Week_5 - 3D Scanning and Printing

Assigment

- group assignment:

- test the design rules for your 3D printer(s)

- individual assignment:

- design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively

- 3D scan an object (and optionally print it)

Group Assignment

On this week group assignment we explore the design rules for your 3D printer(s)In fablab we have two types of printers: FDM and SLA. In the description below I will describe the operation and design principles under Zortrax M200, Formlabs 1+ and MAKERBOT. For testing I used a file made available to ctrV on thingivers.

Zortrax M200

Zortrax is a Polish company that is very well known in the market

for creating armoured printers that may not print the most

beautifully but print almost always, and if they do not print

it is your fault. Over the years these printers have had a very

closed infrastructure, so only the manufacturer's materials could

be used and the software was very limited. At the moment, after

many consultations with users, it is possible to print from any

material to save presets and turn off the raft (which can only be

useful for quick test prints at a perforated table).

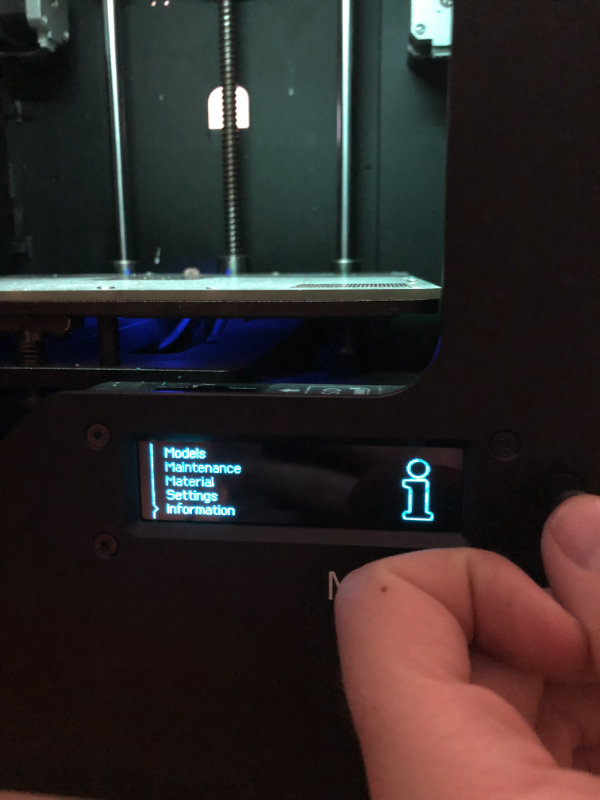

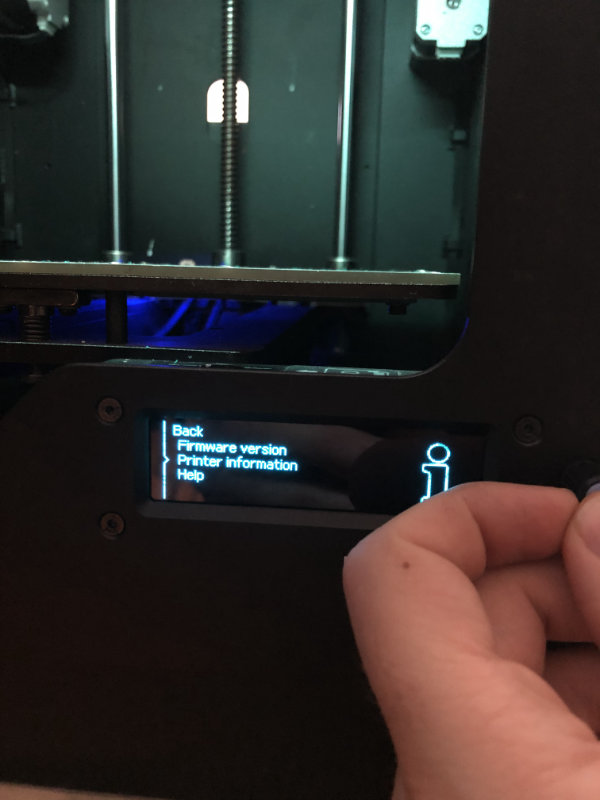

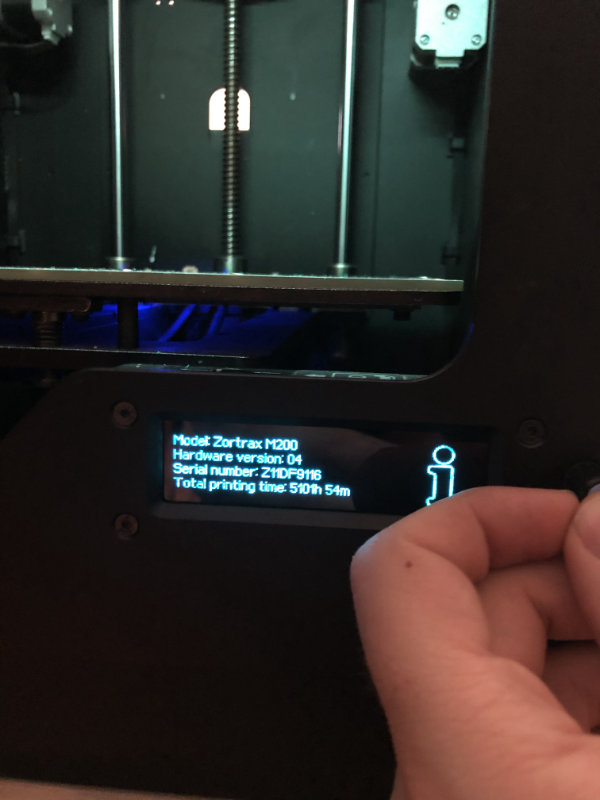

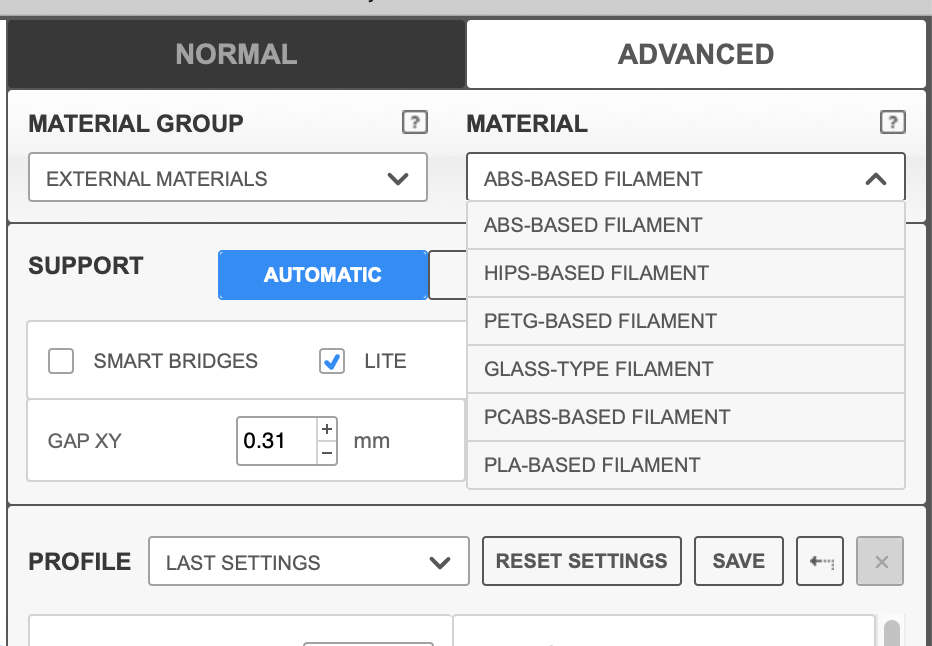

On the manufacturer's website there is a program for Zortrax,

called Z-Suit ,

which is on Win and Mac. For installation we will

need a serial number, which is on each printer in

Information=>Printer Information (uff this printer has

been running for over 5k hours and still works great).

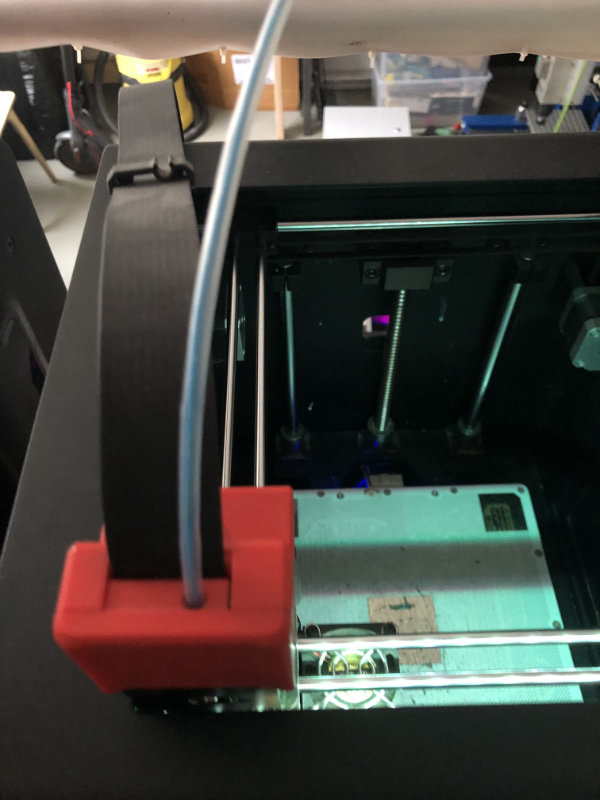

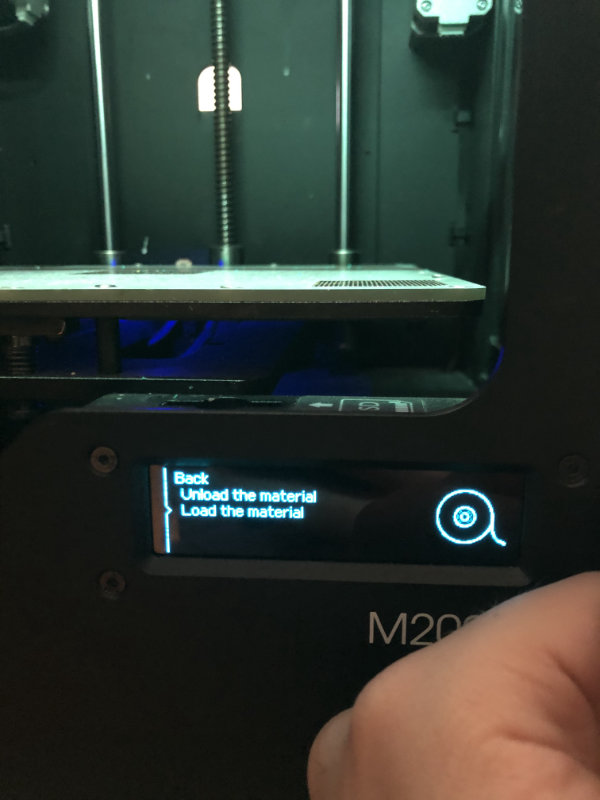

Changing filaments

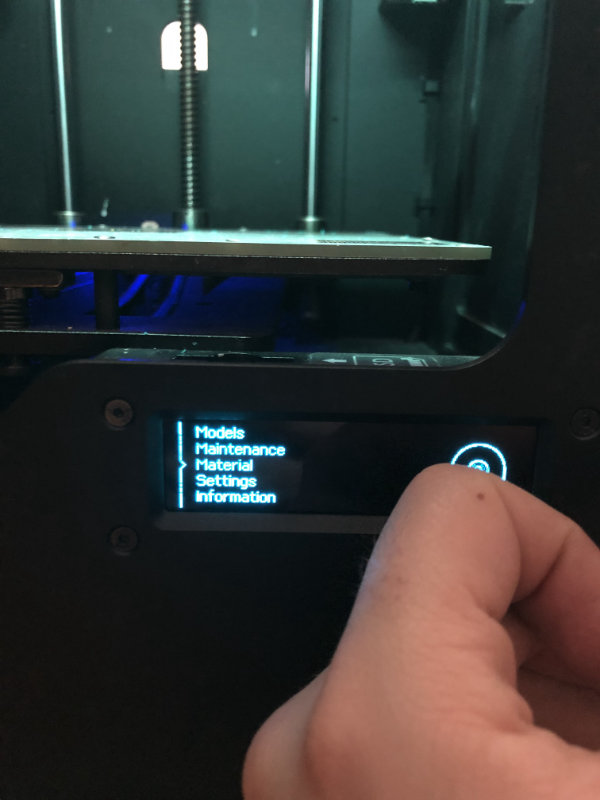

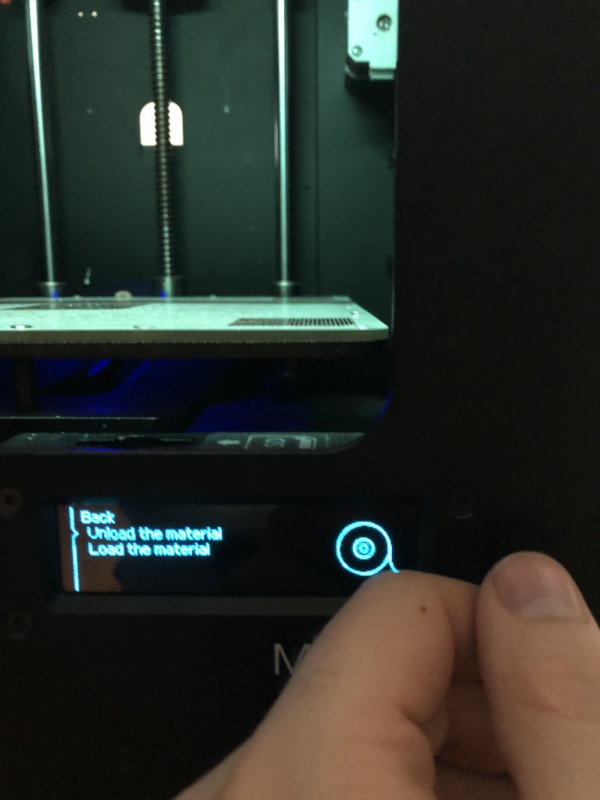

Once we install the Z-suit we change to our material and release the print.Change the material: Material=>unload the material

wait for the nozzle to warm up, remove the filament and cut off the tip distorted by the filament drive gear.

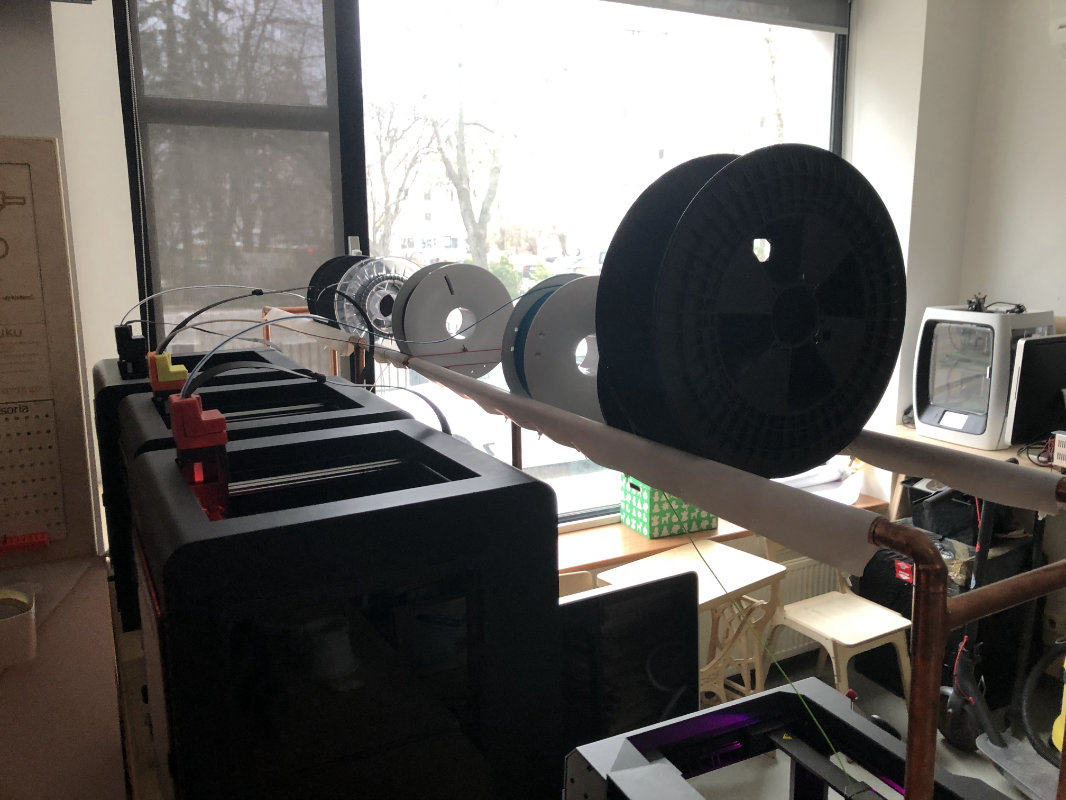

Place a new spool on the rack pillar whose copper pipes are covered with Teflon (thanks to which the spools rotate freely).

