Assignment

- design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively

- 3D scan an object (and optionally print it)

A desktop 3D printer that's engineered to perform

It is a machine that allows us to print almost the shape we want, using many materials, and it dissolves and prints these materials, and it is a machine with coordinate axes

Advantages of 3D printing 3D printers are usually faster, easier and easier to use than other manufacturing technologies.

3D printers allow developers to print complex overlapping parts.

Ability to personalize products according to individual needs and requirements

limitations of 3D printing Limited Materials,The size of the machine is so small that if you want to print something big

The first thing I will design is a shape that cannot be made on any CNC except on the 3D printer

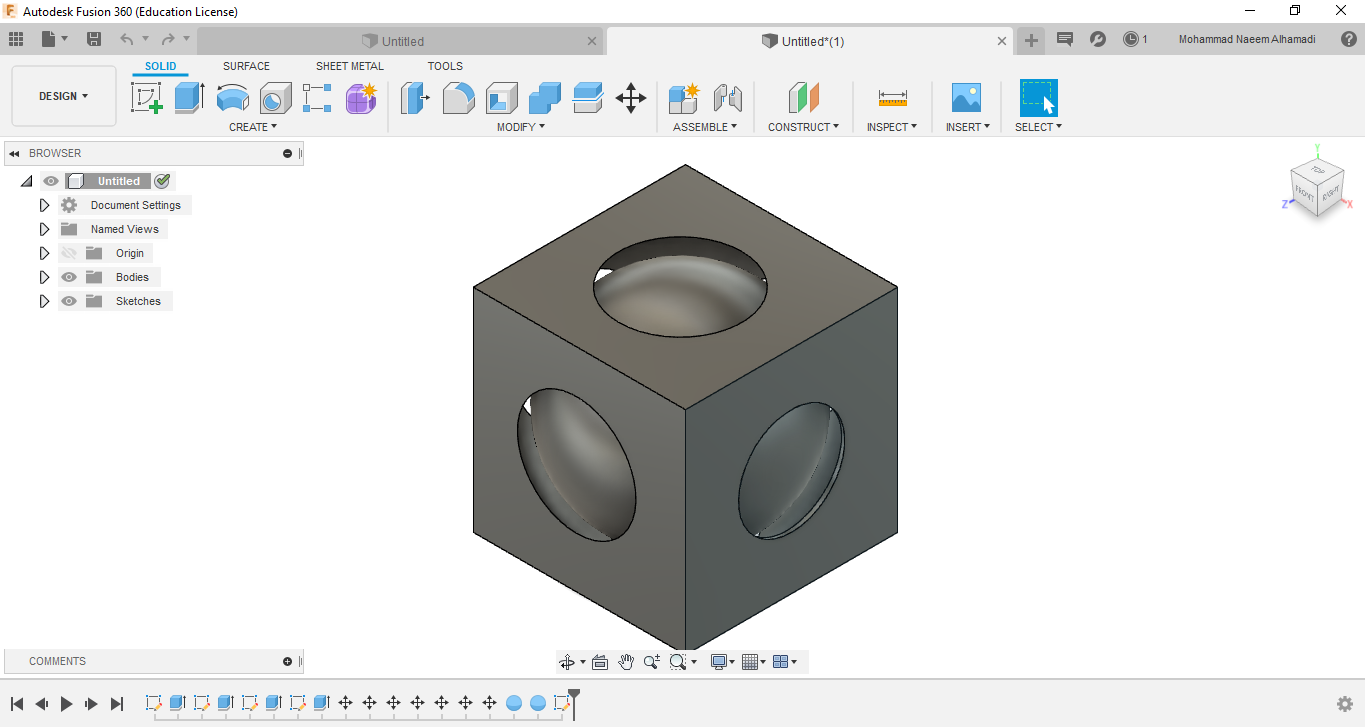

Using Autodesk Fusion 360, I will work with the design

After I have designed a 2D shape, I will convert it to 3D using the tools as shown in the image below.

I will draw a square hollow circle from the inside from the Create command we choose the extrude command, and then do I draw a smaller circle of the circle that has been hollowed out box inside the box to get this shape.

