week_16

Wildcard Weed

First, this week I want to produce the sample of 3C mobile phone which I design by week_02. I’m going to use a three-axis machining center this week.

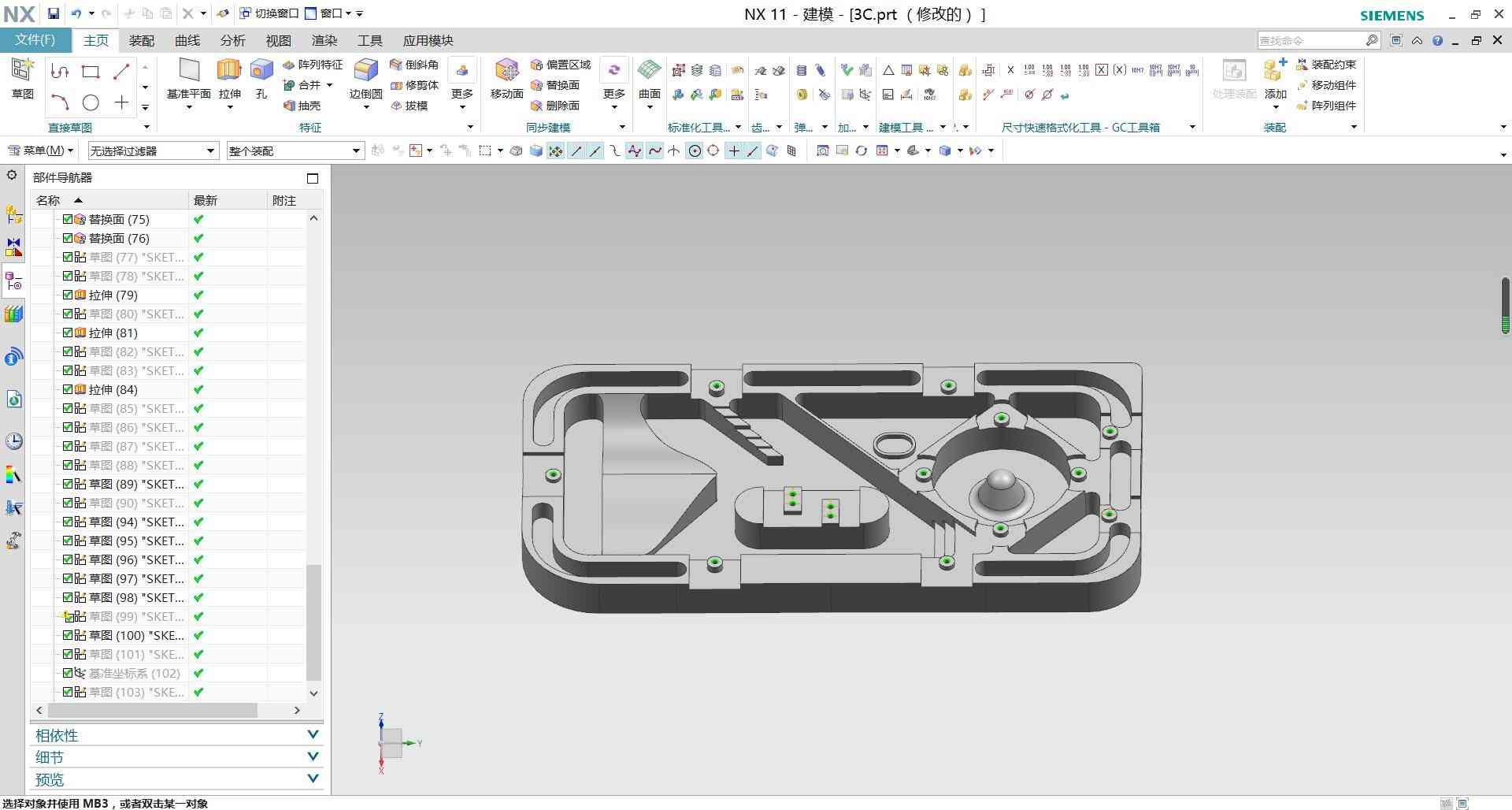

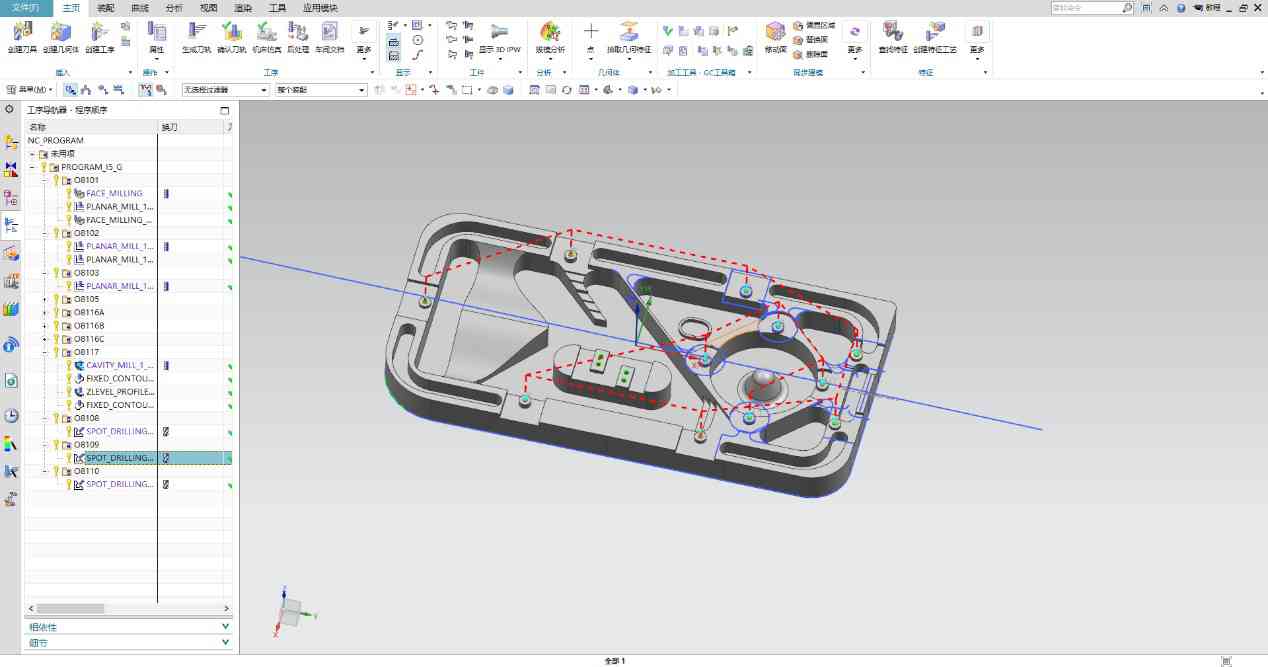

In week_02 computer aided design, I used the software of NX UG to design this sample which I integrated many machining features of many 3C mobile phone industries into one part.