Insert the filament into the input hole of the extruder

and in the printer menu select Material=>load the material

we gently press the filament to enter between the drive gear and the guide bearing.

After inserting the material, clean the nozzle with tweezers and remove the spilled filament.

Calibrating zortrax is and easy task (you can say semi automatic) and there is very nice tutorial on company website, i recommend to familiarize yourself with it.

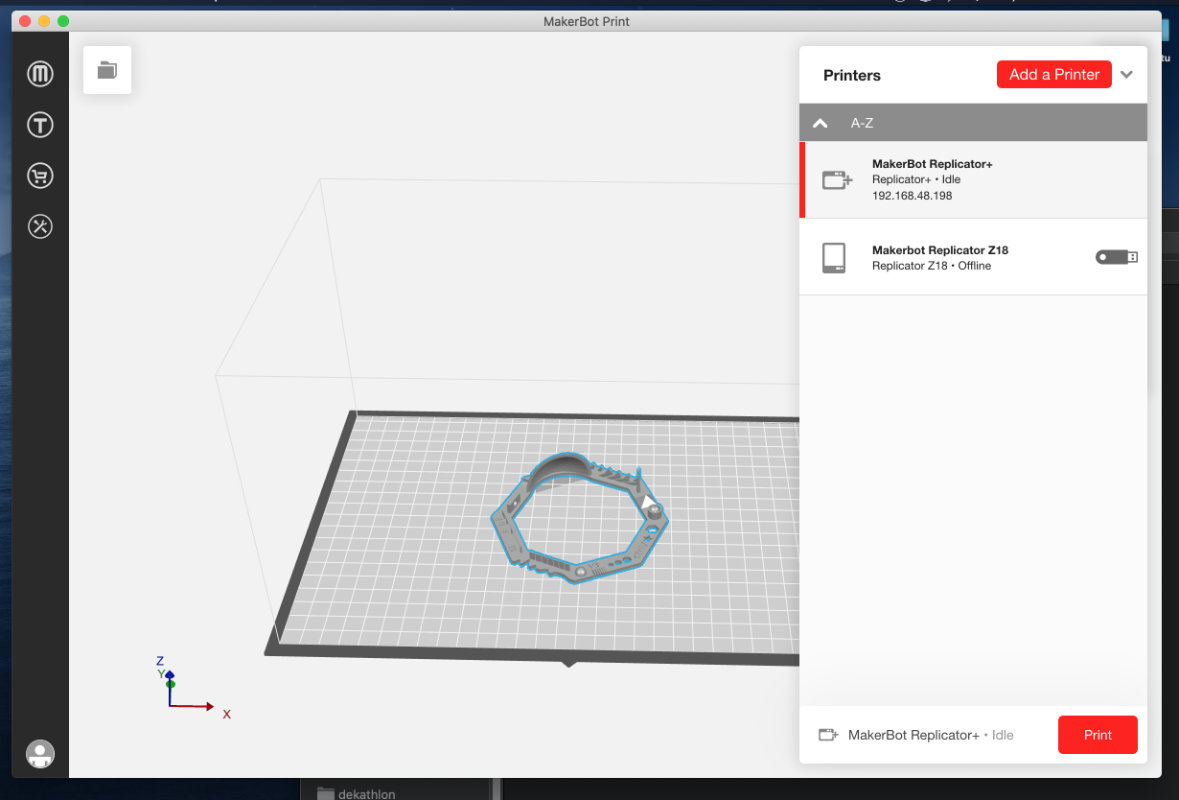

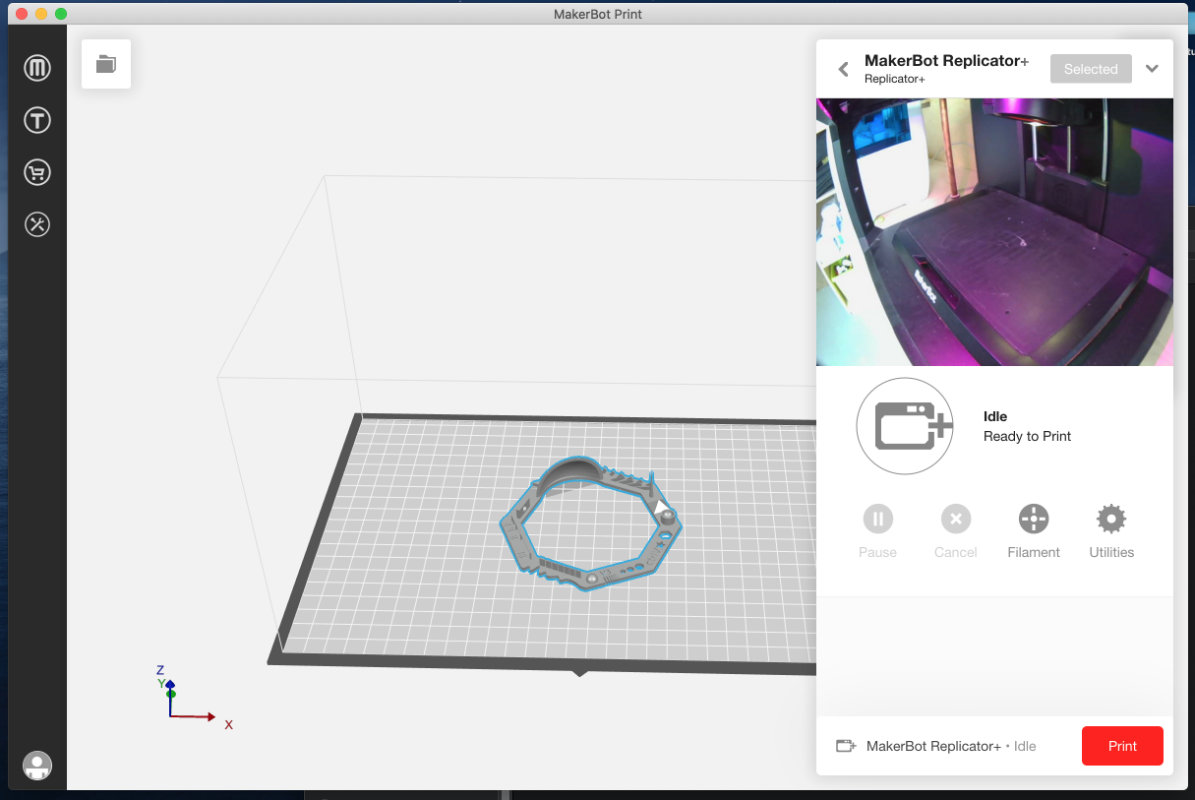

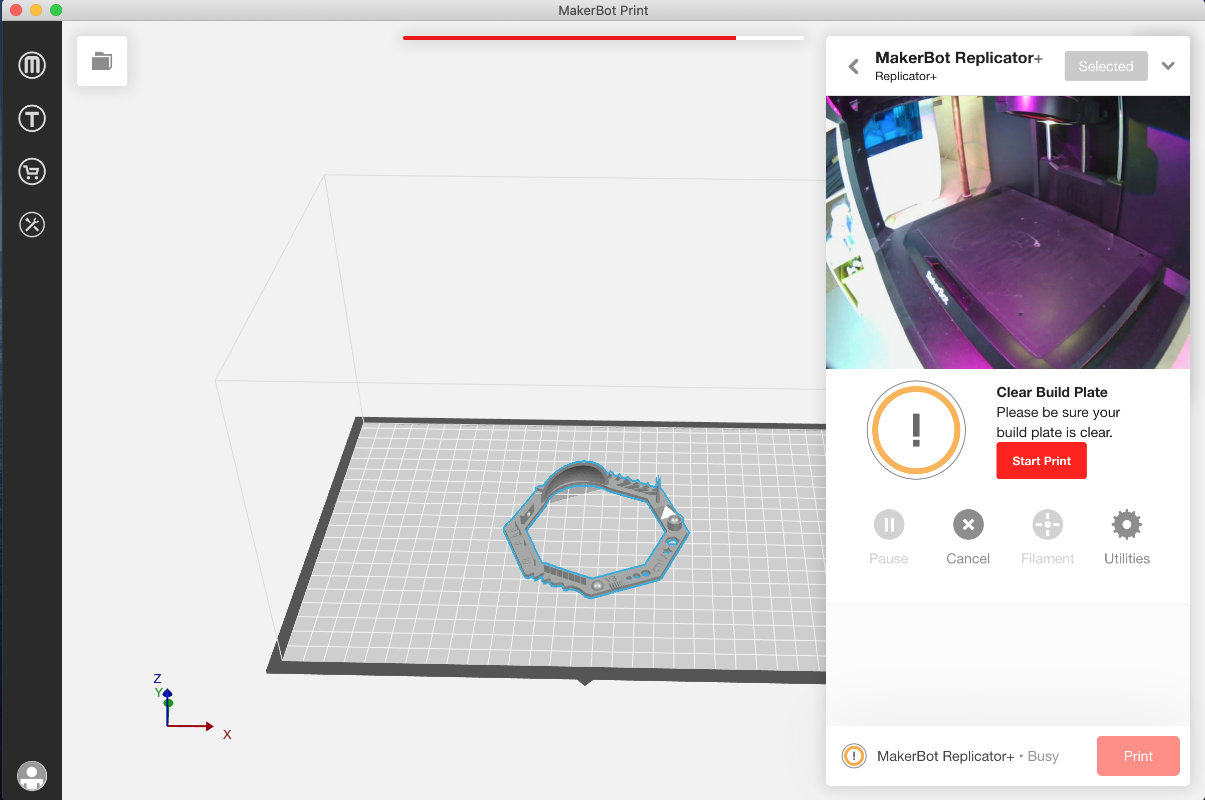

Makerbot Replicator+

Work area: 295 x 195 x 165 mm

Materials: PLA, TOUGH PLA

Software: MakerBot Print,

Layer height: 100-200-300 microns

Dimensions: 528 x 441 x 410 mm

Weight: 18.3 kg

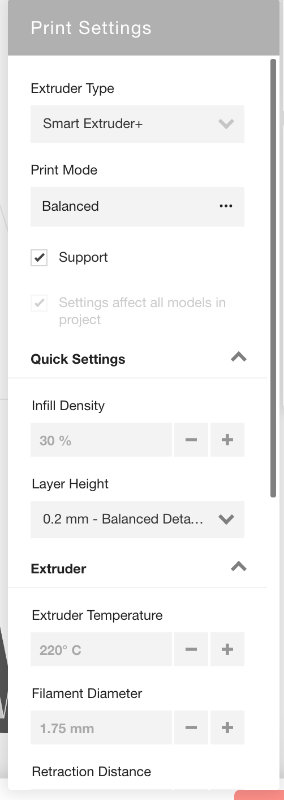

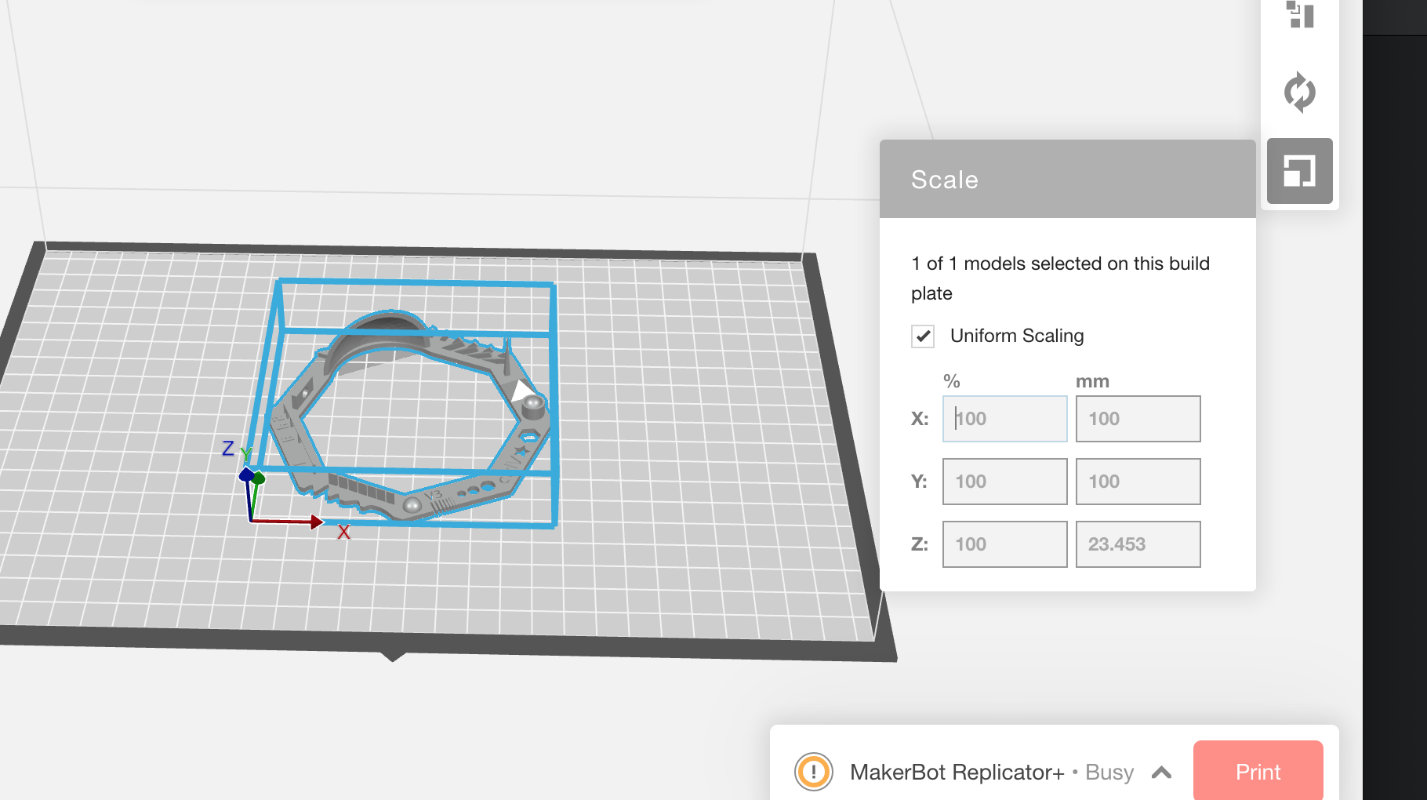

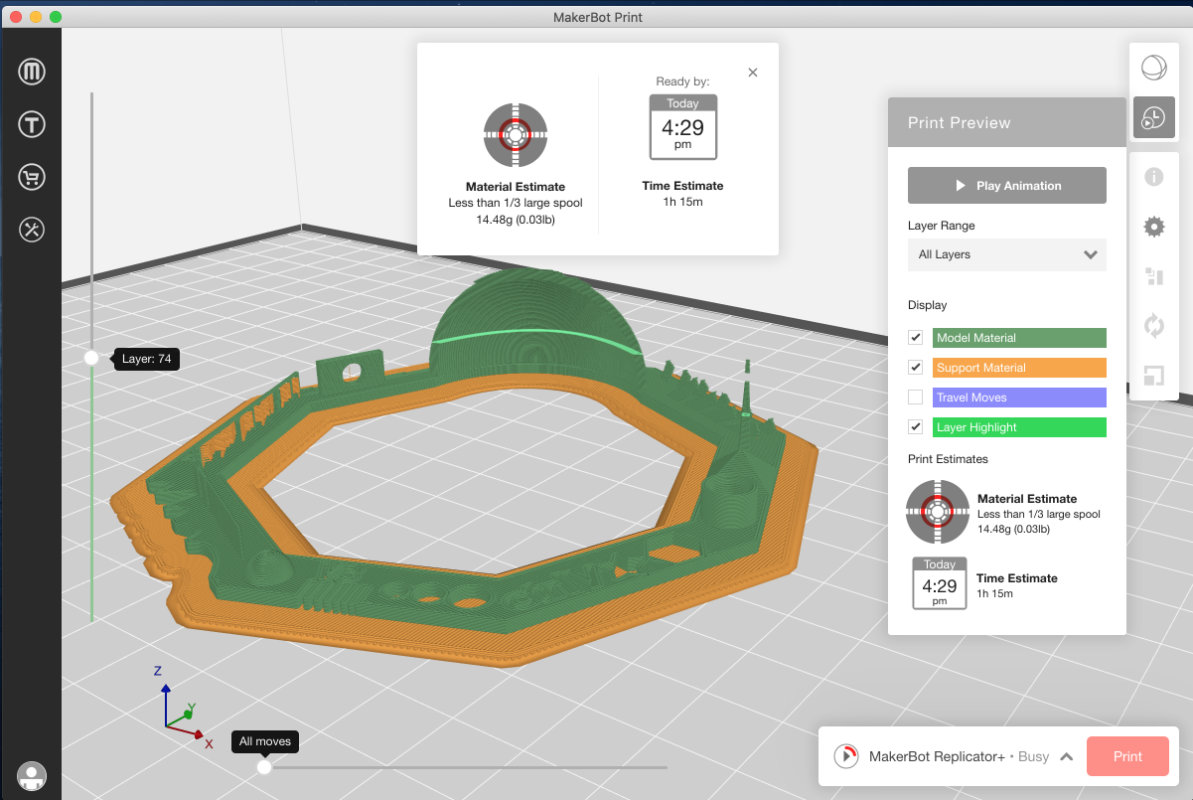

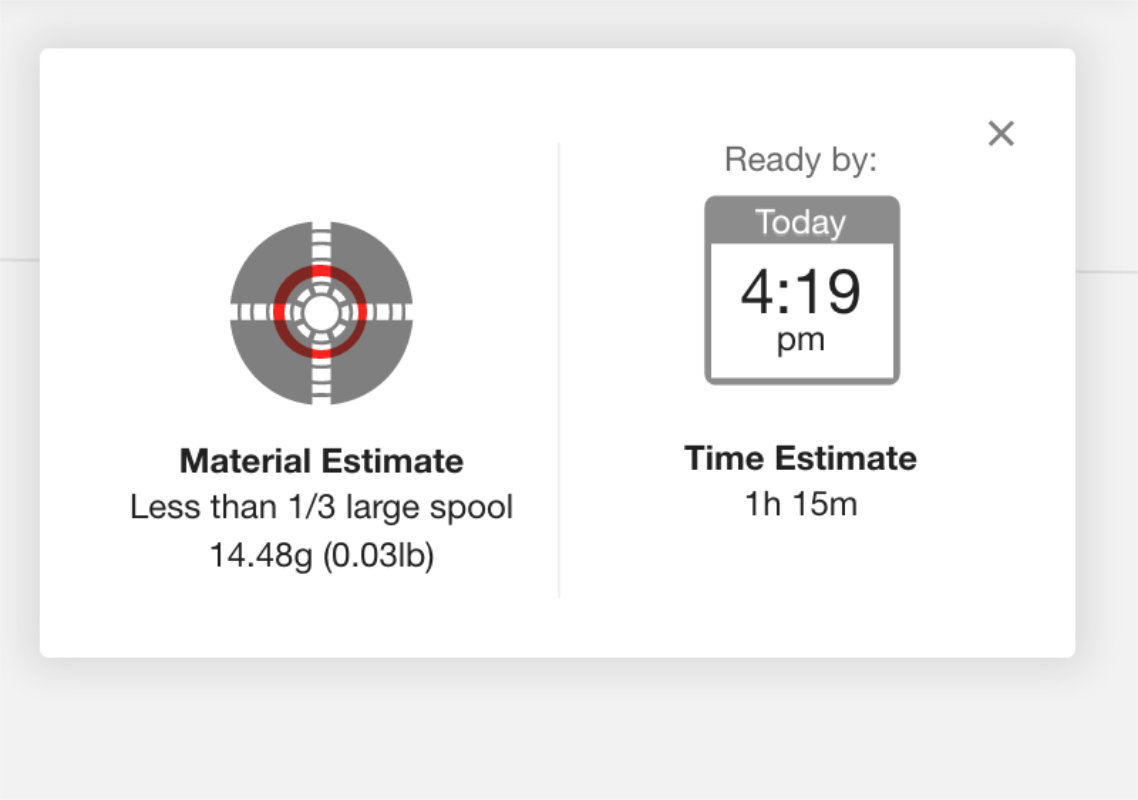

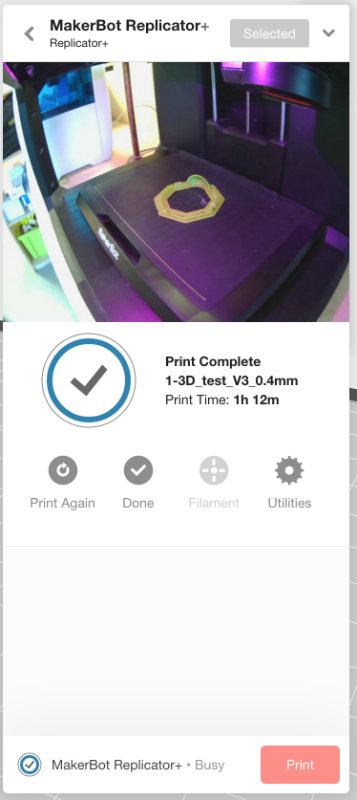

Operating the slicer for this printer is trivially simple,

but unfortunately it also has its limitations due to the

few options available to users and the simplest options

such as print settings are hidden.

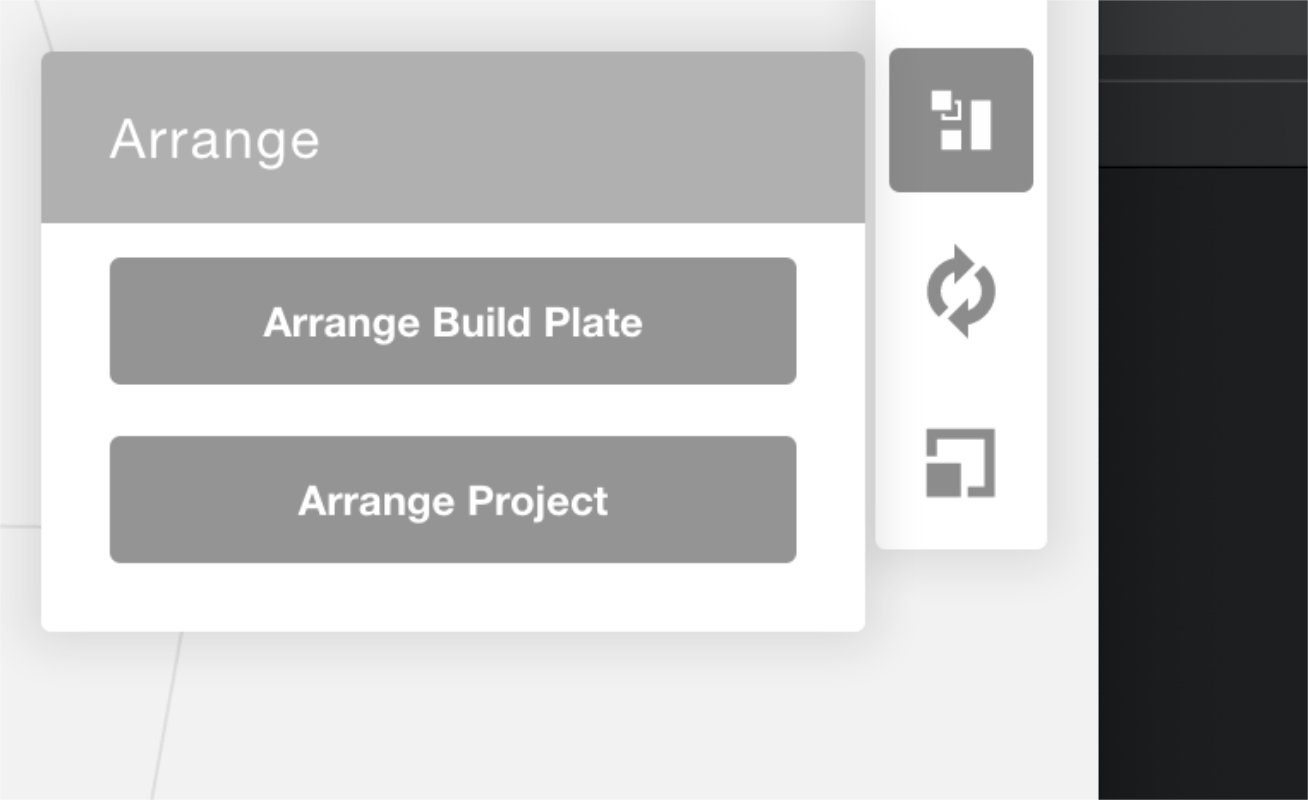

Select a file and upload it by drag and drop or choose from import.

Choose a printer from the network (after the ip address)

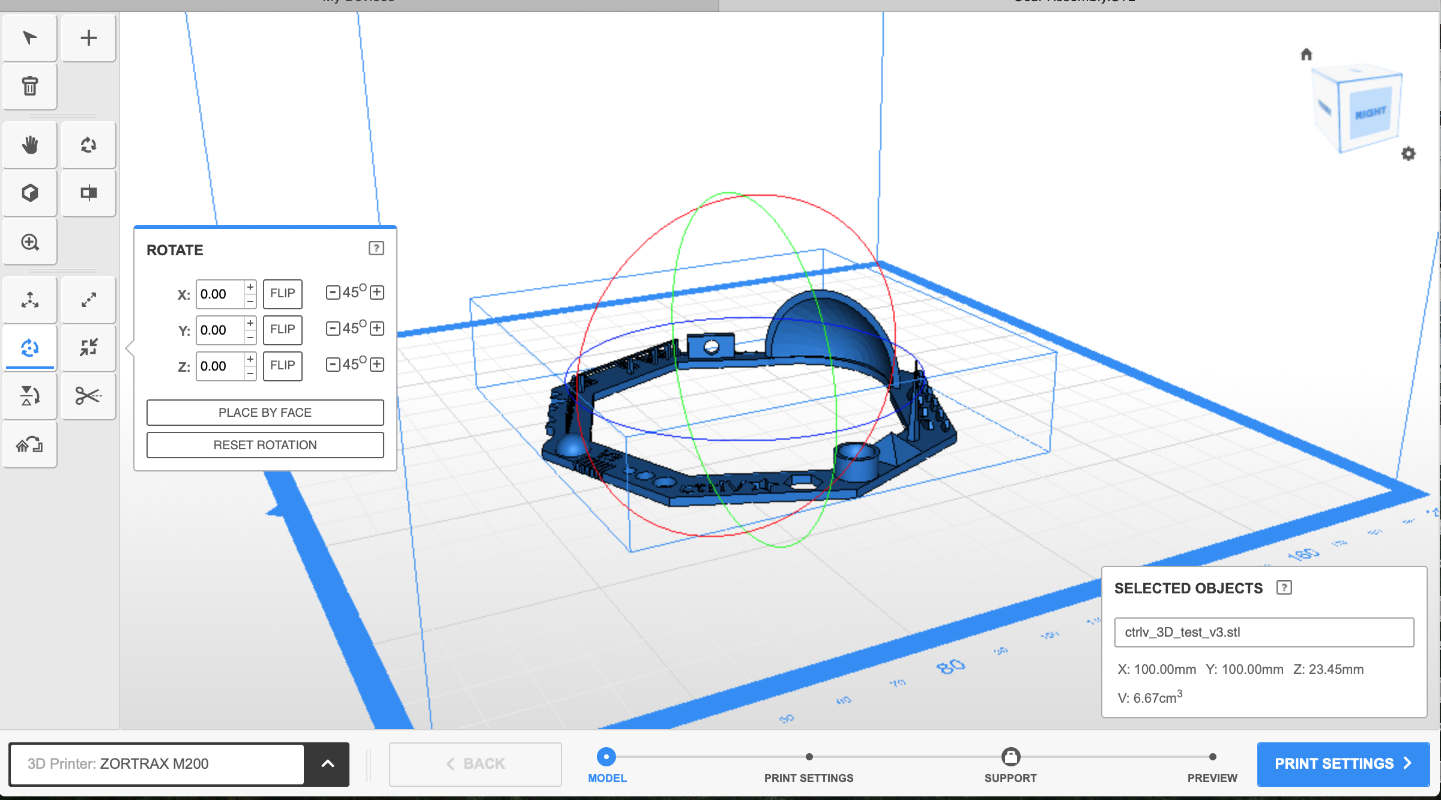

Preparing files with the example of Z-suit

