Applications and Implications

Assignment Requirements:

- 2D and 3D design

- additive and subtractive fabrication processes

- electronics design and production

- microcontroller interfacing and programming

- system integration and packaging Where possible, you should make rather than buy the parts of your project. Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable.

Learning Outcomes:

- Define the scope of a project.

- Develop a project plan.

Questions:

- (1) What will it do?

- (2) Who has done what beforehand?

- (3) What will you design?

- (4) What materials and components will be used?

- (5) Where will they come from?

- (6) How much will they cost?

- (7) What parts and systems will be made?

- (8) What processes will be used?

- (9) What questions need to be answered?

- (10) How will it be evaluated?

Answers:

(1) What will it do?

- Inventory tracking is one of the main issues at most fab labs and makerspaces. At San3aTech (Fab Lab Egypt), it takes a lot of time and effort to re-arrange and organize components after each workshop or educational program. So, I am passionate about solving this problem and decreasing time and effort consumed every week, by designing and making a smart system (Smart Drawer) for maintaining components in an easy way and tracking inventory.

- Functions:

- Maintaining components in an organized system (Hardware and Software).

- Ease of finding and locating the required component by blinking its box.

- Keeping record of the existing components and the ability of adding and removing a quantity.

- Wirelessly system access through a browser of a pc or mobile.

(2) Who's done what beforehand?

I searched Fab Academy Archive if a student made this before as a project/assignment and fortunately I found 3 potential projects as follows:

- Inventory Bot, made by Kohei Morimoto from FABLAB Kitakagaya Japan in 2017. The mechanism is based on core XY system which is attached on back of the cabinet. A shaft with servo motor is attached on the head which pushes out the desired drawer, when a person needs any component, he/she has to give two inputs to machine a name of component and no. of quantity after that if the component is available the core XY system moves toward that box and push it out. The arduino is used to control the core XY system which gets instruction from PC and act according to it.

- Wally, made by Kenzo Prada Abiko from AS220 FabAcademy in 2015. This project also designed to maintain the inventory for the specific projects. To interface with machine LCD is placed alongside buttons which are also fabricated, a person needs to input a number of project and the boxes which have component of those project lights up to mention them. After taking desired component a person needs to enter the number of component, he/she takes. And inventory updated with respect to it.

- Smart Inventory System, made by Noor Ahmed from Khairpur Fab Academy in 2018. The user inputs the IP address in the browser, a list of items and their quantities will appear, user should select an item to add or remove and its quantity and then press locate, an RGB led will be blinking indicating the box where the component located.

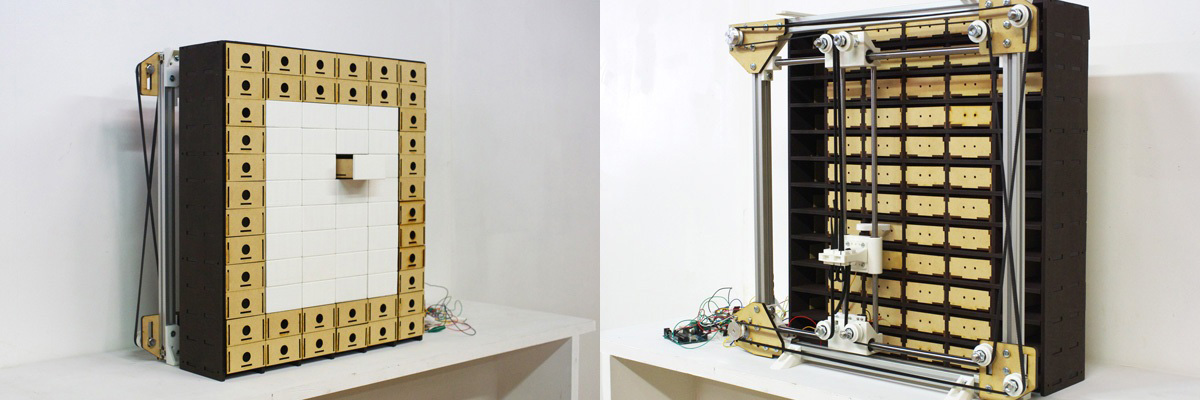

- 3D printed modules/structure to be modular and parametric, light weight and ease of assembly and disassembly.

