Fab Lab ECAE

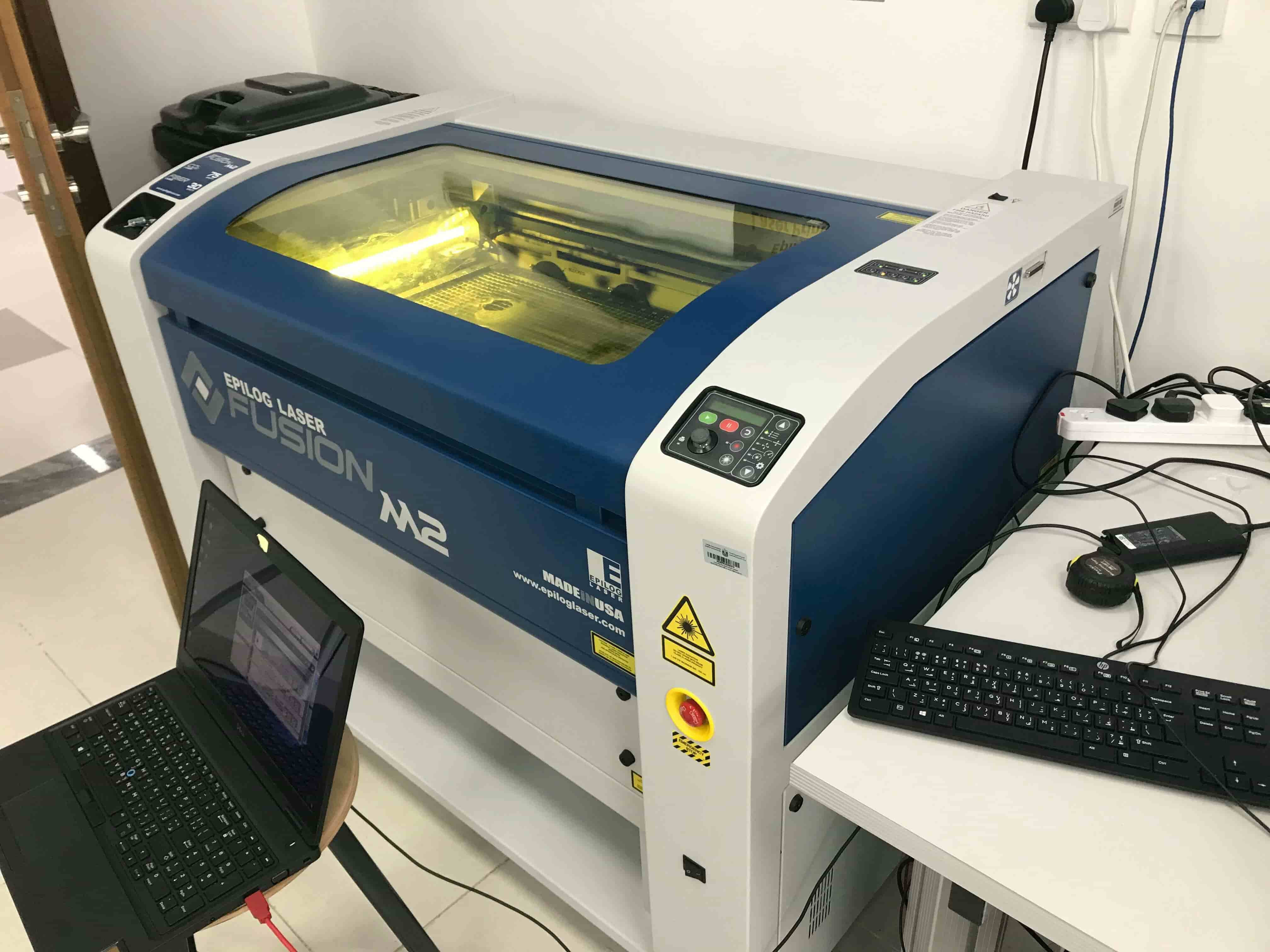

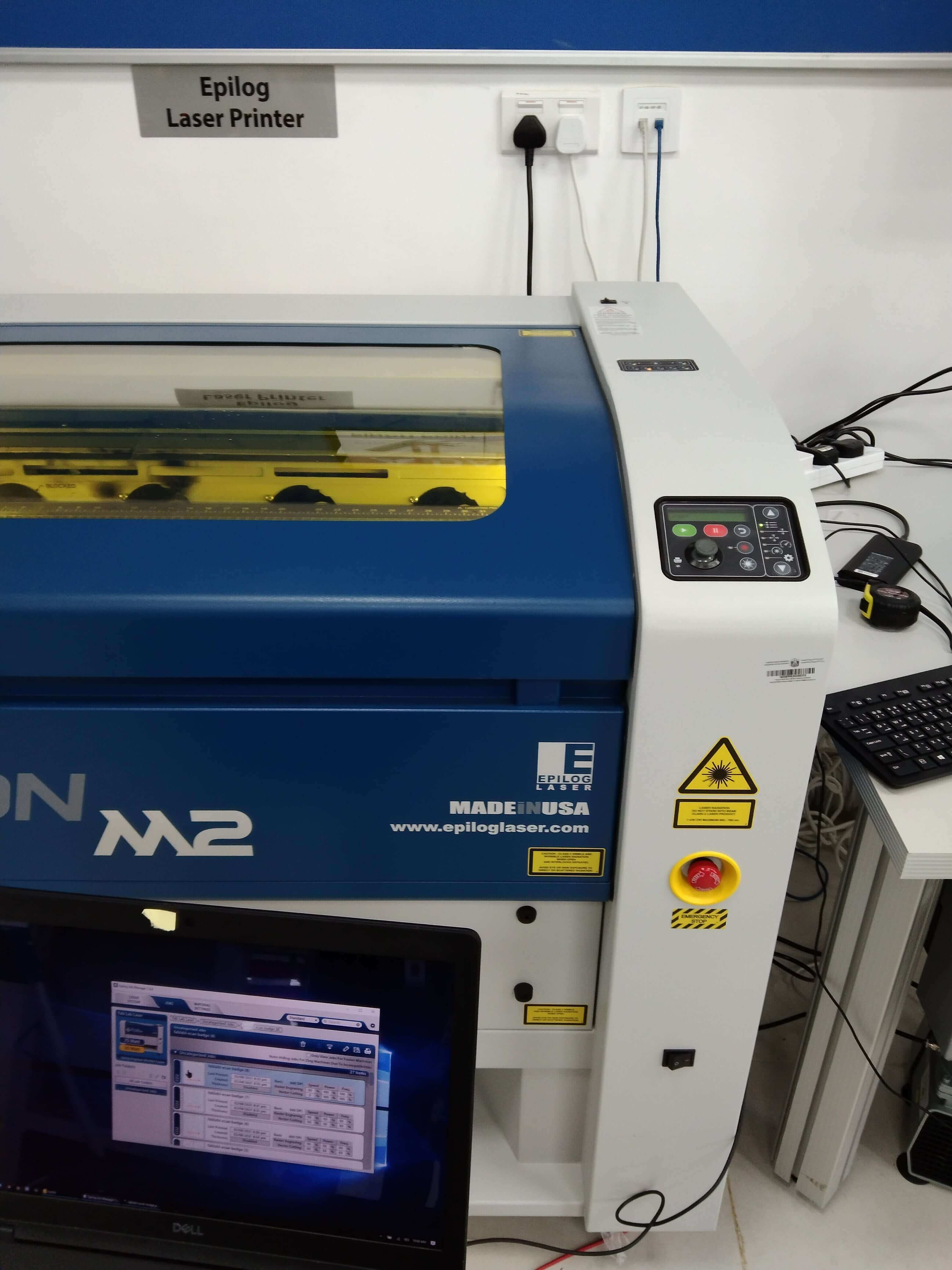

Epilog Fusion Laser Cutter

Group Assignment: Mohammed and Cicely

characterize your lasercutter's focus, power, speed, rate, kerf, joint clearance and typessearch tags:

+ Safety rules

+ Cleaning optics

+ Kerf

+ Focusing the laser

+ Air extraction

Mohammed:

