♦ Mechanical design & machine design ♦

This week is all about make a machine.In this week we have to make a machine which work in 3 axis.For this week we did brain storming with our all instructor.There were lots of idea came into mind.We checked all posibilities ,application of each idea.After lots of discussion and search we decided to make a block printing machine.

Group assignment:-Design a machine that includes mechanism+actuation+automation.

-Build the mechanical parts and operate it manually.

-Actuate and automate your machine.

-Document the group project and your individual contribution.

So,for this week we are going to make "Ajrakh-block printing machine".The idea behind this machine is to automise cloth printing process.Because in traditional method they do block printing manually.It takes lots of time so by considering all these factor ,we decided to make this machine.

For this assignment we have 5 members as one team.We divided all work in each member.Due to covid-19 our two members shreyas and nikhil are not present in lab.So we decided to give task to them as they complete from home only.Me and vikram working on electronics.Tejswini will work on design and shreyas will work on coding .Nikhil will work on documentation part.As me ,vikram and tejswini prsenet in lab ,so we will do assembly together.

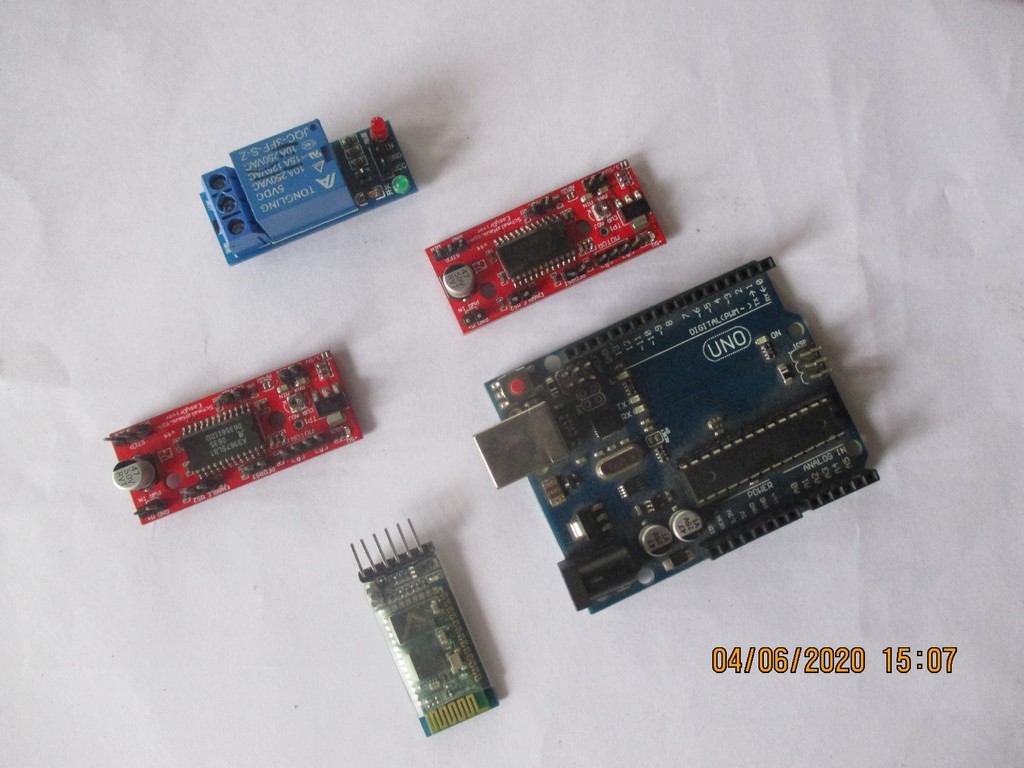

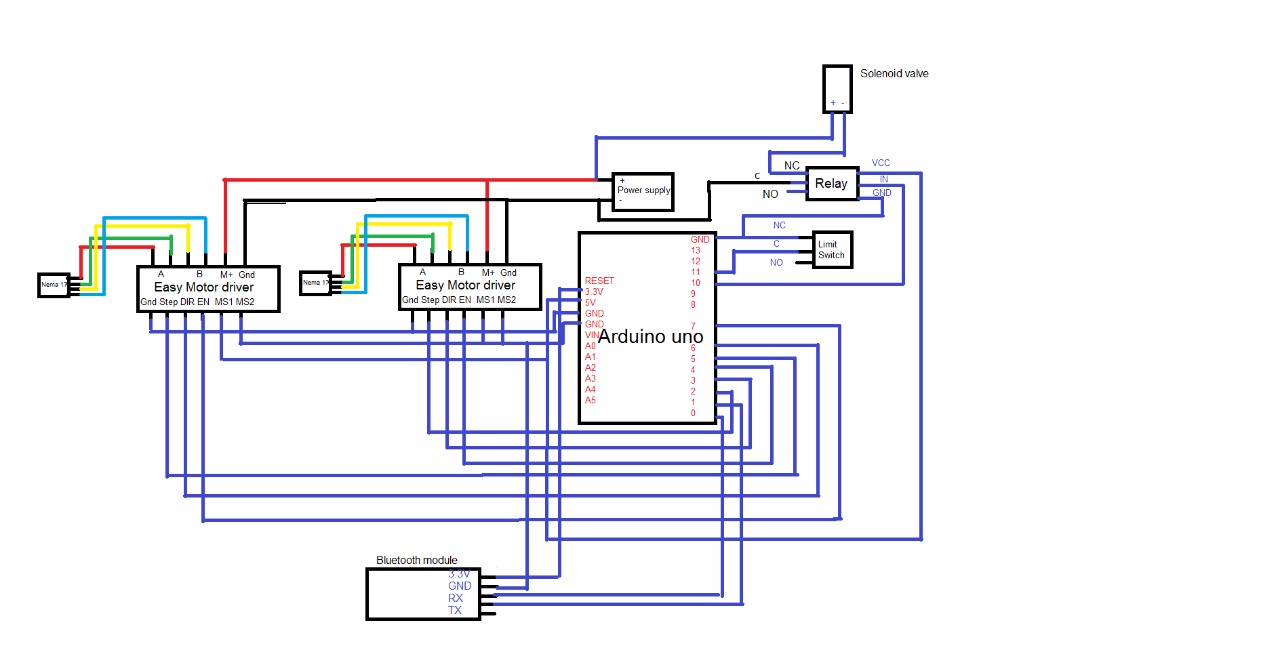

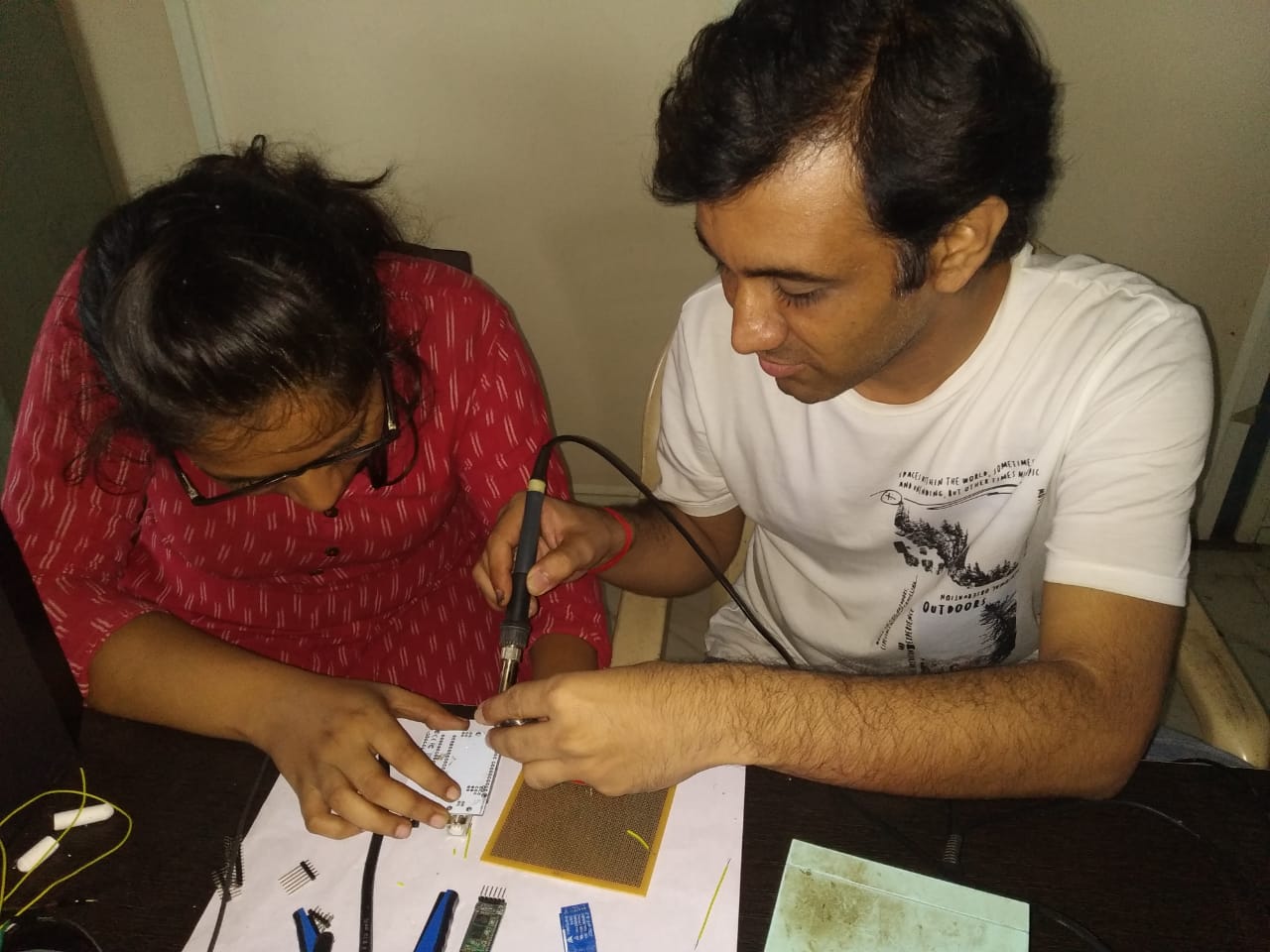

I worked on electronics part ,in that we have used arduino board.For switching we used relay.And for end effector we used solenoid.We are going to make App so this app will operate using bluetooth module.I have tested nema17 motor using easydriver.Also we have tested solenoid using relay.

Me and vikram made block diagram of electronic circuit.