- A drawer for each module, drawers may be with different sizes and shapes to maintain various components.

- An Addressable RGB led strip for each module, it has 3 RGB leds for better flashing/blinking and connected with other modules.

- A control box in the middle of the structure to receive the signals and control the RGB Leds.

- A back cover for the structue to help fix it on walls.

- A single connector/adaptor for powering up the system

- A search box for typing the component name and then a window includes the quantities and type of target operation.

- Plywood sheet.

- Transparent Acrylic sheets.

- WS2811 Addressable RGB LED Strip 1-meter DC12V.

- WIFI Circuit based on ESP8266-12E.

- Control circuit between the WIFI circuit and the RGB LEDs.

- Adaptors (12 V & 5 V).

- PLA filament for the modules.

- Jumpers, connectors and wires.

- WS2811 Addressable RGB LED Strip 1-meter DC12V, bought from Makers Electronics.

- ESP8266-12E, bought from Makers Electronics.

- 3d printed modules.

- Laser cutted drawers.

- Laser cutted control box.

- PCB of the Atmega 328p board.

- PCB of ESP8266-12E board.

- Web interface.

- Networking and communications between the Atmega 328p board and the ESP8266-12E board.

- Wiring and cable management.

- 3D Designing > design the modular structure on Fusion 360 (Parametric design) and export .STL files, and also the controller enclosure and export .STL files.

- Laser Cutting > cut the .dxf files of the drawers using the Morn MT3050D laser cutter.

- 3D Printing > using Prusa I3MK3 to fabricate the modules.

- Electronics Design > design the atmega 328p board and the ESP8266-12E board on Eagle and KiCAD.

- Electronics Production > Using Fabmodules.org and the MonoFab SRM-20 milling machine for PCB fabrication.

- Networking > Using ESP-12E wifi interfacing with PC/mobile and wired interfacing with 328p board.

- Interfacing > design a web interface using Bootstrap.

- Where to fix the controller box?

- How to fix the RGB leds on each module?

- How to make the structure modular in both mechanical and electronics aspects?

- How to power up the system and where?

- How to make a simple interface?

- Ease of assembly of both modules and drawers.

- Stable circuits and wiring.

- Covering all the wires and cable management.

- Ease of handling and fixation on a wall.

- Speed response and blinking for the target component.

- Quatities to be stored correctly in the EEPROM.

(3) What will you design?

(4) What materials and components will be used?

(5) Where will they come from?

Most of the materials and components are existing in Fab Lab Egypt inventory except for the following:

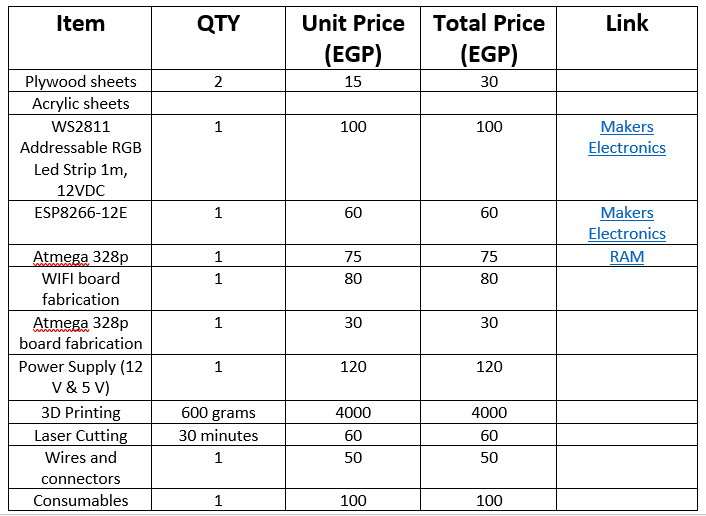

(6) How much will they cost?