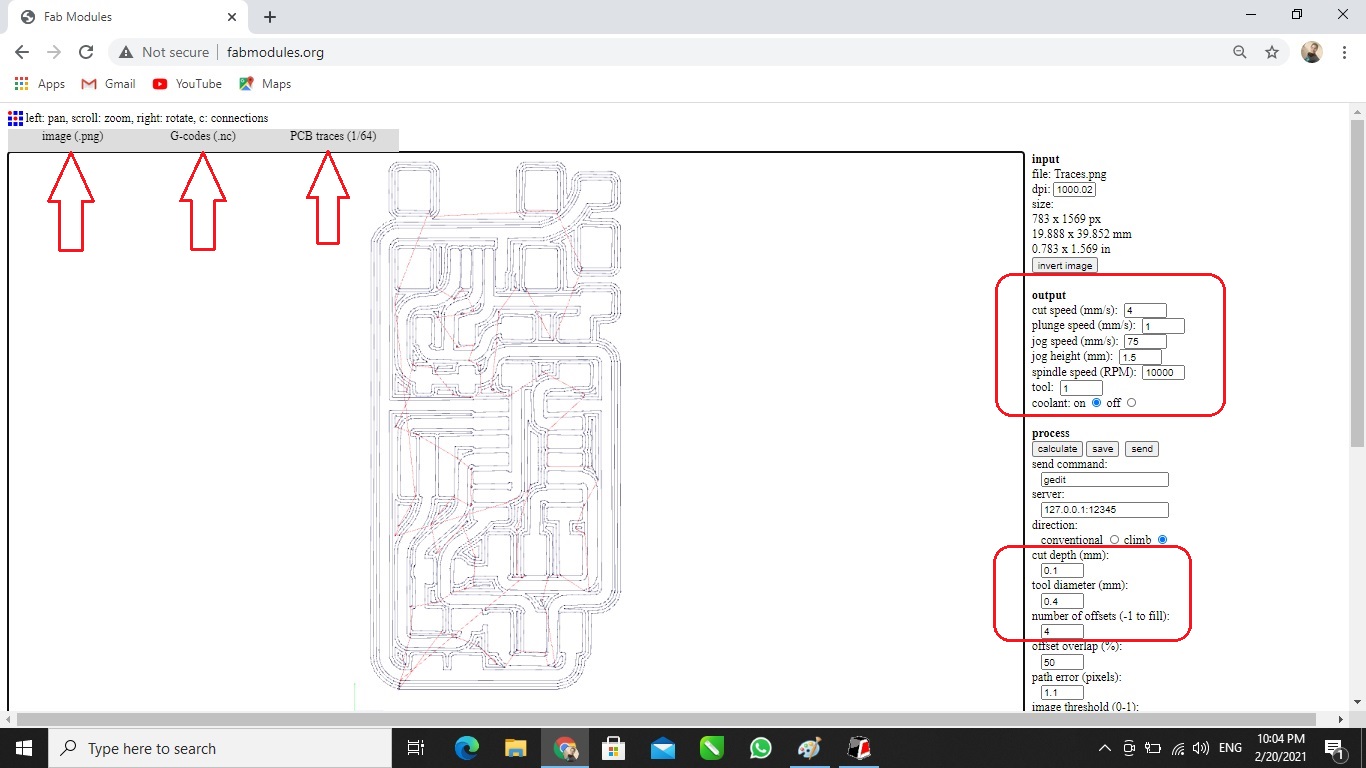

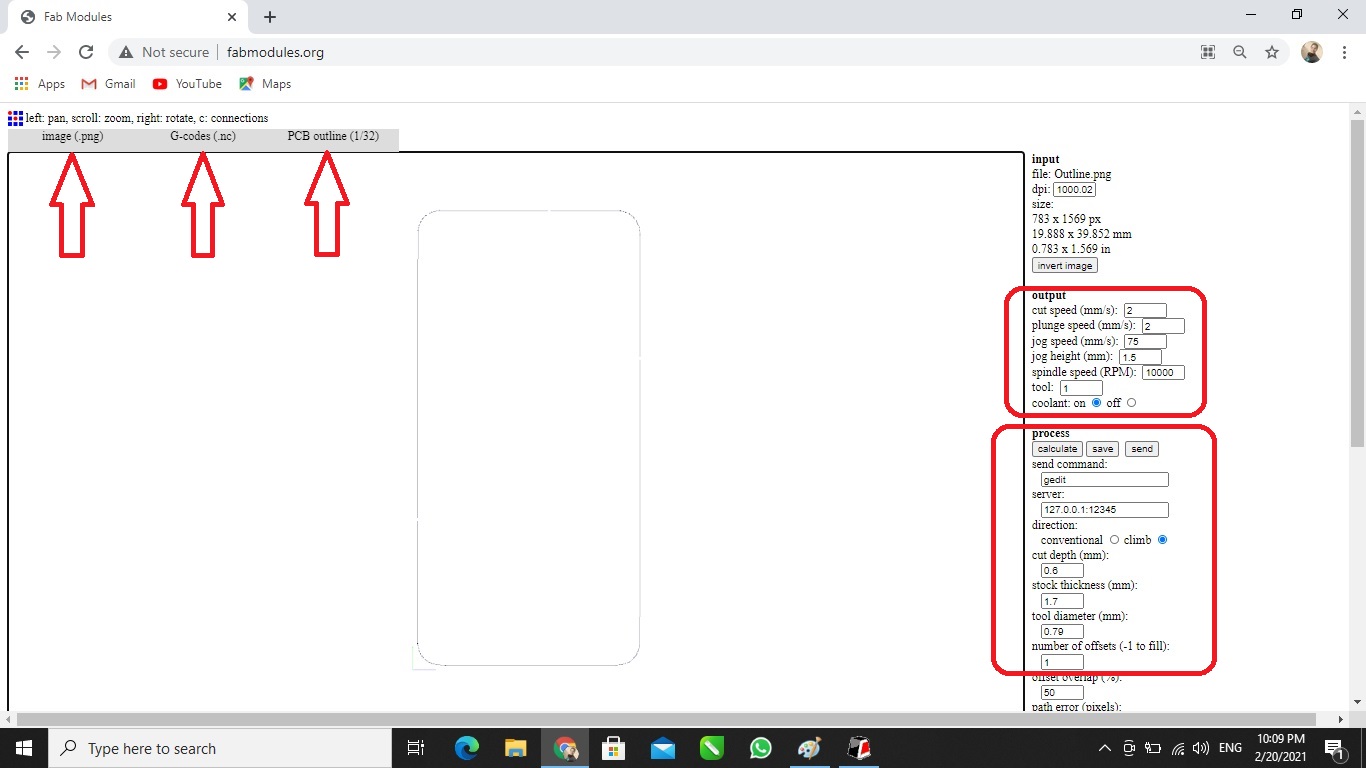

- I opened Fabmodules.org on Chrome, From the input format I selected image (.png), From output format I selected G-code (.nc) and then chose PCB traces (1/64)

- I set the cut speed to 2 mm/s instead of 4 mm/s, made the plunge speed to 1 mm/s and the jog height to 2 mm

