About

Hello! My name is Alejandra, and I majored in Architecture in San Francisco University of Quito. I have lived in many countries during my childhood because of my father's job (Venezuela, Peru, Brazil, Colombia), so I have had the luck of being acquainted with many different people and cultures. I enjoy designing and creating objects, especially those that may help me make my life more efficient. I am very interested in sustainability and the environment and did my thesis in sustainable modular architecture.

Follow my progress as I learn and study the FabAcademy 2019 course, complete the assignments and accomplish the final project.

Directly from FabLab ZOI website:

"FabLab ZOI es un laboratorio de investigación y desarrollo tecnológico que promueve ciencia, diseño y arte como centro del desarrollo humano para mejorar la calidad de vida en Latinoamérica. Nace en 2014 en la ciudad de Quito y ha generado proyectos de impacto en Ecuador y Latinoamérica enfocados en la inclusión y democratización de conocimientos y tecnologías emergentes. Somos parte de FabLab Network, red global de laboratorios que promueven la educación de calidad de manera distribuida y el empoderamiento tecnológico. Donde se generan programas educativos liderados por los intelectuales más destacados del mundo en diferentes áreas del conocimiento. Aquí se puede hacer realidad cualquier idea."

Directly from FabAcademy website:

"The Fab Academy is a fast paced, hands-on learning experience where students learn rapid-prototyping by planning and executing a new project each week, resulting in a personal portfolio of technical accomplishments.

It offers a distributed rather than distance educational model, students learn in local workgroups, with peers, mentors, and machines, which are then connected globally by content sharing and video for interactive classes.

Fab Academy runs in more than 70 Fab Labs, for more than 250 students per year in the largest campus of the world. Fab Academy Program is part of the Academany, the Academy of Almost Anything."

The Fab Academy is responsible for:

I am a Fab Academy student, responsible for:

Alejandra Loaiza

For my personal reference

milling PCB's

Mods

All other parameters were the default ones in the g-code milling mods program

January 16-22

Our first assignment was to plan and sketch a potential final project.

I arrived to class with no idea of a project, even though I knew that was a major part of the FabAcademy course. However, I did have two clear objectives in mind about what I wanted my project to be about:

I wanted to have a lot of information before deciding upon any project. Therefore, I searched projects that had been done before on fab academy, researched new inventions that had been made, and problems that could be solved by the invention of objects. With this information, I arrived upon some options for my project. For each option, I explain the why, and the pros and cons of each idea. All this was to better weigh out each idea and decide upon a project that could be possible and I would be interested in.

The first option I considered was either a self-heating mug, of a spoon like device that would maintain a beverage hot.

Why? Because my coffee was cooling too quickly, and it seemed like an object I needed.

Pros- It would seem to be a very possible and not that complicated project with the skills we would learn. Would include sensors and integration and may become a commercial object.

Cons- Does not align with the objectives I had in mind

Then there was the idea of a wand-like printing machine for students. It would be a device that I could pass on top of a page and it would print whatever I set it to

Why? So that students wouldn’t have to go to a printing machine or printing place, they could just pass this object on top of a notebook or a piece of paper regardless the size and it would print out things almost immediately. It would be portable, and they could carry it with them

Pros- seems like and interesting project and would be very useful

Cons- also sounds like a complicated process and I have no knowledge of whether the printing technology could be shrunk down in a portable object.

Another idea was that of a heating/massaging scarf. While working on a computer with poor posture, it is very common to have back and neck aches. This object was intended to alleviate those problems.

Why? help with back and neck pain

Pros- sounds like an interesting object and does not seem to have too complicated technology. Would probably be marketable.

Cons- does not align to the objectives I had in mind

As a fourth idea I proposed a food digestor-cycler to turn scraps of food into fertilizer.

Why? To change waste into something useful and help the planet

Pros- does align to one of the objectives I had in mind (good for the environment)

Cons- the composting process involves many things and would probably turn into something complicated. Also, there are many objects on amazon that already offer thins functionality, therefore it may be redundant.

My fifth idea was some sort of tracking sticker technology that would incorporate virtual reality through a smartphone. There would be these stickers with small chips integrated in them that would track the location of objects, which I would be able to see through a virtual reality app in my phone

Why? To not lose objects again

Pros- sounds like something that would be very helpful and useful

Cons- involves a lot of technology of which I have no knowledge of, so it would probably be something very complicated.

Finally, the last idea that I had would be some sort of machine that would turn wooden scraps into new, useful pieces of wood by first turning the scraps into dust, then creating a mix with that dust that would then be flattened out and dried into a new, solid piece of wood.

Why? Recycling materials would help avoid waste

Pros- would be very helpful for the environment

Cons- has a whole lot of processes behind it, is probably more than one machine. Might have to be a very big machine to do all this.

That was my initial thought process behind deciding what final project I would like to do. However, none of these ideas aligned with both objectives I had in mind, so I continued researching and came upon:

-This amazing structure-

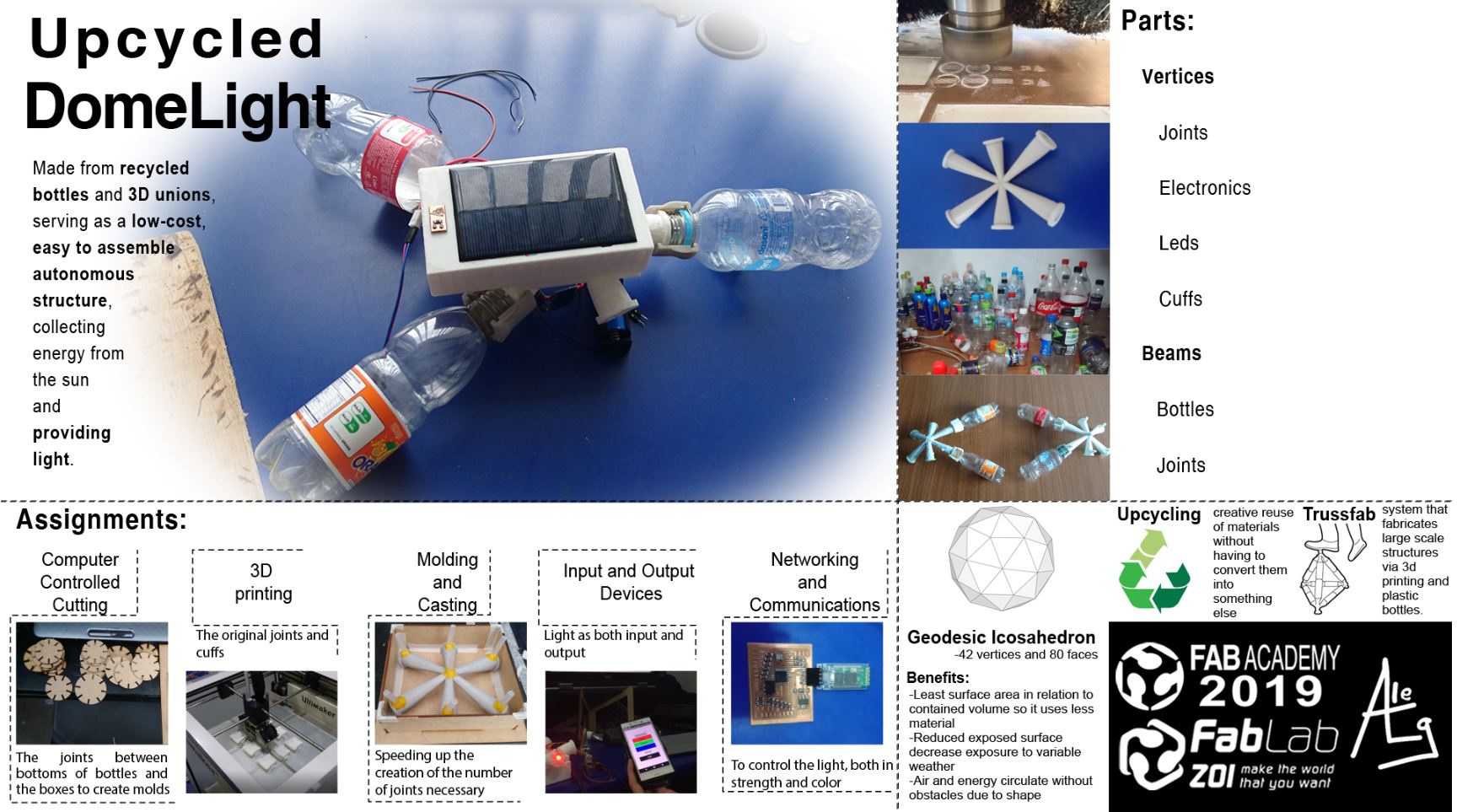

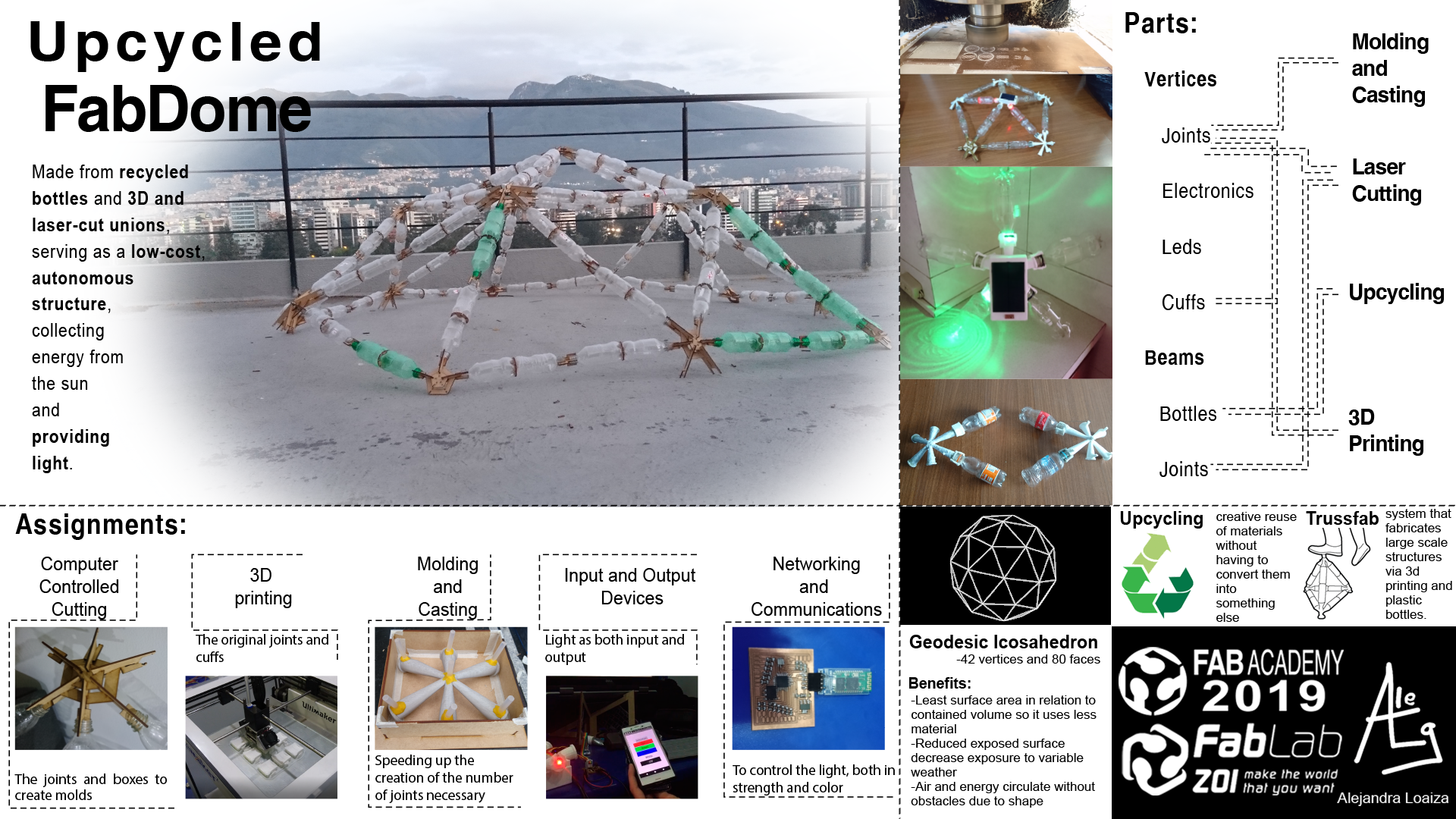

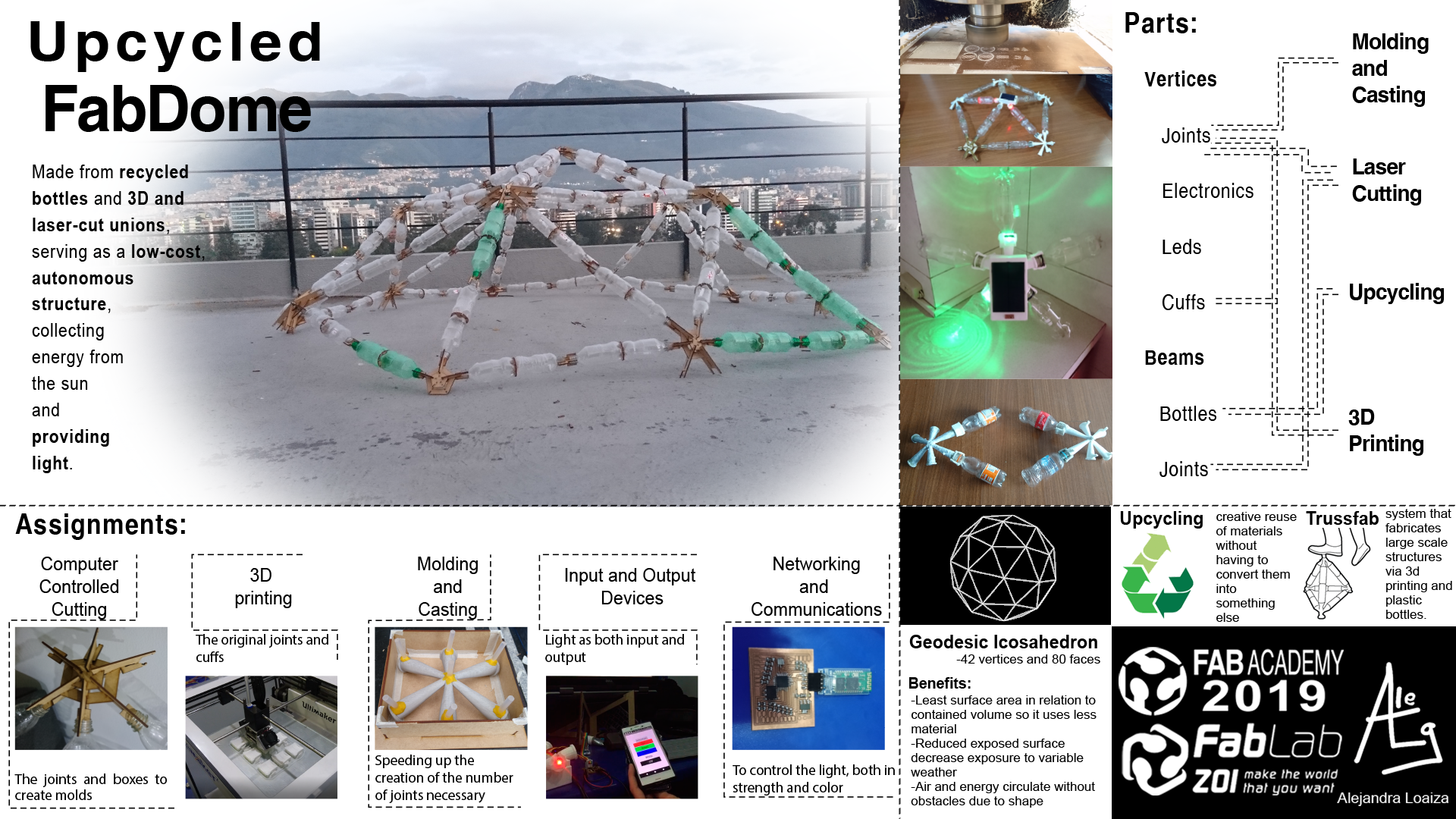

PhD researcher Robert Kovacs and his team from the Human Computer Interaction Lab at the Hasso Plattner Institute in Potsdam had developed a SketchUp plugin that made the creation of these structures easy. You can read more about this here, and see the original article from archdaily where I got the idea here. Also, click here for the trussfab manual.

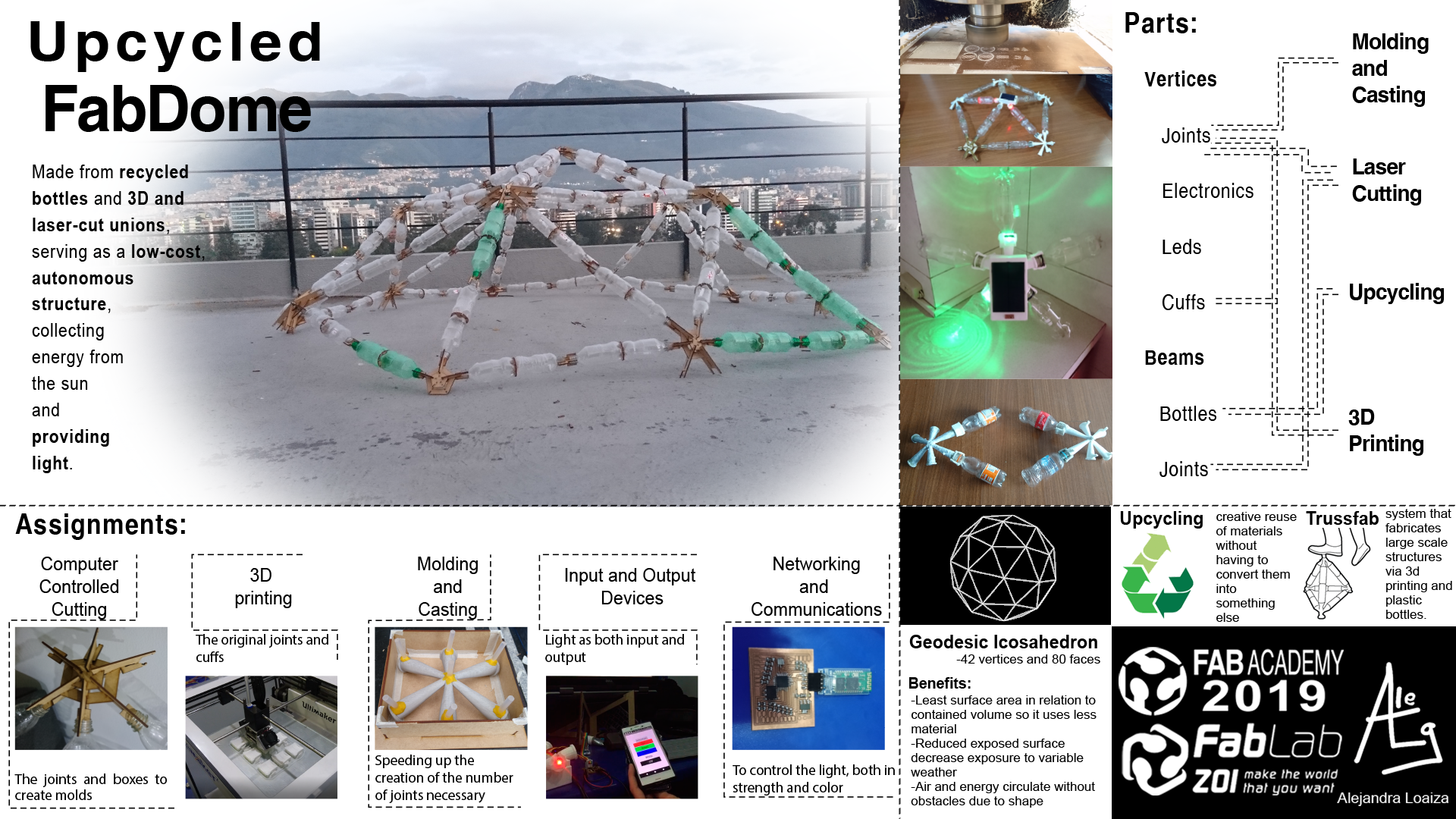

I had found a starting point for my final project. That structure caught my attention. Its structure has that which I was seeking for my project- both modularity and environmental friendliness, as it is reusing plastic bottles. The modularity in it allows an infinity of configurations, for which I could find many functions.

The shape itself I could configure to be a dome, or some sort of hut- refuge system. It enables the creation of a structure that could be both strong but cheap, so it could help provide a solution for the immigrant crisis we are now living in Ecuador, where Venezuelans fleeing their country have nowhere to be and many can be seen living on the streets or in tents until they find a place to stay. Therefore, a structure could be made that could help these people.

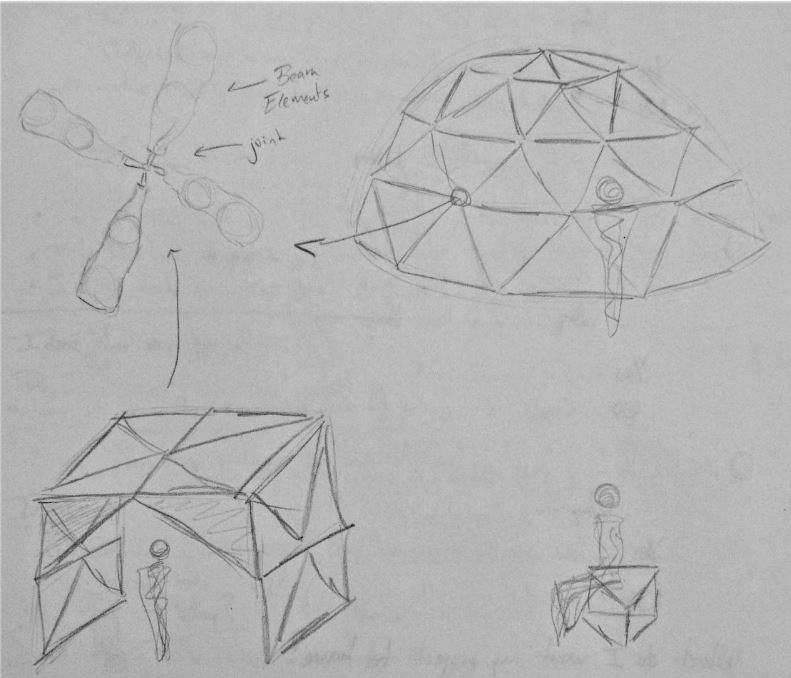

Something sort of like this:

This is an image to illustrate the idea, taken from this source

As I mentioned, the possibilities are endless. I want to create something that can be a shelter, but the same modules can also be used to create a sculpture, a pavilion, a table, chairs… many many things. By inserting different sensors into these modules or creating modules that can be combined with the others, a solar panel sensor could be incorporated which would charge a battery which will later be used to turn on a lightbulb at night. There could also be some sort of air filter process so that it could be placed as a sculpture somewhere in the city that could also help clean the air. It could be purely aesthetic, incorporating a series of lights that change colors and light up according to sensors that sense the movement of people around it, in case it was a pavilion. These are only a few of the possibilities of this project.

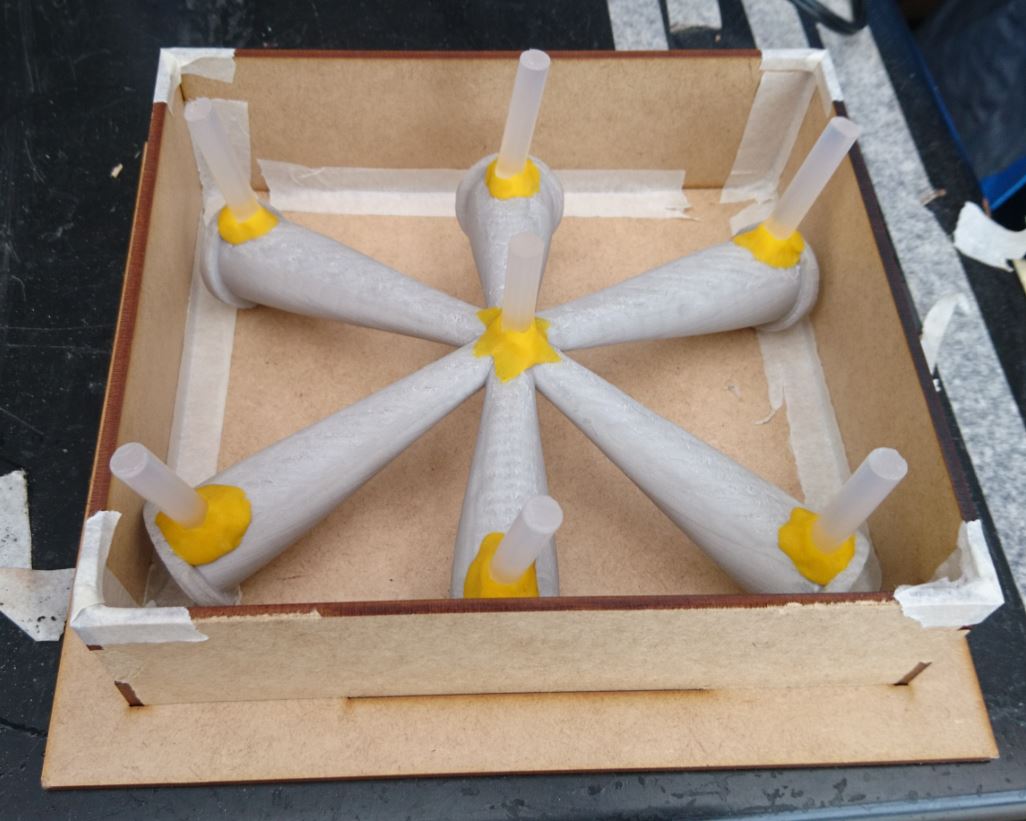

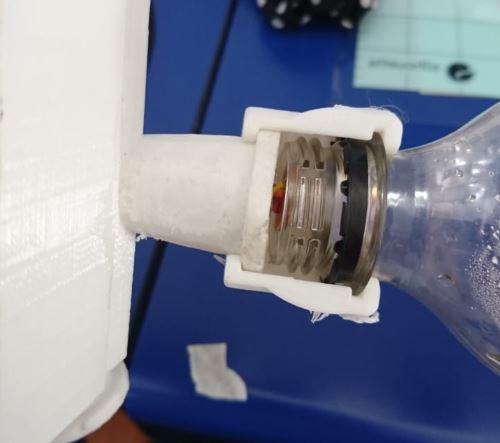

In shape, the way that is project works is using bottles as beams, joining two bottles through their bottoms to create a beam. These beams are in turn connected through joints to create a structure. The joints must be analyzed to either be laser cut or 3D printed in order to have the correct angles and be able to create the right shapes for the structure to work and for something interesting to be formed.