Most of the Slicer works very similarly, it is enough that we know the basic

functions and naming and we can print on practically any printer, so before

I take a look at the detailed operation z-suit will describe some important settings.

Model positioning

A very important option depends on how long the object will

print and in which plane it will be stronger and more resistant to

particular stresses. More info here

For FDM, the top surface is smoothed by the extrusion

tip, the surface in contact with the print bed will

usually be glossy and the surfaces above support structures will have support marks.

Material types:

Basic materials used in our Fablab

PLA

ABS

HIPS

PETG

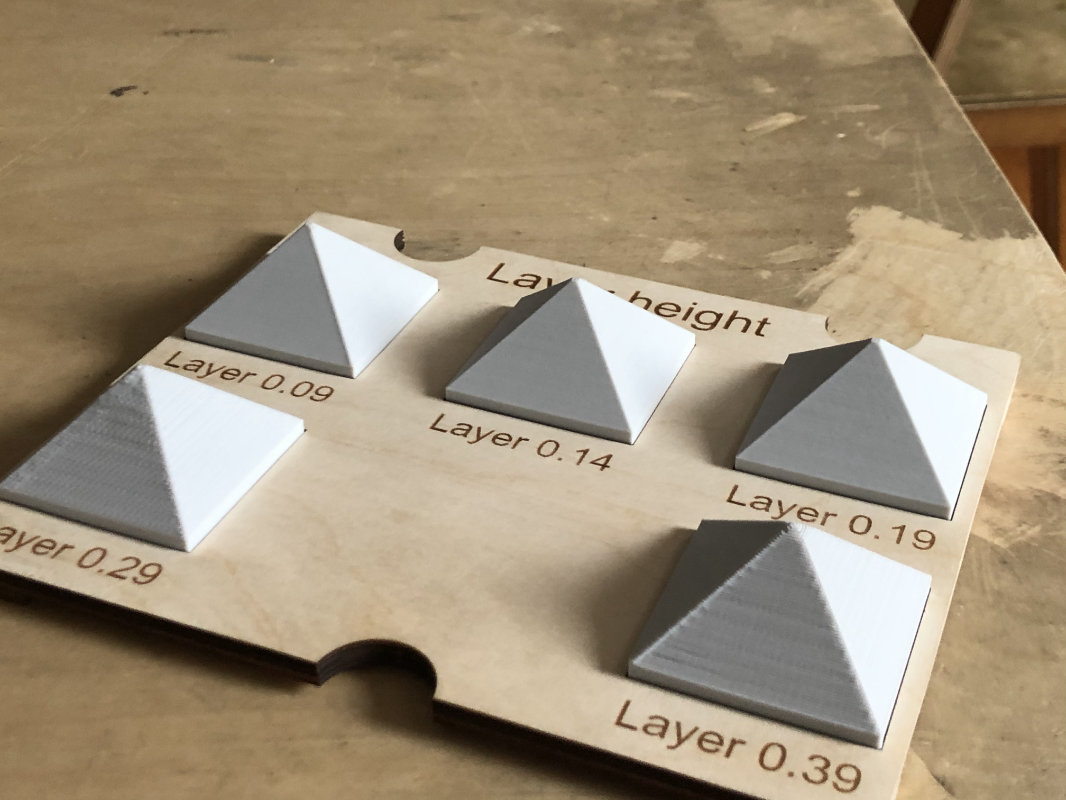

Layer height:

The quality in the Z-axis depends on the height of the layer.

It has been assumed that layers from 0.29 mm upwards can be easily

set for prototypes and models without much detail. Thanks to the high

layer height we can quickly have the object for testing and further

modifications. In addition, the printout can always be post-processed

and the ideal surface can be obtained. For more detailed prints we use

smaller values up to 0.6mm on FDM printers.

Unfortunately, a low layer extends our waiting time for the final product,

so it is always worth considering why we will need a printout. Below is a

picture of a board with sample layers and printing times on zortrax m200.