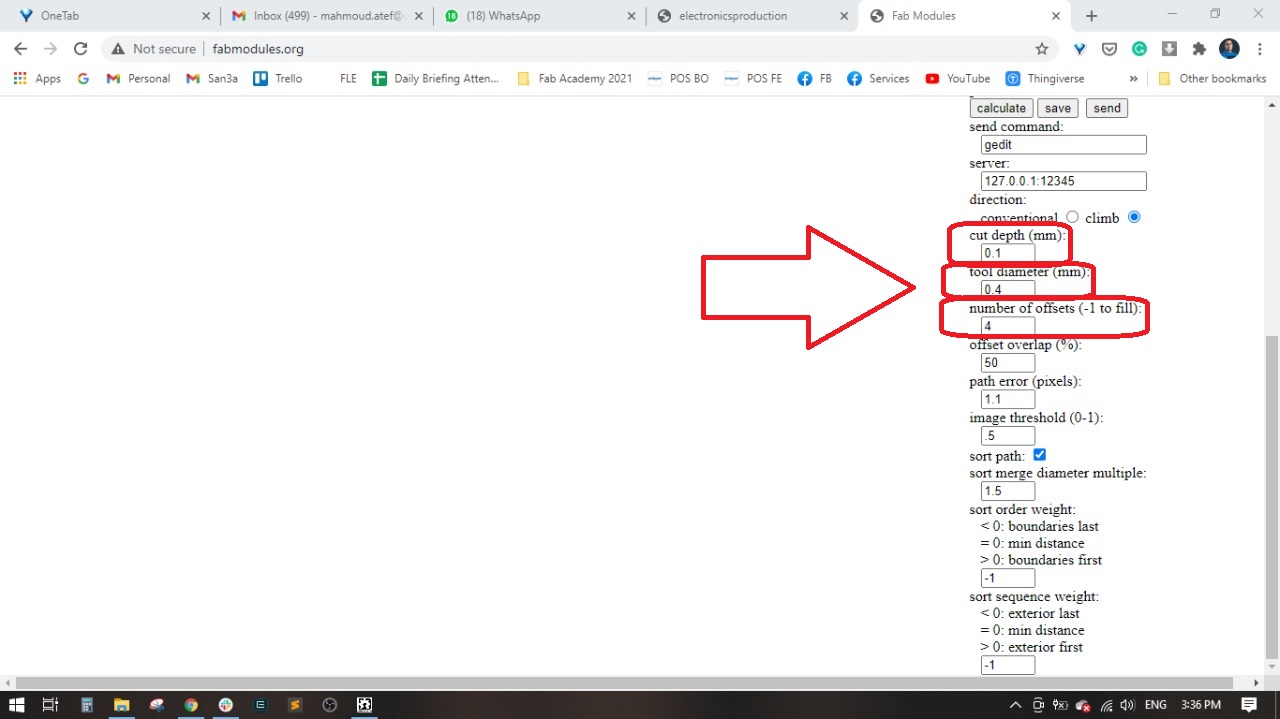

- Cut depth was set to 0.1 mm and the used tool was a v-carve 0.4 mm and made the no. of offsets 4.