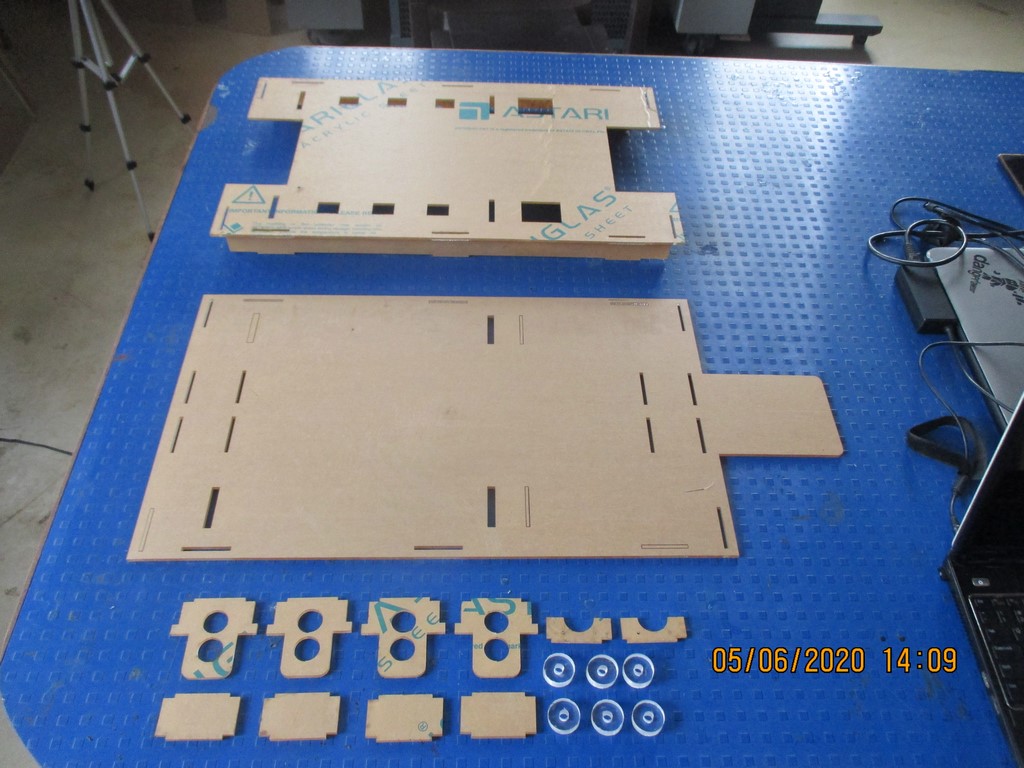

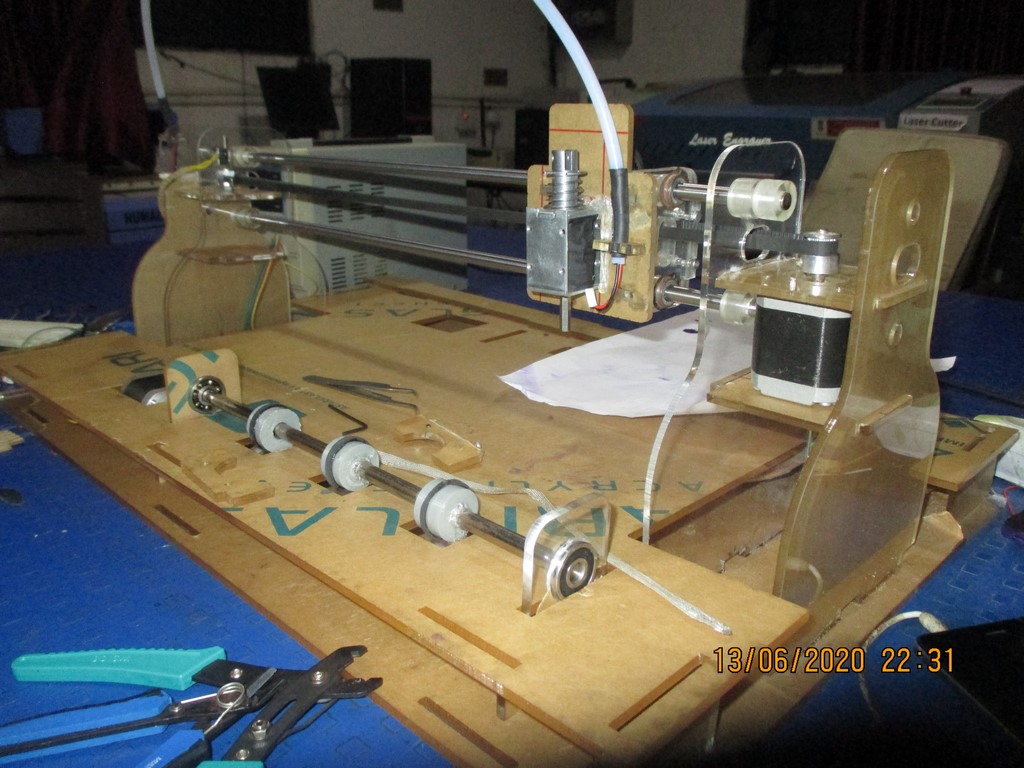

Apart from this I did laser cutting and 3D printing.All designs made by tejswini .So we all did all task.Becuase only three of us are present in lab.First we tried all design part on cardboard.We assembled all parts.

These all are laser cutted parts,which required for our machine assembly.