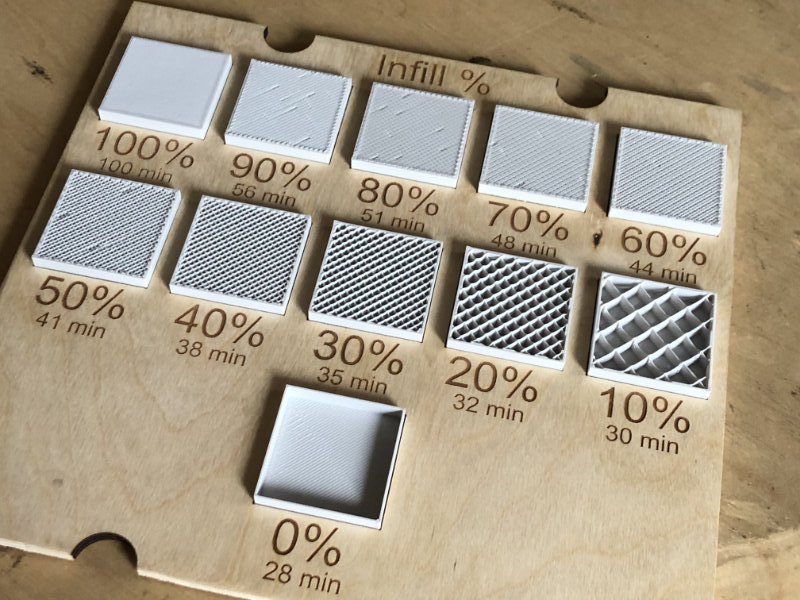

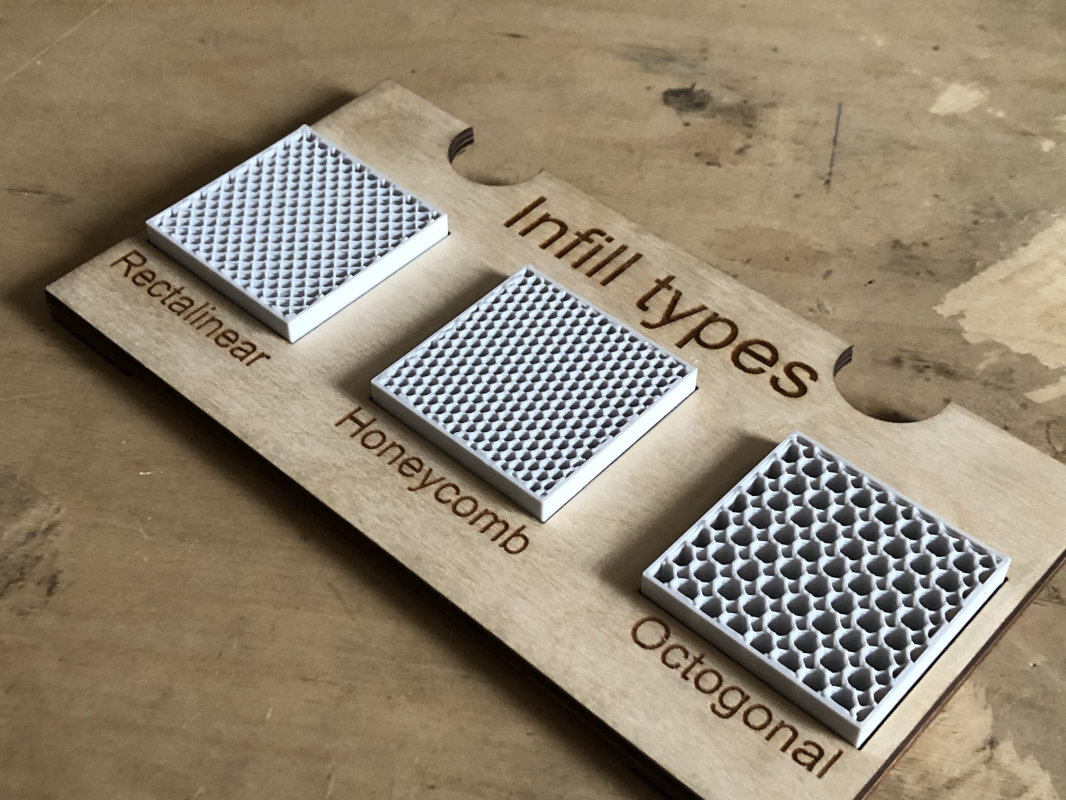

Infill:

Infill, i.e. percentage filling of the object. You might think that the

bigger the filling the stronger and stronger the print. Fortunately,

this is not the most optimal infill for commercial objects ranging

from 15-25%, and the stronger the printout is 40%.

But why not 100%?

Large fully filled objects are more fragile

fully filled objects are susceptible to cracking and shrinkage of the material

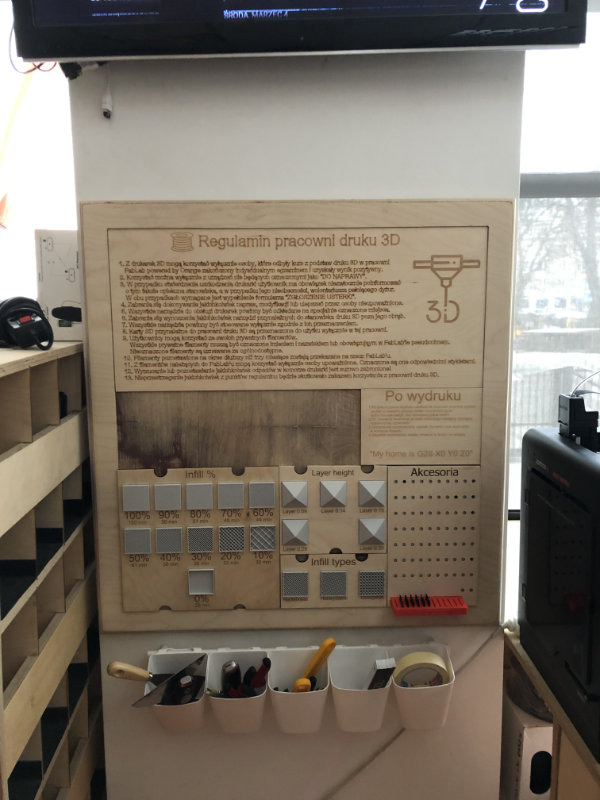

3D printing rules in our fablab

Before printing

During printing

After printing

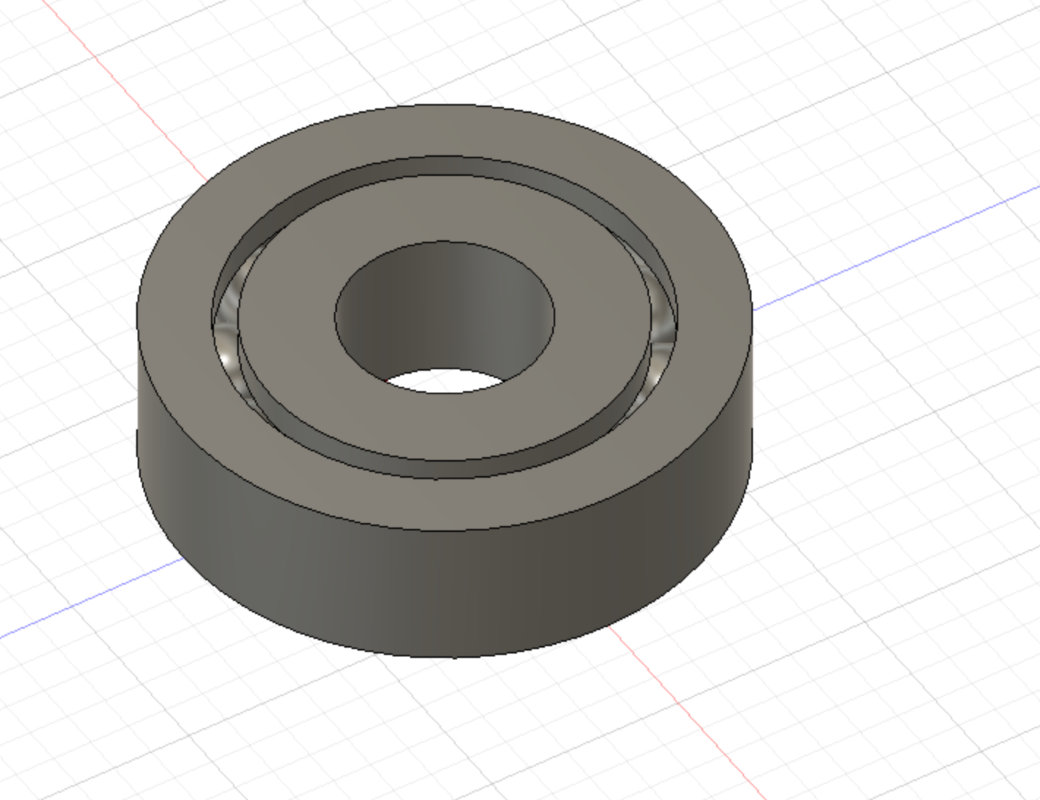

CAD-designing a part not possible with subtracting processes

I had a little difficulty in choosing the things I would like to design...

the problem was time and a multitude of options:)

More and more projects can be seen on the Internet

that use the incredible add-on systems, i.e. ship in bottle syndrome.

How did it get there? Did someone tweezers piece by piece build it in a bottle?

In Sum, by means of 3d printing, it could happen that the bottle was created on a

par with the ship and the dilemma of what was the first egg or hen falling out...

hmmm or maybe space engineers printed the hen and the egg at the same time?!