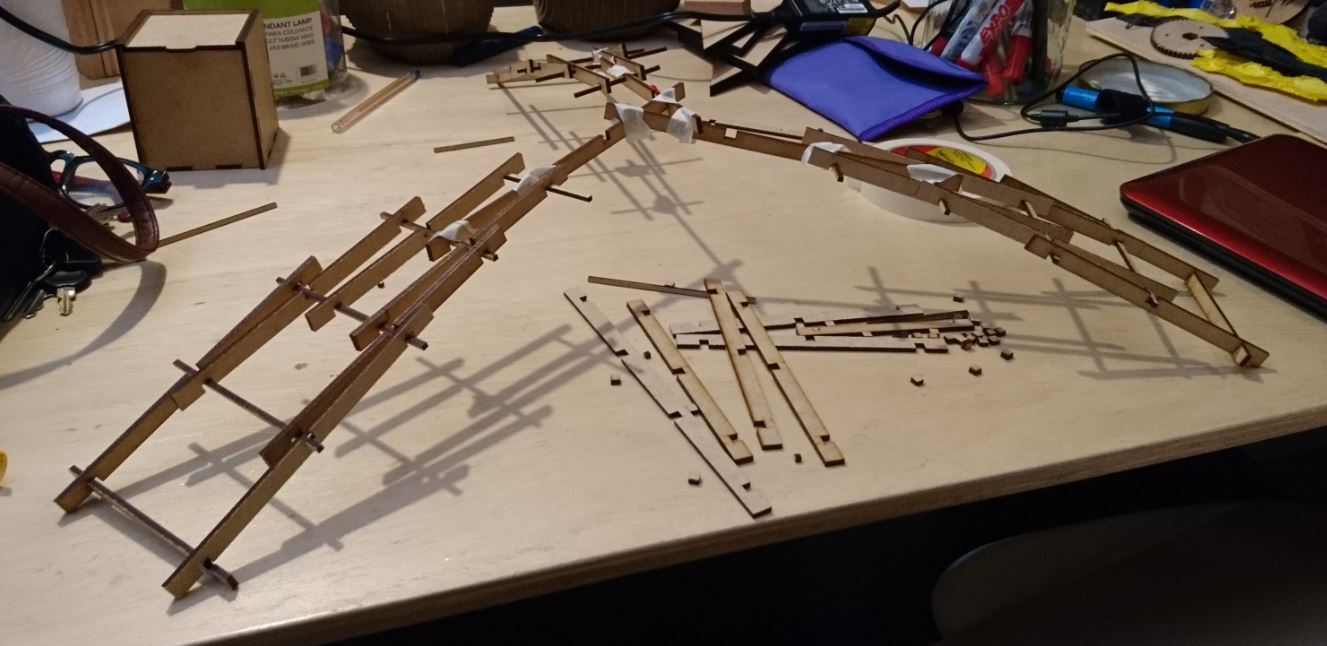

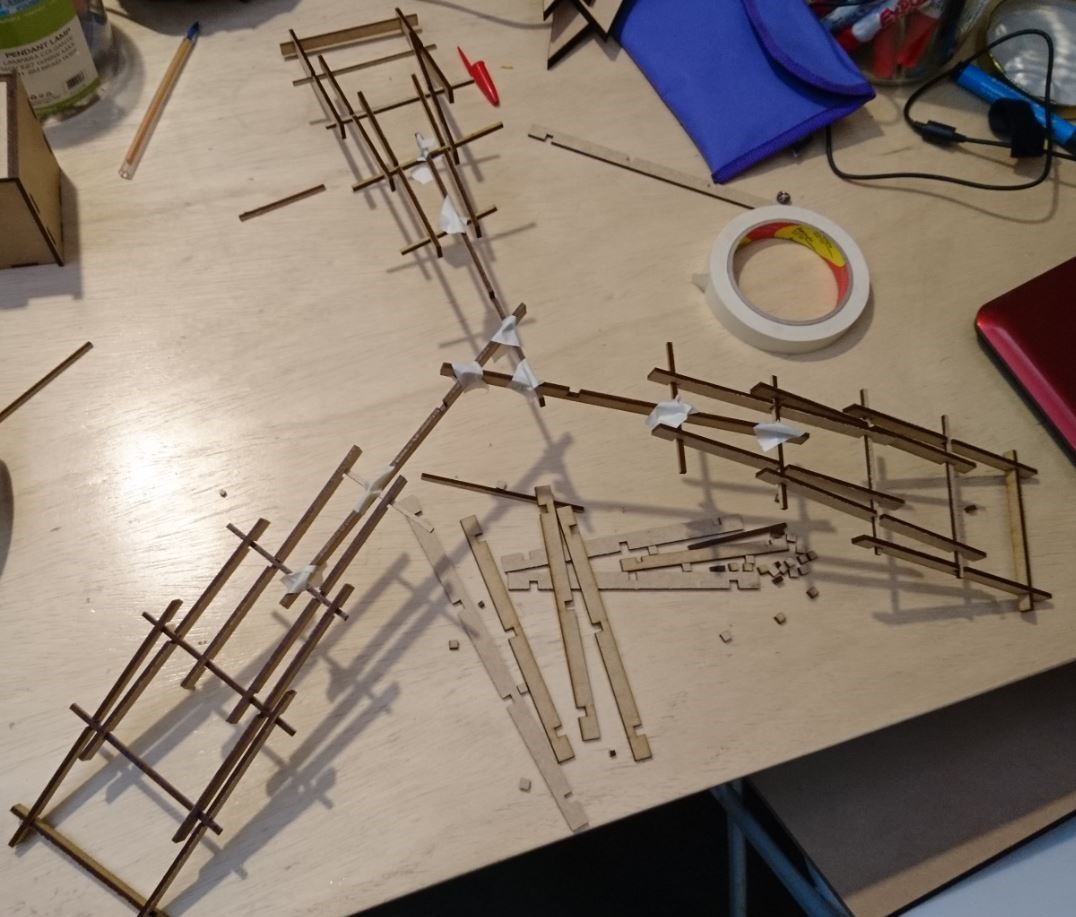

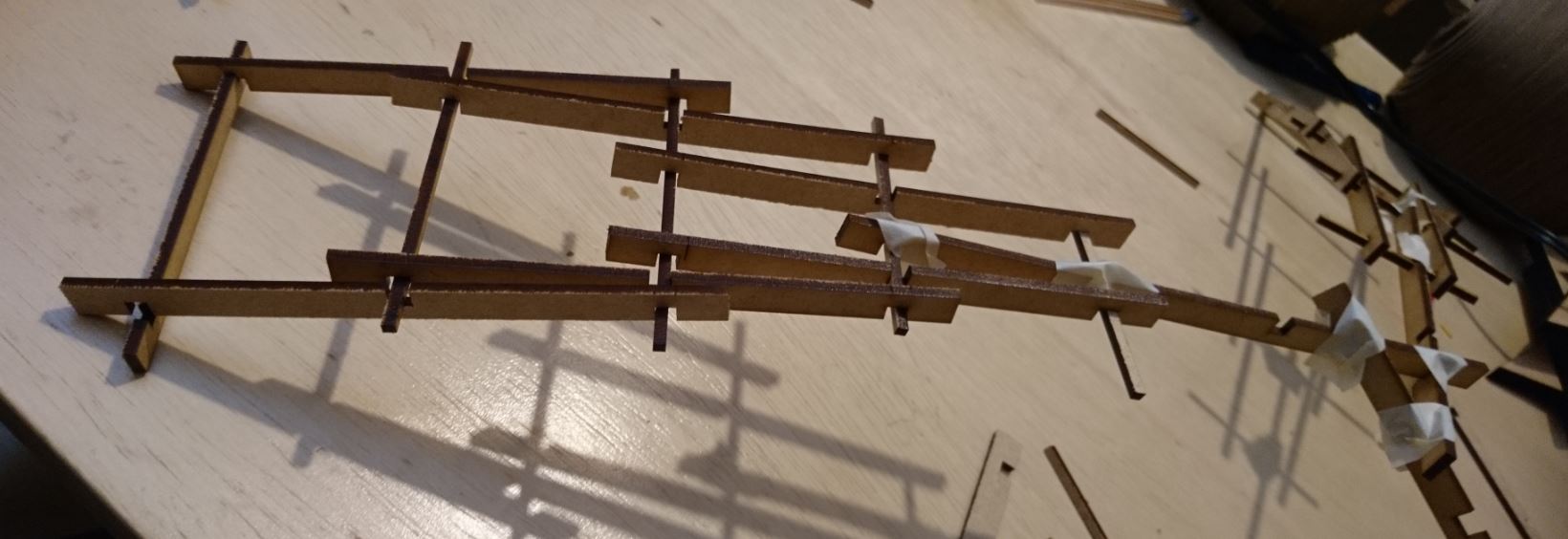

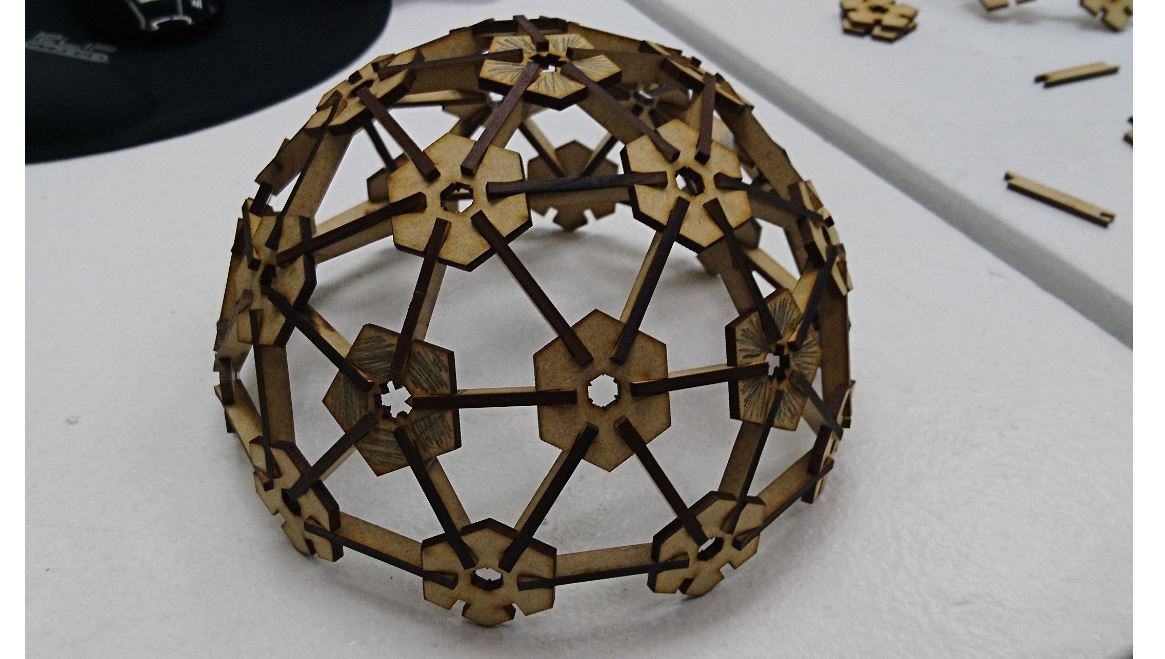

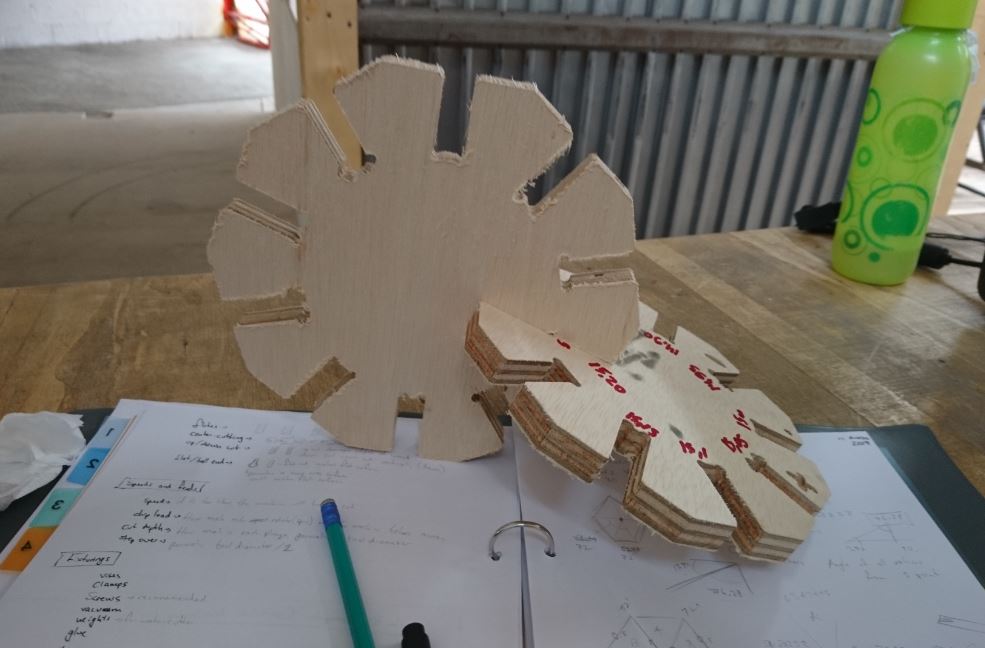

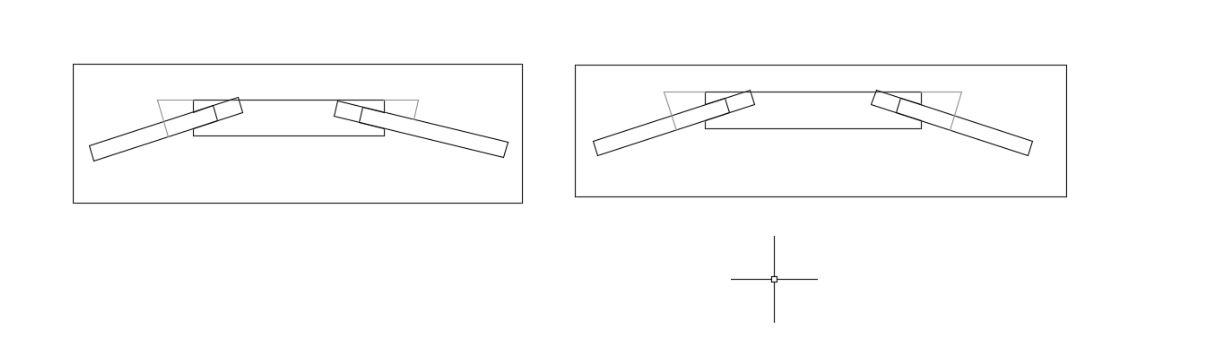

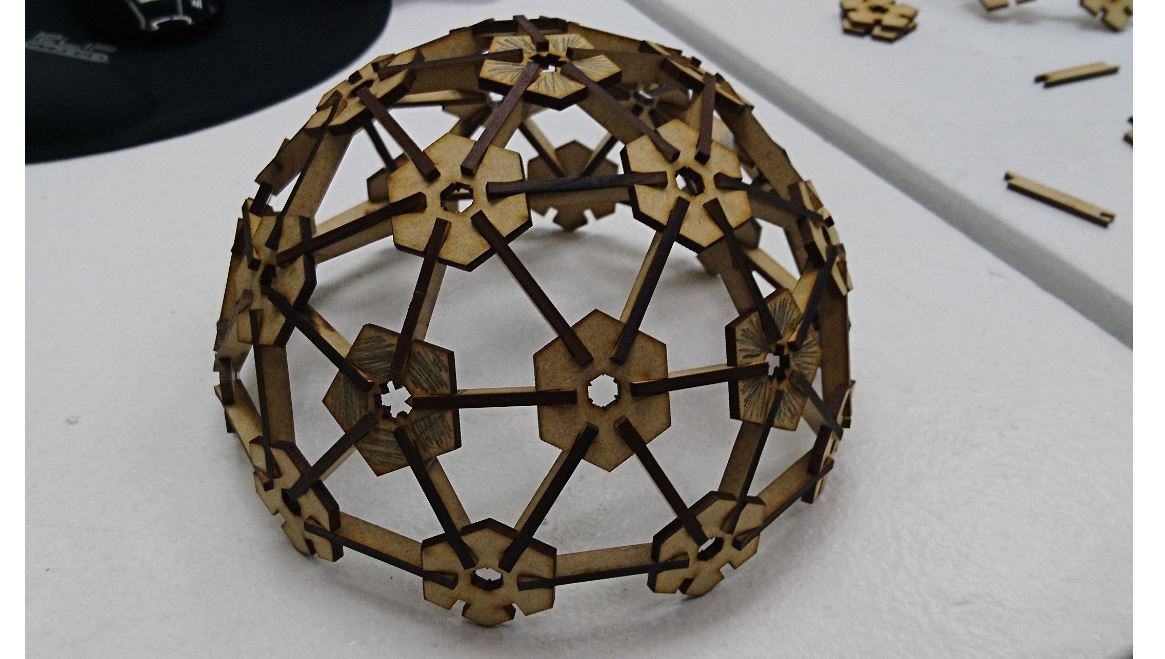

As part of the investigations of possible shapes of the project, I experimented with a dome-like structure which I had designed during my first year of architecture. It was during a model-making class, in which we were experimenting with reciprocal frame structures (self-supporting). I used a combination of a basic structure with the da Vinci bridge which would create a dome. Click the button to access the file.

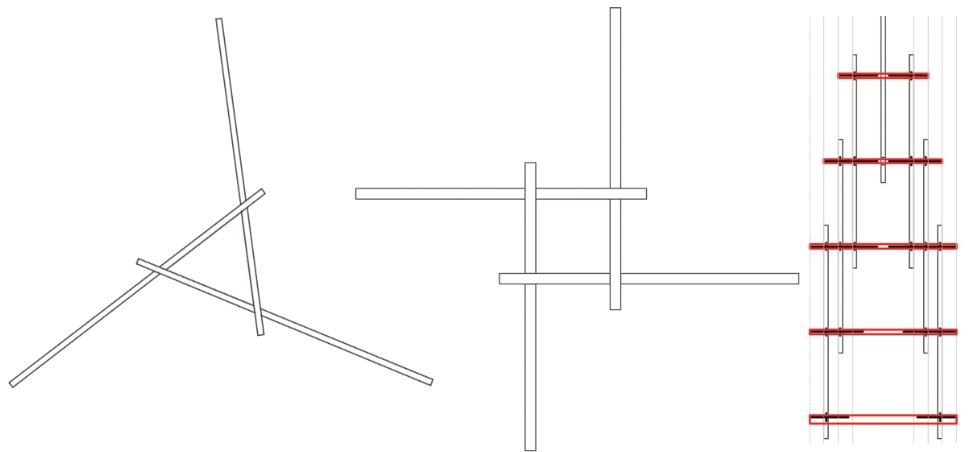

Reciprocal Frame Structure Plan

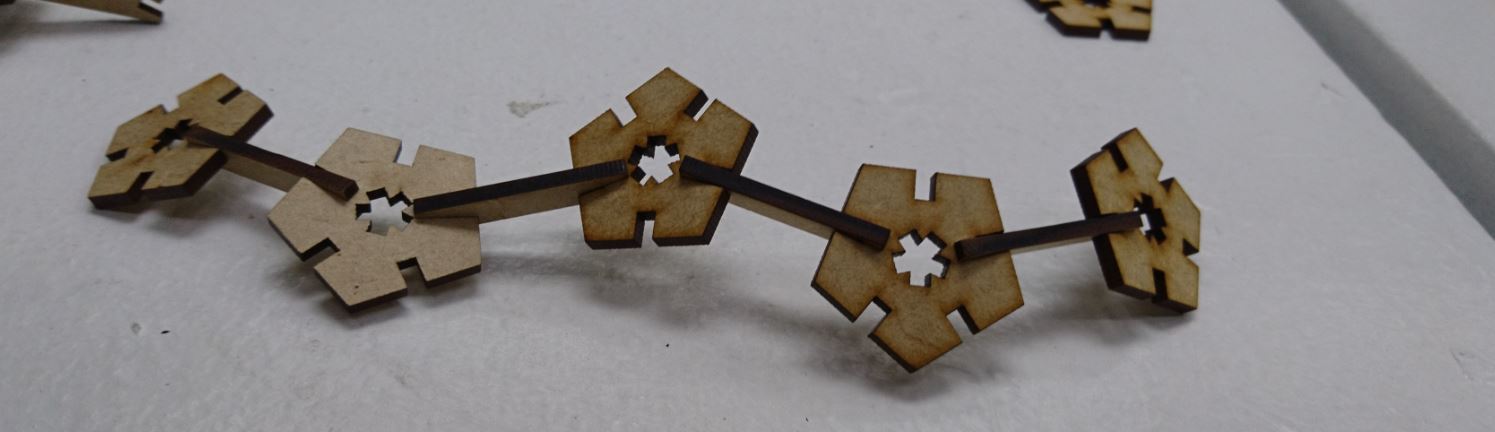

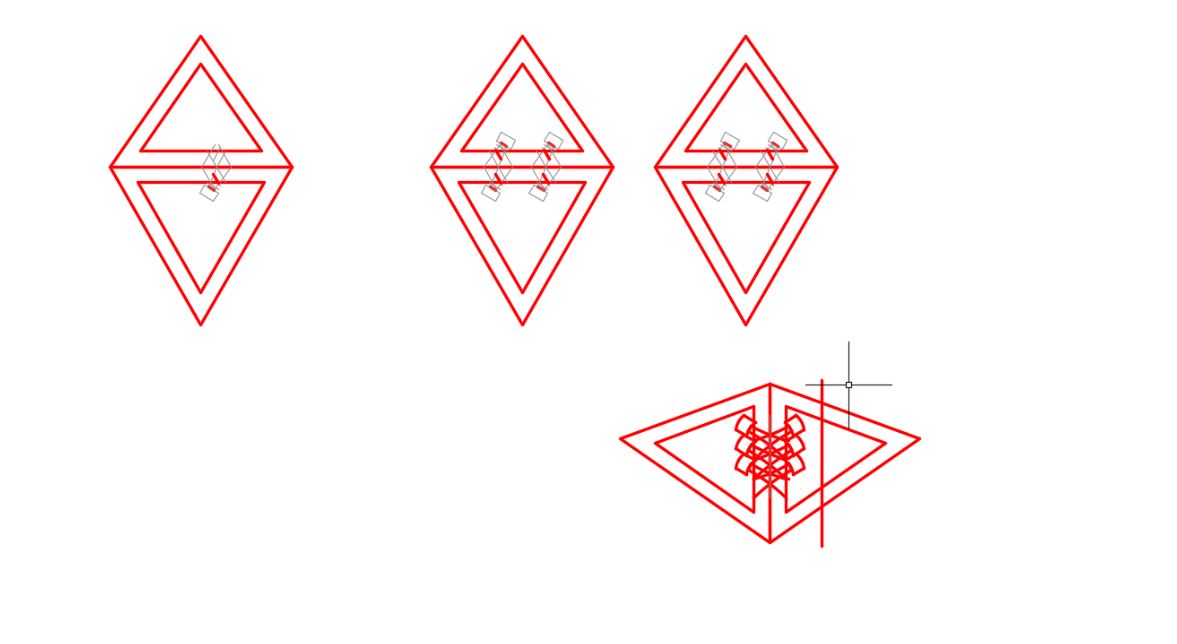

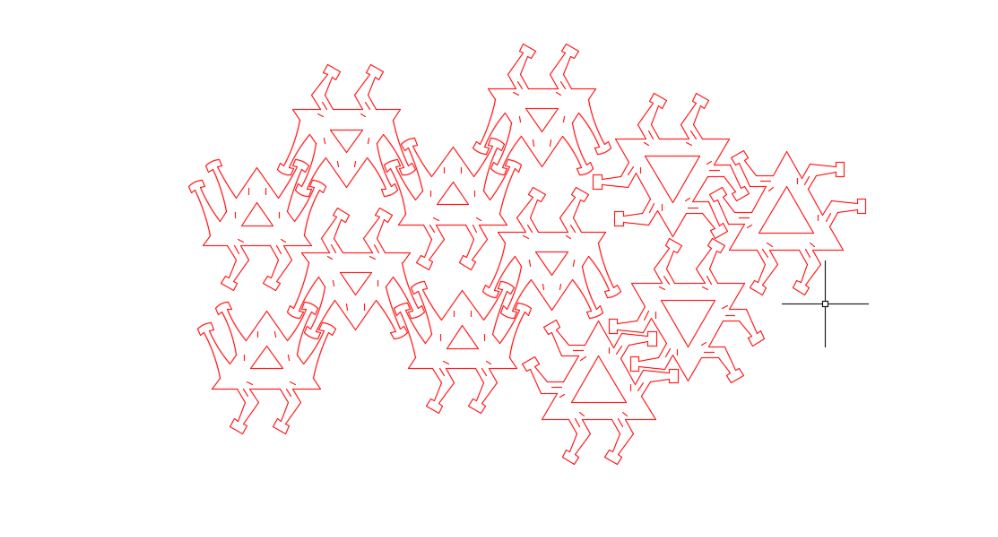

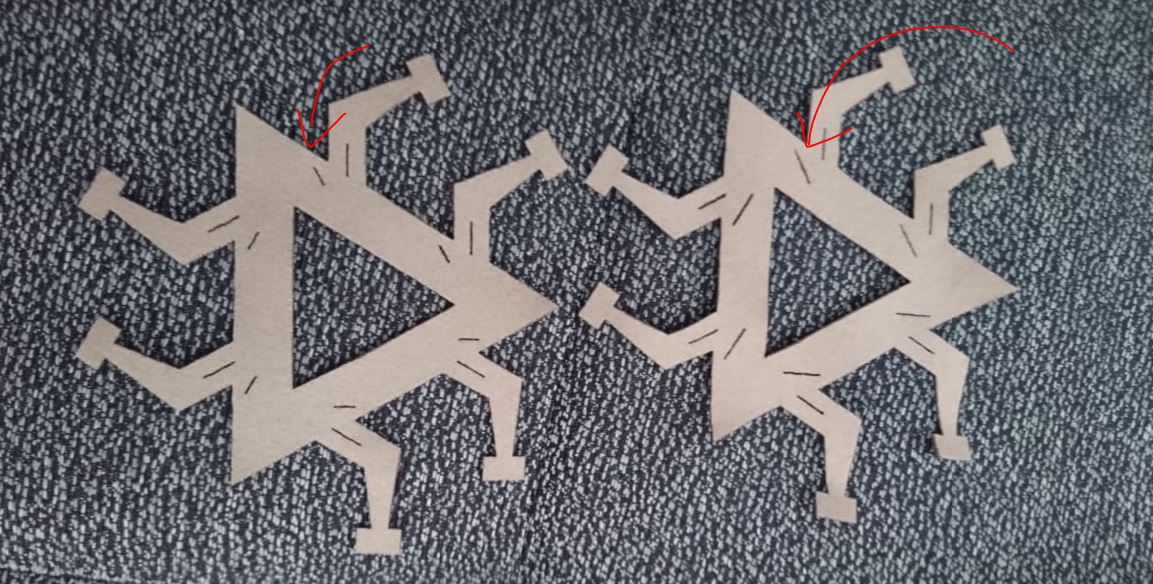

I created a general sketch in cad, then created the pieces and laser cut them in order to test it out.

It worked well, however the cuts on the pieces were too deep, which in turn made the dome flatten out and not be as concave as I would have liked. This could be fixed by reducing the depth of the cuts, and by tweaking with this measure, I could adjust dome to have a different height.

This week was all about searching for an idea for my final project. I am happy with the idea I have right now, with this recycled bottle beam system, and I hope to be able to develop this idea further during the following weeks.

These are my initial musings.

During the next weeks I will continue working on this idea to refine it and focus it better.

Go on to see how this project progresses during the second week

My project proposal is to create a modular structure through 3d modeled joints and empty plastic bottles, embedded with sensors and technology so that it can have a variety of functions such as filtering air and incorporating lights.

It can fulfill a variety of functions, such as being a shelter, a pavilion, a sculpture, or anything else that can be created with these modules.

If it where a shelter, it can help refugees or homeless. If it were a pavilion, it would be for people to walk through it and around it. If it were a sculpture, it will be for people to see and probably interact with it.