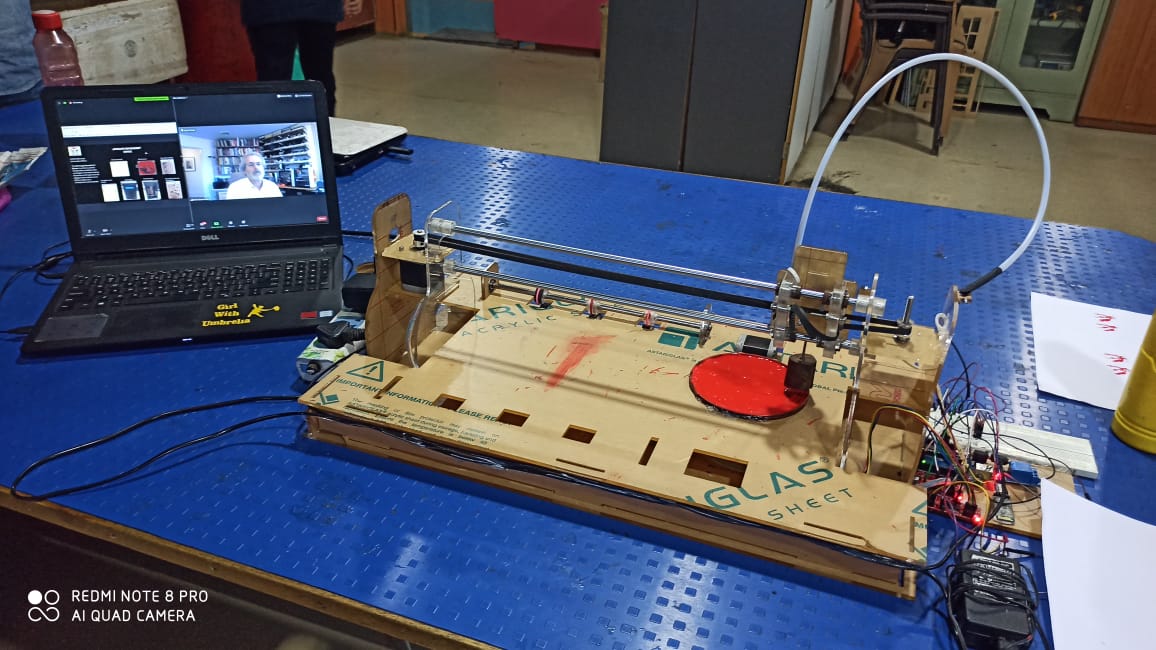

After lots of trials and efforts finally we assembled our machine.

Me and vikram soldered all circuit and tested it.

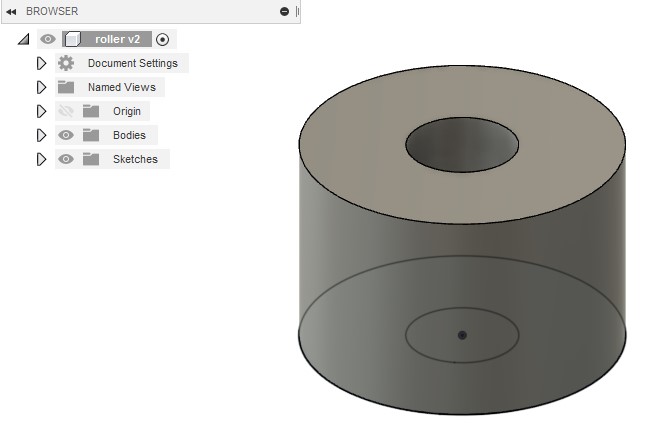

Also I have designed roller for our roller mechanism. I have designed in fusion 360.