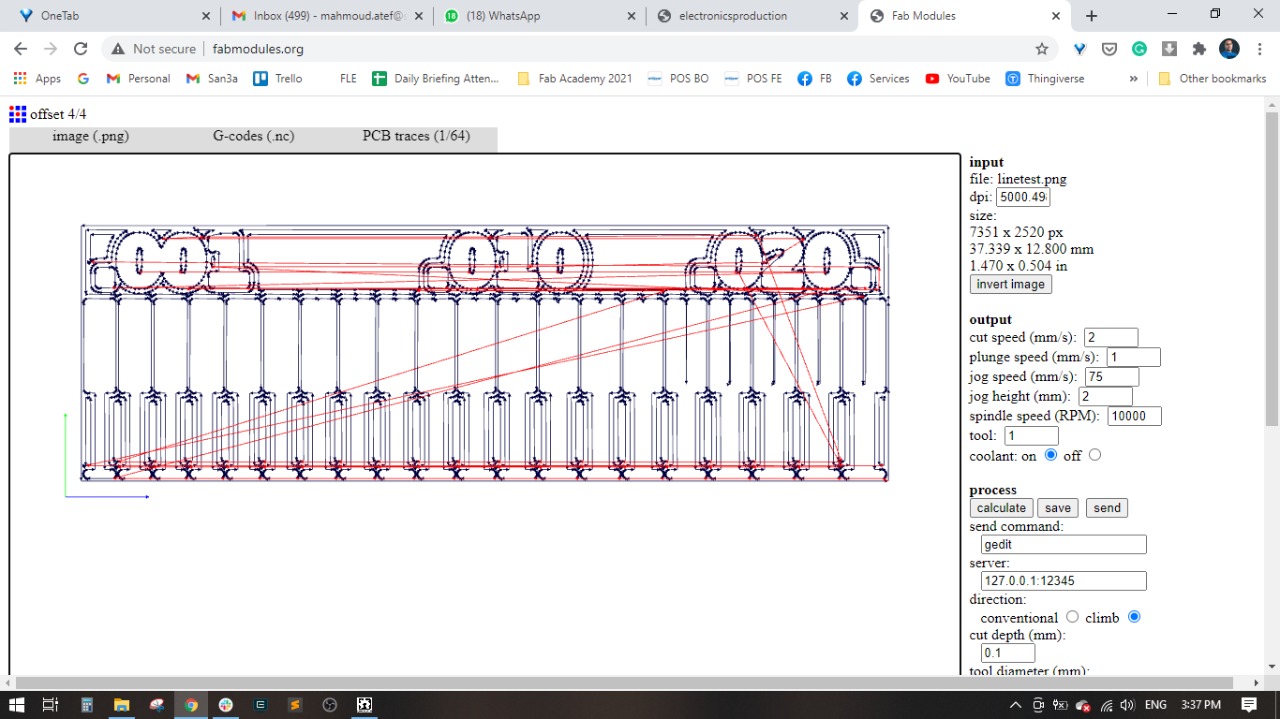

- Clicked on Calculate then Save, the output files will be traces.nc

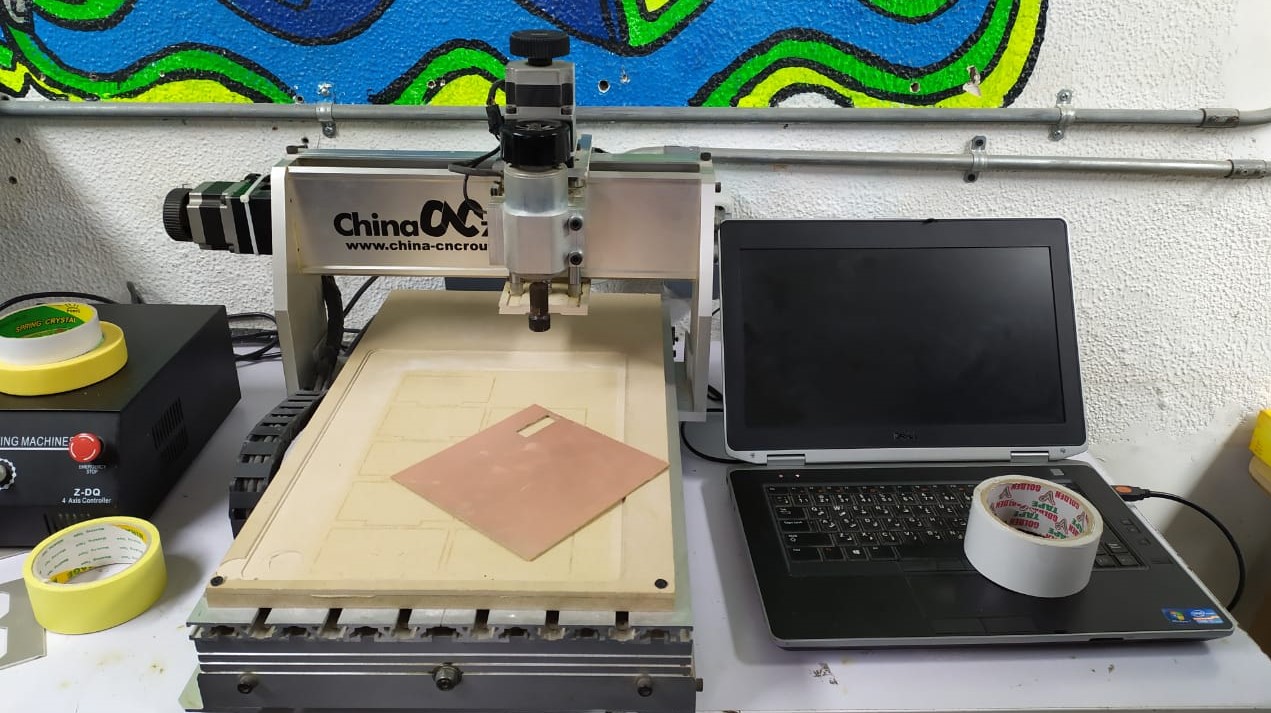

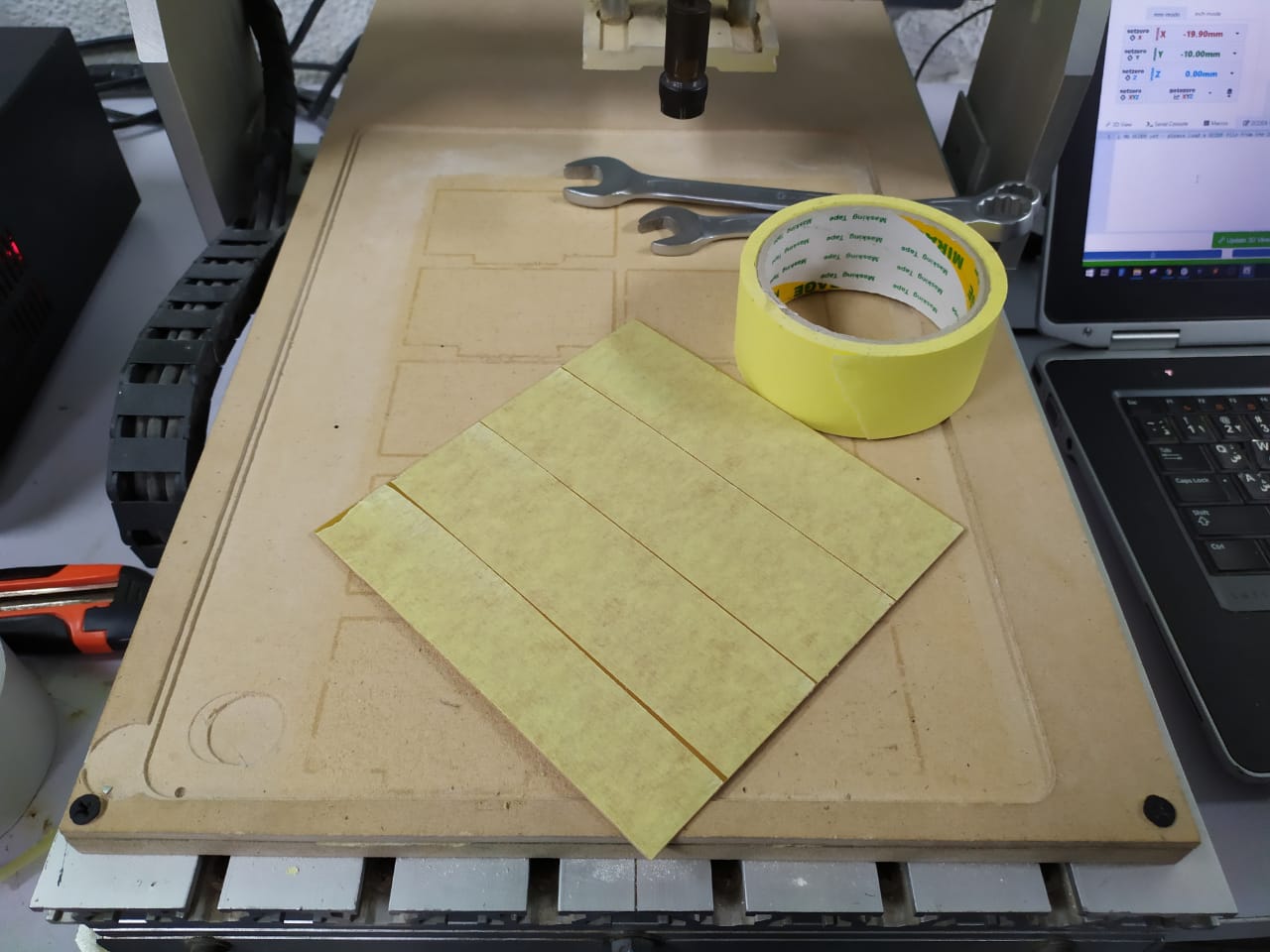

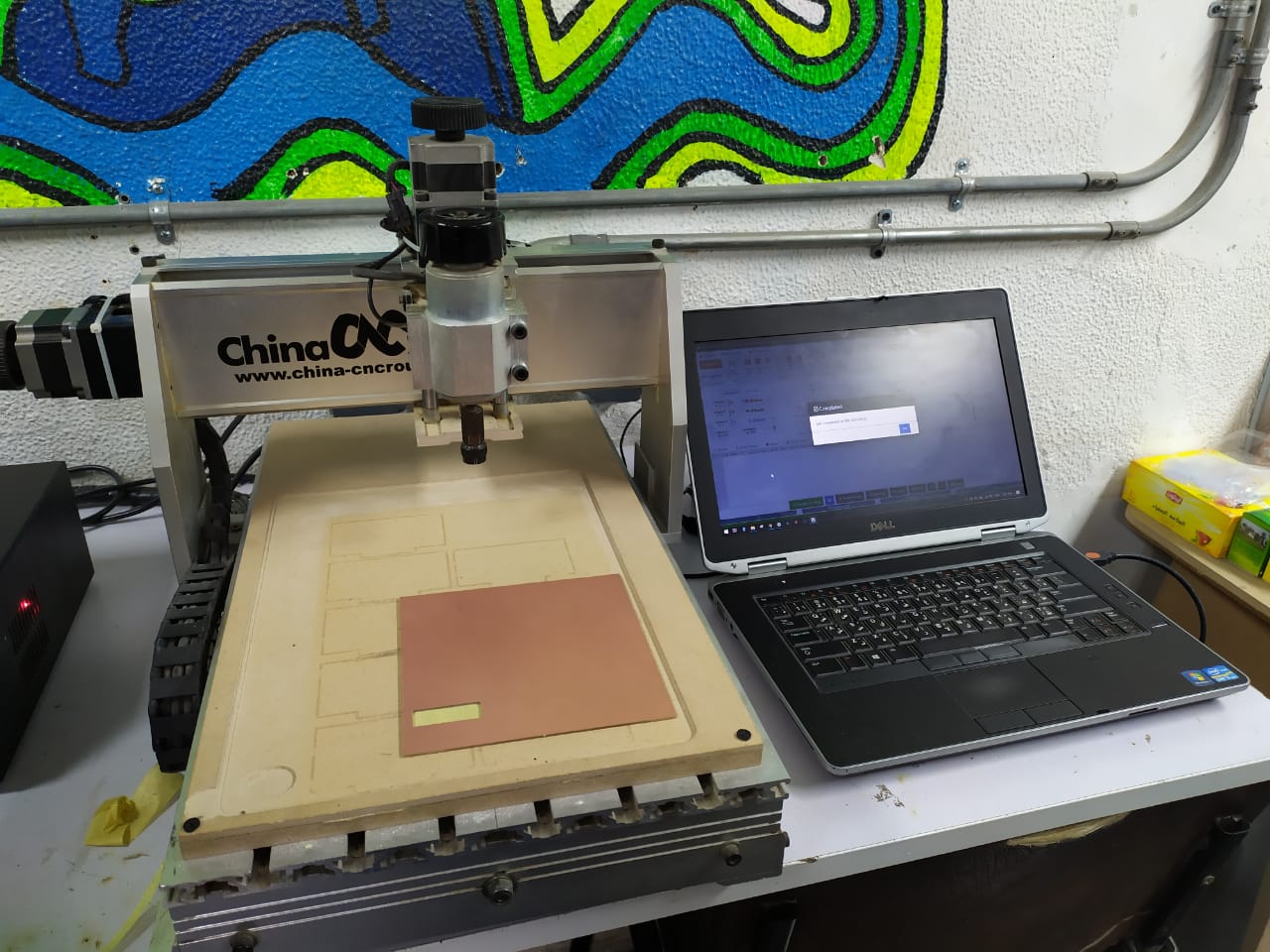

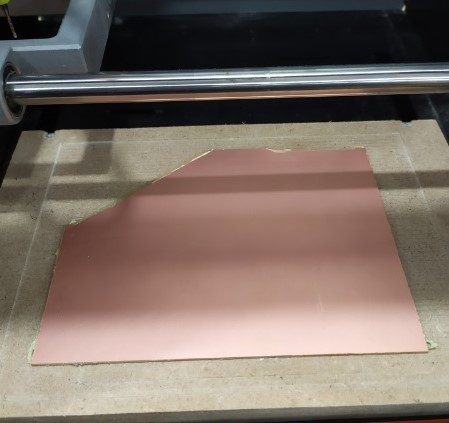

- I will be using a chinese CNC milling machine, its area is 30 cm * 40 cm and we, at Fab Lab