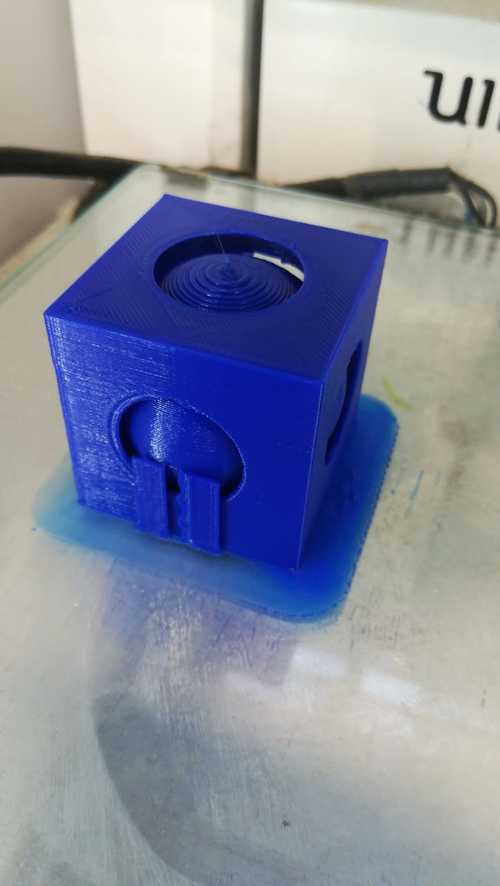

I designed and 3D printed something that cannot be made by milling or CNC machining.

To do a design that couldn't be done by subtraction, I made a square with a ball inside.

The design consists of two parts: A Cube with spherical cavity/hole and a sphere inside the cavity.

This would not be possible without making a Cube complete with a bore and inserting the ball inside the Cube.

These are the areas where 3D printing really shines as additional layer-by-layer fabrication enables this design to be made in one piece.

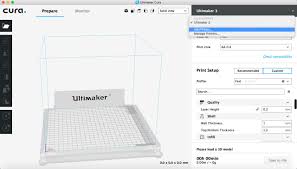

CURA (CAM) program that simulates the machine where we put the ready model

Explanation for most important settings in Cura:

Layer Height: is the distance in Z direction the printer moves after completing a layer. As this value goes smaller, the quality of print gets better, but it will take more time because more layers have to be printed.

Wall Thickness: the printer starts to build outer boarders of the object as a rigid fully filled wall.This number will _define_ the thickness of this wall it should be at least as twice as nozzle diamete.

Top/Bottom Thickness: the printer prints 100% filled layers at the top also at the buttom of the object.

Print Speed: the speed of printer while extruding material .

Travel Speed: the speed of printer while moving without extruding material.

There is an inverse relationship between all speeds and both time and quality of printed object.

Support: if check Generate Support Cura will build a structure to support some parts of the model which have overhangs. Without supports these object will not print successfully.

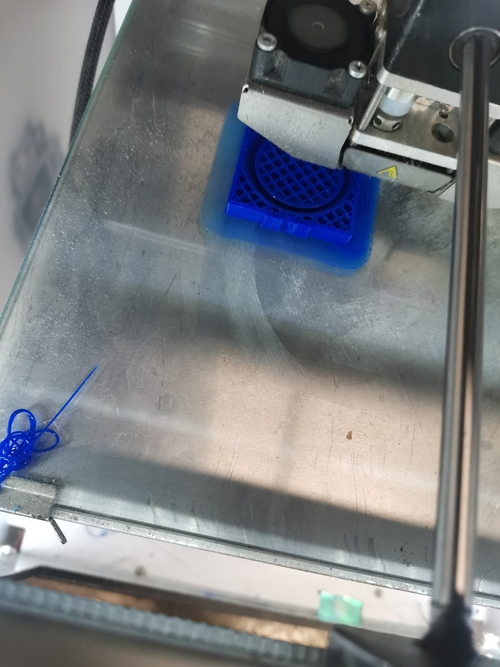

After I entered the design into cura 3d printing slicing software and set up the design on Ultimaker 2+ and added support for the design without affecting the shape of the design(Design often requires support with a substance called PVA, a water-soluble substance), I will save it in gcode format on the memory card to be ready to start printing it

This is the shape after finishing printing

This is a video clip to see the print result

3D printing technology uses FDM technology and type of plastic thread used PLA melt at 210 temperature and ABS melt at 260 ° C.

Manual navigation gives you the freedom to auto-scan wherever you want to capture

The possibility of copying the designs using a digital scanning system for the first model by a Webcam computer

Here is the scanner shape

First we download Sense 2 Scanner I downloaded it from hereand opened it as in the picture below

Then we start scanning after choosing the thing to scan it. We have to do the scanning process slowly and carefully to make the shape look perfect

I put this object on a table, press Start triangle button and hold scanner and tried to rotate around the object because this my first time I couldn't keep my hand at a fixed level so the error message Lost Tracking always appear :

Then we save it in Stl format and enter it into the cura program in order to set the printer settings and save the file in gcode format on an external memory card and then do the printing process

This is the file for Circle and Square in

This is the site for group assignments:Press here

group assignment:

test the design rules for your 3D printer(s).

This link contains documentation for group work.