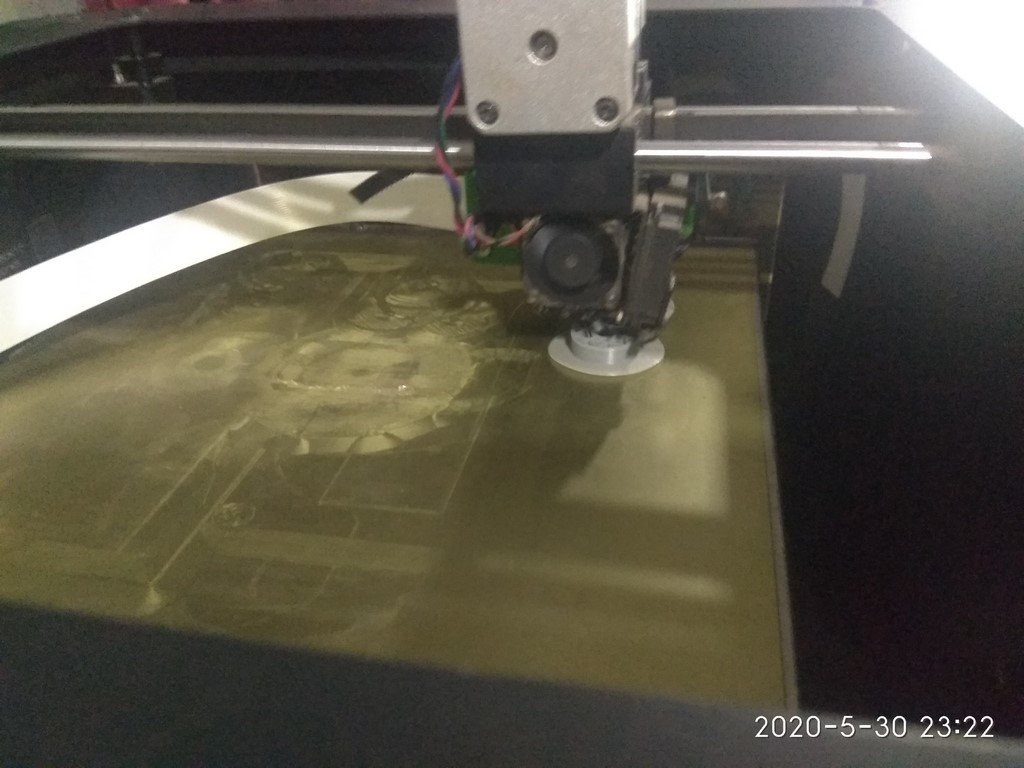

File given to printer.

This is final 3D printed object.

I have given design file of this roller.

After completion of whole assembly and electronics part,we have taken trial using our mobile app.It works perfectly.

This is our end effector.It is our block which will print on cloth in number of iterations.

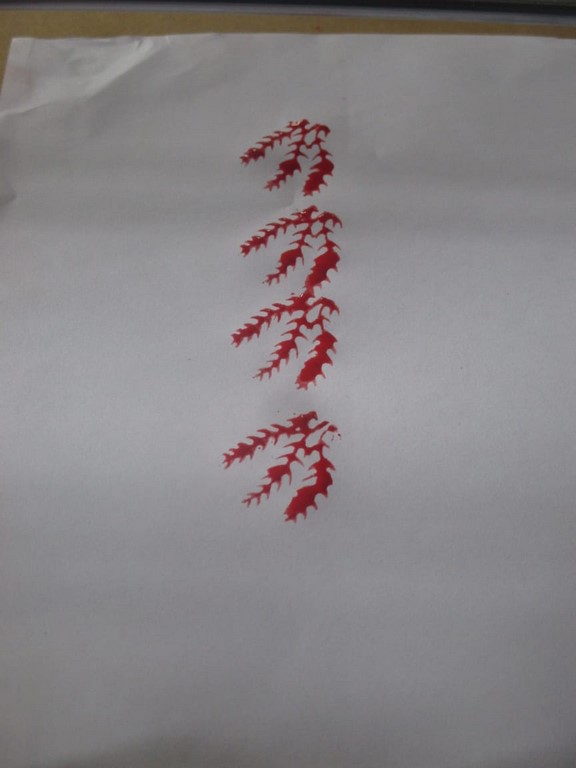

This is our final output printed on cloth.

We never made such machine before.It was challenge for us to make a machine in one week.We all worked very hard to make it successful .We worked day and night .It was wonderful experience for me.

The whole documentation of machine available on group page.I am giving link of group page here.

All design files ,coding files are available on group page.

I am giving here bill of material and downloadable file.

Learning Outcome:

In this week I learned many of things like how to make XY plotter.How machine can be build?What are the consideration should take during making of machine?Also I learned how to work in team. After lots of efforts ,when your machine works properly ,it feels very happy.