Egypt, changes its control board to OpenBuilds controller.

- I used an FR1 single layer PCB sheet with dimensions of 15 cm * 15 cm.

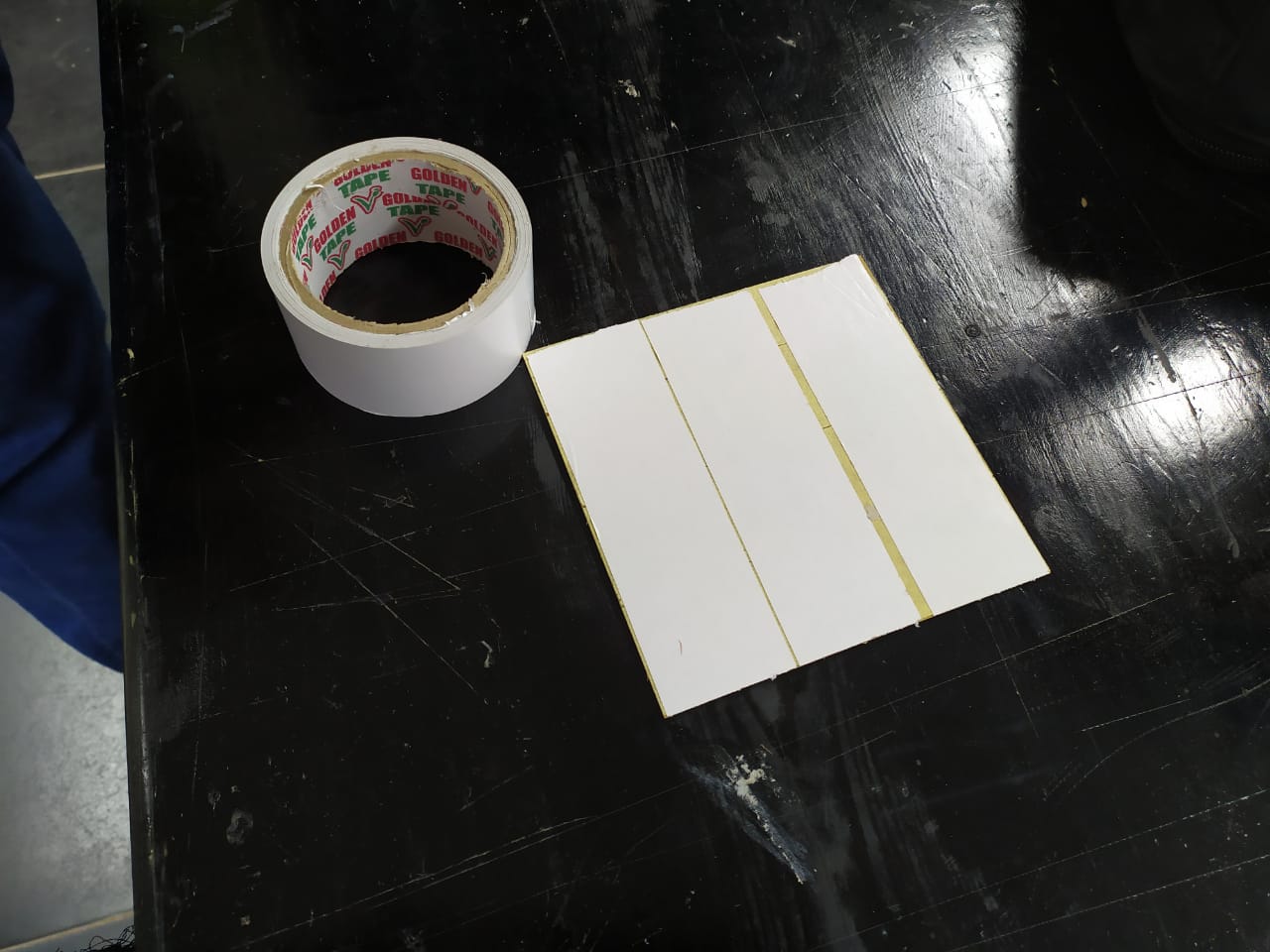

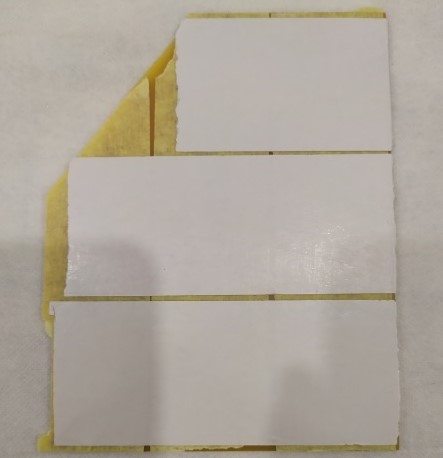

- I used a yellow paint tape on the other side of the board and then used a double sided tape in order to fix the board on the sacrificial bed properlly.

