Applications and Implications (Week 11)

Individual Assignment:

For this week we were tasked by Neil sir to answer some question regarding our Final project.

1. What will your project do?

2. Who's done what beforehand? v3. What will you design?

4. What materials and components will be used?

5. Where will materials andd component will come from?

6. How much will they cost?

7. What parts and systems will be made?

8. What processes will be used?

9. What questions need to be answered?

10. How will it be evaluated?

11. Where possible, you should make rather than buy the parts of your project

In my honest opinion answering these question was not less than a headache , which everyone has to go through now or later so , taking this headache now is better than taking it later.

IMPORTANT NOTE : ALL OF MY IMAGES ARE POP UP IMAGES , IF YOU HAVE ANY PROBLEM READINGS THOSE IMAGES , PLEASE CLICK ON THEM AND THEY WILL ENLARGE AUTOMATICALLY AND YOU CAN READ THEM EASILY

Q1. What will your project do ?

Aim of my project is to is to make a cost effective and moduler air purifier,s which runs on the basis of a custom designed PPM meter which we can easily placed on wall .

Motivation for my project was - My college which is 'INDERPRASTHA ENGINEERING COLLEGE' is situated in the SAHIBABAD industrial area is covered with lots of industries from all side and is just adjusent to a open rumming sewage drain. And this kind of environment creates a deadly cocktail of gases which has a very bad foul smell and this gase is injurious to our health also. so air purifier.

Q2 Who's done what beforehand ?

ORIGIN OF AIR PURIFIER

In 1830, a patent was awarded to Charles Anthony Deane for a device comprising a copper helmet with an attached flexible collar and garment. A long leather hose attached to the rear of the helmet was to be used to supply air, the original concept being

that it would be pumped using a double bellows. A short pipe allowed breathed air to escape. The garment was to be constructed from leather or airtight cloth, secured by straps.

In the 1860s, John Stenhouse filed two patents applying the absorbent properties of wood charcoal to air purification (patents 19 July 1860 and 21 May 1867), thereby creating the first practical respirator.

A few years later, John Tyndall invented an improvement to the fireman's respirator, a hood that filtered smoke and noxious gas from air (1871, 1874).

In the 1950s, HEPA filters were commercialized as highly efficient air filters, after being put to use in the 1940s in the United States' Manhattan Project to control airborne radioactive contaminants.

The first residential HEPA filter was reportedly sold in 1963 by brothers Manfred and Klaus Hammes in Germany, who created the Incen Air Corporation which was the precursor to the IQAir corporation.

For more info you can go and read about it through this link .

THINGS MADE IT DURING FABACADEMY

1. The first project which came up on the search of air purifier was JayMok he come from FabLabXH, China . and he completed his diploma in 2016 and as a final project he planned to make a air purifier for his lab . you can go and visit his site through this link.

2. Second person which did this type of project during his fabacademy cycle was 'Eng Hwa Lucas Lim' from FABLAB Singapore . As final year project he maid a ppm meter to detect the elevated polution level in his lab ,you can go and visit his site through this link.

Q3. What will you design?