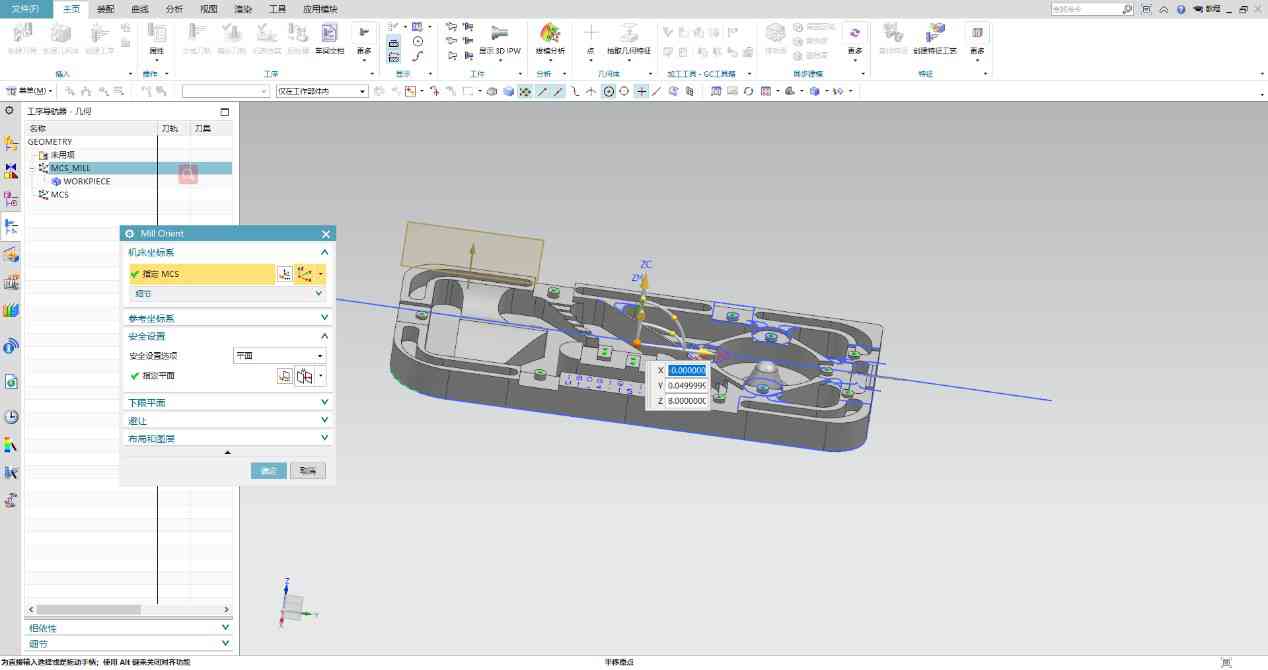

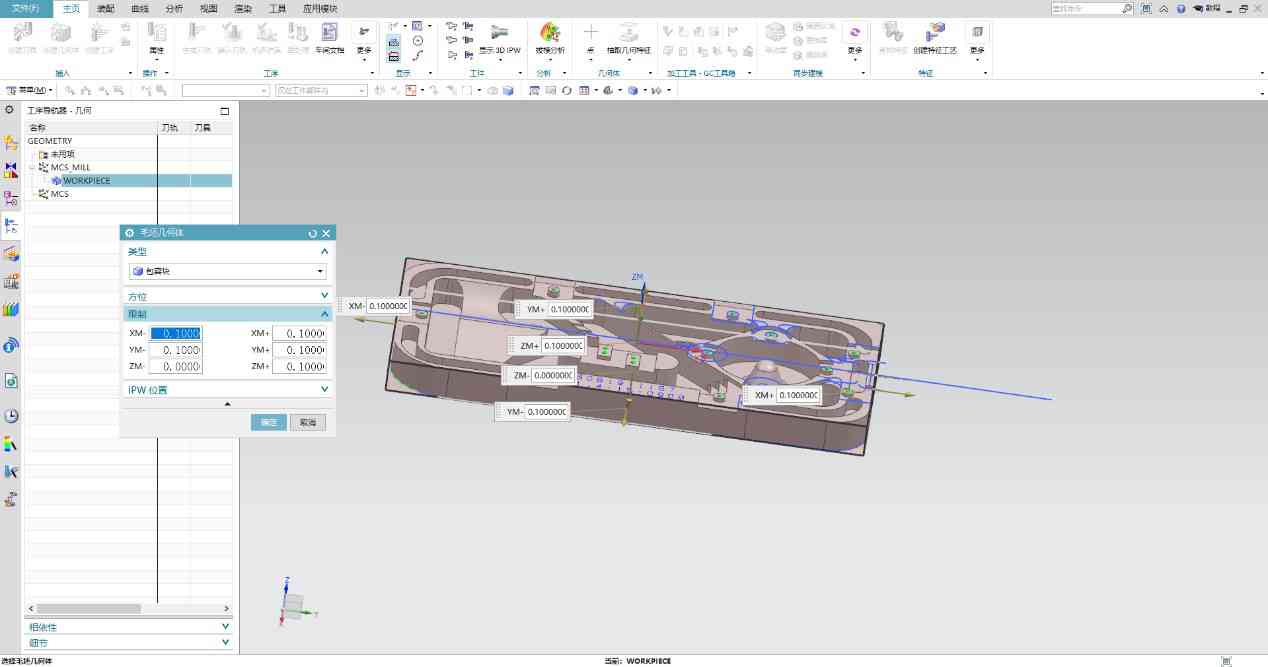

In the first step of NC programming, I need to determine the workpiece coordinate system for machining the workpiece. So, I used the very common machining coordinate system which is the center of the workpiece.

In the first step of NC programming, I need to determine the workpiece coordinate system for machining the workpiece. So, I used the very common machining coordinate system which is the center of the workpiece.