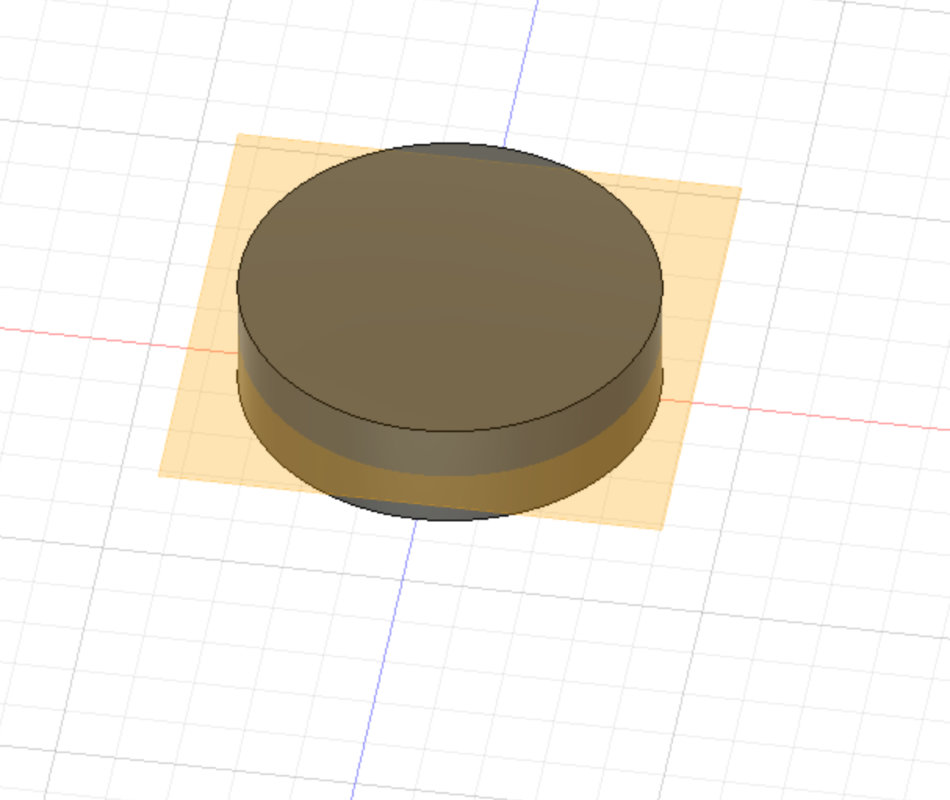

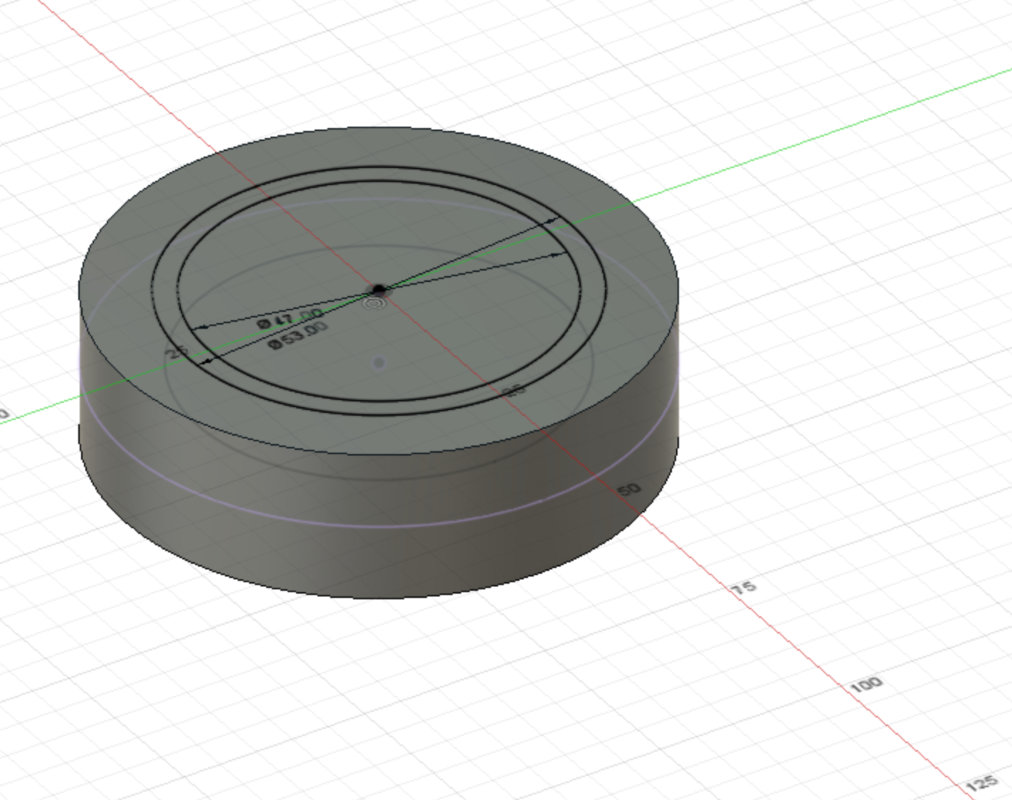

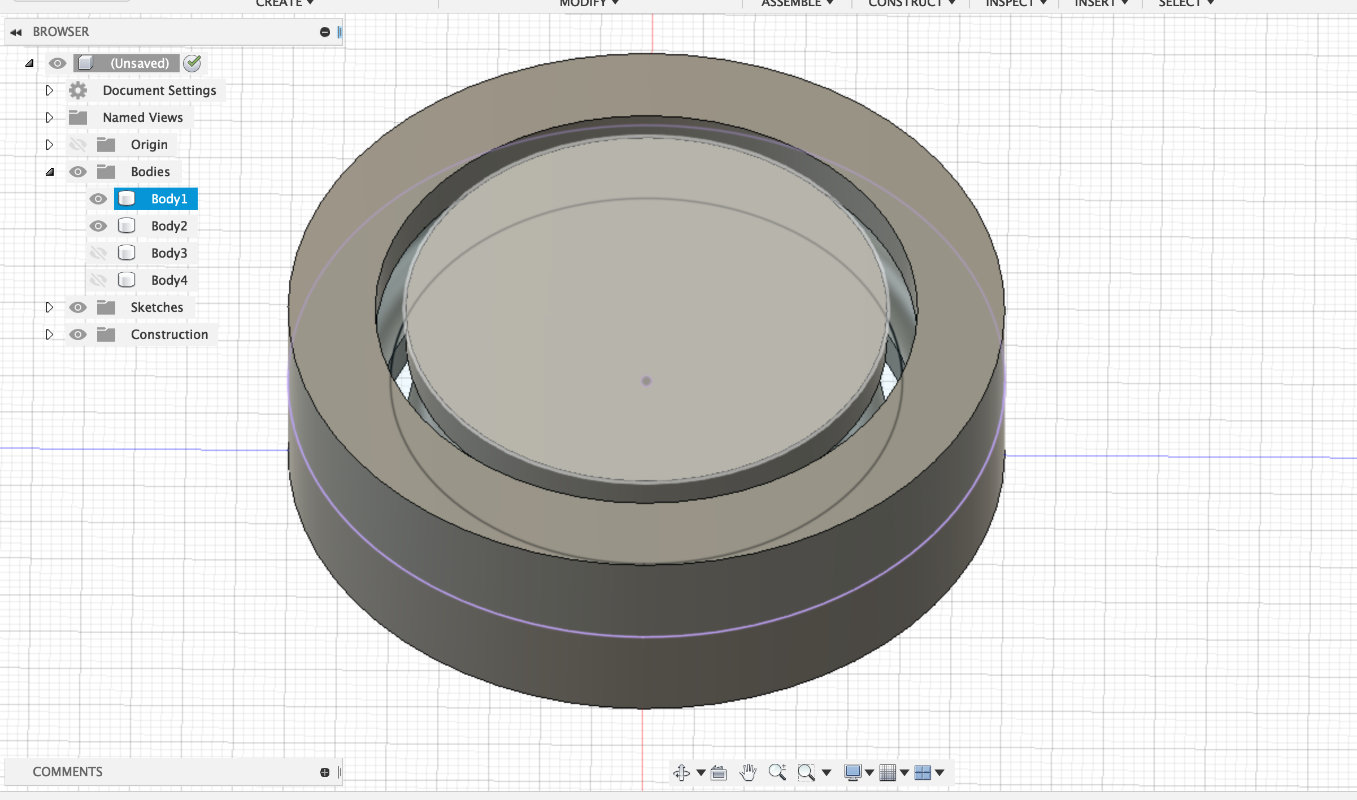

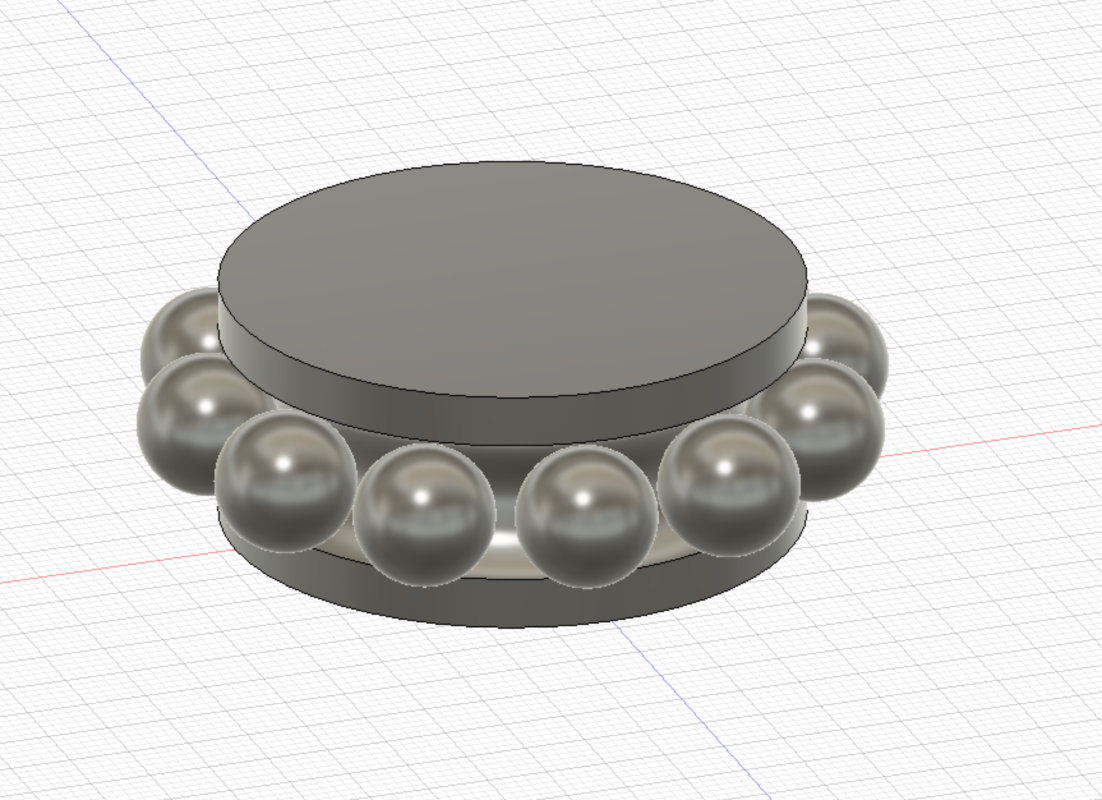

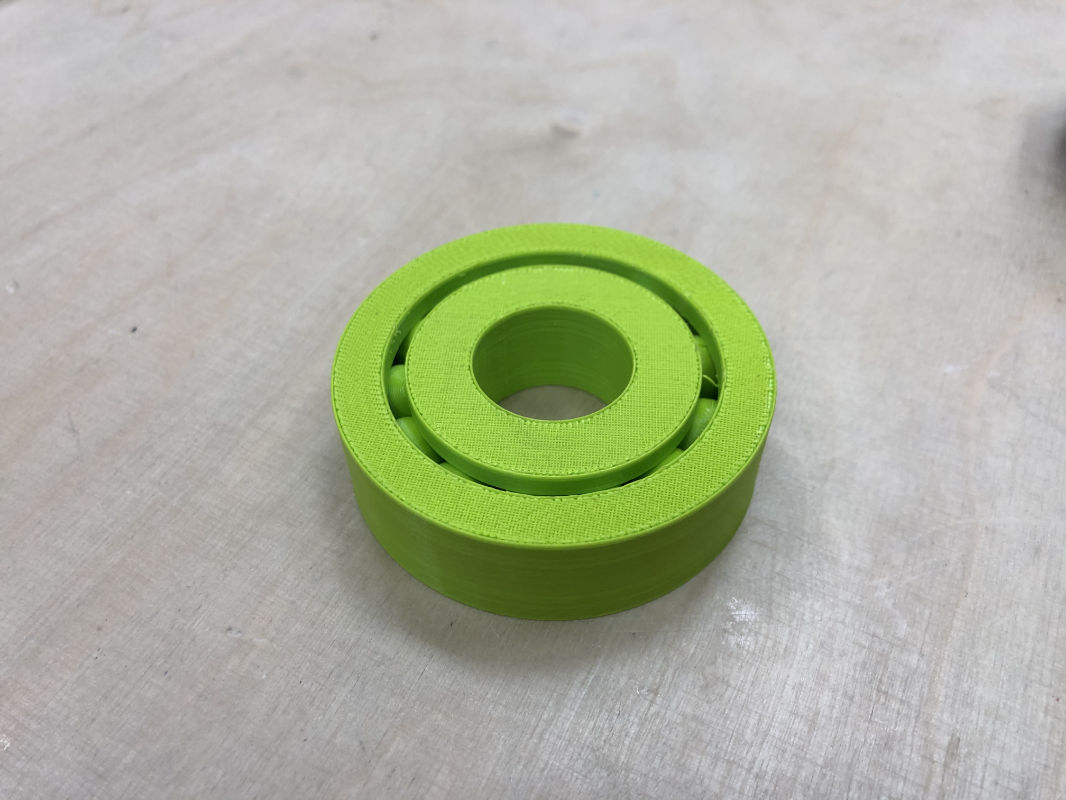

It was quite a simple thing, I'm sure I'll come back to it, the bearing!

