Computer controlled machining.

Group Assignment:

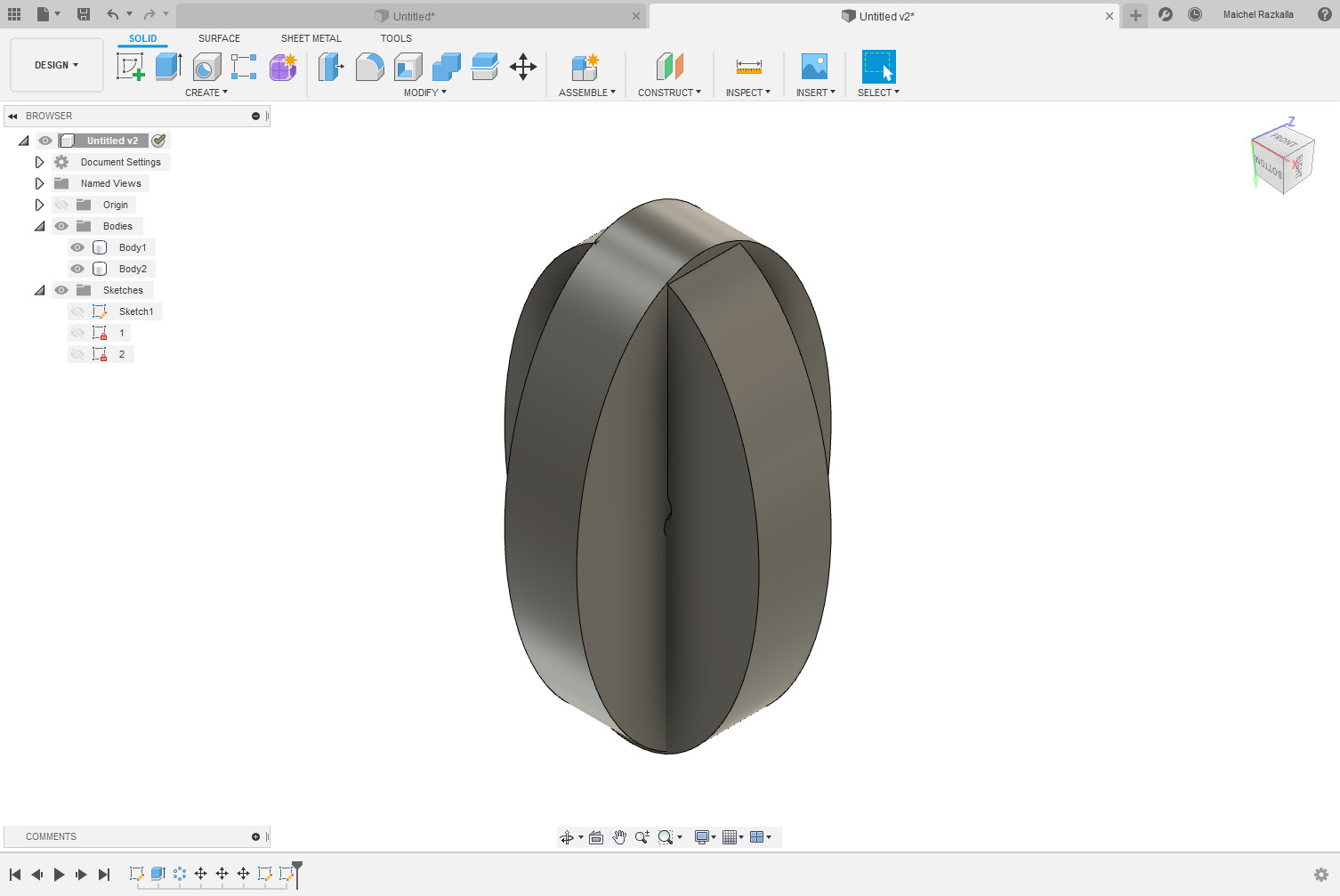

I designed a simple press-fit American football to test the runout, alignment, speeds, feeds, and toolpaths for the machine.

So I started with drawing my parts on fusion, and after I finished my college sad to me that I was massing something call "Dogbone" so at first when I draw the parts I dow it with a hard edge from inside but when the CNC cannot make hard edge from inside it will be Cornard, and I will explain this more with pic in the CAM process.