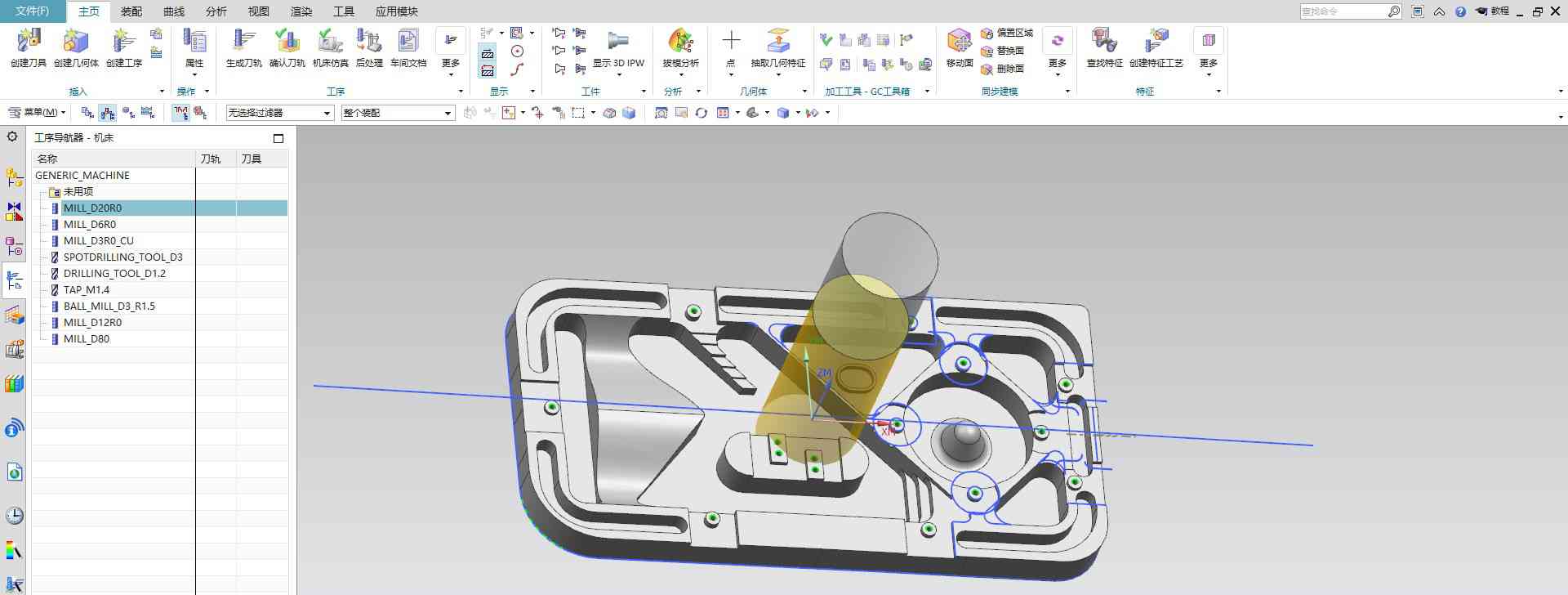

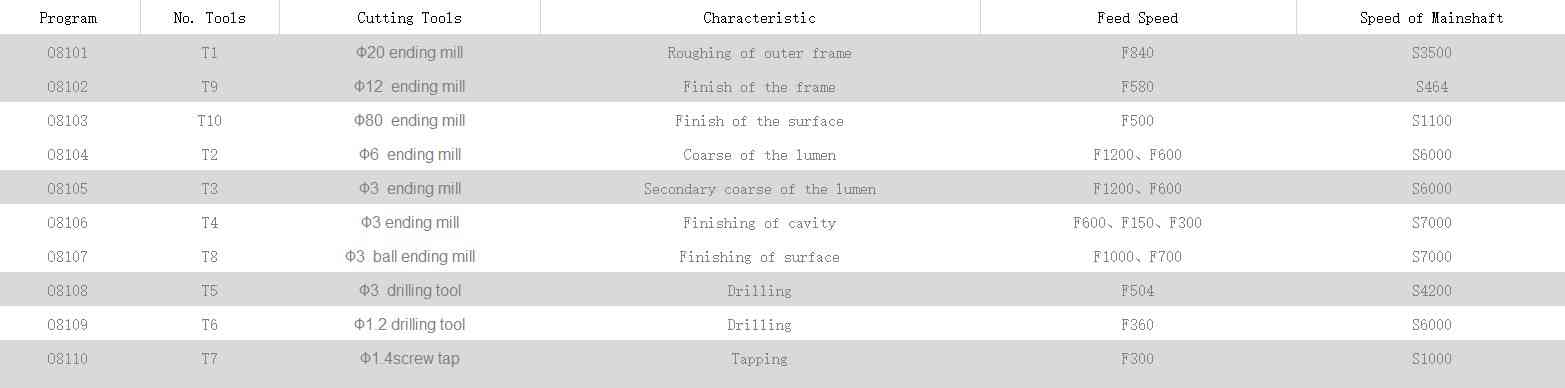

I used nine cutting tools, which is the D80 ending mill, D20 ending mill, D12 ending mill, D6 ending mill, D3 ending mill, D3R1.5 ball ending mill, D3 drilling mill, D1.2 drilling tool, D1.4 screw tap.