January 23-29

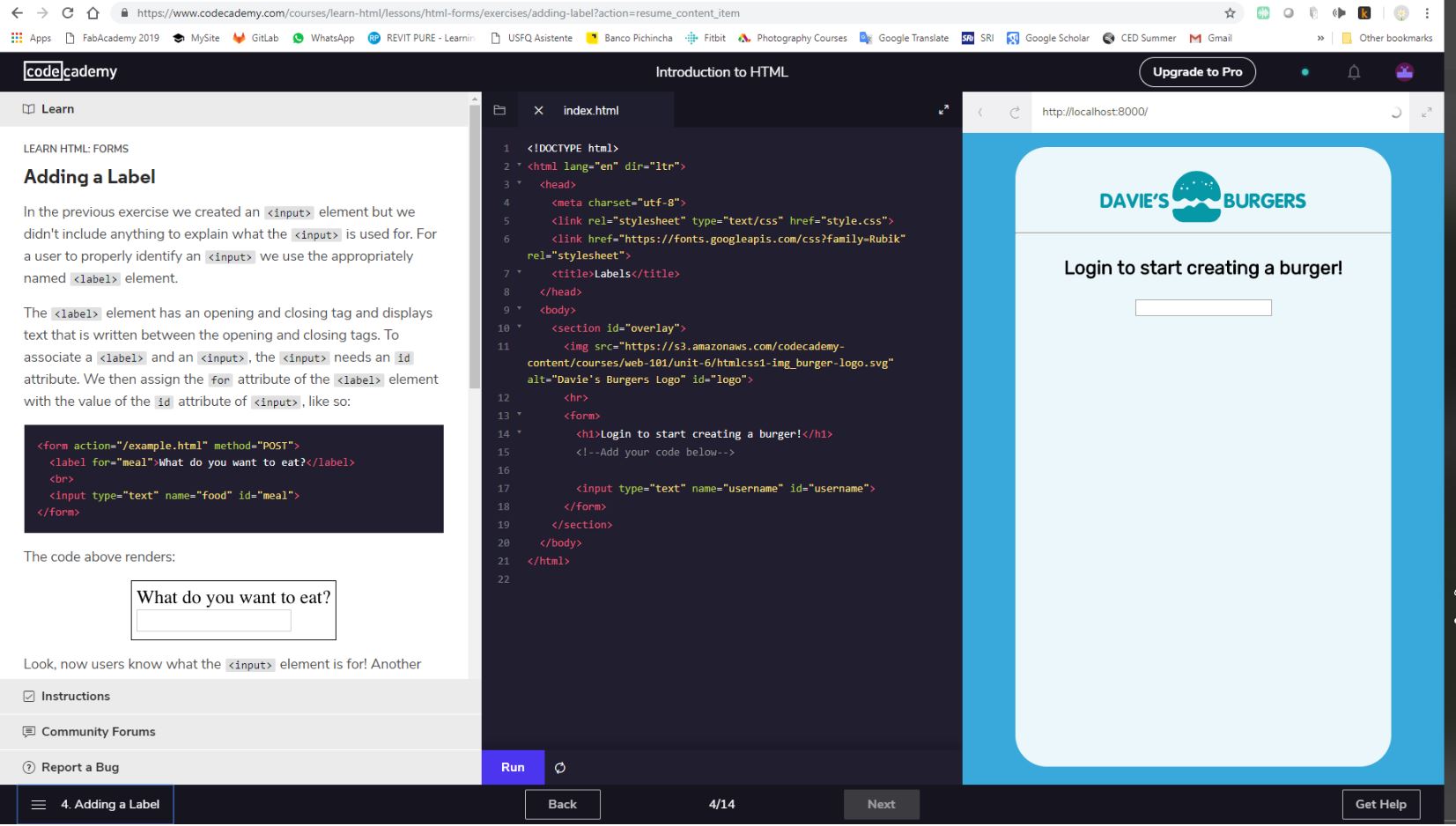

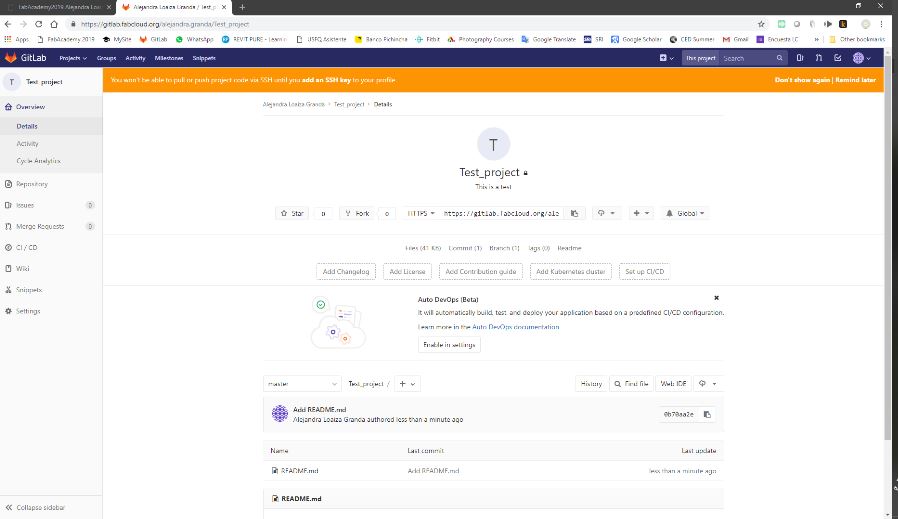

This week’s assignment was to build a personal site describing me and my final project and upload it to the class archive. We are using GitLab to host our sites.

First, in order to be able to create a site (or modify and existing template) I needed to understand HTML and CSS, or markdown. I chose to learn HTML through Codecademy and managed to get more than halfway through their HTML introductory free course. I plan to finish it, and learn CSS, but for now, what I learned was enough to create my site.

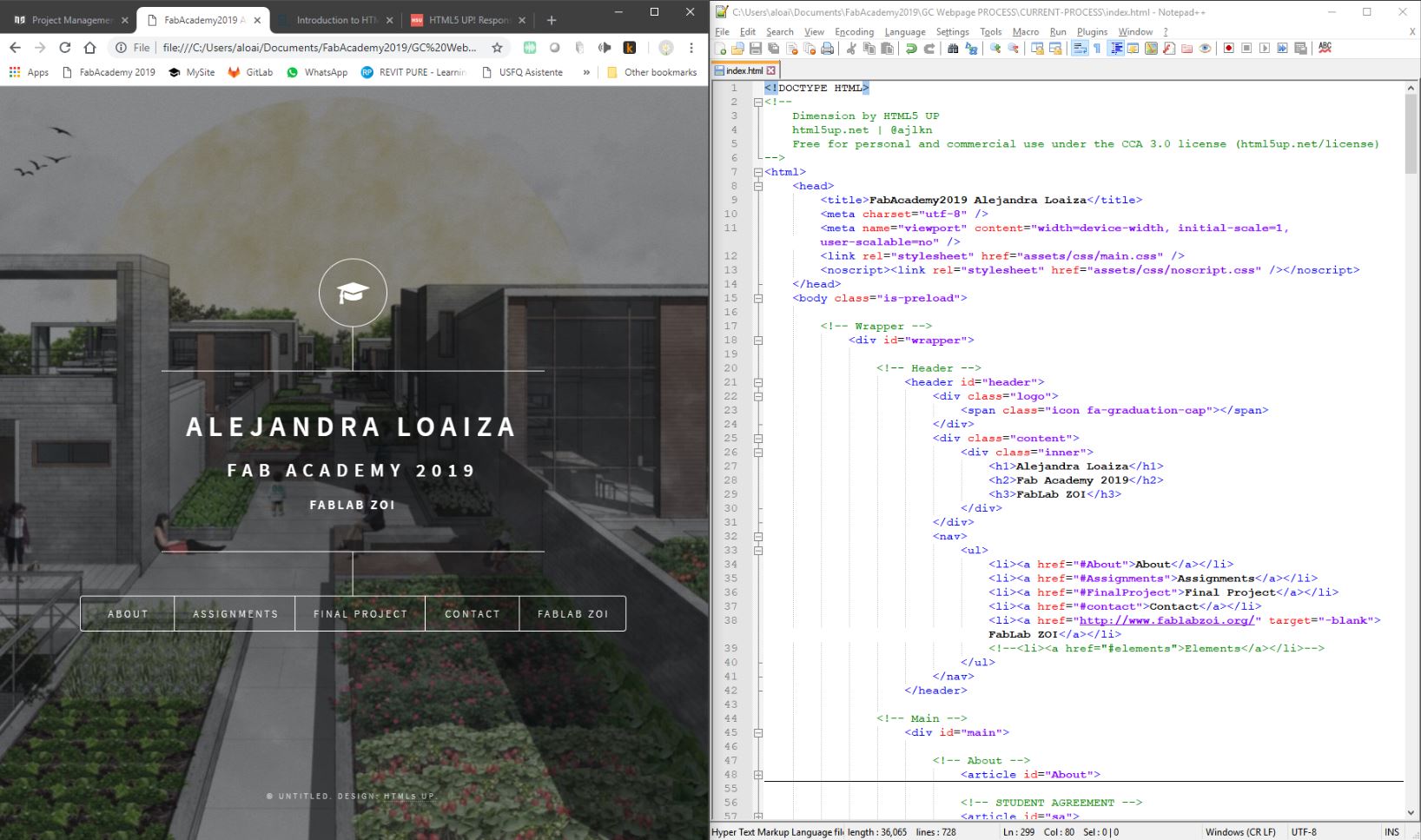

I checked the website HTML5 UP and found a template I really liked, called Dimension, which I chose to use as the base for my site. The entirety of the code of the website (all the assignments, final projects, etc.) is in one html document, so I am using a lot of whitespace in order for everything to stay organized and legible.

I started tweaking the template, changing images, changing the buttons and the characteristics of the paragraphs until I liked how it turned out. I worked on it locally in my computer until I was satisfied with it, before pushing it unto GitLab.