.png)

As I understand without dogbone the parts will note press-fit right together so I started with surfing the youtube and I found this great video that explains everything about dogbone types and how to create them and after I follow the video tutorial I end up with that ""D

.png)

last is to mirror my body and fit everything together.

CAM prosses.

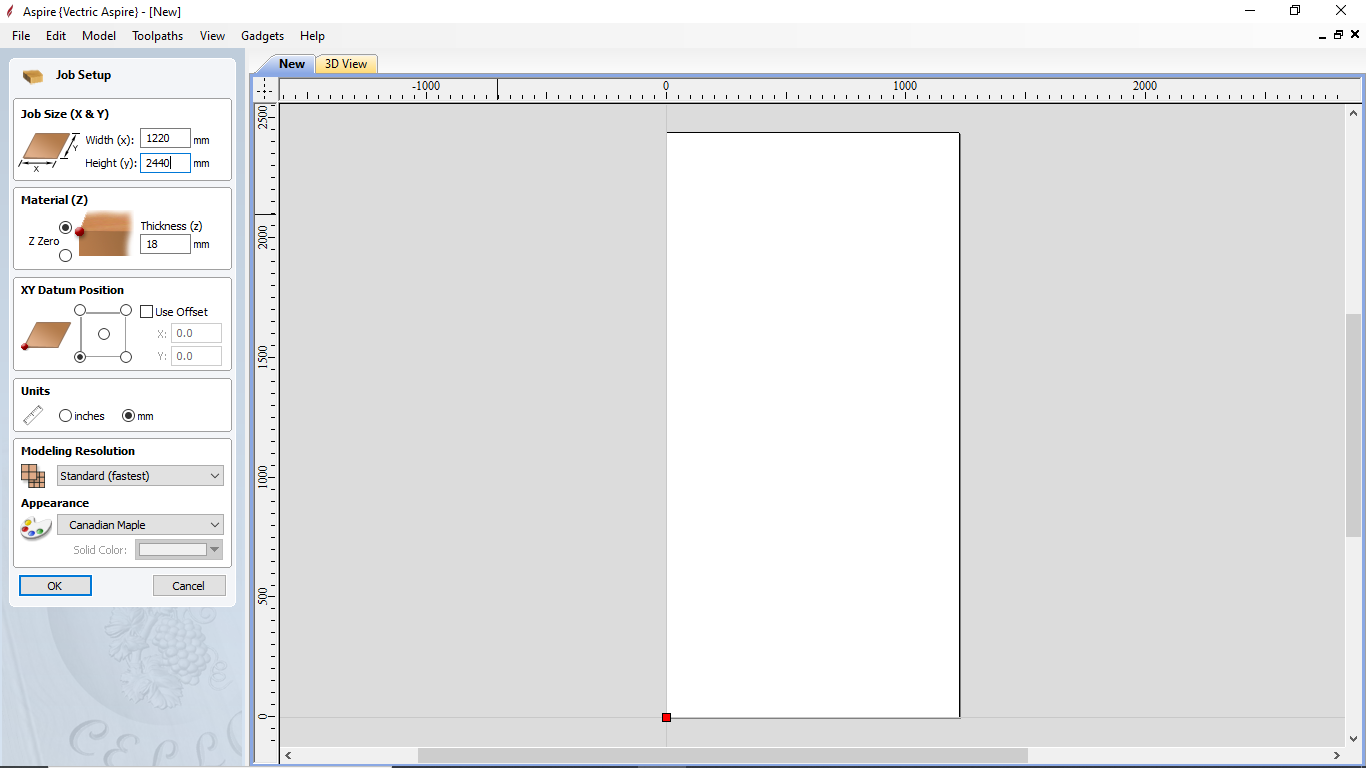

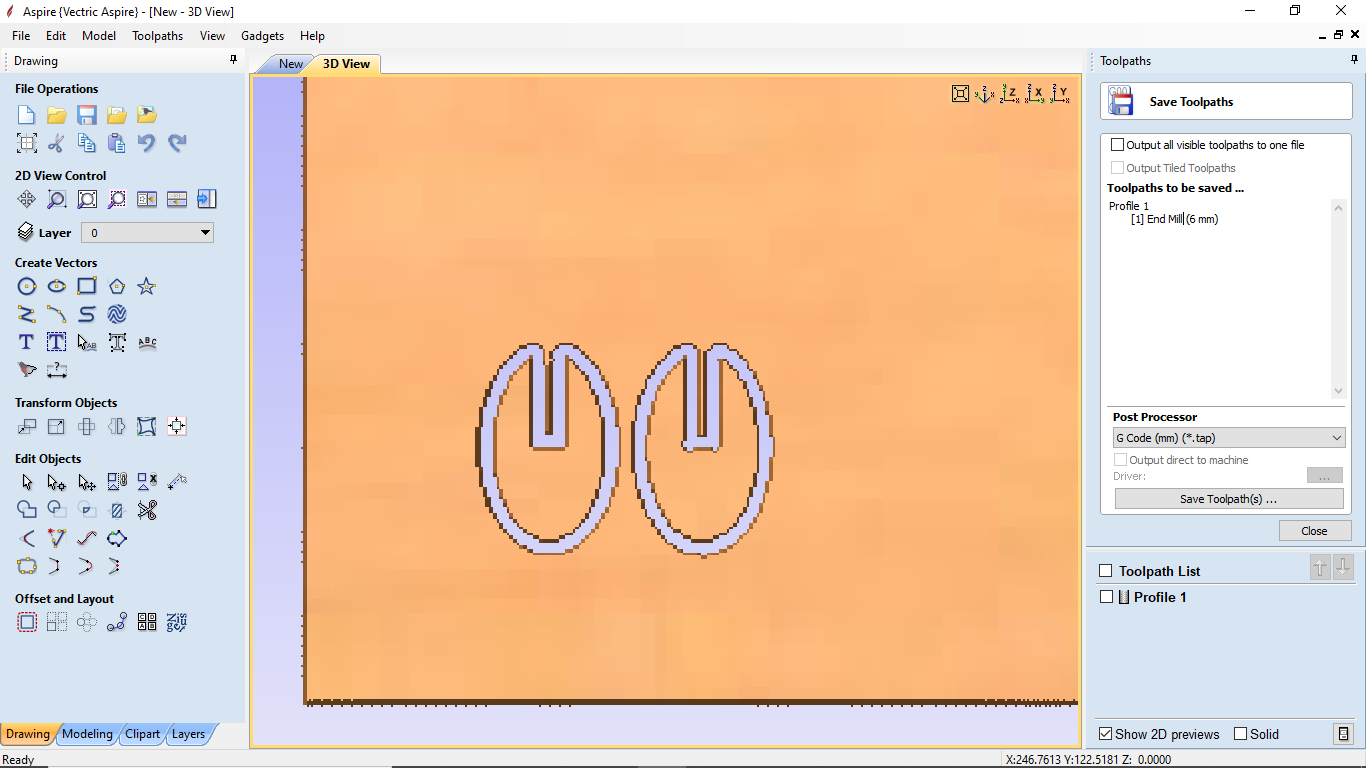

so everything looks great, now we need to export the DXF from the sketch to use it at the CAM process, I will use "Aspire" so at the start you need to add the wood area I'm going to the machine.