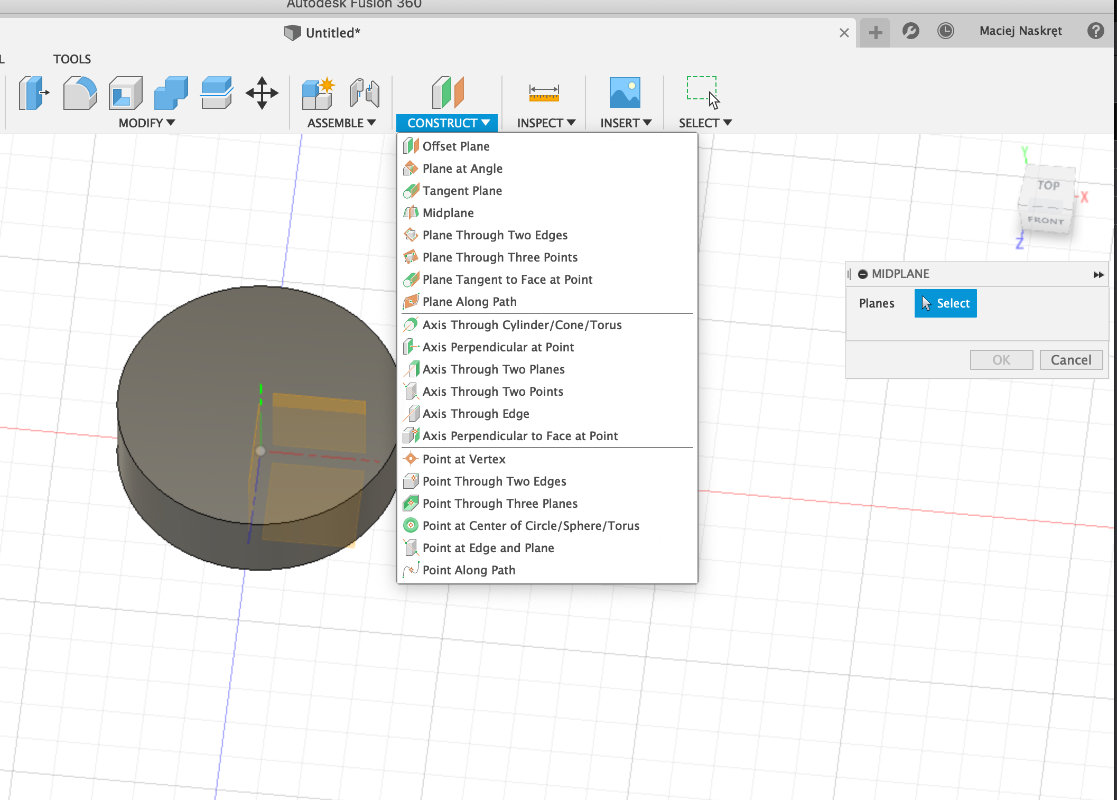

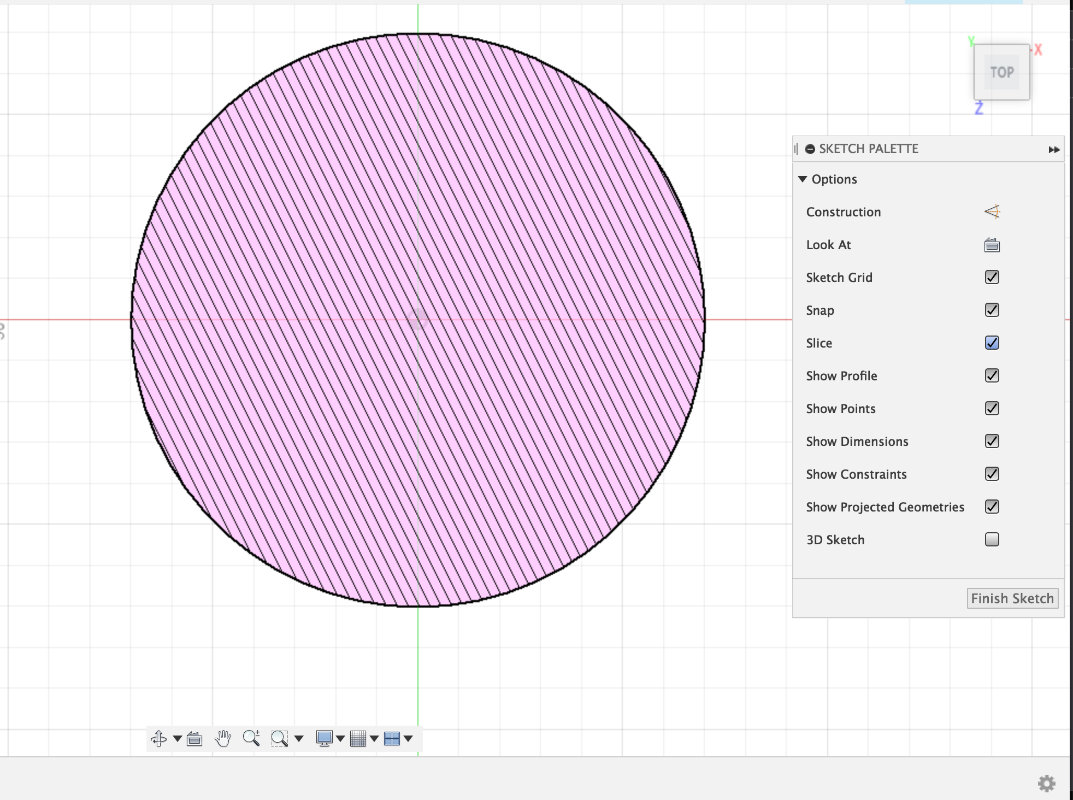

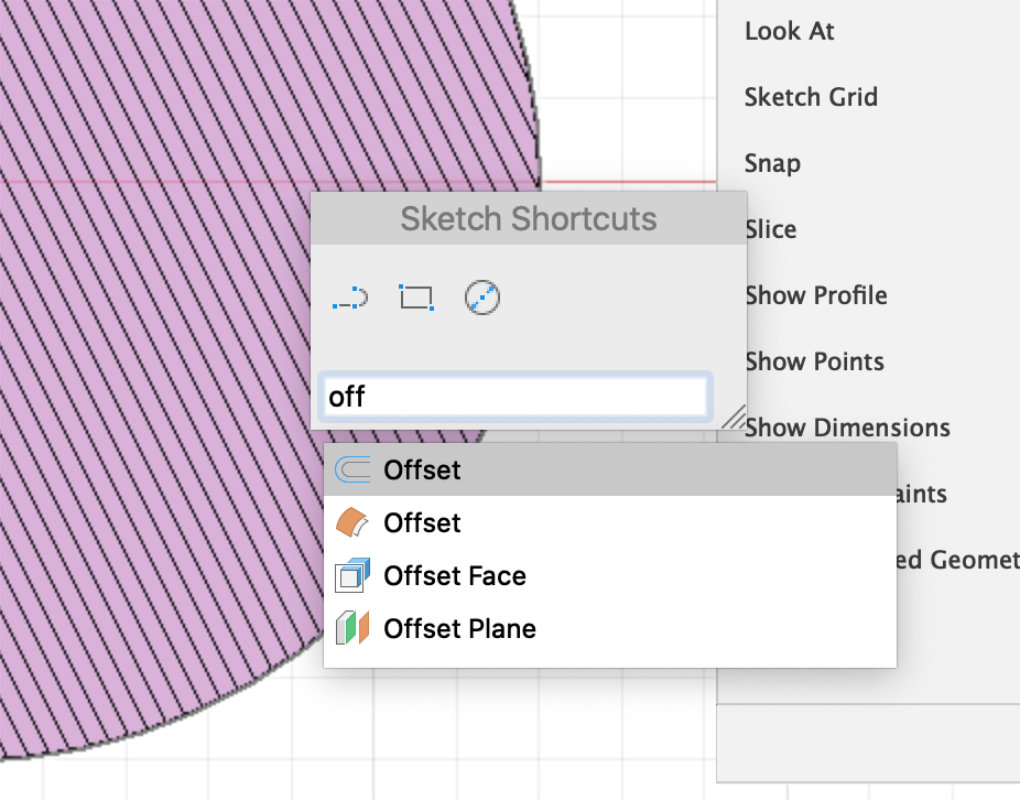

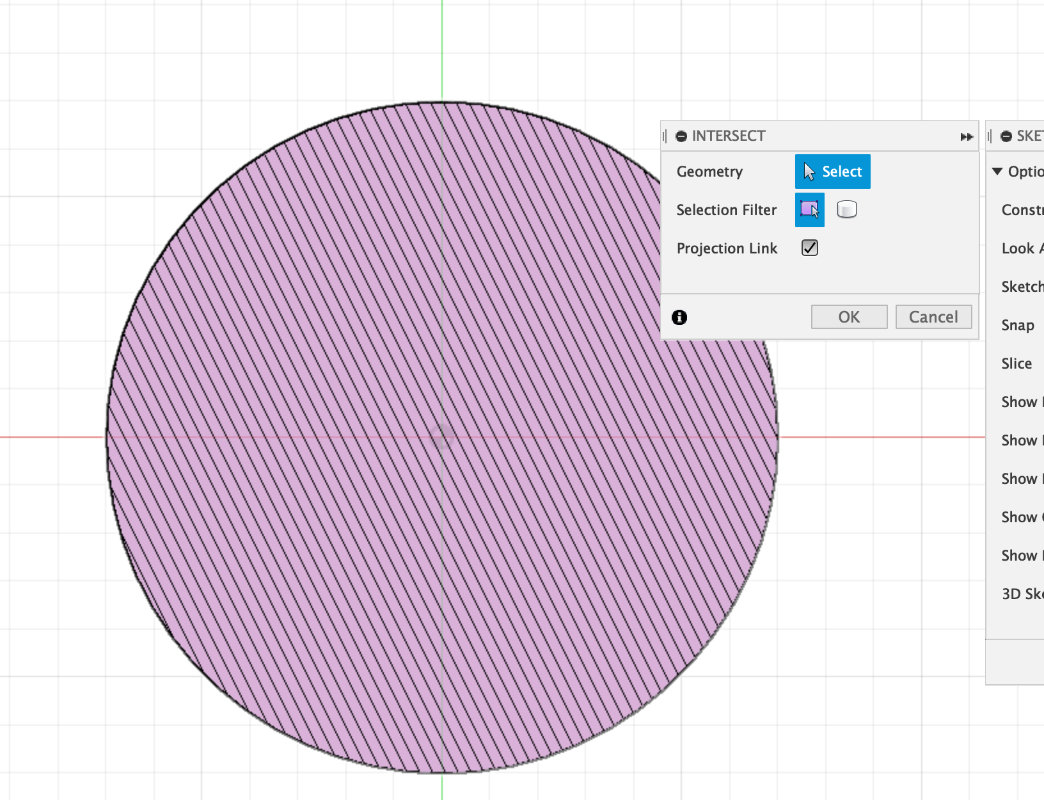

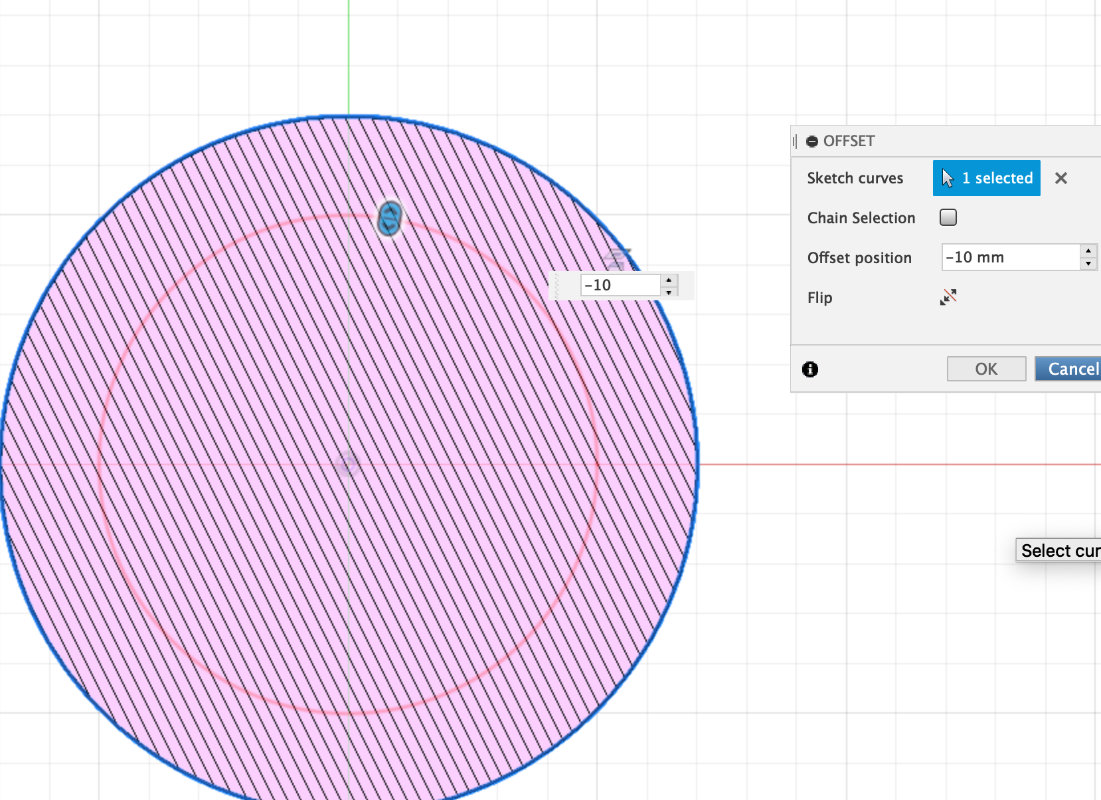

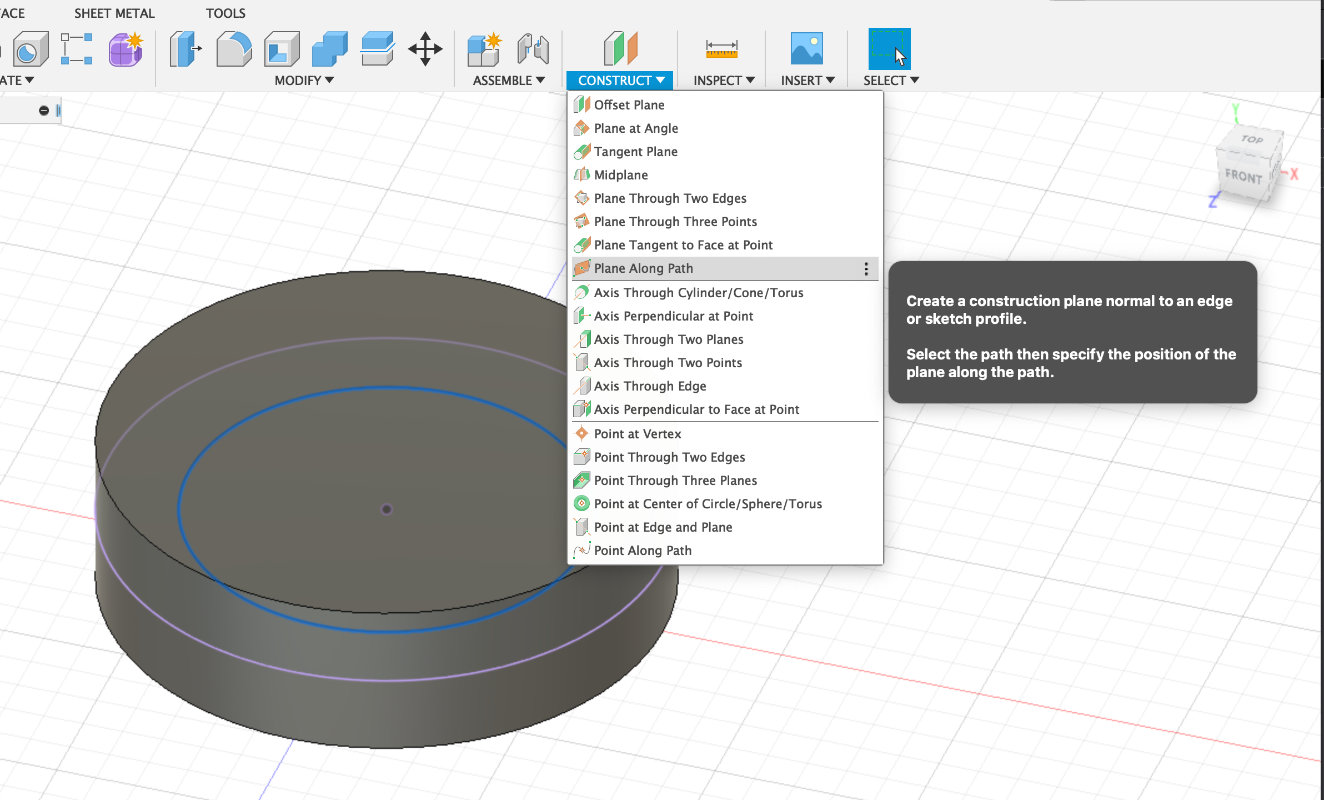

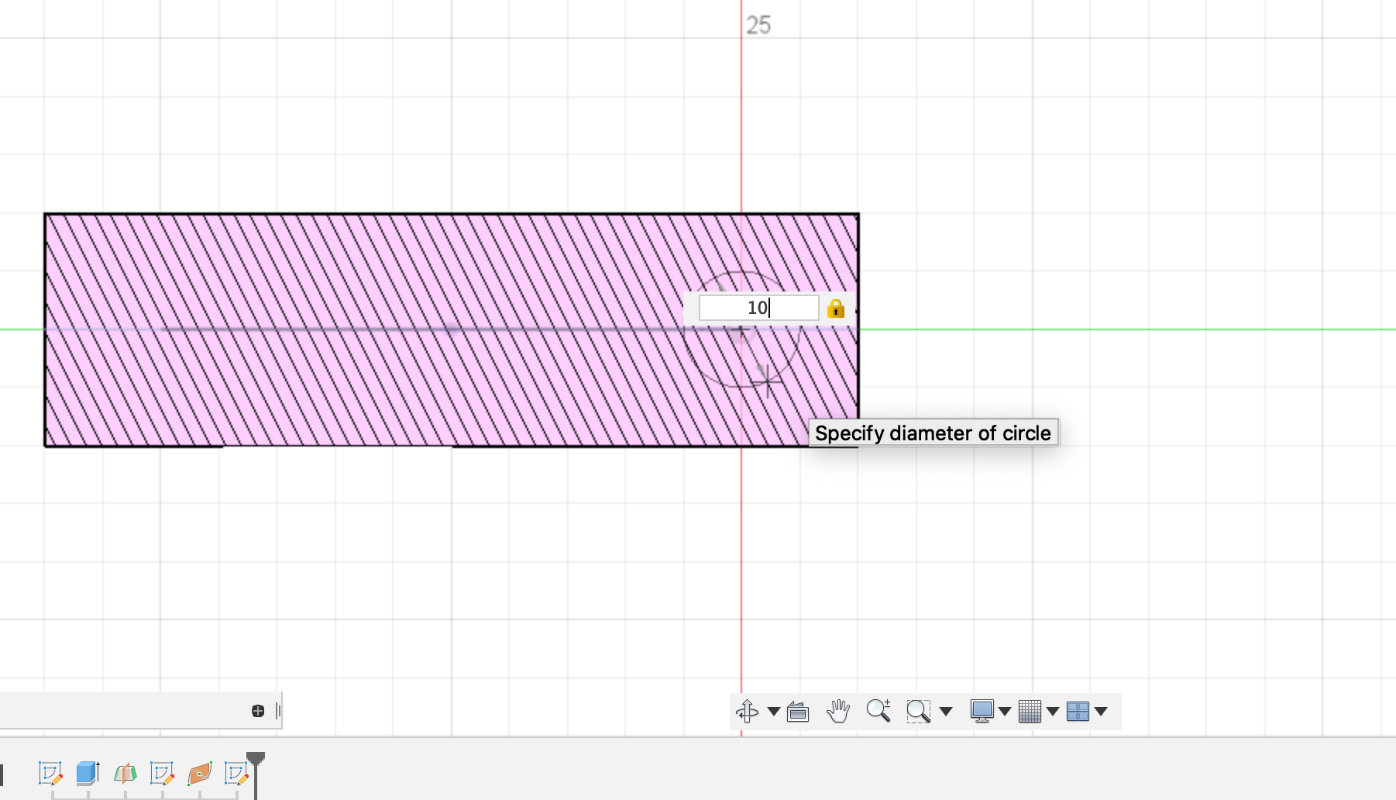

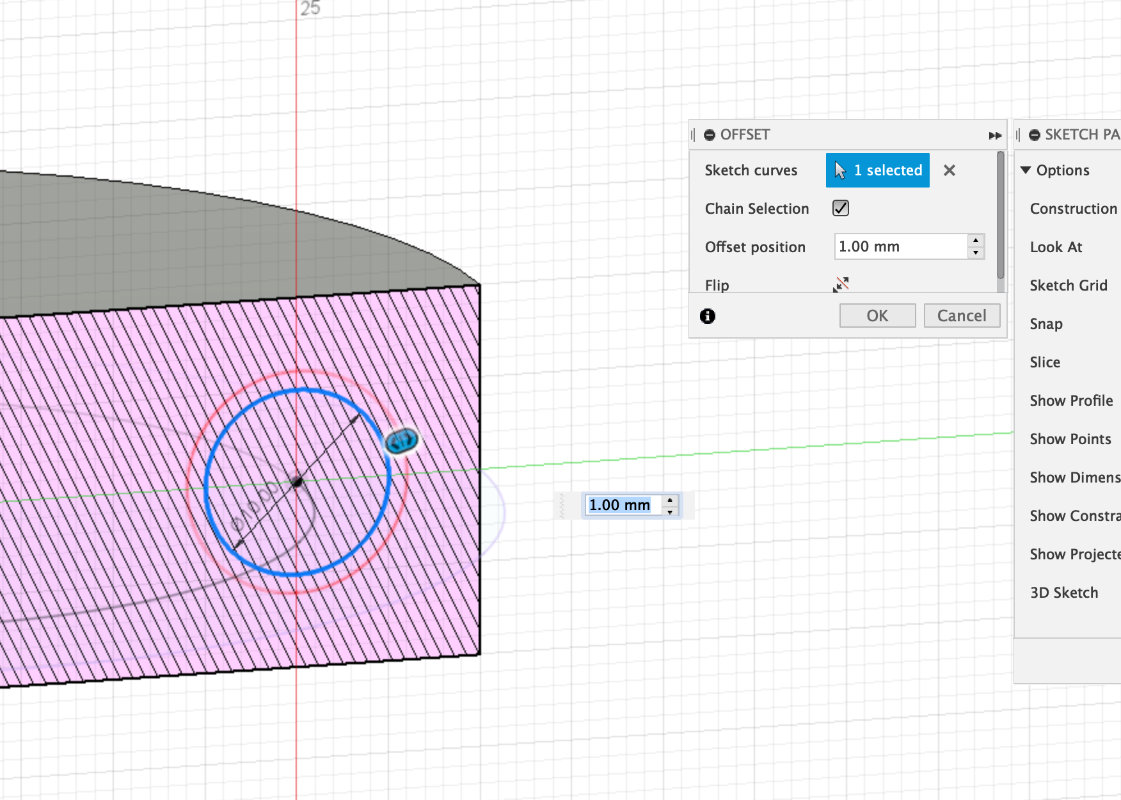

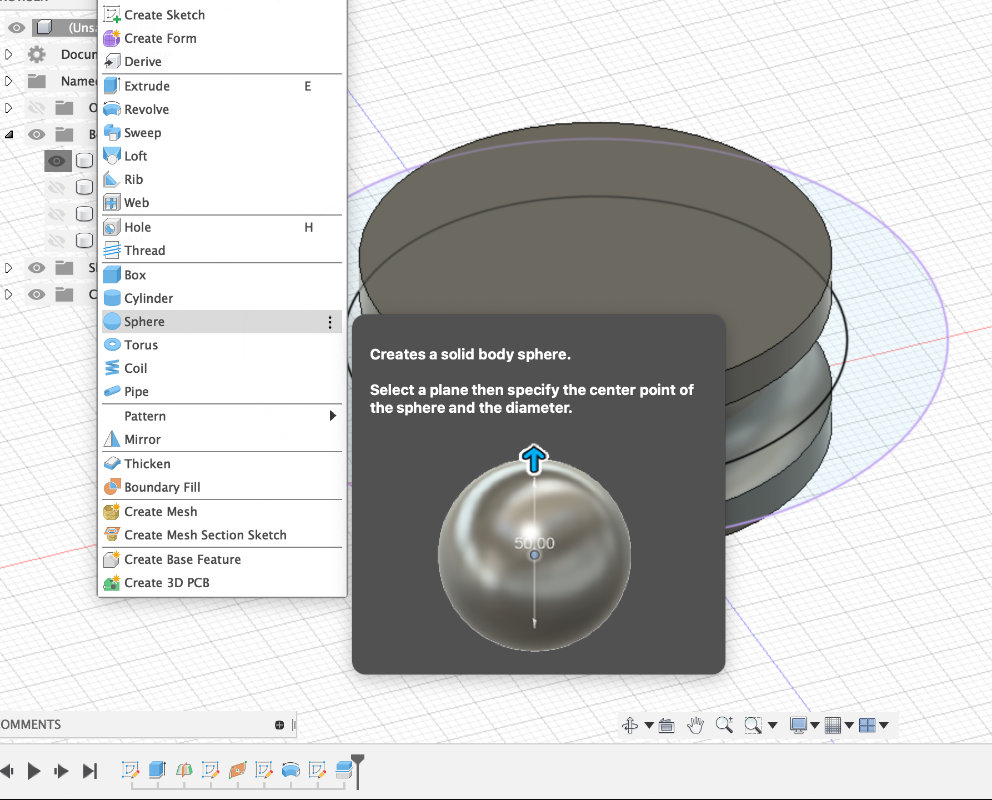

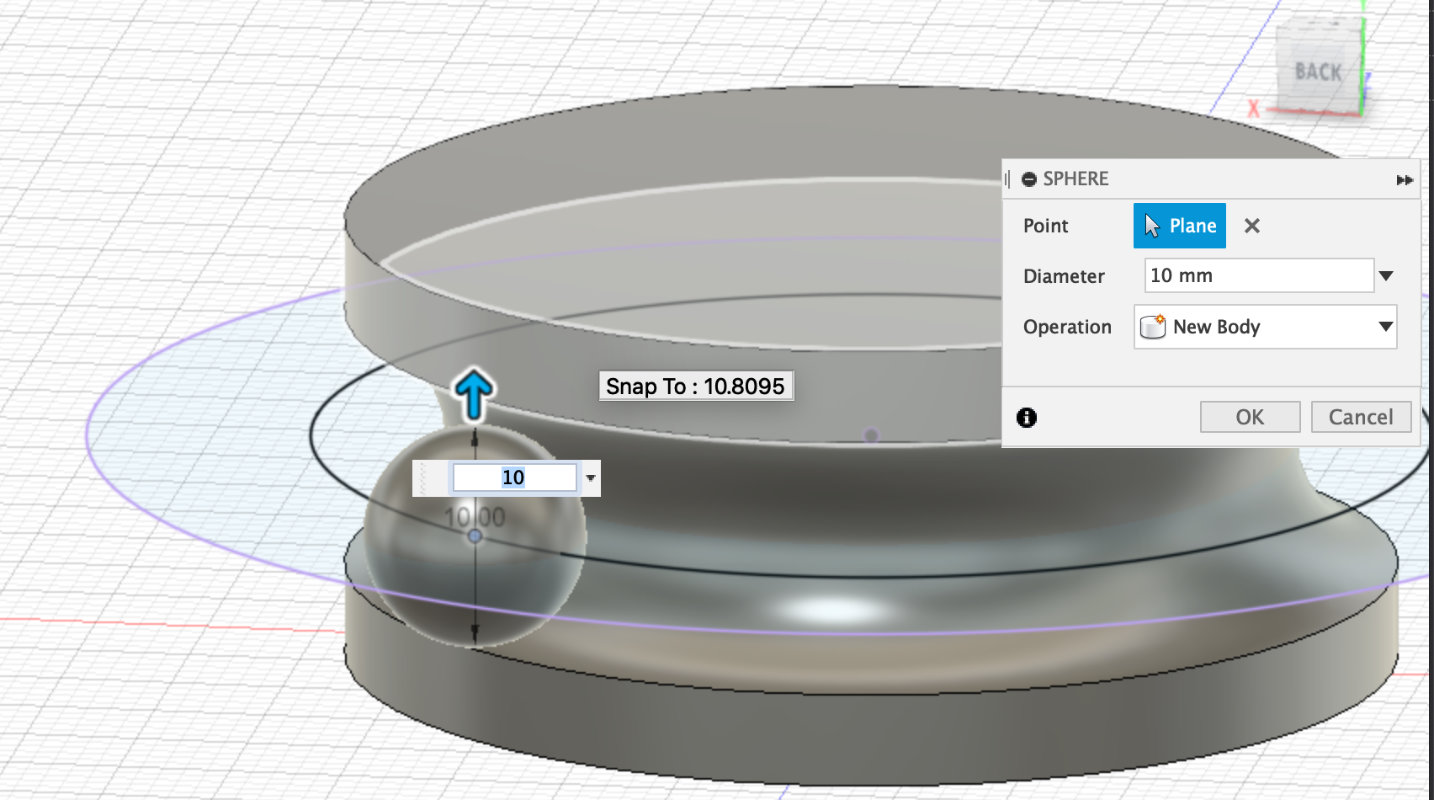

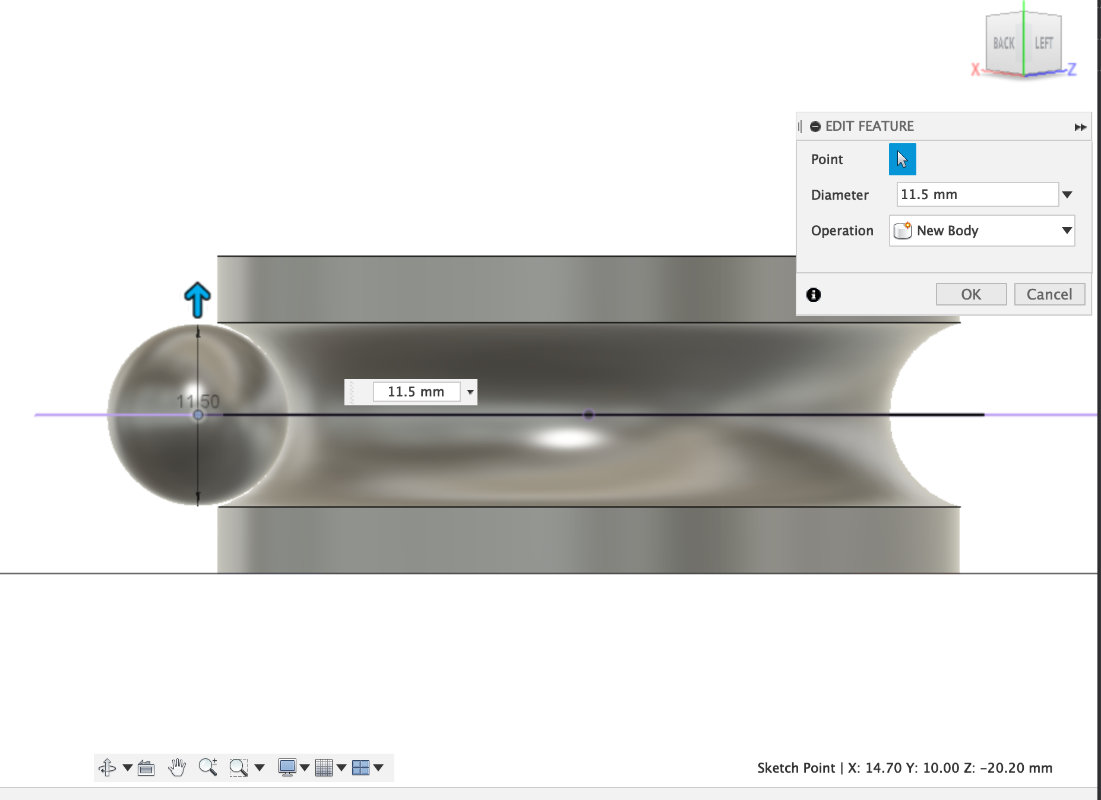

The project was created quite classically, that is a sketch of extrude

revolve cut, but the most interesting element used in fusion 360 useful to

look inside the project was section analyst.

At the end I left the spheres so that they gently touch the rims.