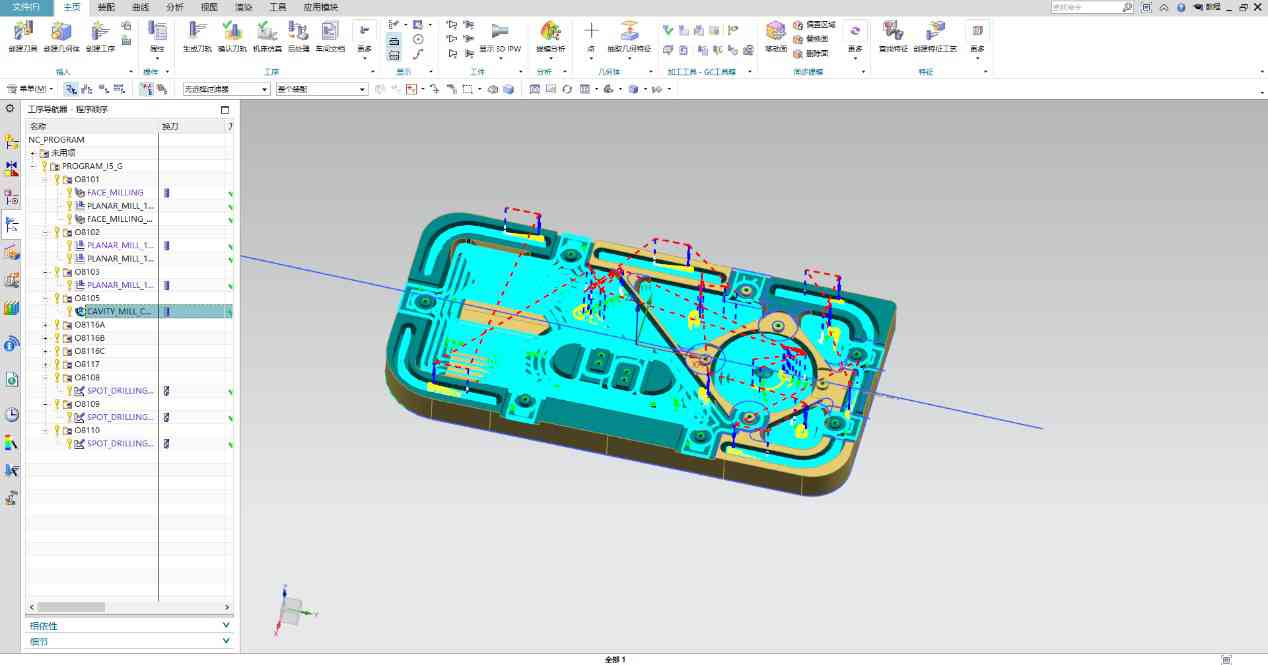

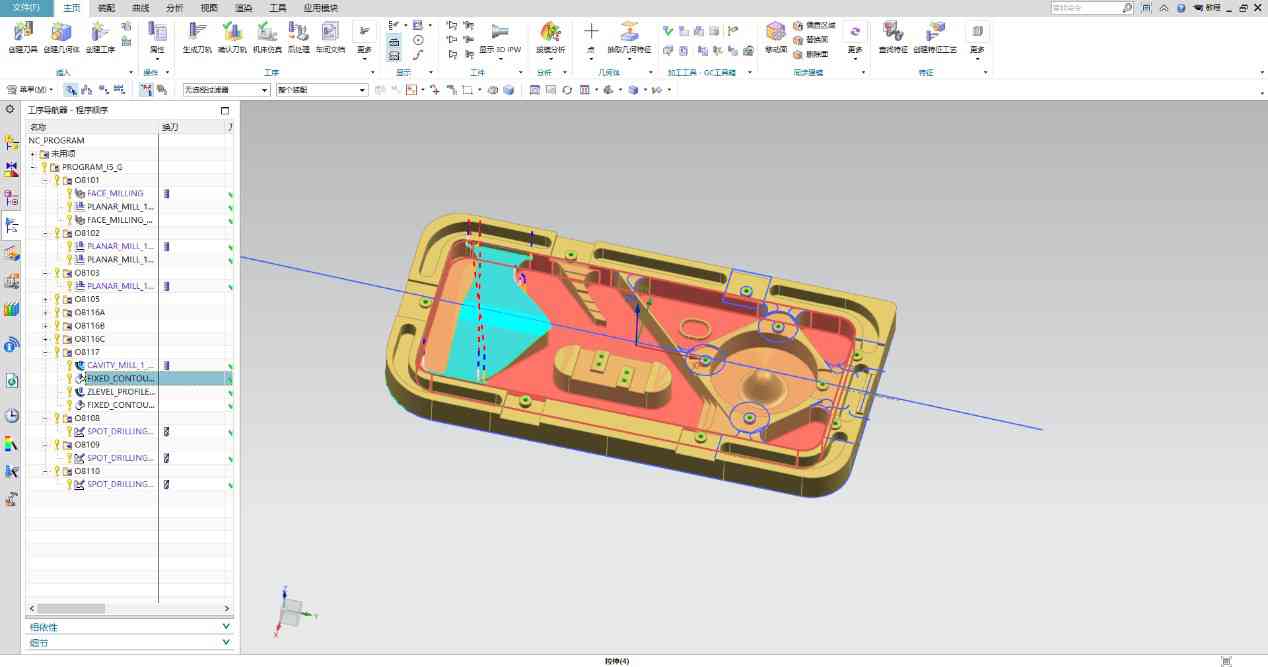

Then I began the formal numerical control programming, the programming ideas are mainly advanced line contour open thick, finishing, then to the cavity open thick, finishing, then, the surface of the surface finishing, finally drilling, tapping.