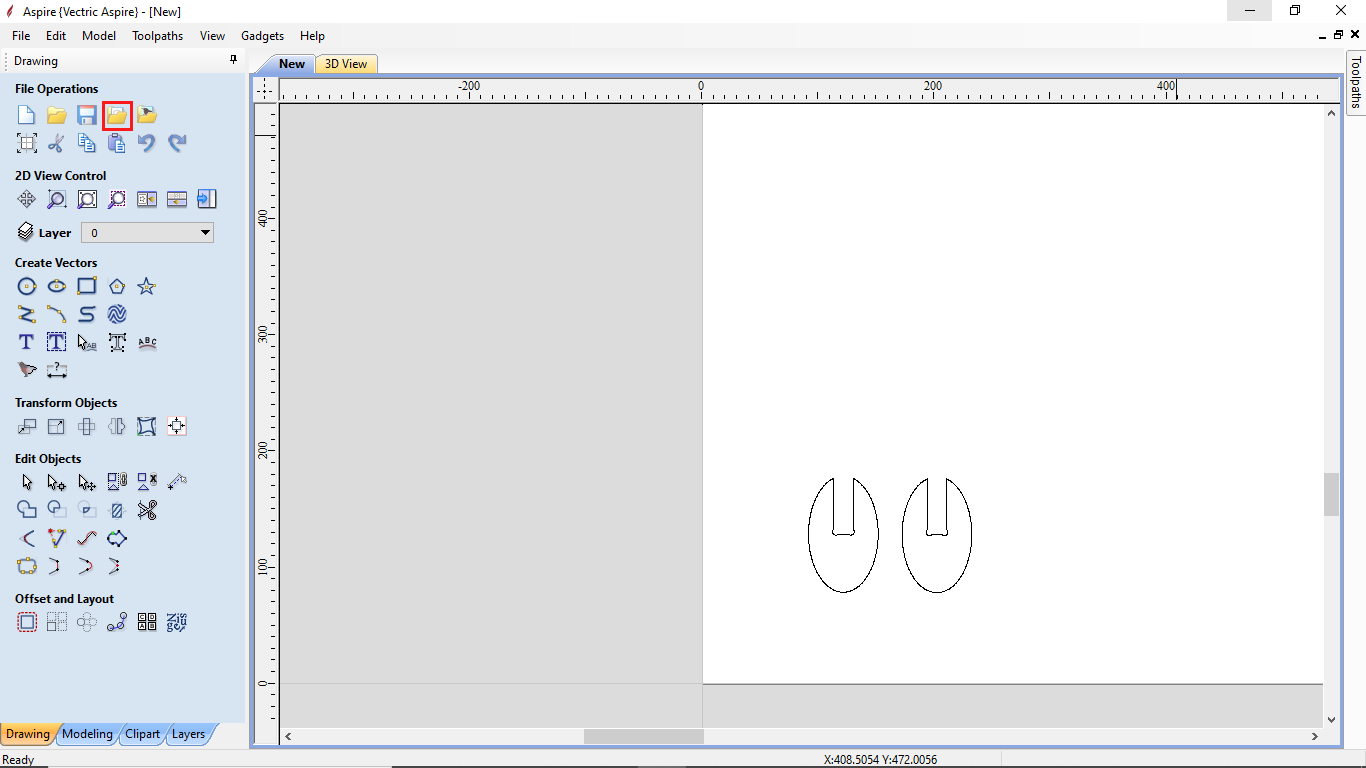

next to import the DXF files and from here we start the action X"D

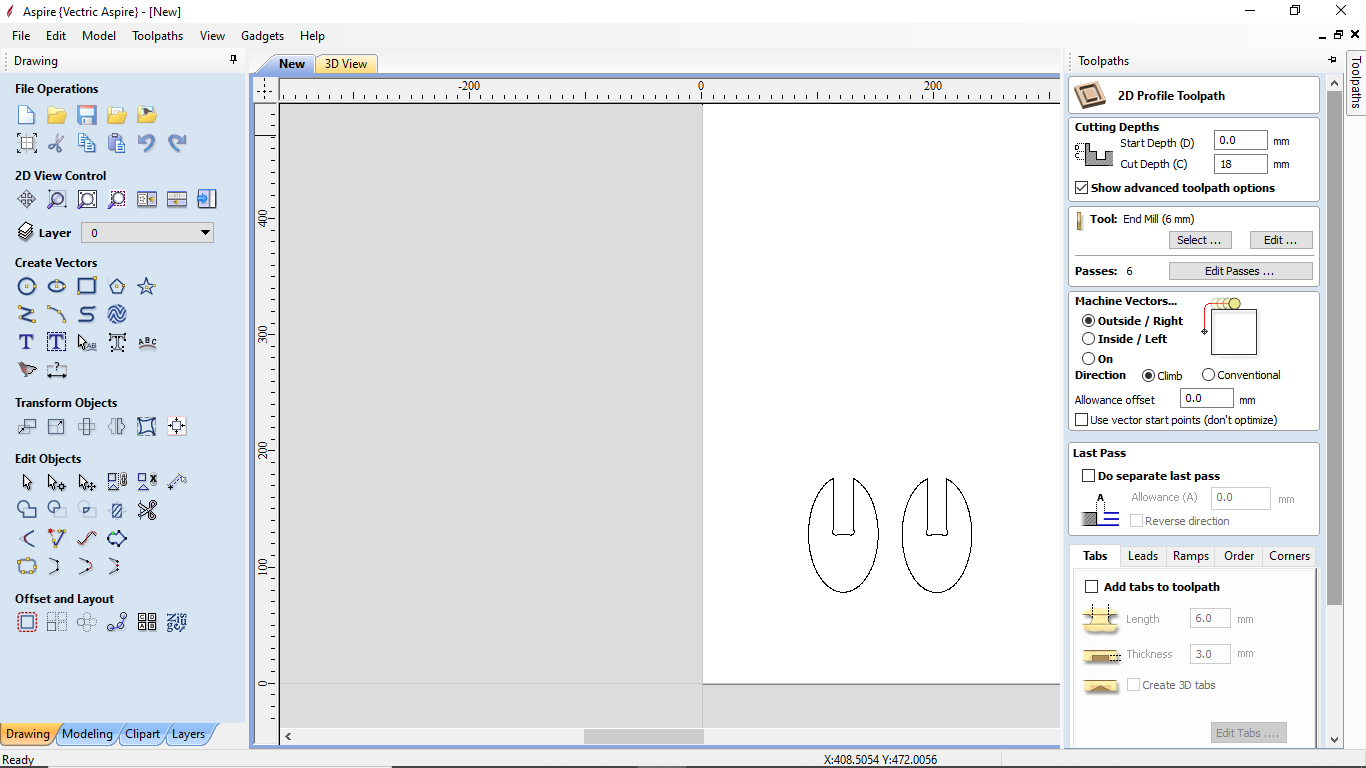

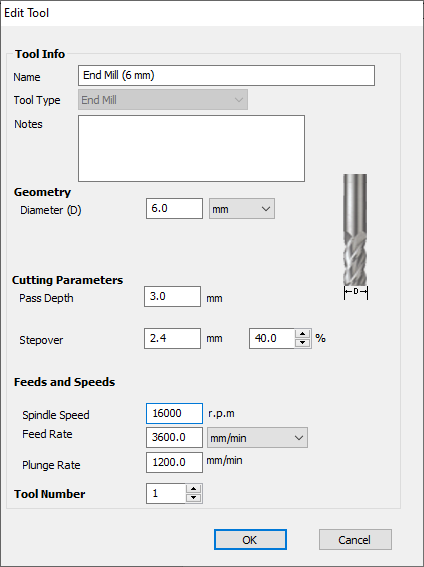

now I will generate the toolpath for the machine from "Profile toolpath" and now we have a lot of options to set X"D , so at the start, we need to set the cut depth and we will wright the wood material thickness, next to choose the cutting tool and we will use "6MM End mill".

for the "Edit" option from there, we can set The "cutting parameters" and the "feeds and speeds ", so for the cutting parameters I will set it as default but for the feeds and speeds it changes from machine to another and witch material you will use so for