to not print with the supports. or to minimize their number.

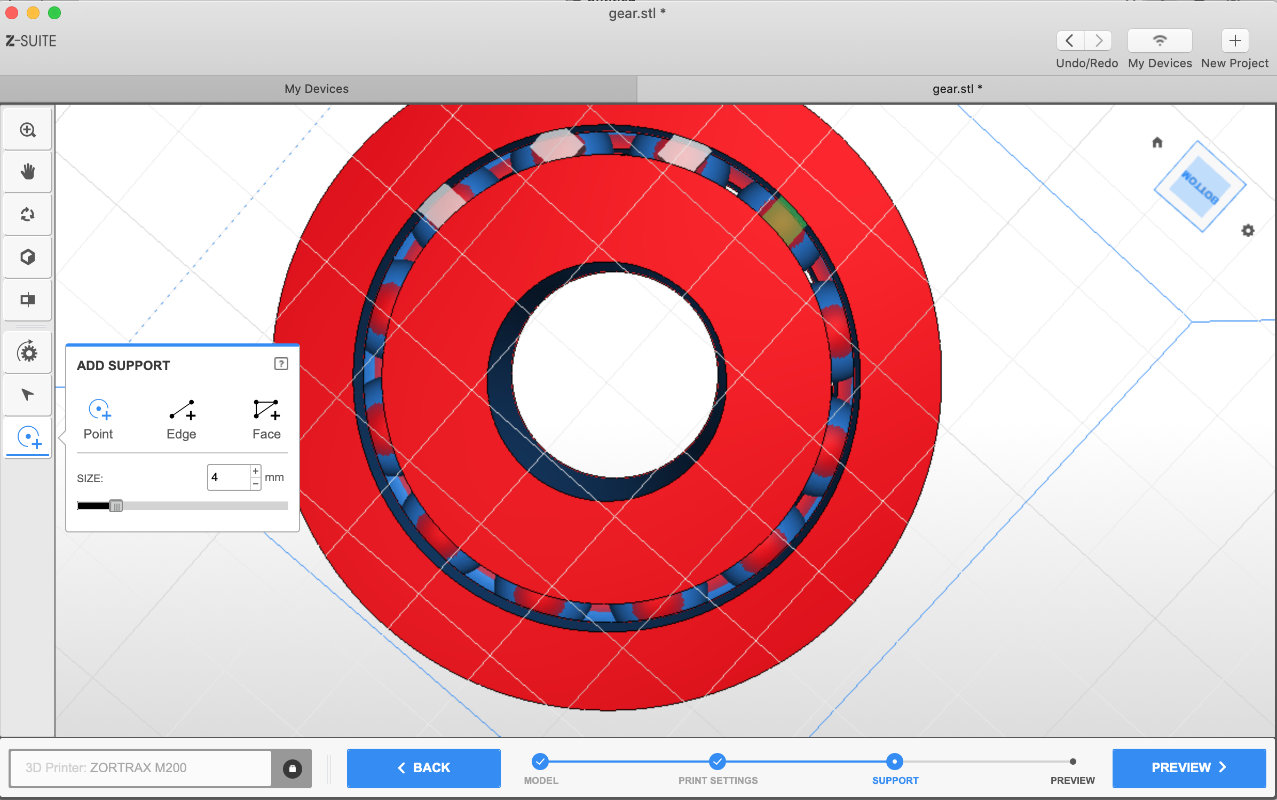

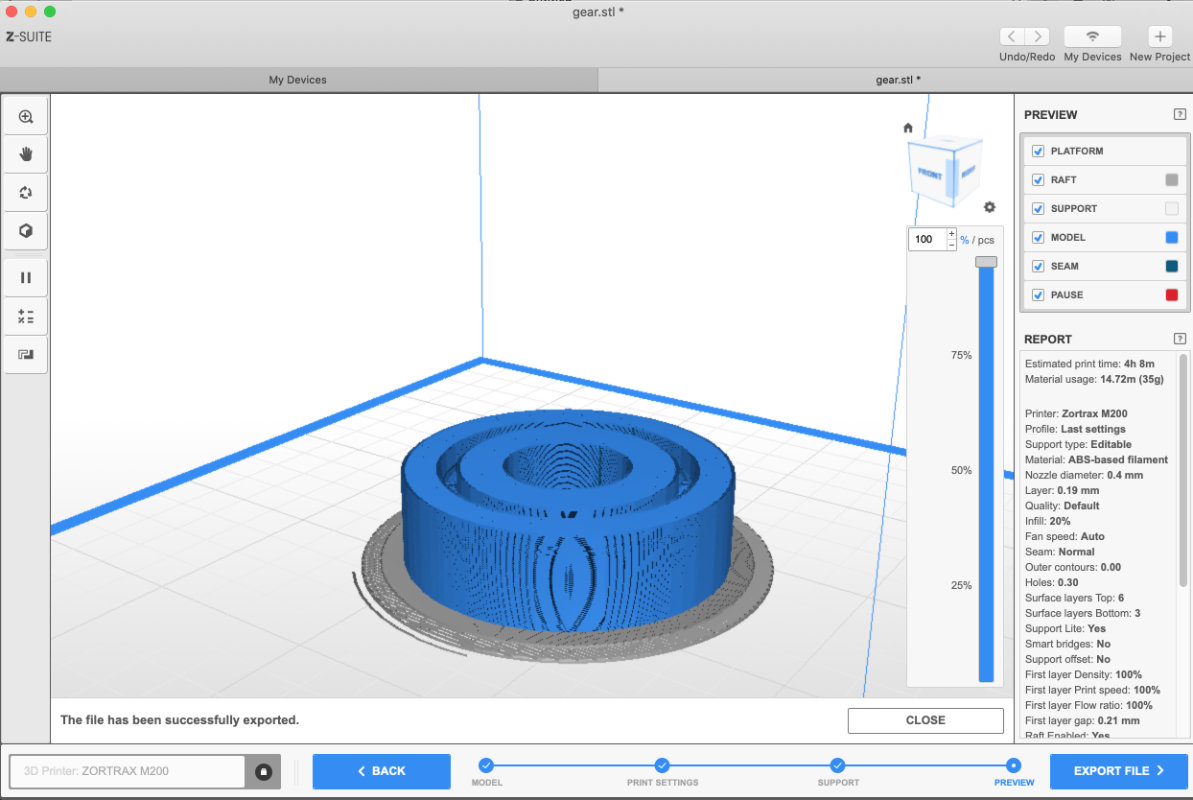

In Slicer Z-suit I turned the project around and manually set up the

supports where I thought they were most needed.

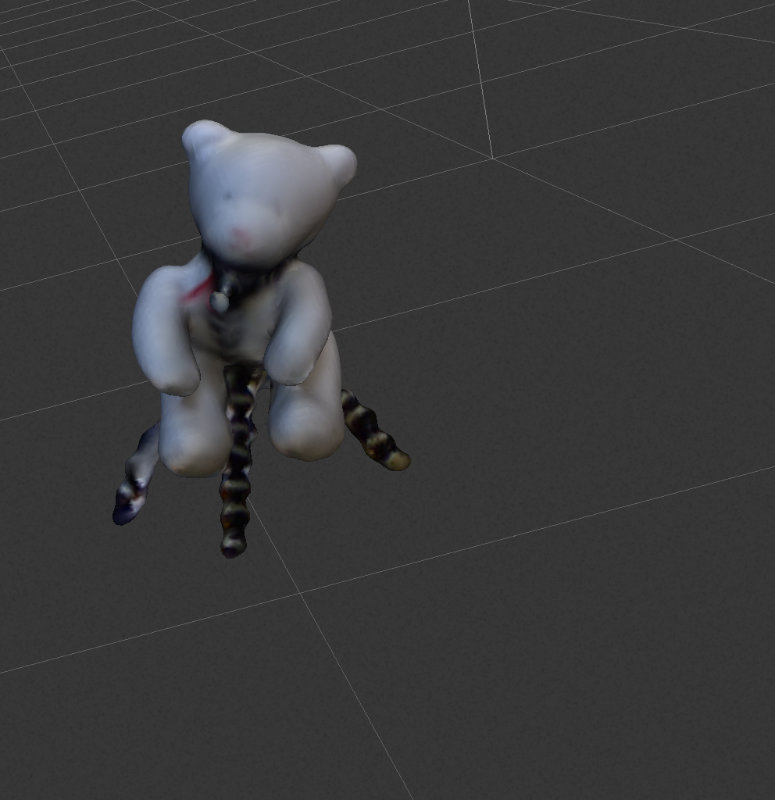

3D Scaning

3d scanning is not the best way to reproduce models. Much better technique

is to collect individual object dimensions and recreate them in CAD programs.

This is at least in case with these simpler models but what if we have to model

some more organic object? Then it is worth to use 3D scanning as a design

support but still rely on dimensions and design.