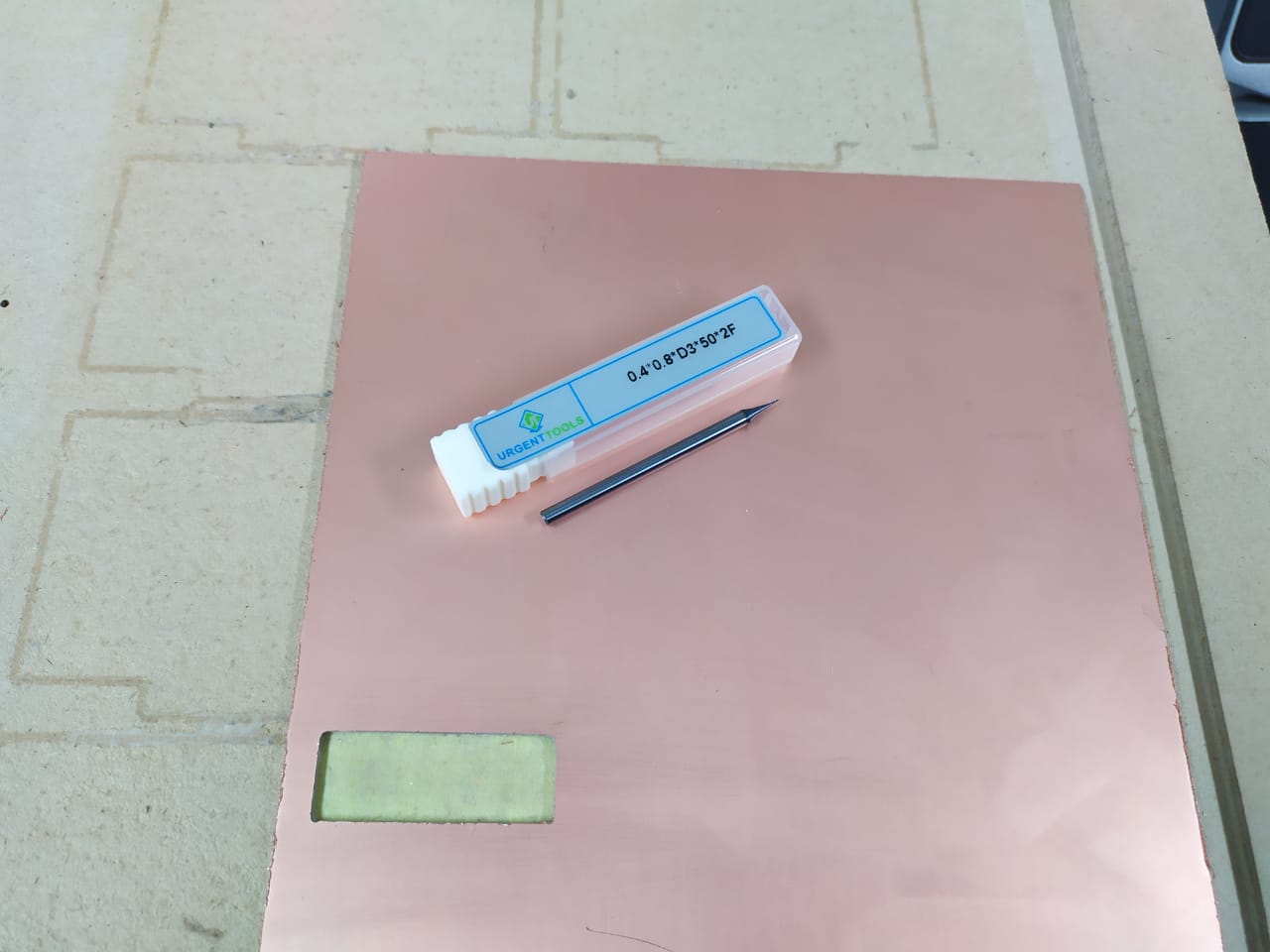

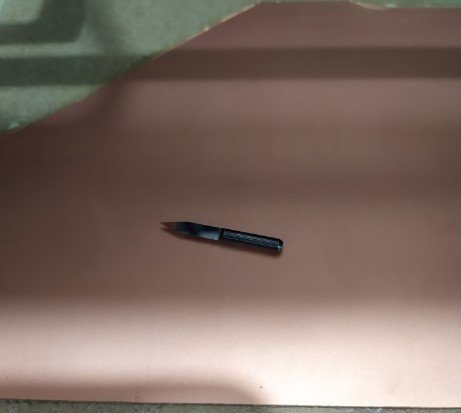

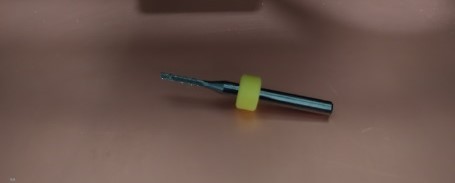

- I used the 0.4 mm end mill for the traces. I have to be carefull while using this end mill as it can break easily.

- The machine will run milling the traces, it removes copper at each track side.

- After finishing the traces, I used a 1.5 mm end mill to cut the outline.

- I noticed that the machine requires calibration in X and Y axes, as the trace width is smaller than its designed width. So, I will calibrate the machine and run the file again to have better results.

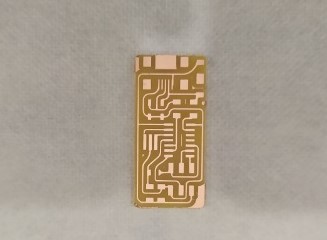

Step(2): Fabricating Ali's FabOptimus ISP on MonoFab SRM-20

- I downloaded Ali's FabOptimus ISP (traces & outline). I chose Design Files (R_pullup=1K+0.5K)

- I used fabmodules to import the traces.png image and selected the output format to G-code (.nc) and selected 1/64 inch end mill to the tracing.

- I set the cut speed to 4 mm/s, plunge speed to 1mm/s, jog height to 1.5 mm

- Aslo set the cut depth to 0.1 mm (it is the copper layer thickness) and 4 offsets.

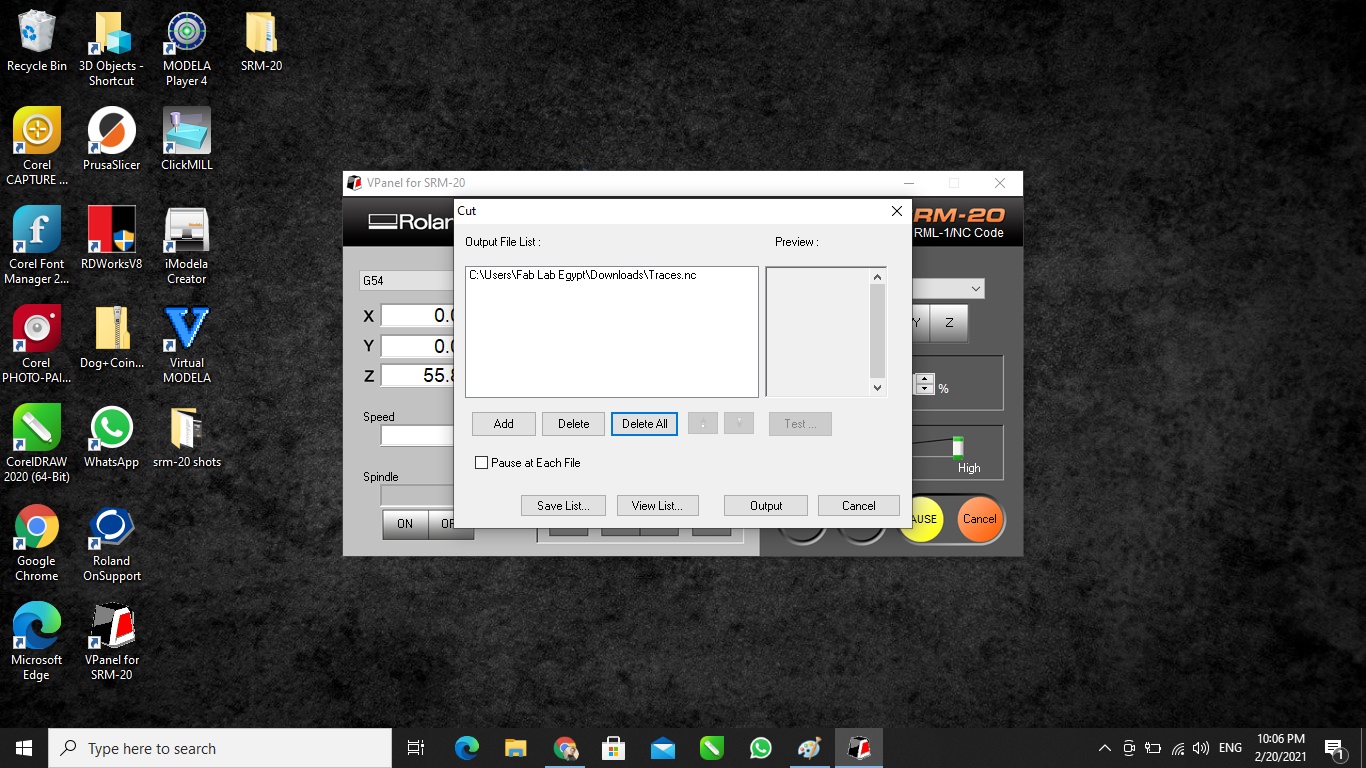

- I saved the file (traces.nc)