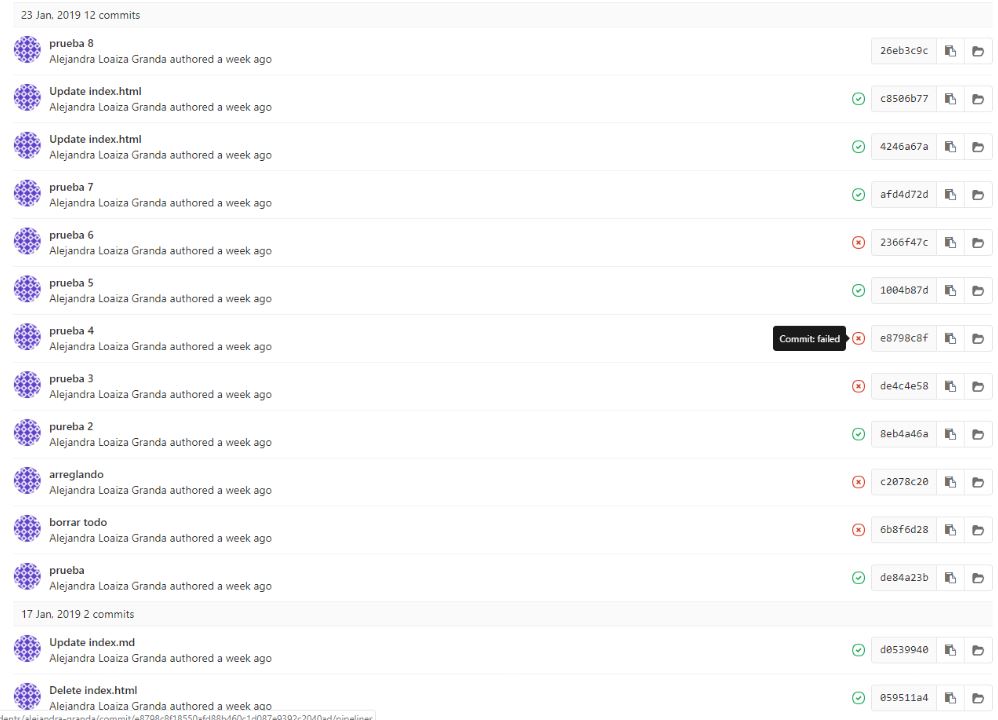

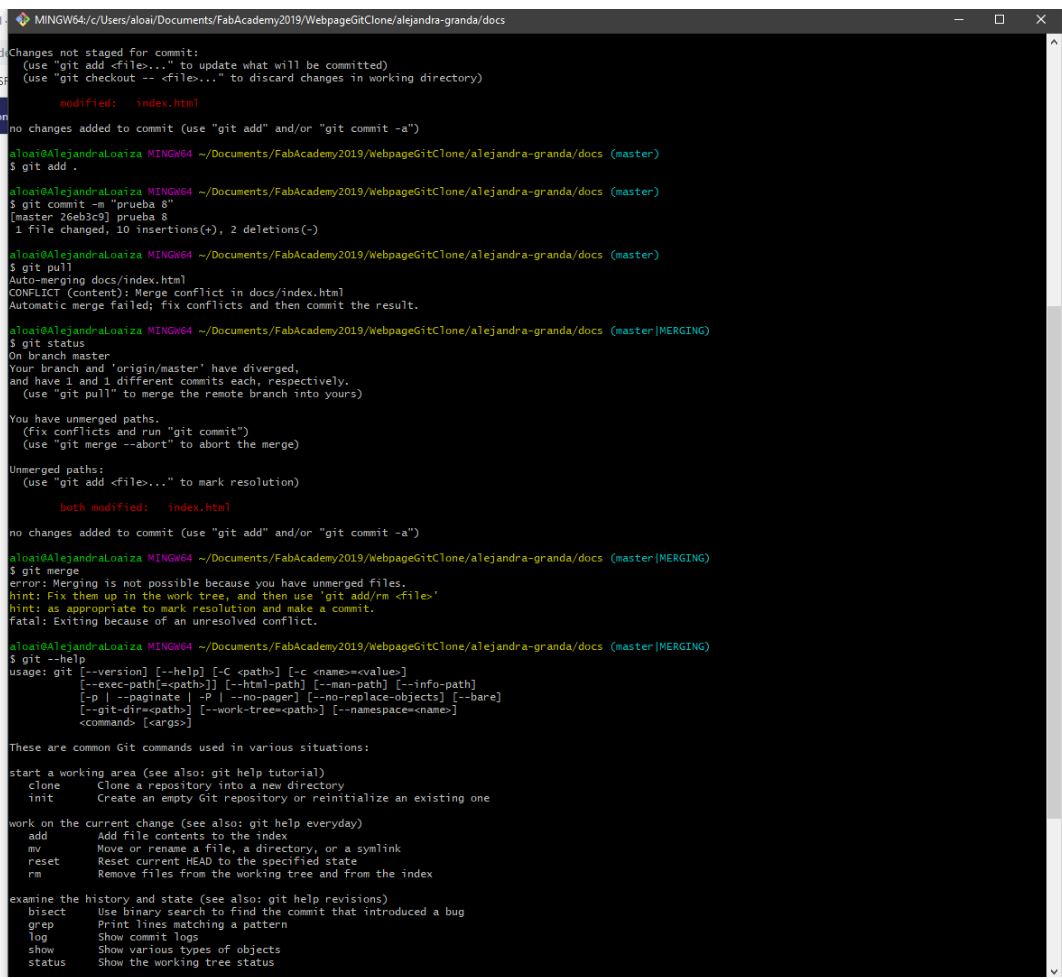

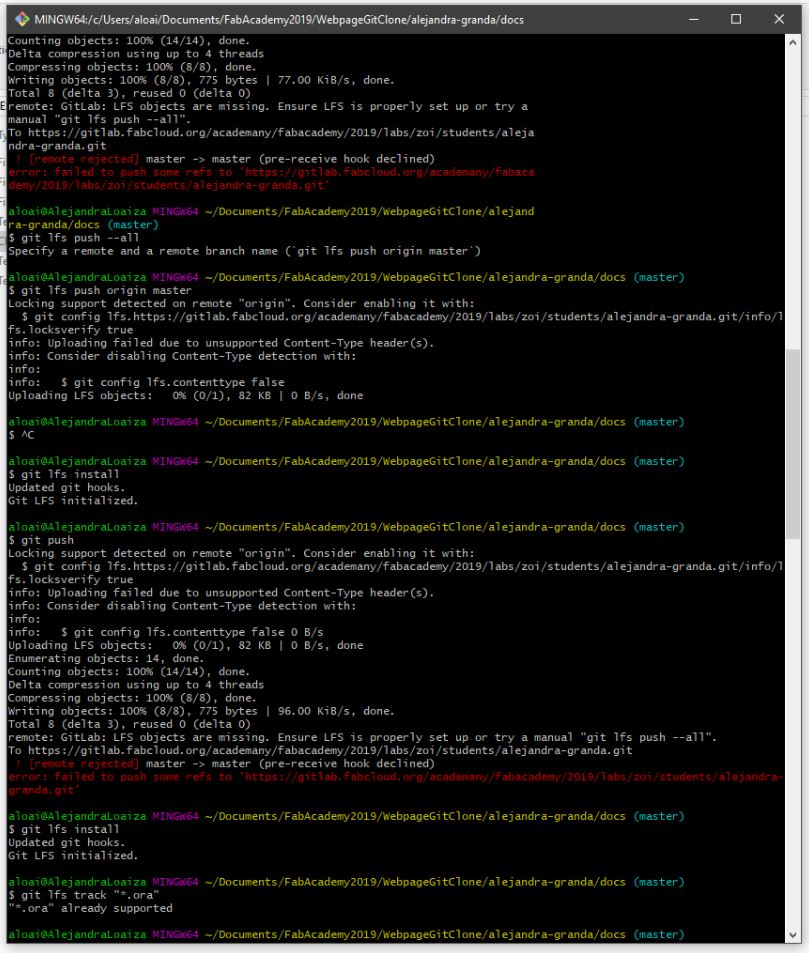

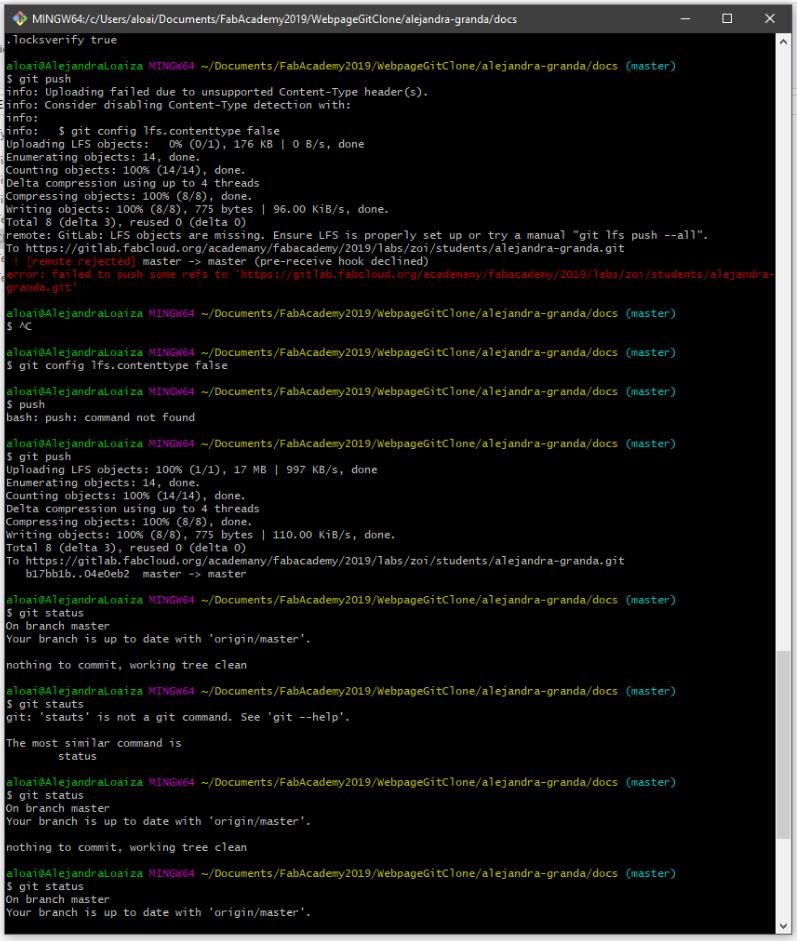

In order to clone the repository into my computer, I downloaded and used Git Bash terminal. First I started playing around with the files, deleting and then adding the original files just to see how everything worked. I got a lot of error messages by doing this, where the commits failed when I deleted certain important files.

Also, I started playing around with the merge command, and noticed that if I changed something in the cloud and then differently in my computer and pulled or tried to merge the files the one that would predominate was the one in the cloud, and it would overwrite the changes I had done in my computer (cloned repository). I had a few errors with this, and eventually decided to not do any changes directly on the cloud.

After fixing what I had done, I decided to upload my site, erasing the template site that was up. It worked well, and I soon got the hang of the pull, merge, add, commit, and push commands on git. Everything was going as expected, and the site was up and running.

There are still quite a few things that I want to change on it, or add to it, but for now it is good.

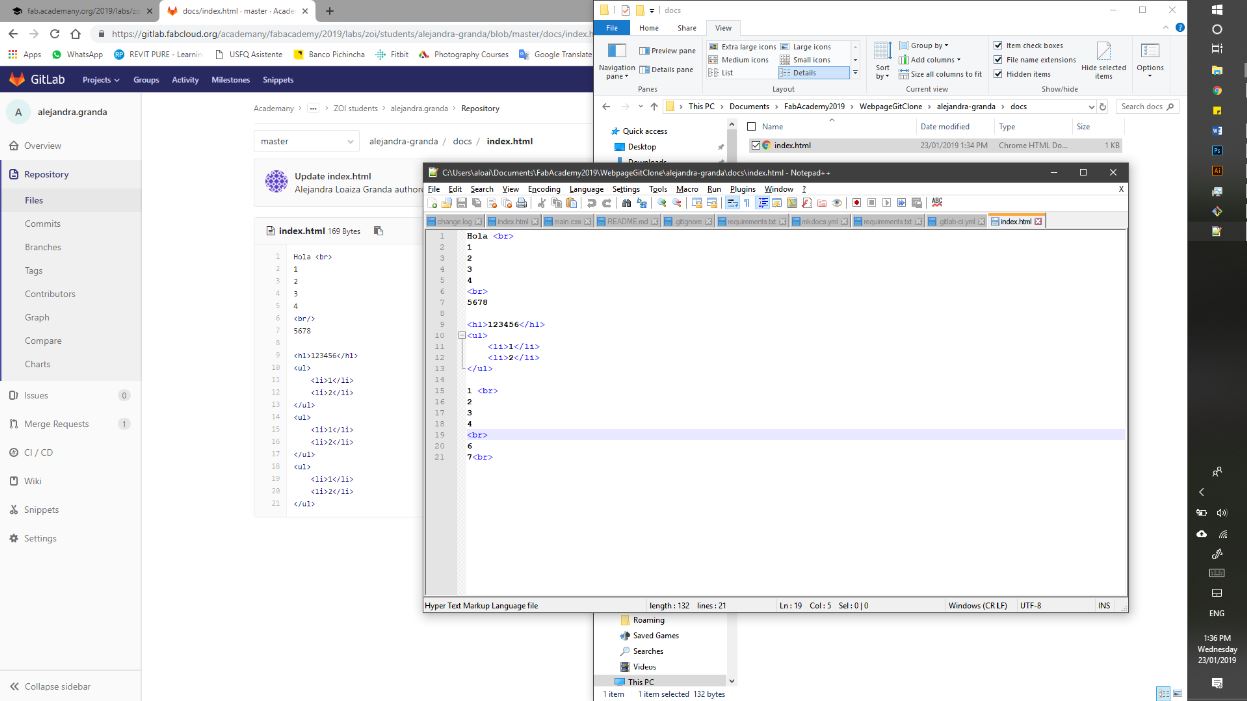

First, I cloned the repository from GIT into a folder in my computer. Personally, I prefer to not work on that folder directly, so as to avoid making mistakes on it, and have a copy of that folder in which I do all changes to the index file, check that it is done correctly, and then copy It to the Git repository clone folder and then add, commit, and push the changes onto the cloud. That way, I double check everything is working well before uploading, given that with GIT version control it is really hard to erase the history of any mistake made.

Also, I signed and uploaded the student agreement to my site. It was in markdown, so first I changed it into the same format in HTML, added it as a page in my website, and created the link in my about page.

Click here to see the student agreement.

To add images, I still have not used a dedicated program to modify them to reduce their size, I have only used the snip tool from windows with which I create a smaller version of the original image that has a small size. I downloaded ImageMagick and understand how to use it, but since the snipping tool gives me small sized images already, I did not see the need to shrink them further. I also tried shrinking them in Photoshop, but did not manage to reduce their size considerably. However, I will look further into it and will try other programs probably during next week.

-edit

I tried again both photoshop (lowering the resolution and image quality) and Image Magick (resizing) and decided once again to stay with windows snipping tool. I will probably continue with this tool, as it lowers the size of an image, but I find it easier to visualize and control the quality.

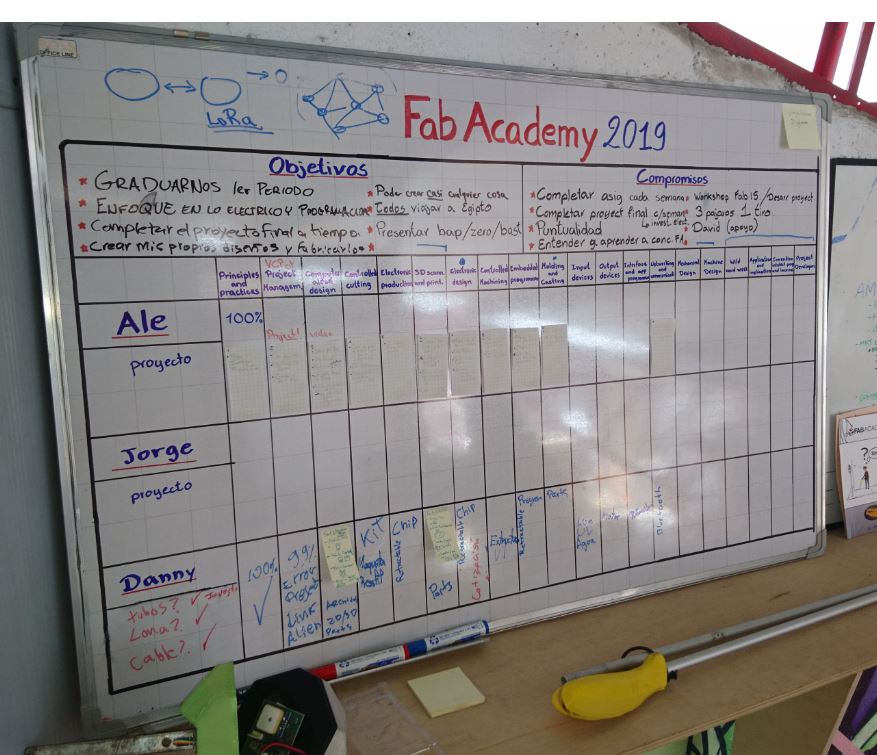

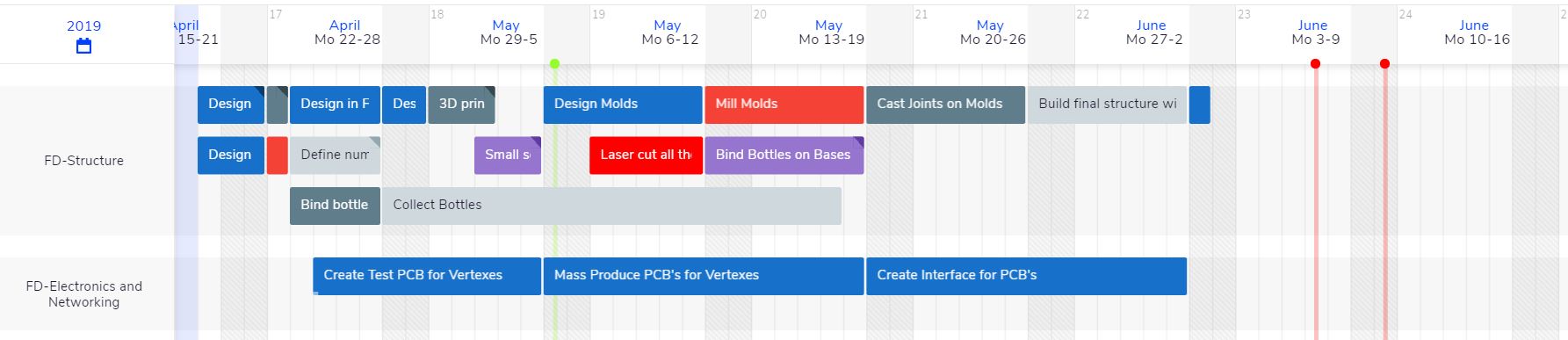

I have not gotten around to investigating on the project management programs that were recommended, but I plan on doing that soon. Meanwhile, in my FabLab we have a calendar with the weeks specified, so I made a plan of what I should do each week in order to work on my project, and what I would do for each assignment.