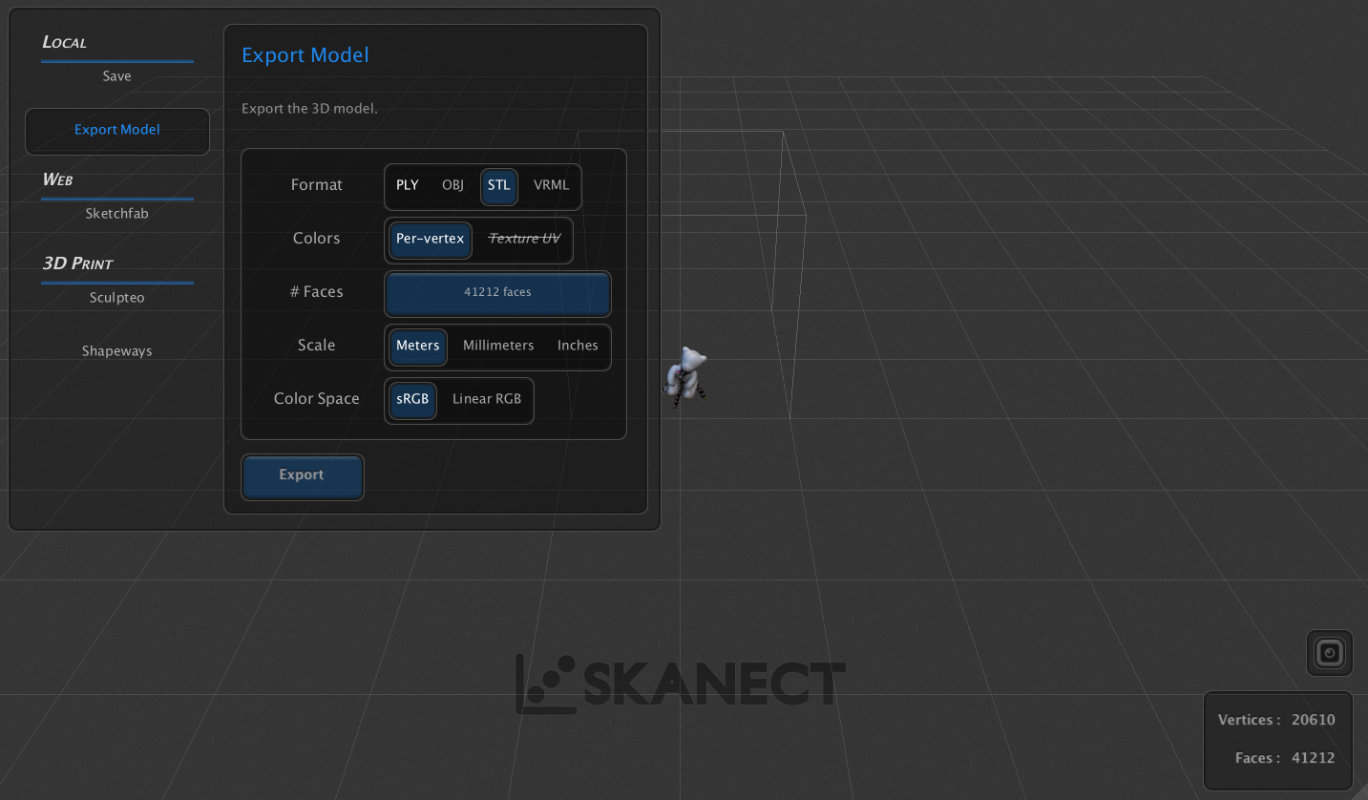

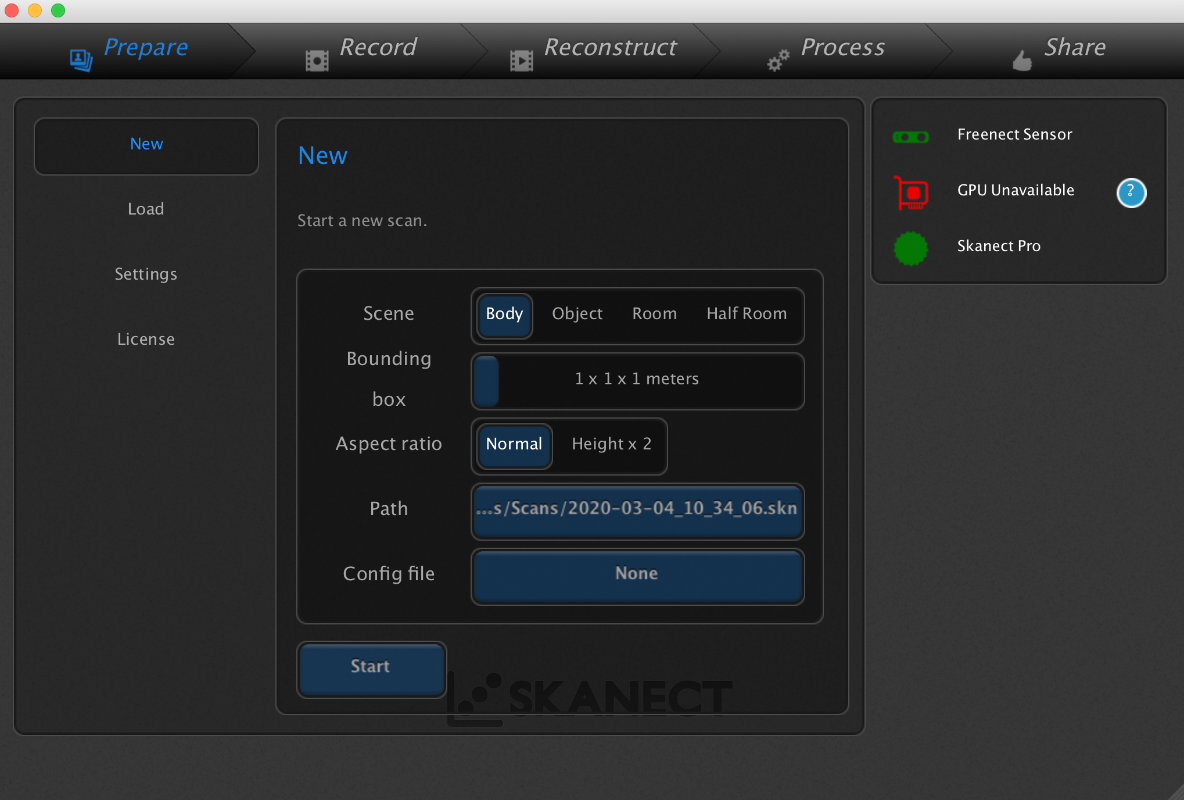

In our fablab we have two Kinect scanners from xbox 360 along with Skanect

software in pro and free version and SENSE

3D scanner with software.

Here I will focus on the xboxs scanner which in my opinion is excellent

as for its price especially when combined with Skanect.

1. settup the size of the objcet

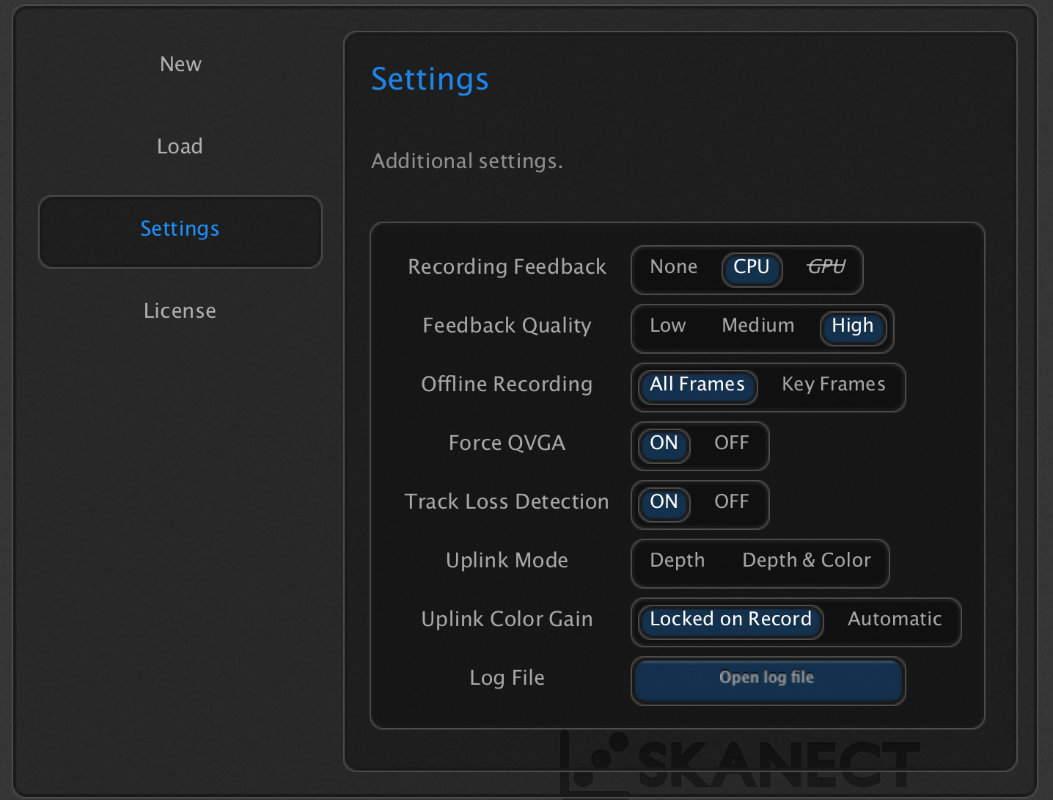

2.settup the quality and recording hardware

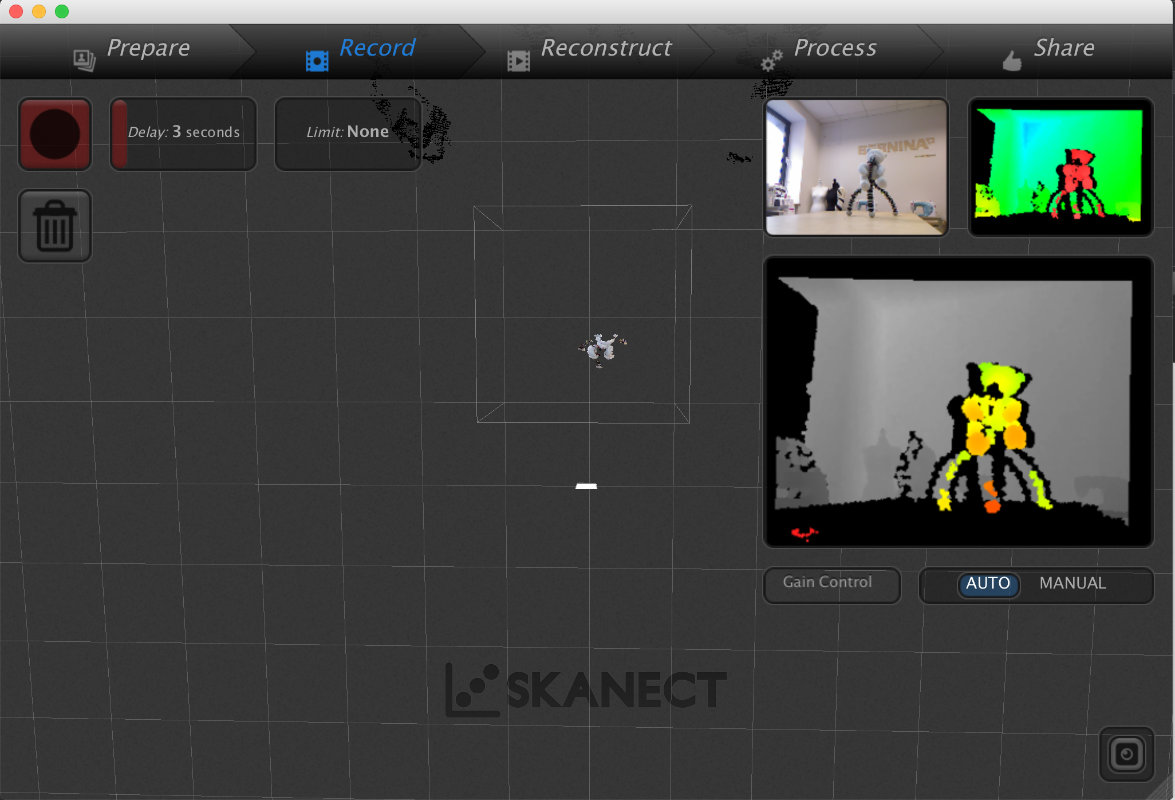

3.press red record button

4.go around the object and scun from diffren angles

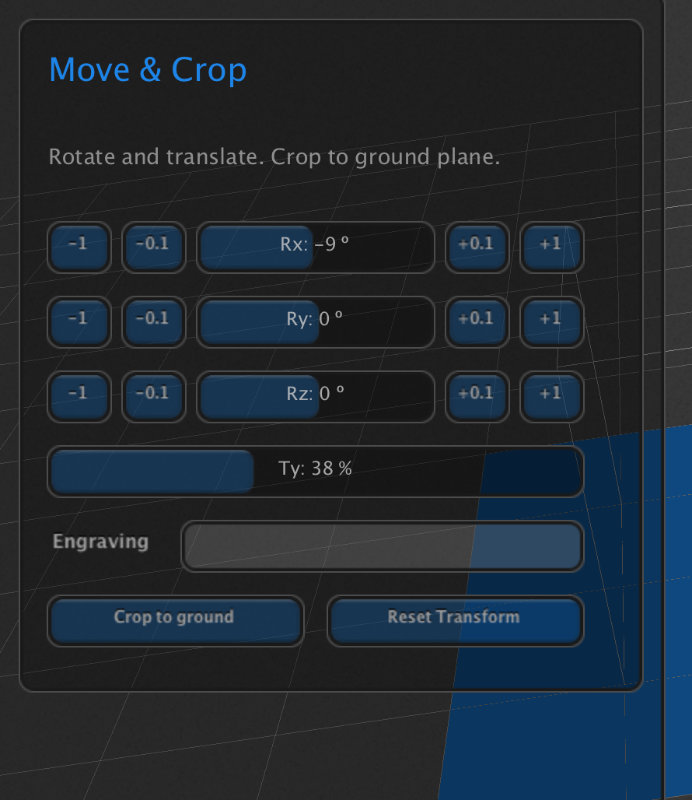

5.first fing when you finished the scanning is transforming the object with tool transform and crop

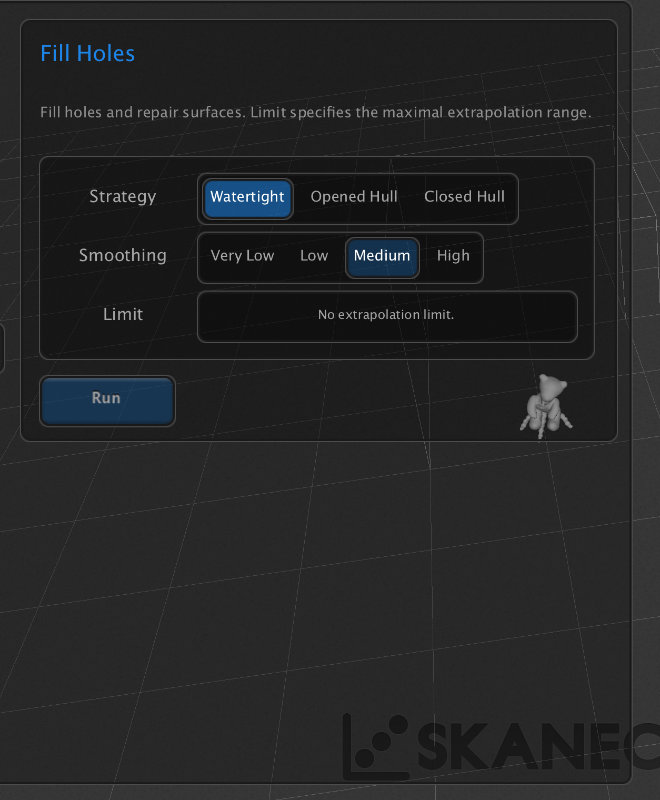

6. remebder to fill holes with fill holes tool

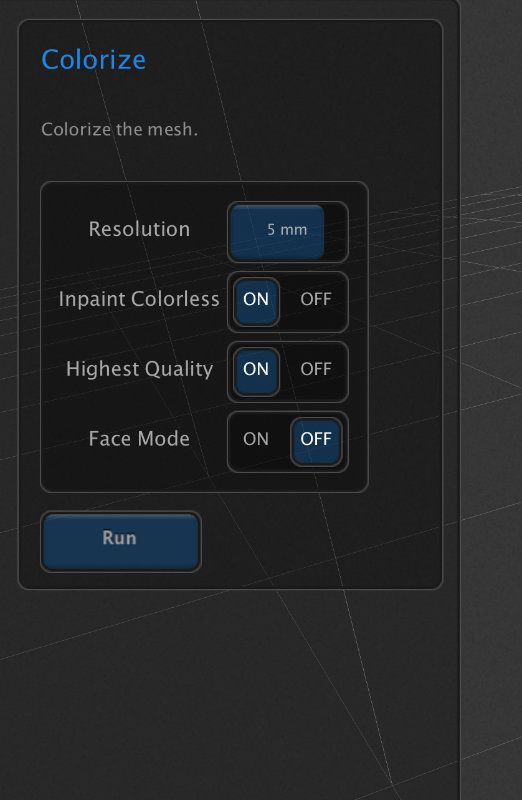

7. there is an obtion to colorize 3d scan but its not necessary for 3d printing

8. ;)

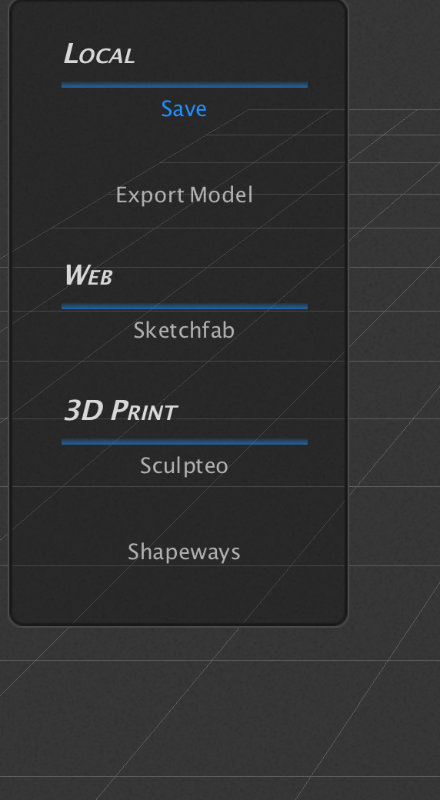

9. last thing save in share bookmark

10. best option for 3d printing is to use .stl files