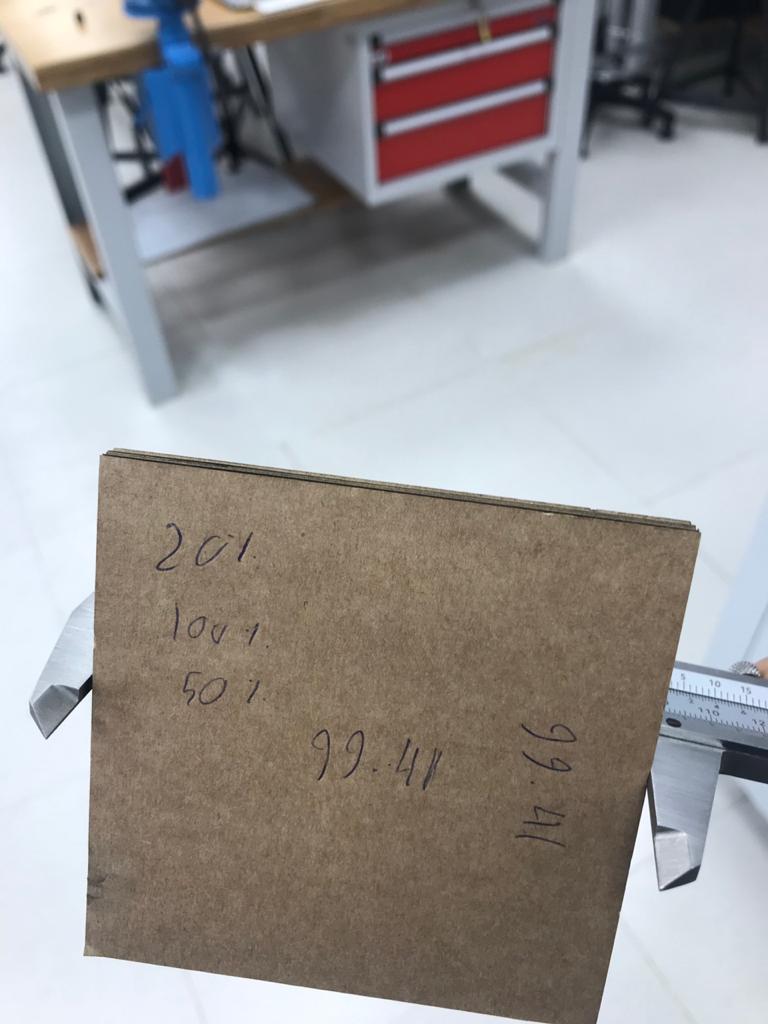

So, the first test that we did a simple dimension test by making a 10 cm square then we measured the actual size to get the kerf number. we also did a fit test, but we forgot to document it

| Speed | Power | Frequency | Actual Size | |

| sample 1 | 20% | 100% | 50% | 9.941cm |

| sample 2 | 15% | 100% | 100 | 9.964 cm |

So based on these values we calculate the kerf to be 0.18mm which is a high kerf that means we probably needed less power or less speed to cut with these settings.

Laser cutter:

Safety rules:

1. Always have at least people in the room before using the laser machine.

2. Turn on the air pump right after you turn on the machine.

2. Turn on the air pump right after you turn on the machine.

3. Make sure that the ventilation system is ready and turned on., and the turn on the filter to filter all the smoke that is coming from the pipes

3. Make sure that the ventilation system is ready and turned on., and the turn on the filter to filter all the smoke that is coming from the pipes

4. Finally make sure that the focus is on point if you do not use auto focus by calibrating the distance between the laser and the sheet.

4. Finally make sure that the focus is on point if you do not use auto focus by calibrating the distance between the laser and the sheet.