You can download all the NC codes at the end of the file

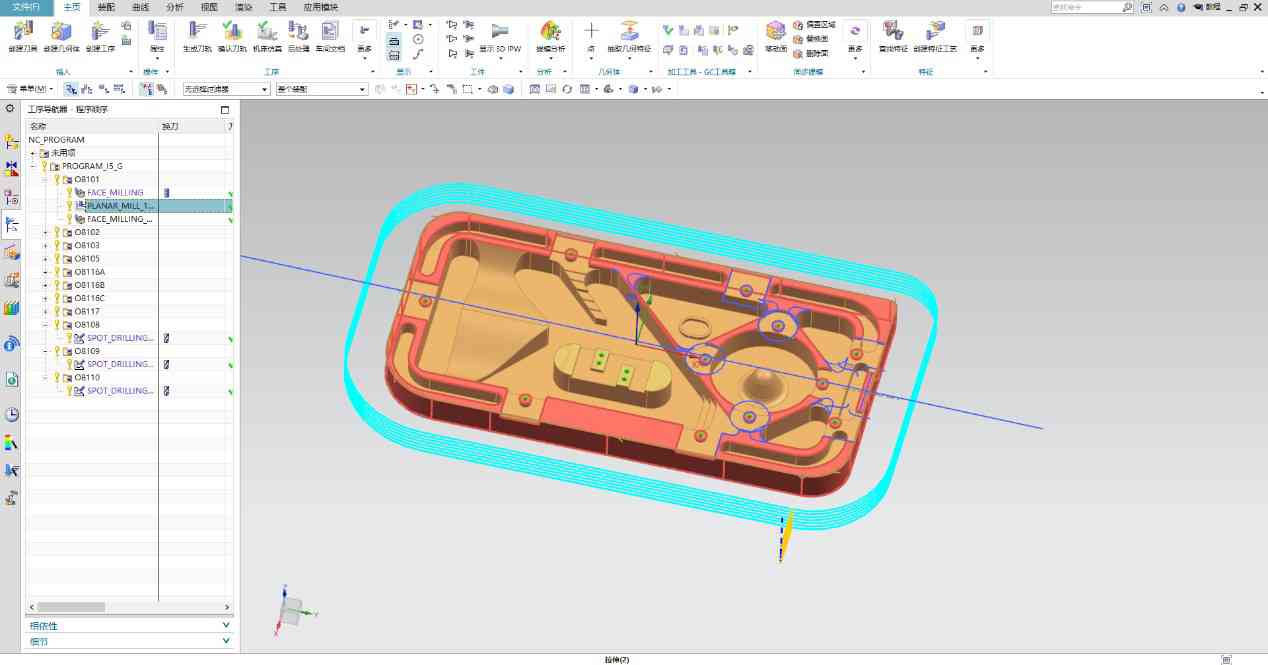

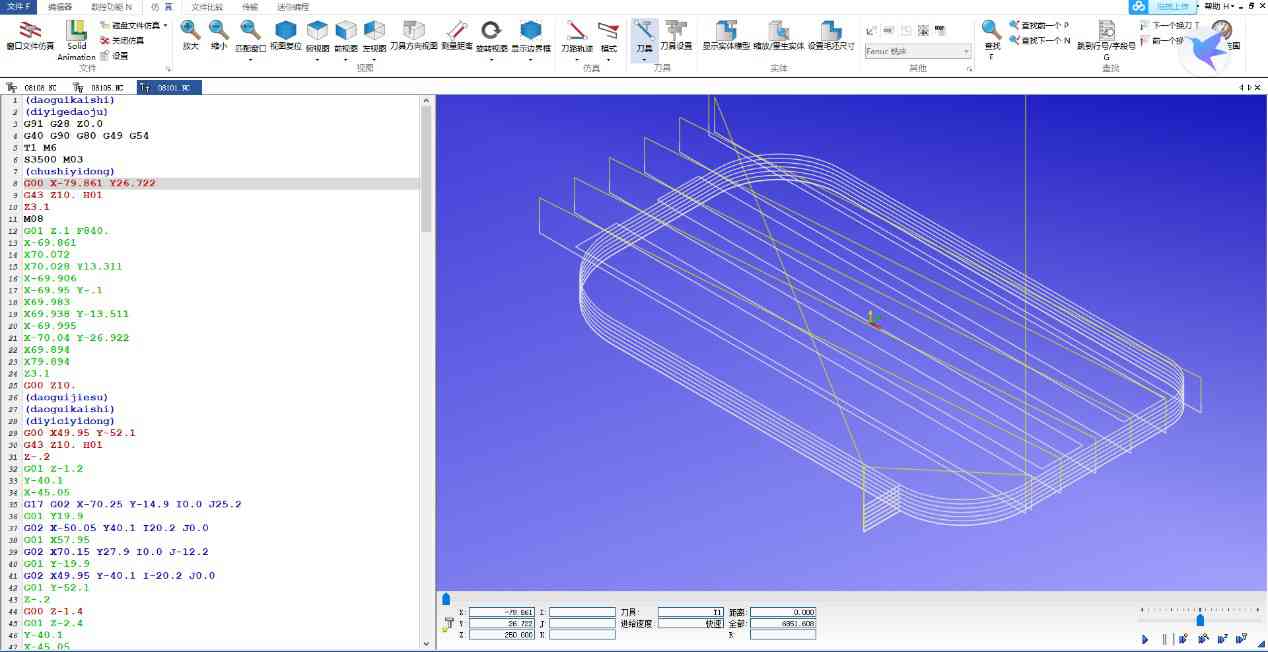

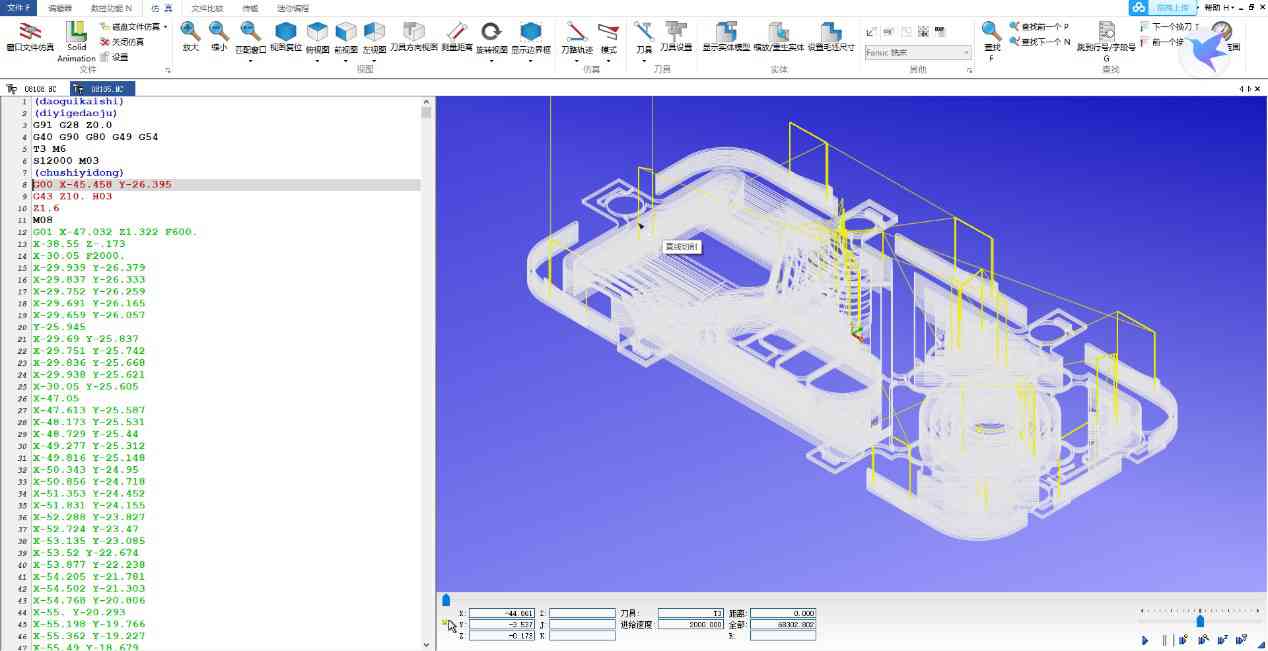

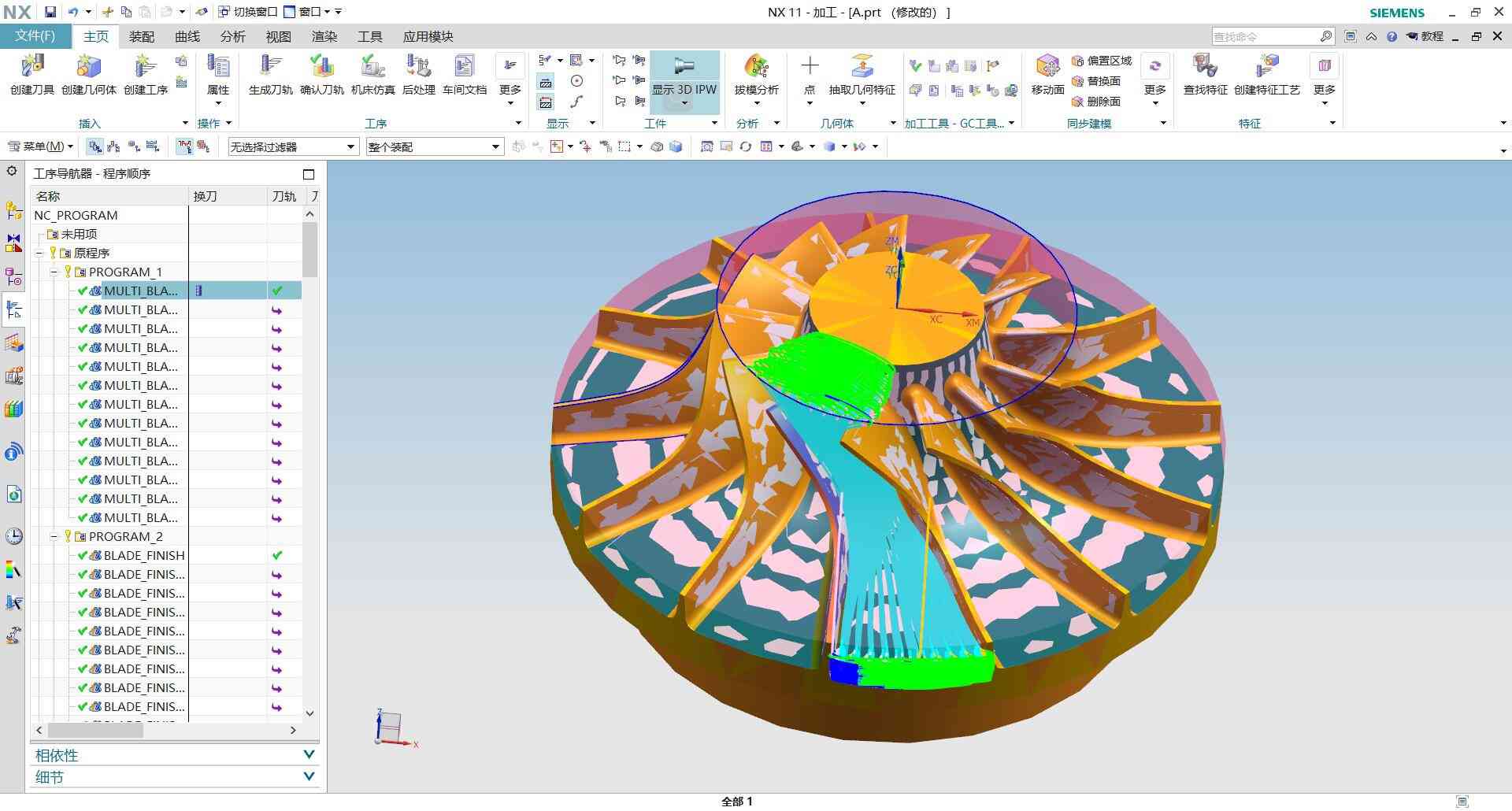

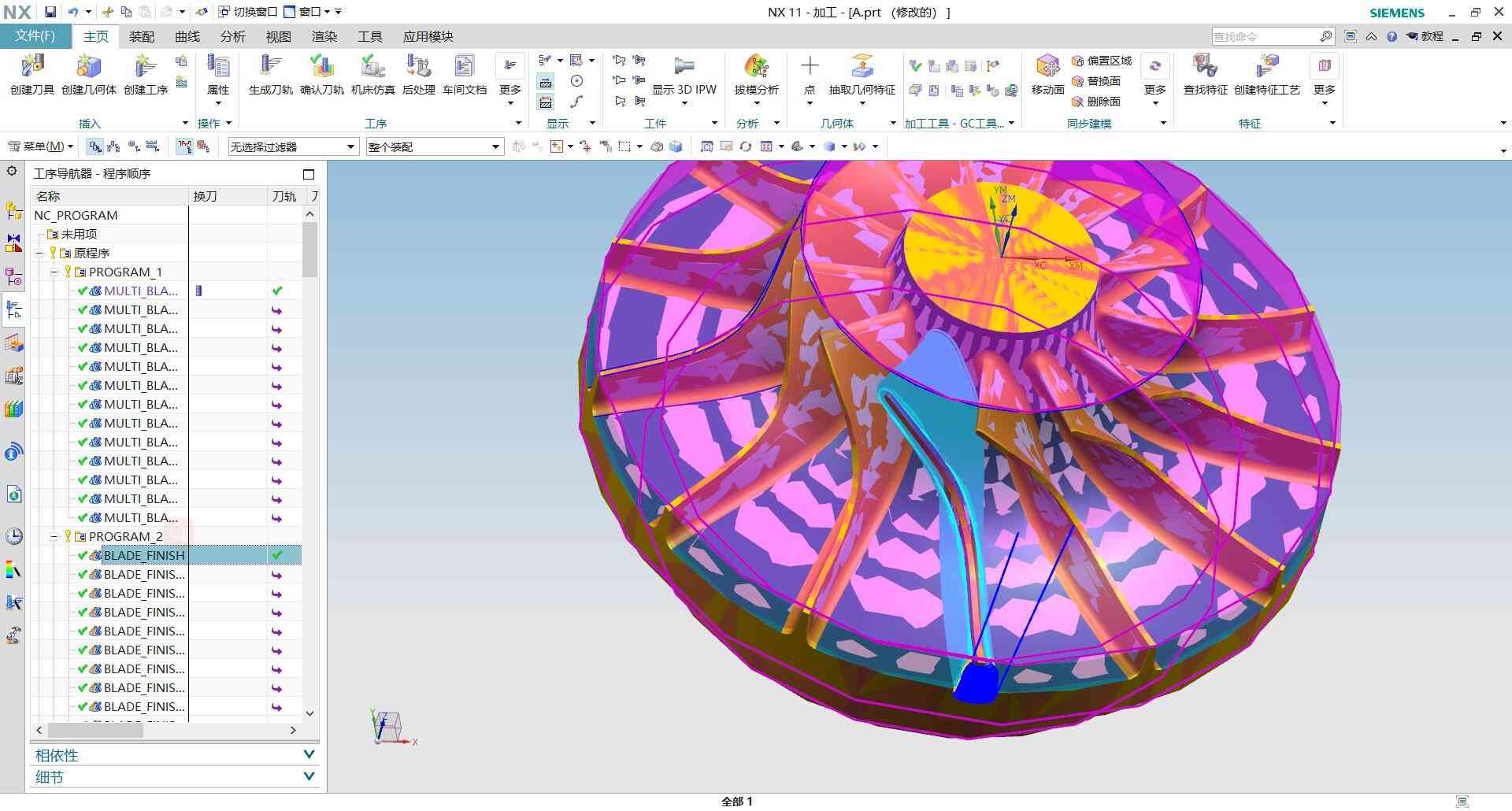

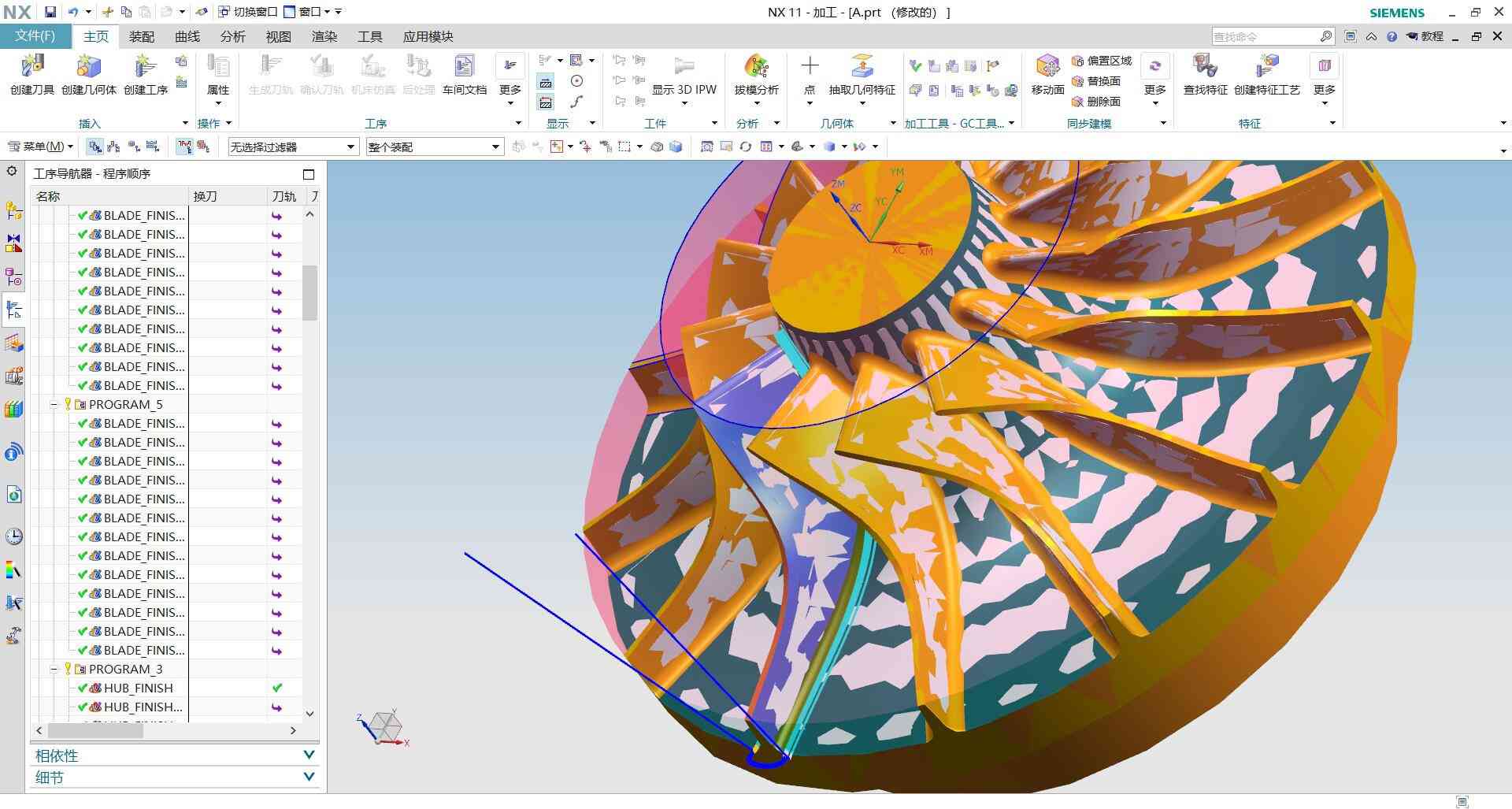

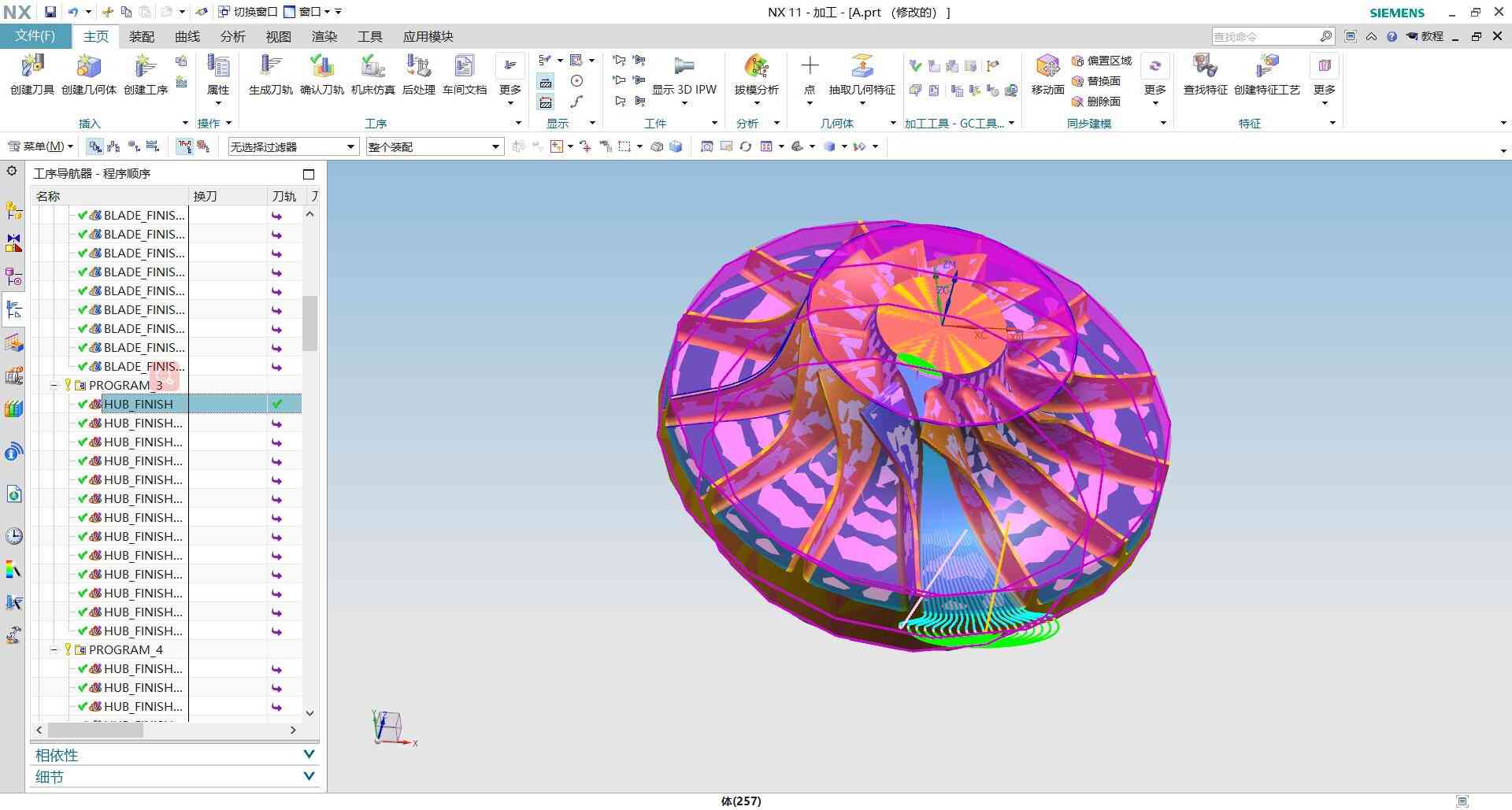

First, I tried to use the software of CIMCO and the NX UG to verify the accuracy of the program before starting the processing.

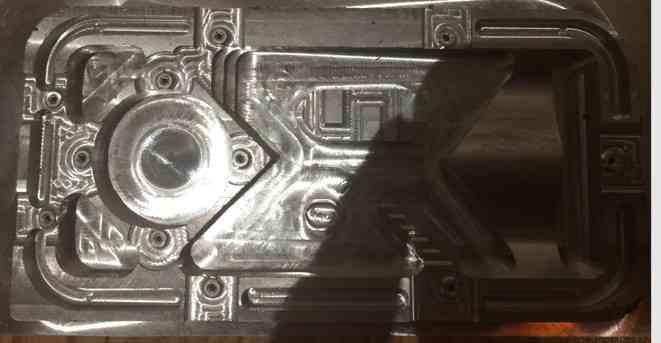

When the program verified that there was no problem, I began processing in the machining center. There is no problem with the rough processing and finishing of the outer contour. The picture below is the picture after the finishing of the outer contour.

