5. 3D scanning and Printing¶

Scanning¶

//todo

Printing¶

I own a SLA 3d printer, COVID lost a battle with me this time.

Setup¶

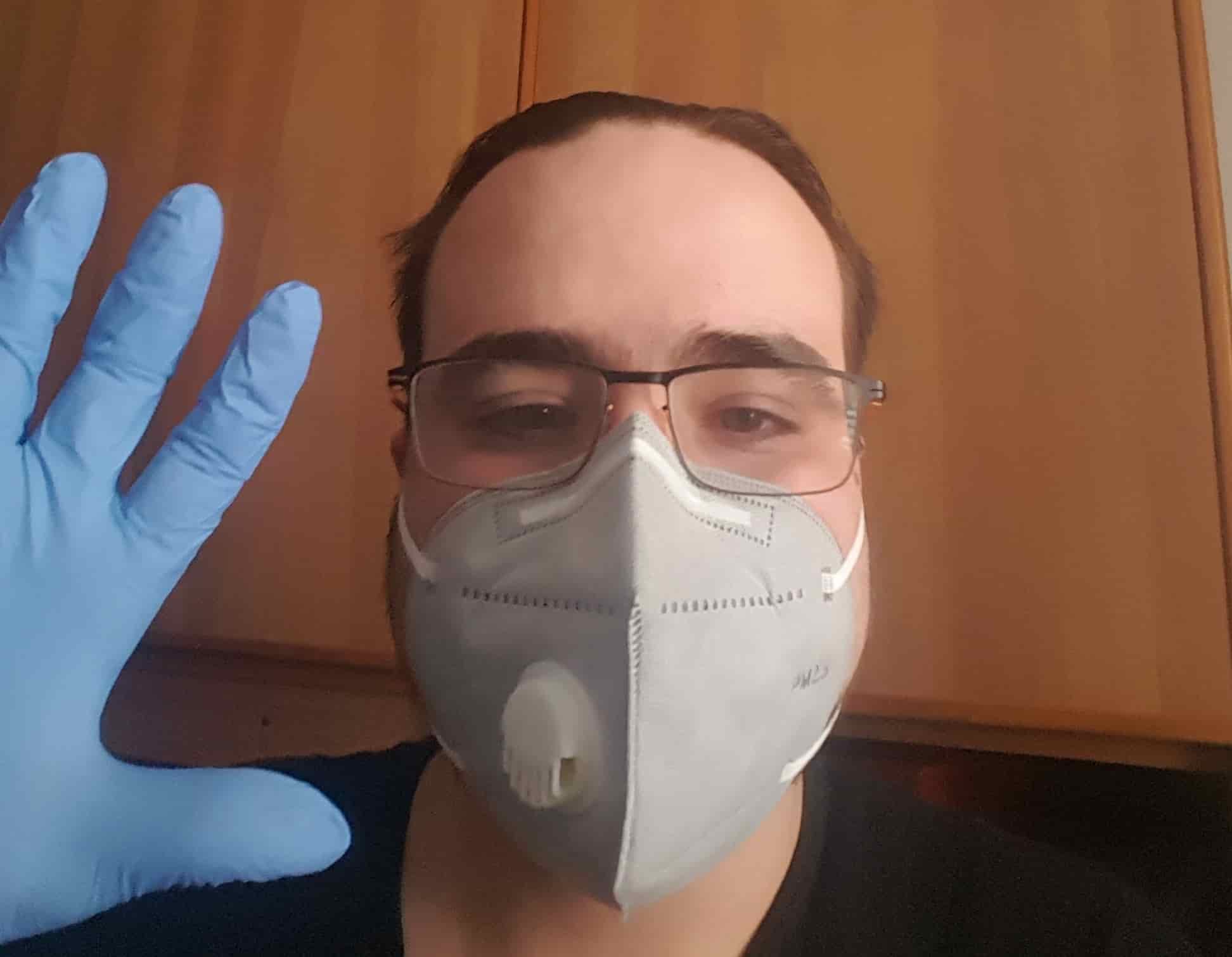

Safety First! the photopolymeric resin used in SLA 3D printers is nasty stuff, and smells awfully, always wear a mask (it’s becoming a leitmotif) and gloves when operating this kind of machines.