--- edit 6 February 2019

Checked various project management tools. Until now, I like trello very much and will use it, if not for fabacademy, certainly for organizing my personal projects. ---

As part of this week’s assignment, we were required to work through a git tutorial. For this, worked on the 4 tutorials that are on the main git webpage, frim this link.

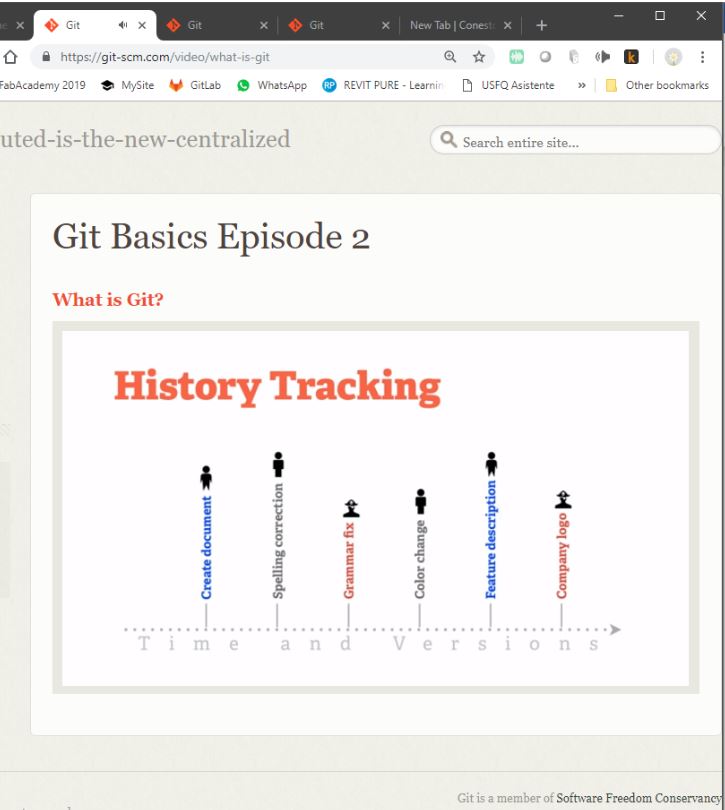

The first tutorial explained what version control is, and it helped me understand what exactly git was, and why it is so important on collaborative projects. It talked about the process of creating, saving, editing, and then saving again, which is the part where version control becomes so important. Being able to check what changed, who changed it and why they changed it helps a lot in collaborative projects.

The following tutorial explained what GIT was, how it works (it is locally enabled), it talked about history control and how to merge the work of people when they work parallelly.

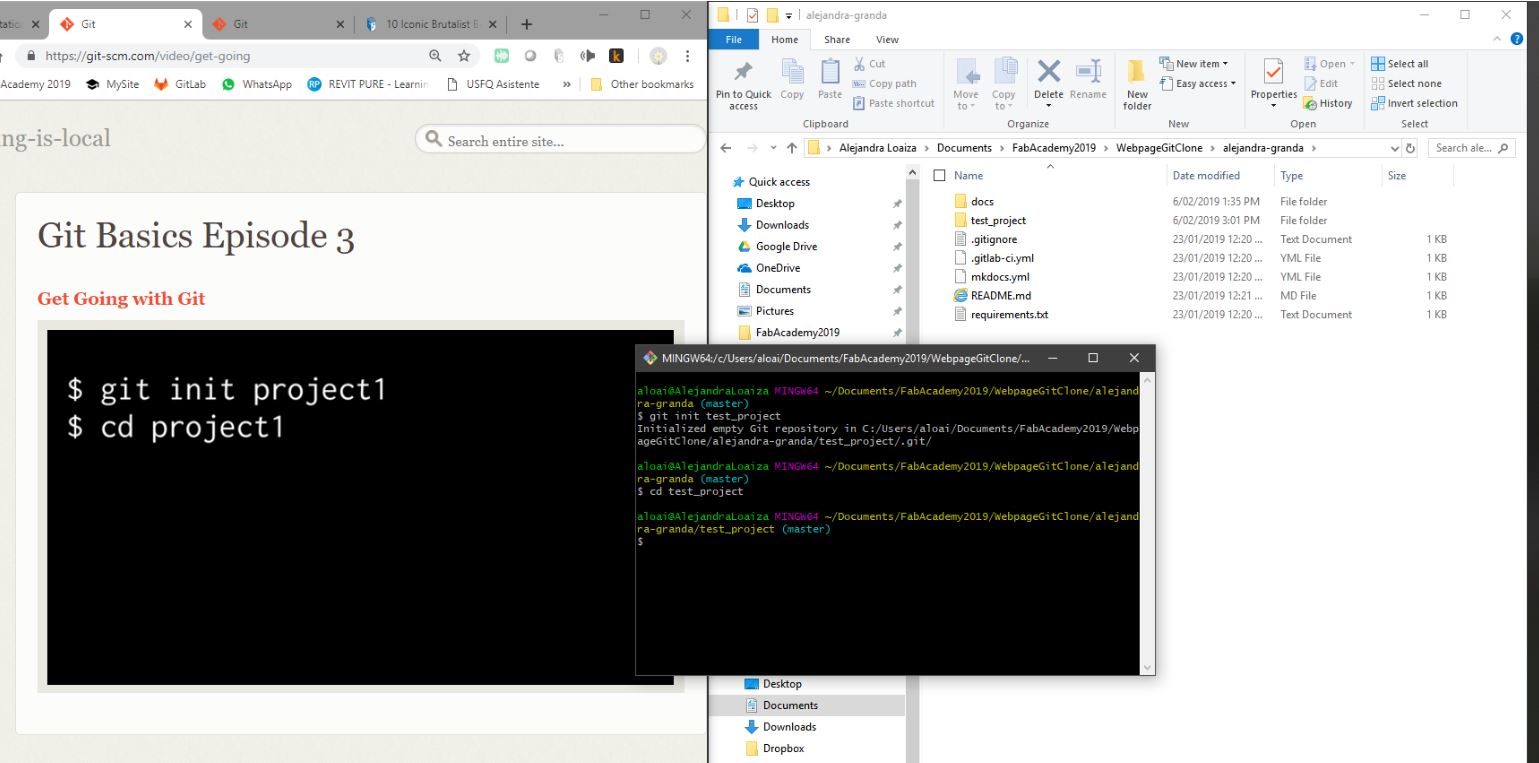

The one after that explained how to start a new project with git, to configure username and email, and gave us the main commands, such as add, commit, merge.

The last tutorial explained some important points of git, such as being a tool which worked as a journal, not a backup, and it being able to copy content as opposed to files.

I found the tutorials very enlightening, and I understood much better what git was and how it worked.

Other options of version control are Mercurial and Bitkeeper , apart from the one that I am using (GIT).

Some commands that I use for GIT:

Clone: copy a repository on the web to my computer.

Pull: retrieve the remote files into my own repository, checking to see if there have been any changes, and if there have then giving you the option to merge.

Merge: update files by mixing the edits I have made with the edits other people have made.

Push: to send the changes and commits that I have made to the files in my personal computer to the remote repository.

As requested, I also created a new project in my cloud on git. I found this to be very easy and now understand better how GIT works.

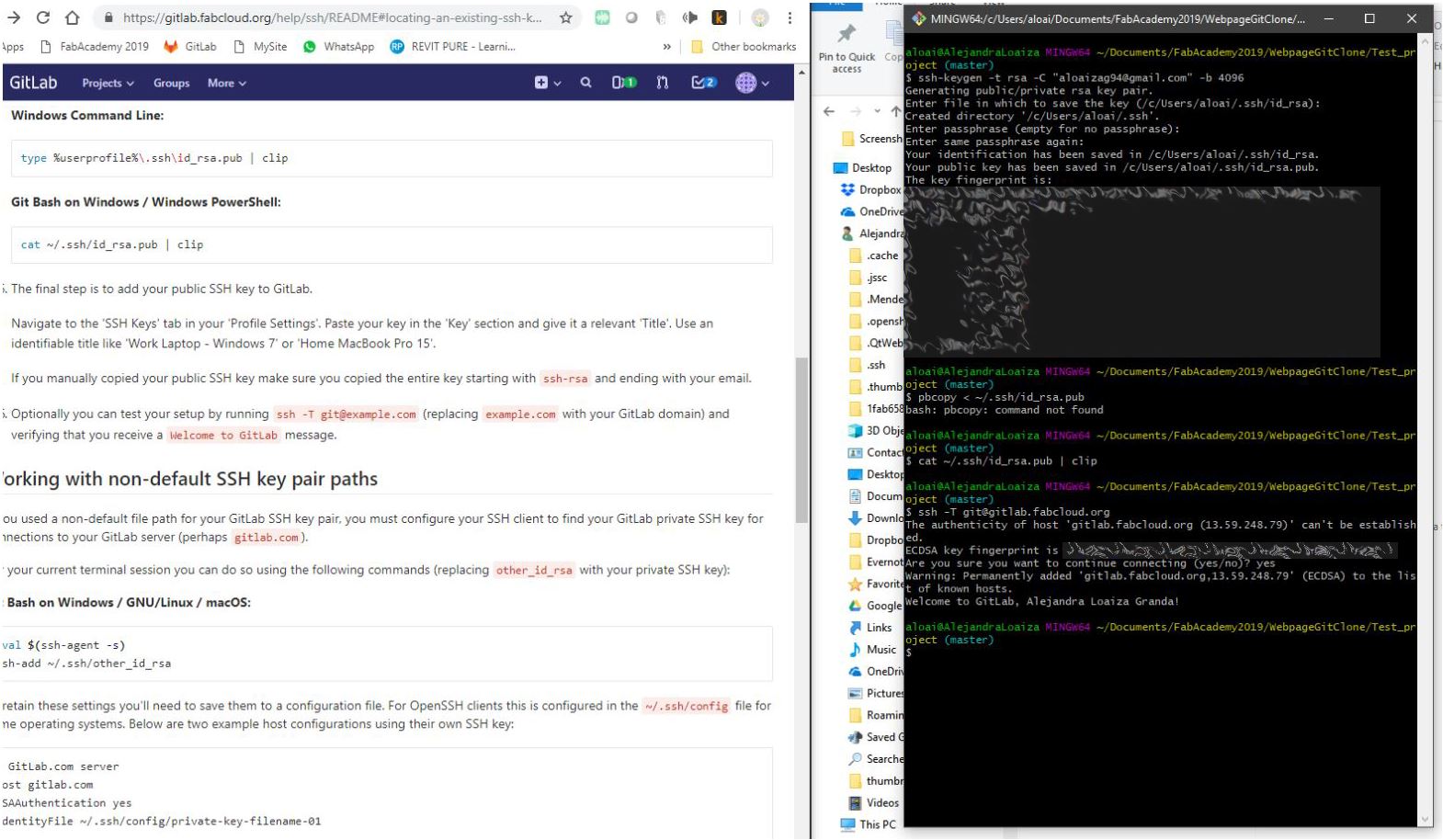

Although we didn’t use an SSH key with gitbash when we pushed our repo, we were asked to generate one. Therefore, I followed the following steps:

ssh-keygen -t rsa -C "your.email@example.com" -b 4096 in gitbash. cat ~/.ssh/id_rsa.pub | clipssh -T git@gitlab.fabcloud.orgWelcome to GitLab message confirming that it is working. These steps were done following this help article.

According to this page the SSH key is a way to handle authentication when using the command line. When using git bash, we were prompted for our username and password (for our gitlab account), so we didn’t use the SSH key authentication process.

I enjoyed this week’s assignment, as I had never understood how websites worked, let alone create one. I liked the availability of templates and enjoyed learning how to modify them and start working on them. Also, I found GIT to be an amazing tool for cloning a repository and adding changes to a remote repository.

---------25 February

My 3rd week assignment is lacking the original design files. This is not a mistake or out of laziness, it is because each file is very heavy (over 10mb) therefore I do not want to upload it to my site as the size will increase very fast, and not following the mb/student/week to do the gb/lab/total.

I tried the LFS file system, managed to upload it and add the files and everything, but from what I understand that helps lower the size when versioning the files, not uploading the files. Meanwhile, I have added two files, the GIMP and the the MyPaint (total 15mb), which doubled the size of my repository. This is not good, and I need to find a new way to add these files so that my repo size does not continue to increase exponentially.