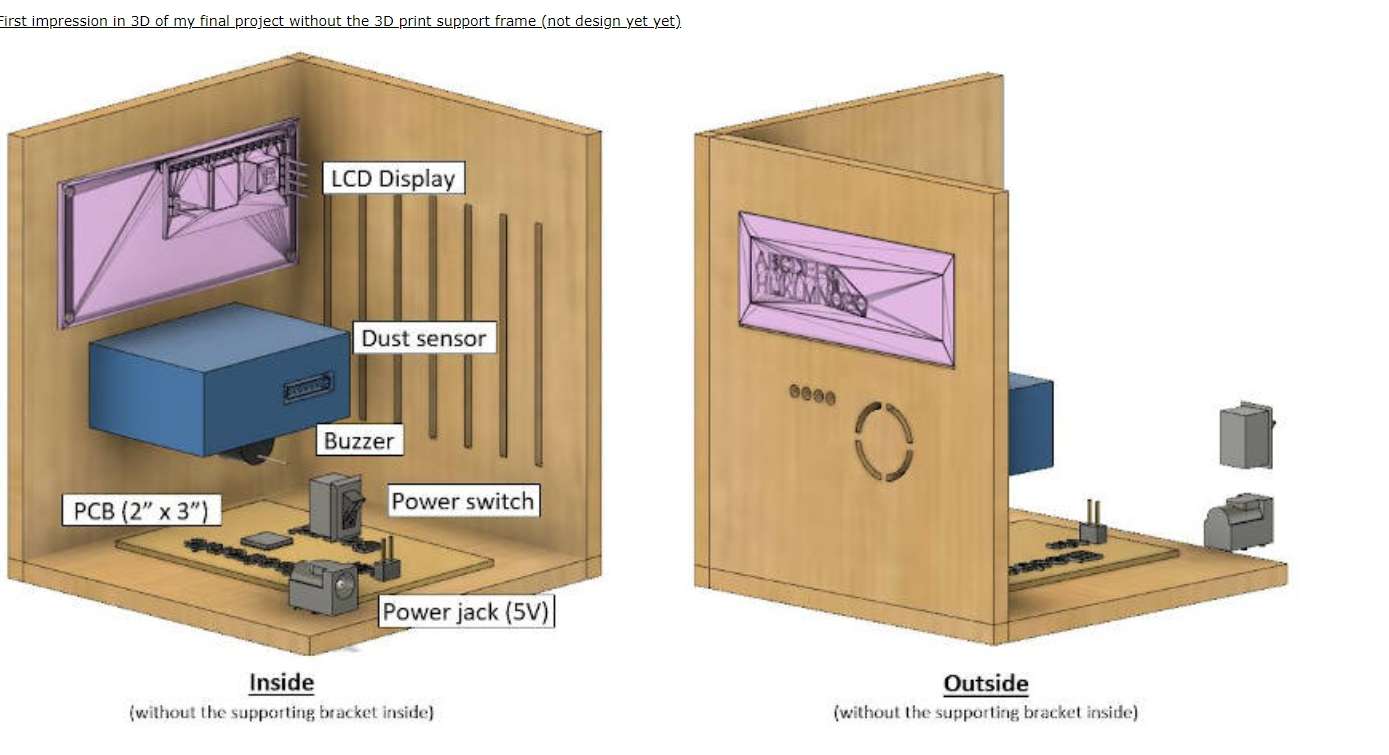

>Right now i have not designed the electronic's box design or how i will place the components but it will be similar to how "Lucas Lim" has designed it.

Things which i will design are:

1. PCB circuit , which will be connected to the LCD screen ,PPM Sensor and DC fan.

2. 3d printed moduler part s

3. 3D printed /Laser cutted enclosure for all the circuit , screen and Sensor

4. A cool design on the vinyl cutter as a sticker.

Things which i will not deisgn (Preffer buying them)

1. D.C fan

2. PPM sensor

3. Air filter's

Q4. What materials and components will be used?

All the parts will be printed in PLA at our lab

FR1 Copper material to create the PCB for Input and Output Device.

Jumper Wires

Air filters

Sensors:

PPM SENSOR

Microcontroller: ATMega328P

Output devices

D.C. Brushless fan

2.4inch TFT SCREEN

LED Switch

Q5. Where will come from?

Most of the components we have at the Fab Lab, but others are going to be ordered online .

1. TZT 2.4 inch TFT LCD Module LCD Screen Module SPI serial 51 drivers 4 IO driver TFT Resolution 128*160 For Arduino

The purpose of using this is screen is that it can display at what percentage the fan is working as well as , what is PPM level its on.

Link for the site

2. PLANTOWER Laser PM2.5 DUST SENSOR PMS7003 High-precision laser dust concentration sensor digital dust particles G7

PMS7003 is a kind of digital and universal particle concentration sensor , which can be used to obtain the number of suspended particles in the air , i.e. the concenteration of particles and output them in the form of didital interface . this sensor can be inserted into variable instrument related to the cocentration of suspended in the air or other environmental improvement equipements to provide correct concenteration data in time.

Link for the site

3. HEPA Filter

A germicidal lamp is a special type of lamp which produces ultraviolet C (UVC) light. This short-wave ultraviolet light disrupts DNA base pairing causing formation of pyrimidine dimers and leads to the inactivation of bacteria, viruses, and protozoa. It can also be used to produce ozone for water disinfection.

4. LED ON/OFF SWITCH

5. D.c brushless fan

Link for the site

Q6. How much will they cost?

Total cost of project reached upto 3500 Indian rupees which is aprrox 36 $

| Name | Description | Quantity | Price/Pcs | $ |

|---|---|---|---|---|

| PMS 7003 ppm sensor | use to measure ppm level | 2 | Rs.1400 | $19 |

| 2.4 inch TFT screen | uses to display sensor data | 1 | Rs.300 | $4.06 |

| 100mm D.C brushless Fan | Uses to create succison | 2 | Rs.750 | $10.16 |

| LED 19 mm switch | Its a latching type switch which has inbuild Led in it | 2 | Rs.200 | $2.71 |

| Air filter | For purifying air | 3 | Rs.400 | $5.42 |

| 3d Printed parts | PLA based material | 1kg | Rs.2000 | $27.10 |

| Nut and Bolts | Fixing all the components in the Base | 1 | Rs.100 | $1.35 |

| Total | Rs. 5150 | $69.8 |

Q7. What parts and systems will be made?

- Laer cut box for parts

- 3D Printed parts

- PCB’s for each component.

Q8. What processes will be used?

- Computer-Aided Design

- 3D printing

- PCB Milling

- Laser Cutting

- Electronic Design

- Electronic Production

Q9. What questions need to be answered?

Does a low power fan can filter this pollutents

Doesthe moduler parts fit easily

Q10. How will it be evaluated?

Project should be evaluated on basis of 3D CAD , Programming , and Circuit Design.Important part is to control to controll the speed of fan on the basis of ppm sensor project.