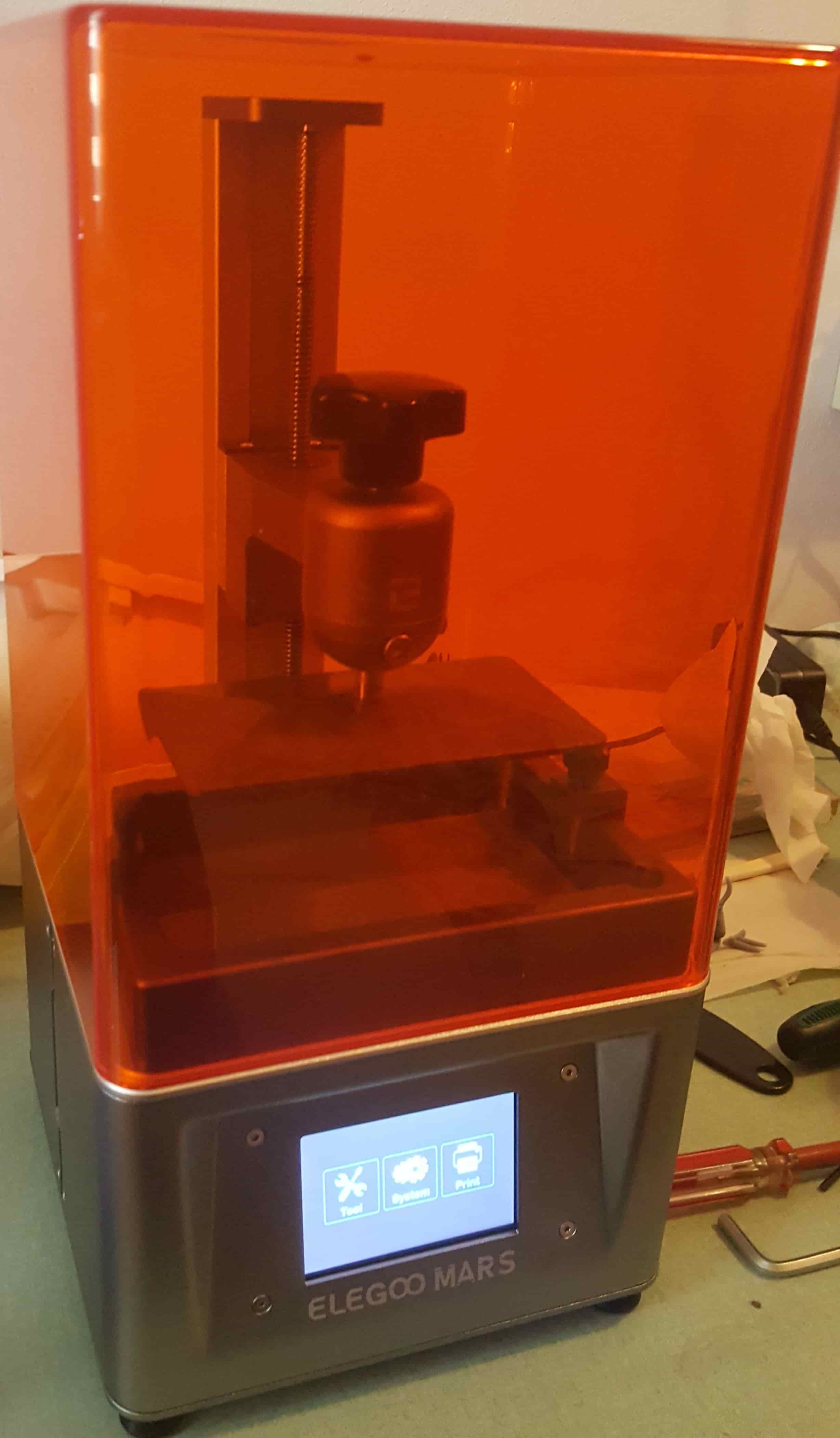

This is how the machine looks like, the cover serves as a protection for both sides, preventing (most) of the UV light from the machine to escape from it and external light to get inside, this however does not protect the resin for longer than 24 hours and in my experience even less

Bed leveling¶

This machine works “upside down” when compared to filament 3D printing and for the piece to fall into the resin would mean total disaster. For that reason the plate is screwed to the Z axis motor but has to be detached when you retrieve the pieces from the machine, compromising the precision of the leveling (i’ve had failed prints, many failed prints because of it).

The machine has an auto level function but you need to do the following:

- remove the resin tank

- place a piece of paper to protect the screen from scratches

- unscrew the screws that prevent the plate from tilting

- activate the level function on the machine

- screw back the screws

After all of this (5 minutes maximum when you get used to it) you are ready to print.

Slicing¶

Slicing is the practice of preparing a 3D file for it to be used with a 3D printer, to do it for my printer i use CHITUBOX.

This software allows you to place 3d models on a virtual printer plate, that replicate the real dimensions of the real printer and model you are going to make

I’m gonna print some miniatures I bought to play D&D at FatDragonGames they make awesome looking sculpts ment to be printed with an average filament printer but when this sculpts are fed into an SLA printer the detail is really astonishing

After you’ve placed the models on the plate, you are one click away from having a file containing the instructions needed to print the piece, you just need to fill the tank, start the machine and press the print button.

Clean up and cure¶

This prints are still mechanically weak, soaked in excess resin and pretty toxic. The resin i’m using is “water washable” THIS DOES NOT MEAN YOU CAN WASH THEM IN YOUR SINK but you can use tap water instead of the much more pricey isopropyl alcohol used to wash other kinds of SLA resins. In my experience you can use the same water for 6 miniatures as long as there’s 3 times the volume of water compared to the volume of resin you are washing. There’s a lot of instruments you can use to enhance the speed and quality of this process but it’s too expensive to me compared to 1 night in a can of water and giving it a mix now and then reminds me that i have to get on with the rest of my works

After this cleaning up, the resin is still soft and needs to be cured with UV light, again, one expensive and professional UV oven or just reuse that old nail art drying thing my aunt left in my family’s basement a geological age ago (lamps still work who-ho!). To be precise, the nail oven has a slightly different light than the one the resin is sensible to, but this just means a little more time (1h) to cure.

Written with StackEdit.