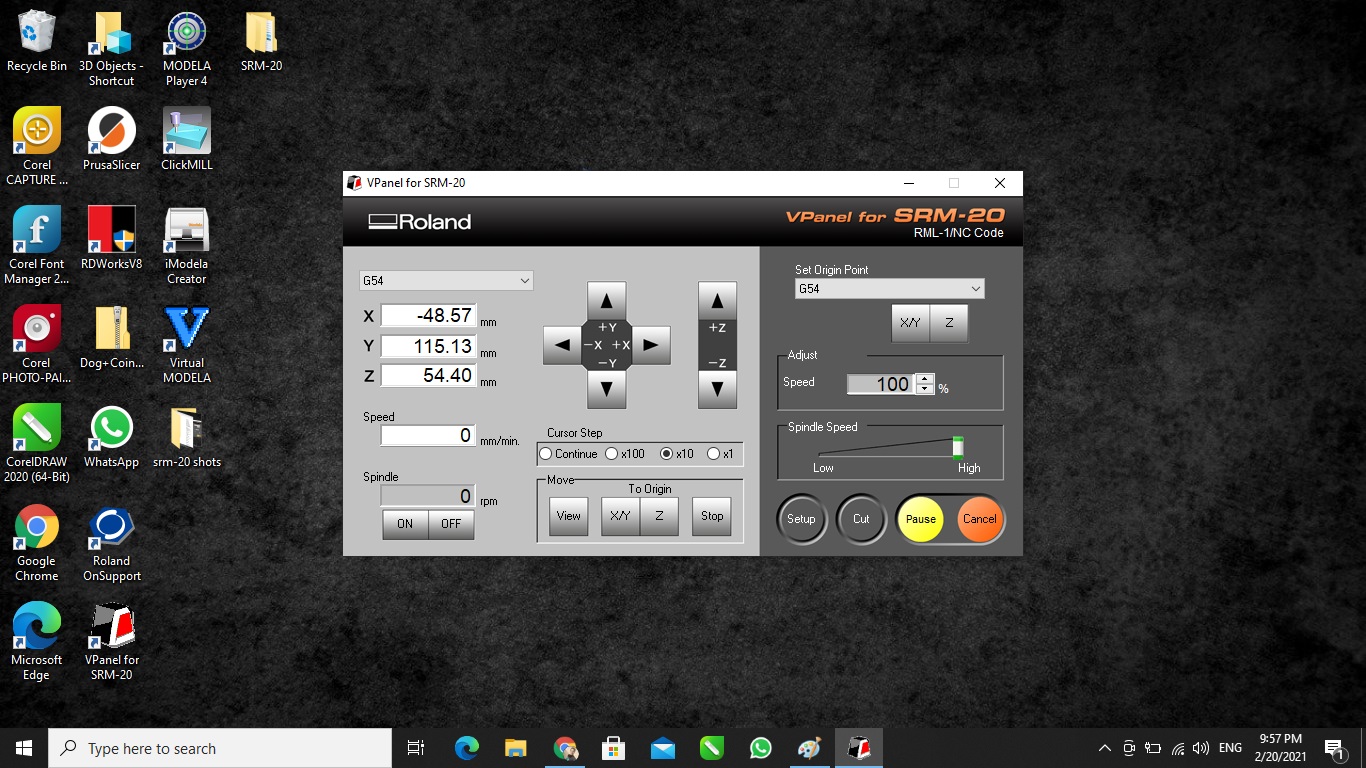

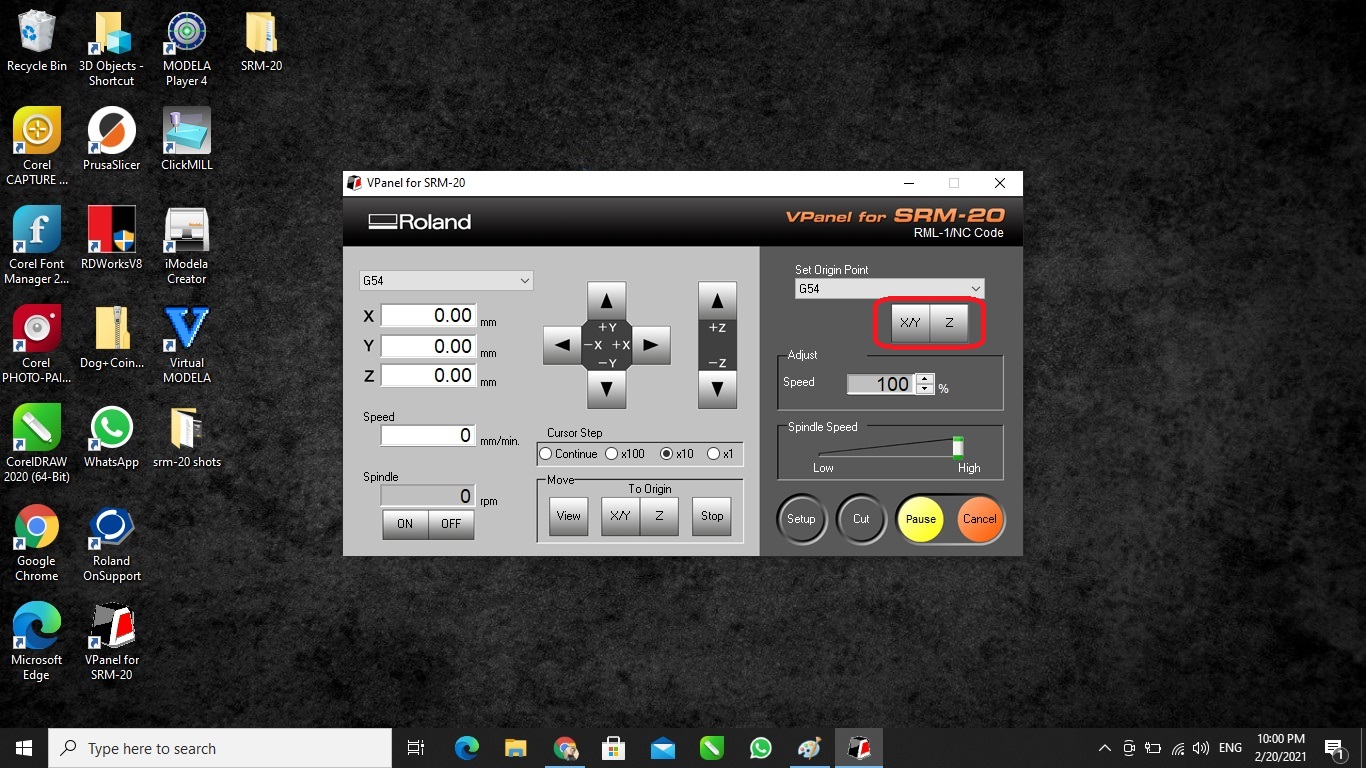

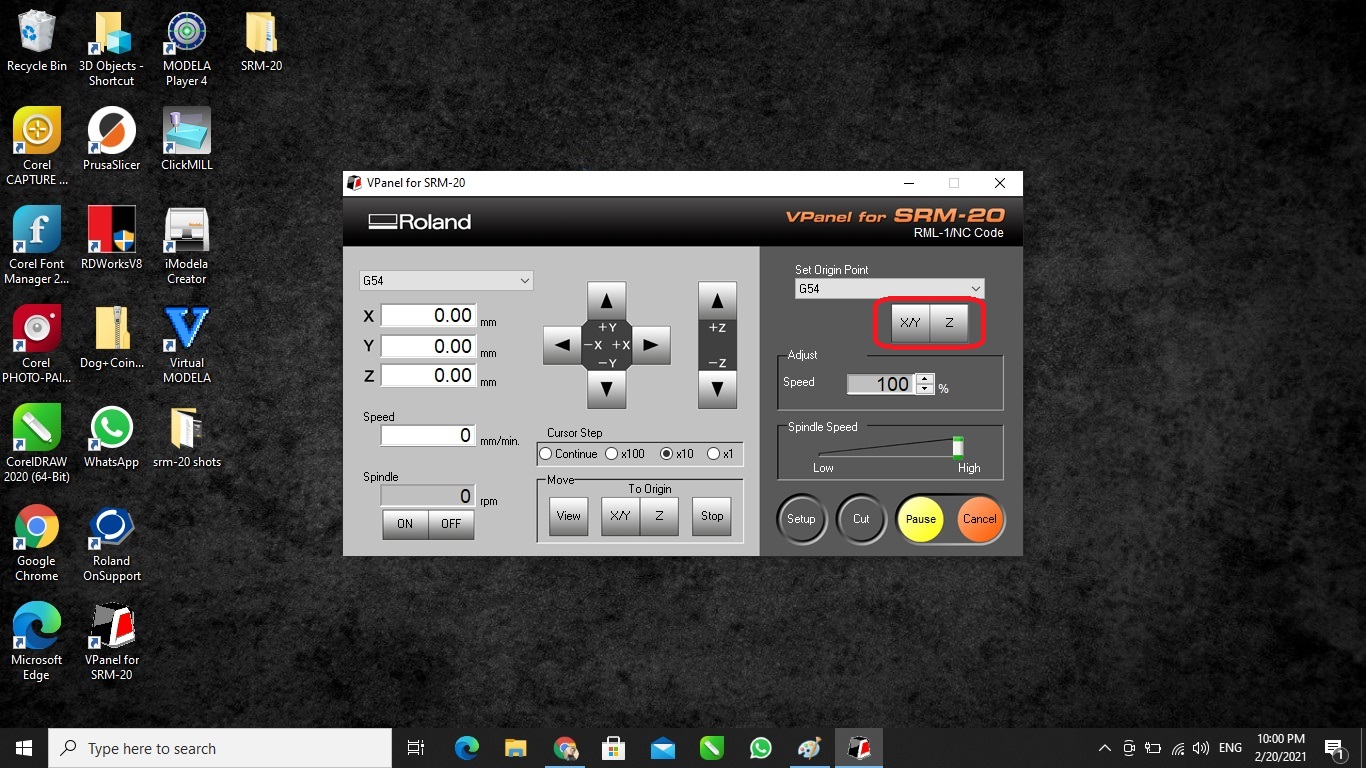

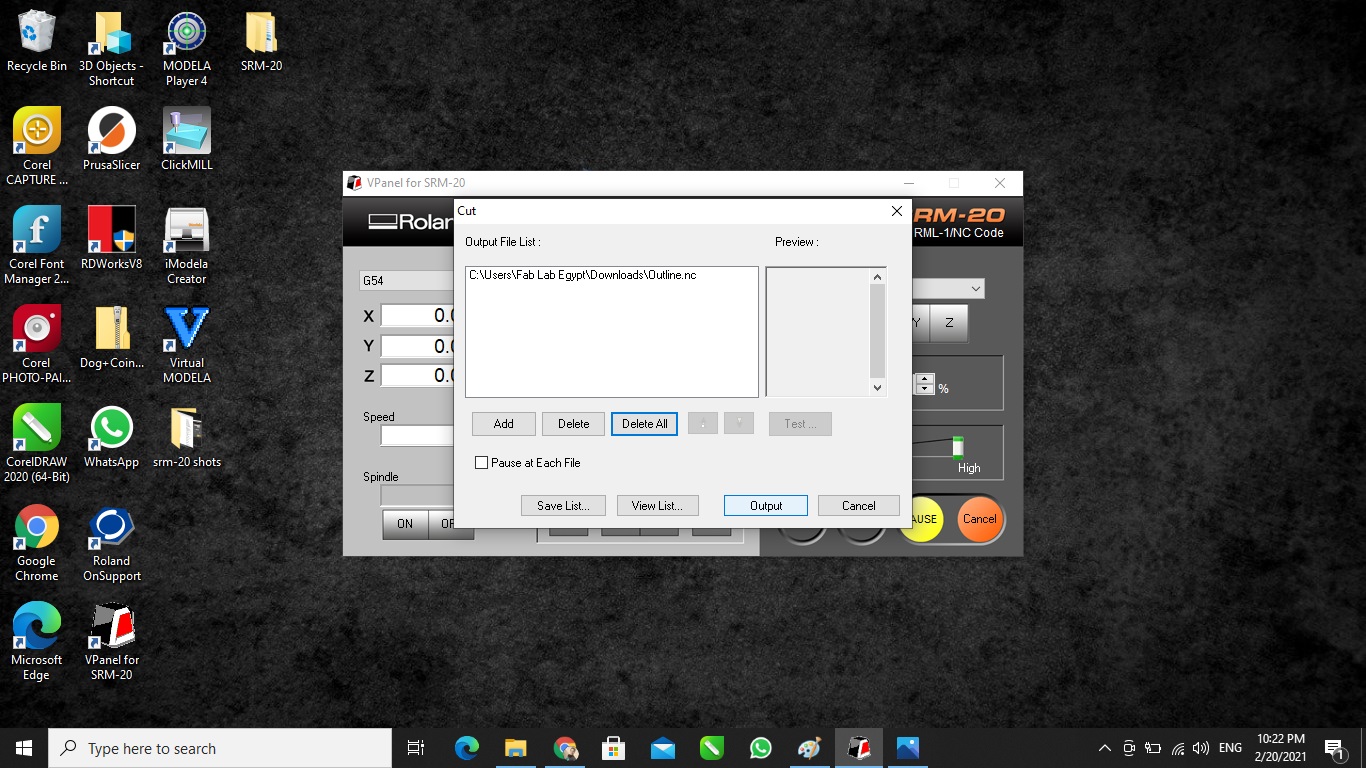

- Opened V-Panel to set the origin of the tool and to load the traces file.

- I used paint tape and double face to fix the board to the bed.

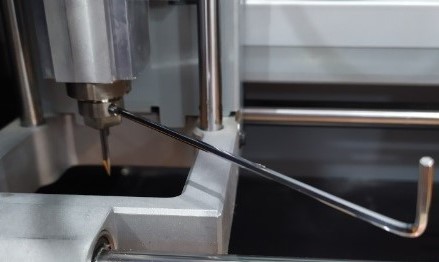

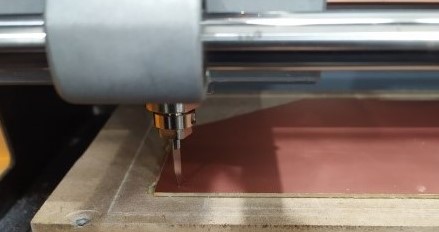

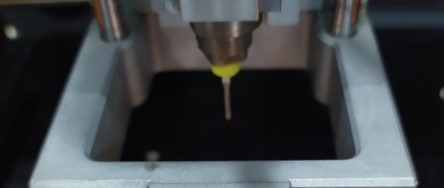

- Then I used the 0.4 mm v-bit to run the trace milling, I used a hex allen to fix the tool into the spindle collet.

- I set the origin to the front left corner and run the traces file

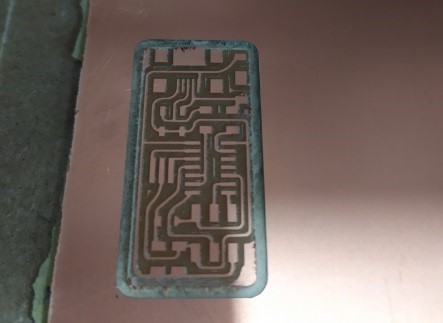

- I imported the outline image to Fabmodules, selected G-code as output format, chose PCB outline(1/32).

- I set the cut speed to 2 mm/s, plunge speed to 2 mm/s and job height to 1.5 mm.

- I set the cut depth (per path) to 0.6 mm to cut the whole thickness of 1.7 mm.

- Then imported the .nc file into the V-Panel.

- I used a 1.5 mm end mill to cut the outline, fixed it on the spindle collet using the allen key

- Finally I removed the PCB from the board and it looked very fine!