the spindle speed I will make it "16000 r.p.m" and for the feed rate I will make it "3600 mm/min"now everything looks ok

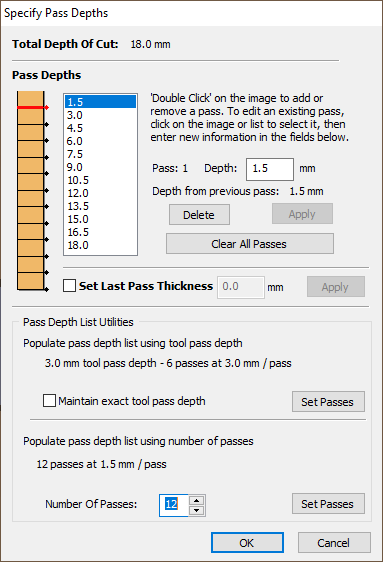

Next for the number of passes so I will make the cut depth 1.5 mm per pass has it's too low but I like to be it the safe zone, now for the machine vector pass there is three options from outside, inside, and last on. so I will choose the outside to not change the part diameter

so everything looks ok now to calculate the toolpath to get the g-code, oh as you know or you don't know g-code has many flavors watch flavor can be used to operate in a defiant machine, so the flavor we will use on the CNC as I told it will be "G Code (mm)(*.tap)"

Milling prosses.