Learn about cleaning the optics on the laser on Mohammed's page ->

Learn about cleaning the optics on the laser on Mohammed's page ->

From Cicely:

Equipment we'll be using

╭─━━━━━━━━━━━━━─╮

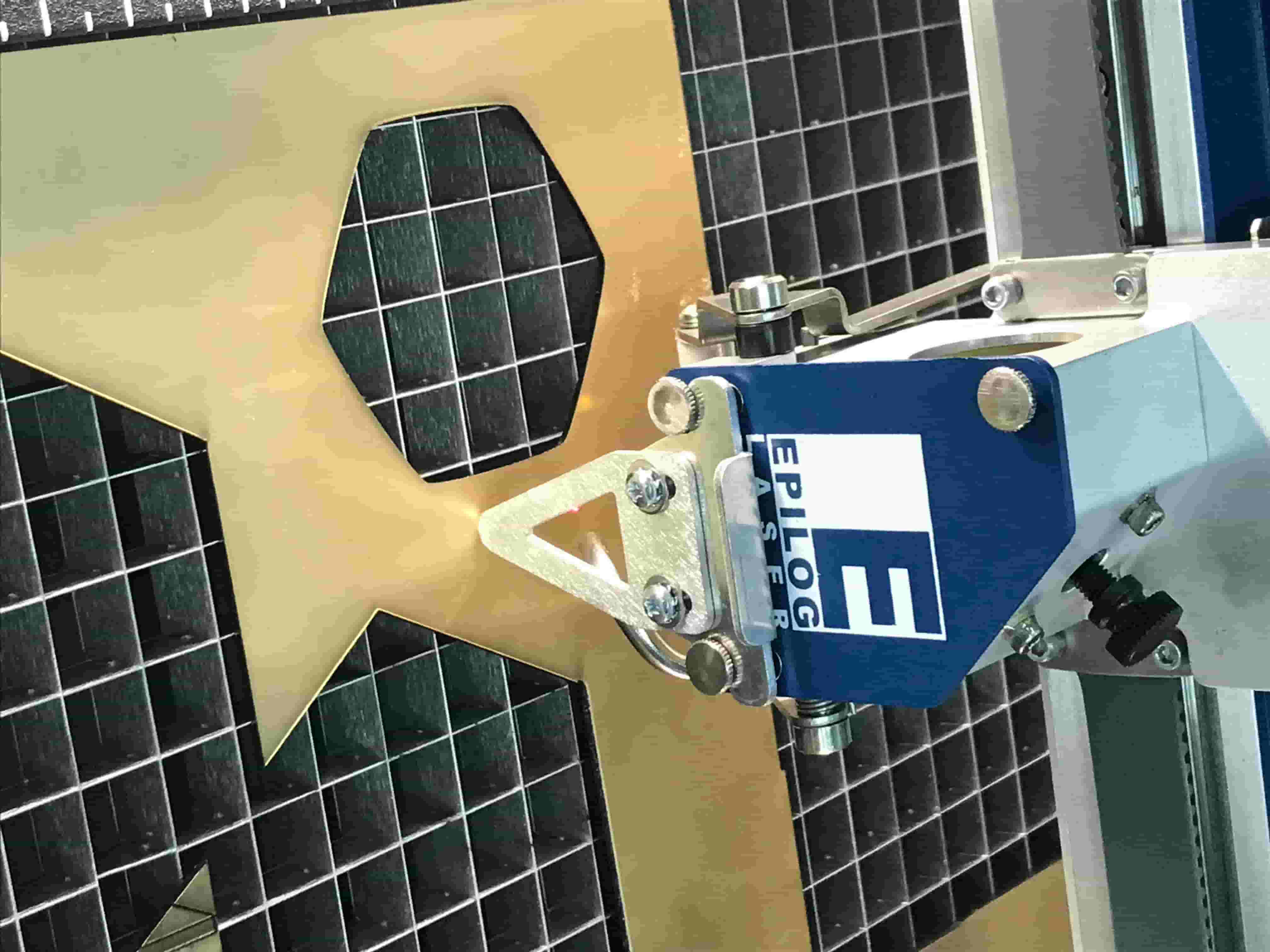

This is the laser-cutter that we'll be using in the lab. This laser cutter will be used to produce things (we've created in Fusion) from numerous materials (wood, acrylic, plastic, etc.) in order for us to further develop our projects.

We've used the laser-cutter in order to make FabLab badges for ourselves also.

The air compressor directs a stream of air to the laser-cutters surface in order to remove heat from the laser-cutter.

The air compressor mainly prevents the machine from causing a fire.

The smoker is used to collect all of the toxic chemicals/fumes emmitted from the laser-cutter when its in use.