But when I was roughing the cavity, about halfway through the process, the 6mm end mill broke. So, I began to look up the reason in the program, after I found that I in one of the subroutines, the machining depth is set wrong, resulting in the cutting depth is too big, the tool cannot bear to lead to fracture.

I revised the procedure and processed it again. Everything is normal.

Machine: Five-axis machining center of Fadia HS 664RT

Cutting tools: R1 taper ball end milling cutter

Materials: aluminium alloy of 6061

blank dimension: Φ64mm*50mm

① Rough machining. The machining step is 1.2mm and the cutting depth is 0. 2mm. Spindle speed is 11000rpm. Cutting feed speed is 800mm/min. The feed/return type is an arc-parallel to the cutter shaft.

② The final finishing of blade. The cutting depth is 0. 15mm. The feed/return type is an arc-parallel to the cutter shaft. Spindle speed is 12000rpm. Cutting feed speed is 800mm/min.

③ The final finishing of the bottom of the blade. The cutting depth is 0. 15mm. The feed/return type is an arc-parallel to the cutter shaft. Spindle speed is 9000rpm. Cutting feed speed is 400mm/min.

④ The final finishing of the impeller passage. The feed/return type is an arc-parallel to the cutter shaft. Spindle speed is 9000rpm. Cutting feed speed is 800mm/min.

① In order to ensure the machining accuracy, I first warm-up machine 1 hour in the condition of spindle speed of 2000rmp. Then warm-up machine 0.5 hour in the condition of spindle speed of 4000rmp.

② Then I made a blank. But in this step, I made a mistake on the Zero of the Z axis and caused an accident. Fortunately, I shot the emergency stop button in time. Then I used the relevant software in the CNC system to test the performance of the machine center. I found that there is no damage for the machine. So I just lost a cutting tool.

In recent weeks, I have been assisting a team in the park to develop the technological process for processing insoles. In the process of developing this process, I was mainly involved in the robot arm grasping the insoles.

Grasping robot arm is mainly through the air compressor to compress the gas, produce negative pressure to adsorb the object on the suction cup. Through this robot arm debugging project, I learned a lot about robot arm programming. Due to the commercial nature of the project, I cannot present the program to you.