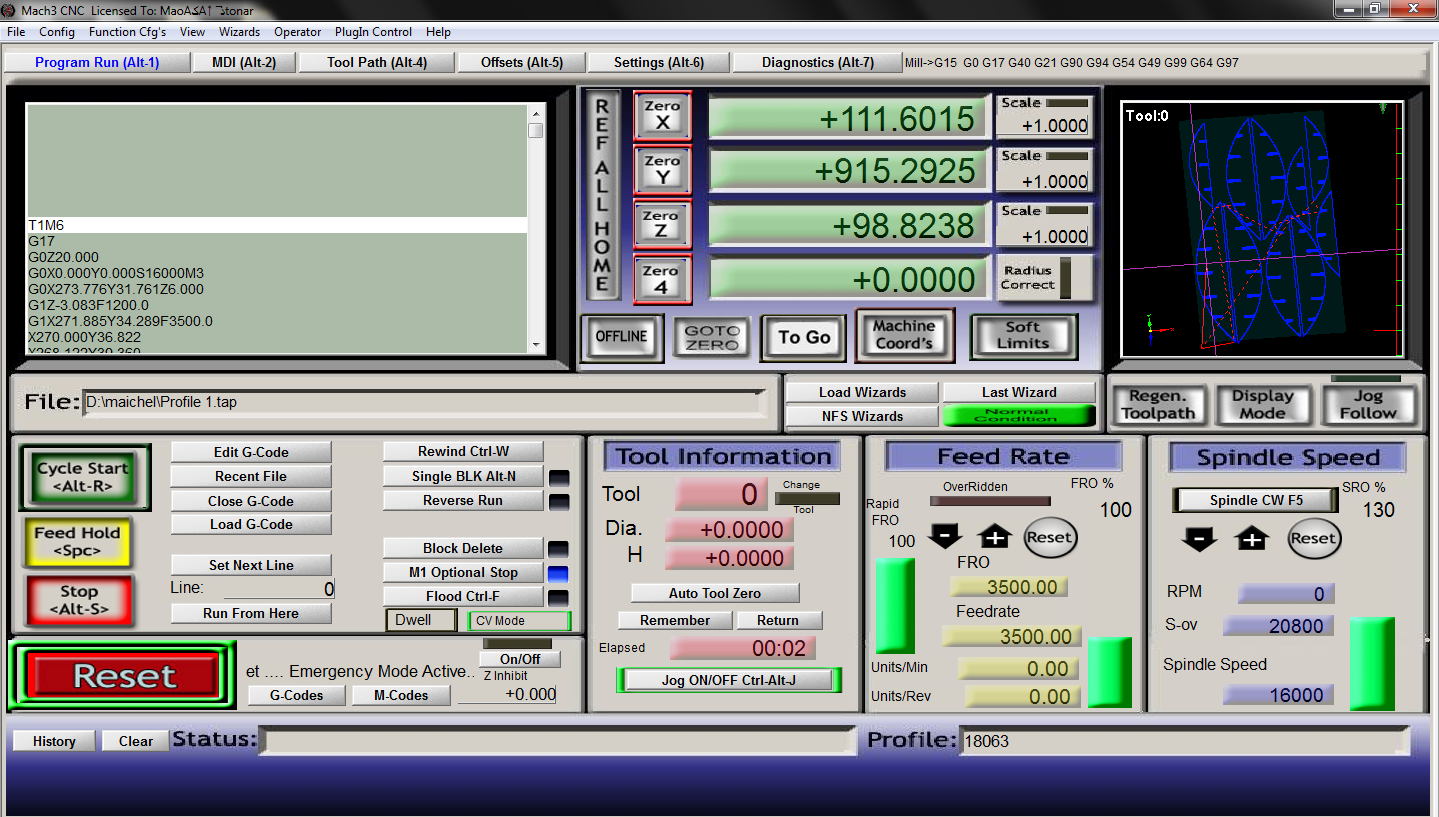

To interface with the CNC and send the g-code we will use a program called "Mach3", oh so I didn't take a pic when I was cutting the example so I will explain the program with final parts sorry for the spoilers " D

Now for milling prosses, we need to "load G-code at first, next to set the {X,Y,Z} origin, last we will start the milling process by clicking "Cycle Start"

So after milling the part's it fits perfectly but there was one small problem the milling the parts, the machine was pitting the parts after searching I discovered that I need to add "Tabs" to fix the parts.