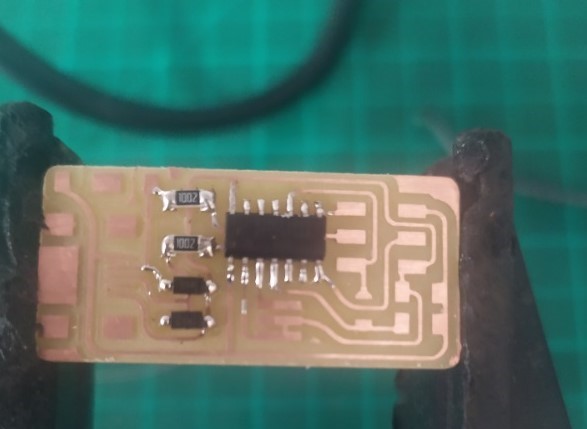

Step(3): Stuffing and soldering the PCB

- This is the components' list and their quantities to be prepared before soldering:

- I started soldering the ATTINY44A then the components from center to outside

- It was useful to use a SMD resistor code calculator to make sure I am using the correct ones.

- Tools used while soldering: soldering iron, soldering stand, soldering wire, solder sucker, tweezer and wet sponge.

| Component | Description | QTY |

|---|---|---|

| ATTINY44A-SSU-ND | IC AVR MCU 4K 10MHZ 8SOIC- | 1 |

| H2961CT-ND | CONN RECEPT MINI USB2.0 5POS | 1 |

| 609-5161-1-ND | 6 Positions Header Connector 0.100" SMD | 1 |

| 311-10.0KFRCT-ND | RES 10.0K OHM 1-4W 1% 1206 SMD | 1 |

| 311-1.00KFRCT-ND | RES 1.00K OHM 1-4W 1% 1206 SMD | 1 |

| 311-100FRCT-ND | RES 100 OHM 1-4W 1% 1206 SMD | 2 |

| 311-499FRCT-ND | RES 499 OHM 1-4W 1% 1206 SMD | 1 |

| 311-0.0ERCT-ND | RES 0.0 OHM 1-4W 1% 1206 SMD | 1 |

| XC1109CT-ND | CER RESONATOR 20.00MHZ SMD | 1 |

| 445-1423-1-ND | CAP CER 1UF 50V X7R 10% 1206- | 1 |

| BZT52C3V3-FDICT-ND | DIODE ZENER 500MW 3.3V SOD123 | 2 |

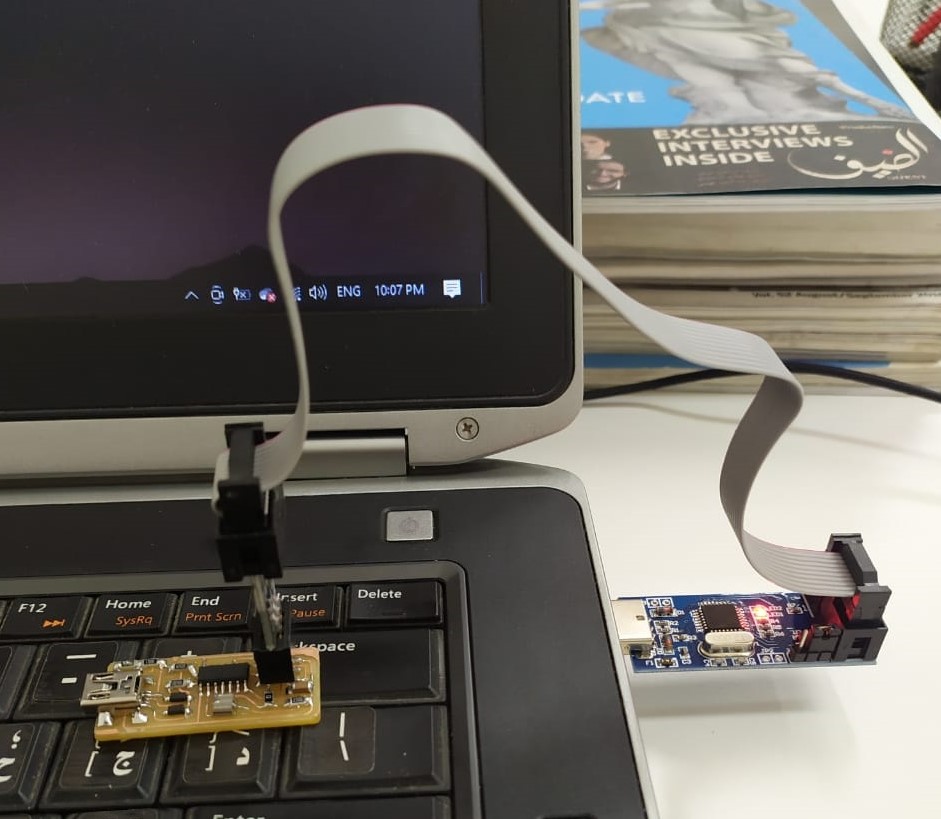

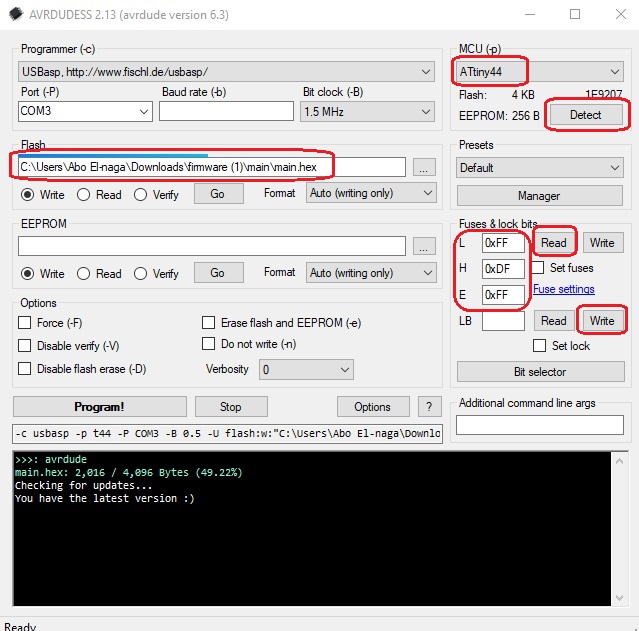

Step(4): Programming and testing

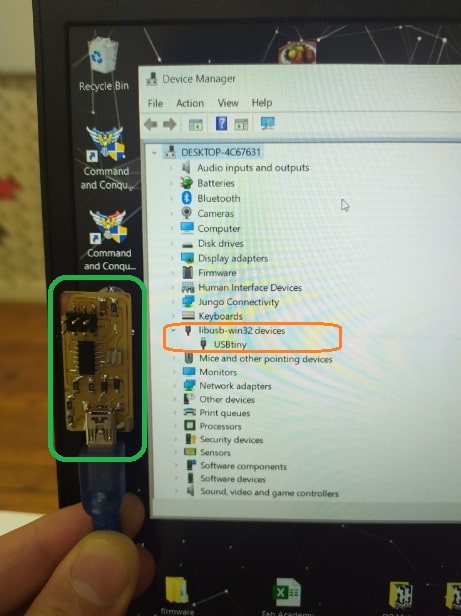

- I used the ATMEL AVR USBasp Programmer and the AVR ISP 10Pin To 6Pin Converter to connect the board to the PC/Laptop and then program it.

- I downloaded the firmware.zip and the windows drivers.zip of the programmer, then I installed the driver.

- I also downloaded the AVRDUDESS and installed it.

- In the AVRDUDESS, I pressed on Detect and then flashed the main.hex file from the firmware.zip and used the shown Fuses & lock bits.

- I connected the board to my laptop and now it is defined and well connected.

Finally, I have:

√ Characterized the design rules for our PCB production process: documented feeds, speeds, plunge rate, depth of cut (traces and outline) and tooling.

√ Made an in-circuit programmer by milling and stuffing the PCB and finally tested it.