January 30- February 5

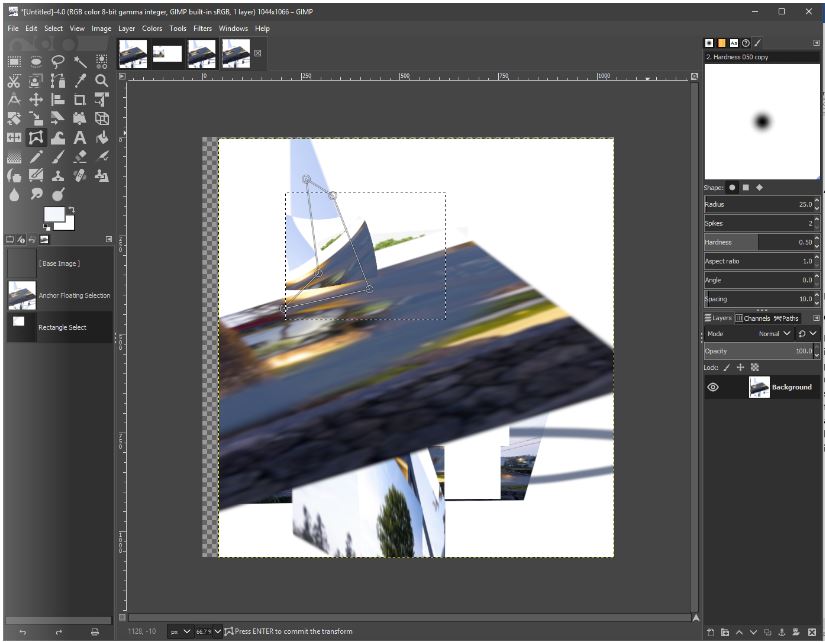

Gimp

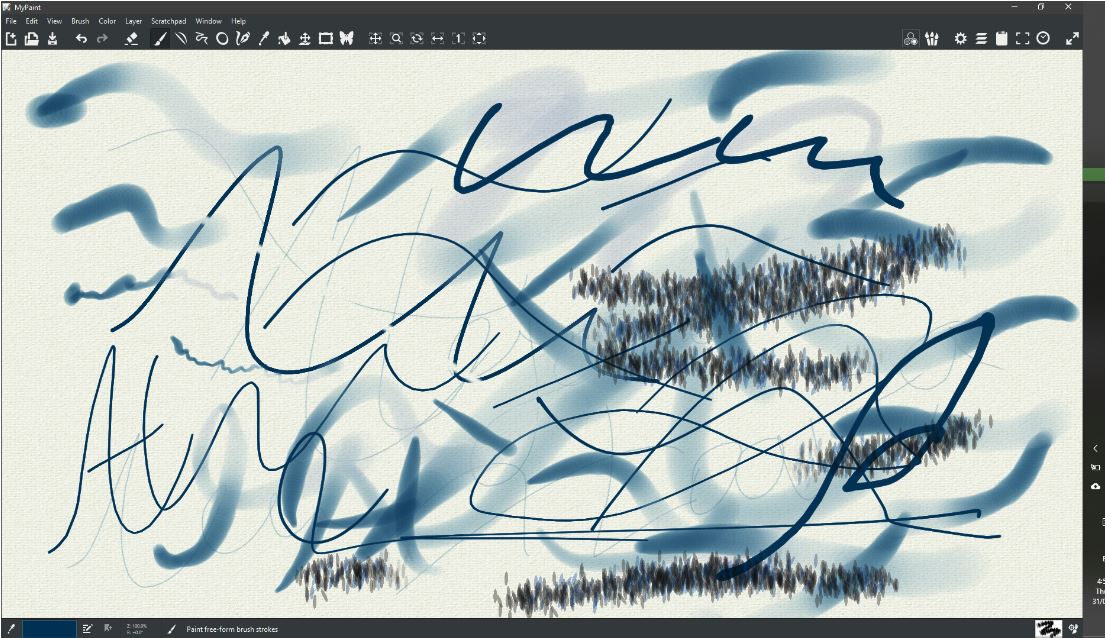

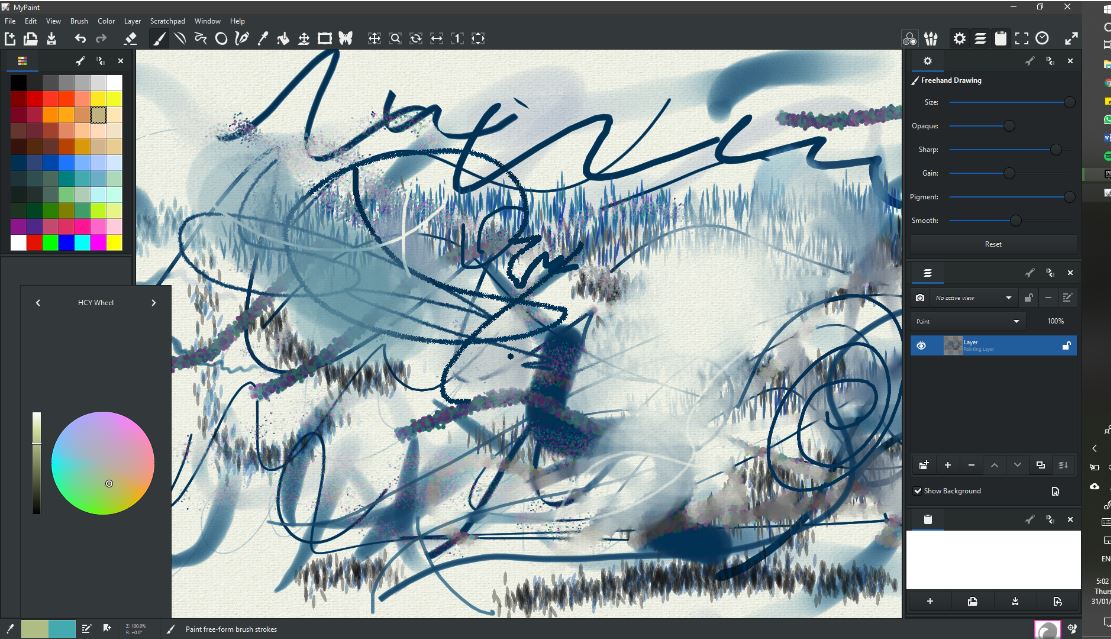

MyPaint

Image Magick

Inkspace

FreeCad

Blender

Audacity

Openshot

Fusion360

Unreal

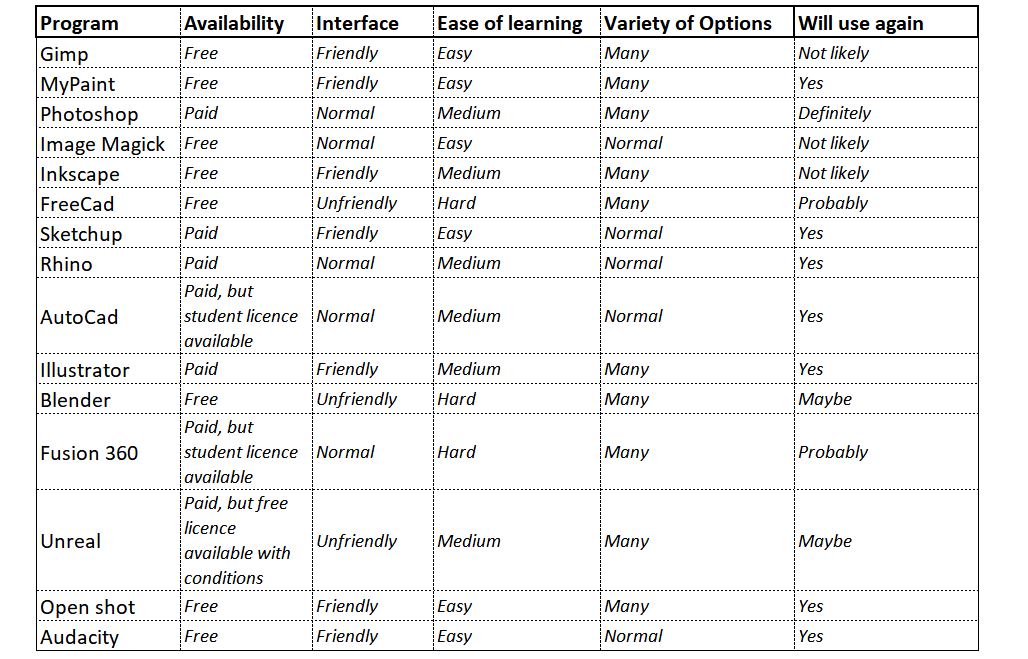

As a starting point for this week, we have to download and try as many programs as we can. As Neil said, the goal of this week is to use the programs, not master them. Having a background in architecture, I have experience in photoshop and Illustrator (2D); sketchup, rhino, grasshopper, and AutoCAD (3D), so I will document my experience with the other programs that I have not used.

First, I downloaded many programs. Here is the list of programs I want to try, and some of which I already know:

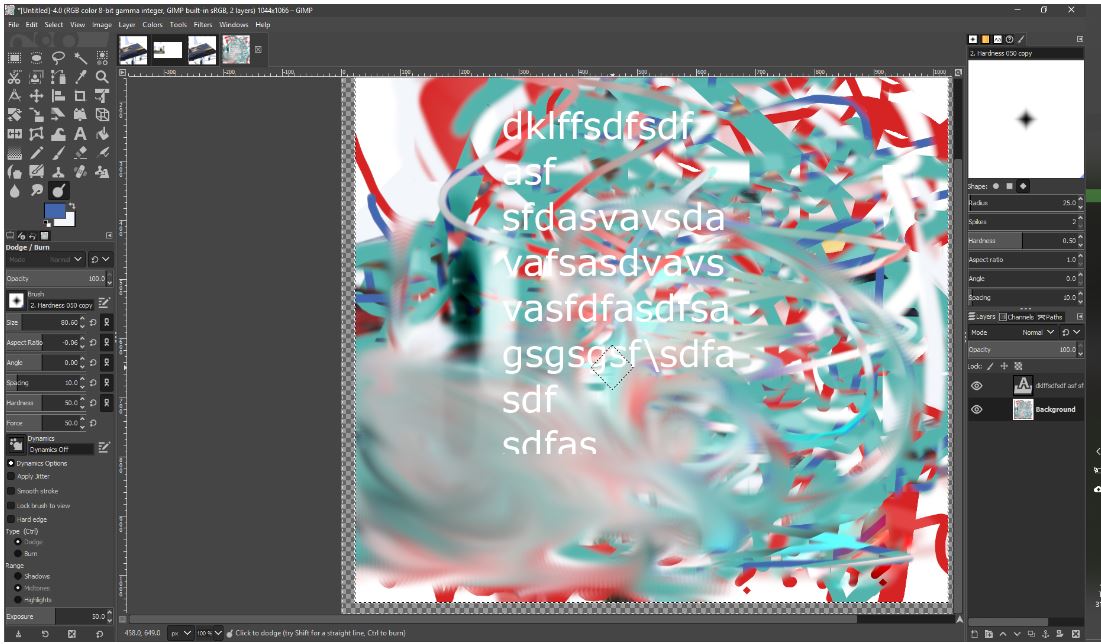

It all started well with gimp. I started with a blank canvas and added a few images from the internet into it. The tool icons seemed to be straightforward and similar to what I have used in photoshop. However, at first, I didn’t understand how to use the different selection tools with the move tool to move only the selection. Had to cut and then paste in order to be able to move things. I still don’t know how to do it any other way. The measure tool seems interesting, but not very useful for me. I don’t really understand how to use the move tool. The shear tool seems pretty interesting, as does the handle tool. I hadn’t used those before. I don’t really understand the difference between perspective and transform. Cage transform also seems to do interesting things to the image. I liked the ease of the gradient tool. The pencils and brush tools and calligraphy tools were nice, and it was really nice that they worked with the touchscreen of my computer. Most times I have problems in photoshop and illustrator on getting them to register input from the touchscreen. The clone and heal tools seemed very similar also, but they were working very well. I did not understand the clone with perspective tool, but that was probably because the image was completely transformed already. Dodge and burn tools also worked the same as I remembered from photoshop. I dislike that I must click directly on the image that is on a layer to move that layer, since some images can be blurry or with transparency so it would be complicated. I prefer the way this works in photoshop where you must click on the layer in order to move that. Making and deleting layers and layer groups also seemed to be easy. I do not understand why the program automatically created new tabs though… or perhaps that is something that I am unknowingly doing. I like the interface of the program, where I have layers on one side and tools and options on the other. The rulers that surround the image are also a nice addition. I liked the whole array of options for saving the image, and all the possible file types to which I could save.

Overall, I liked the program and the options it gives, although because of the selection moving thing and because I am more accustomed to other commands, I prefer photoshop.

The program seems very nice and the interface looks simple, at least in comparison to gimp. It started with this every nice paper texture background, and it also works well with my touchscreen. I like how the lines created look very natural and hand-drawn. I love all the brush options that there are. Even just making squiggles already looks like a work of art. There are so many brush options…. i thought I had gone through all of them, but it turns out I hadn’t seen the arrow on top which means there are dozens more.

I found the tool options panel, it had just been hidden. It is a nice addition to have that turned on, in order to modify size and color and everything. I like the way the color palette is displayed, as it seems it can be configured to only display the colors I want it to. That looks like it could be helpful when creating a drawing.

The tool to draw straight and curved lines is also nice. I like how the program has an information line at the bottom that lets you know which keys to press to get different results and give you information. The bucket tool is also very nice and easy to use. There is also the layer option which is good. I like the way the you move around the canvas, it feels a lot like AutoCAD (using the scroll wheel to zoom). I also like the way the canvas is (or seems to be) infinite, and how you can tweak this using the image frame. Also, the option to draw symmetrically is a very nice addition. The options to move the canvas around, rotate it and mirror it are also good. It exports images in a lot of formats.

Overall it is a very nice program, and I really like the types of lines that can be drawn with it. I will probably use it again as it has different functionalities than the one I normally use for raster 2d (photoshop).Overall it is a very nice program, and I really like the types of lines that can be drawn with it. I will probably use it again as it has different functionalities than the one I normally use for raster 2d (photoshop).

I downloaded this program last week, to reduce the size of my files. Although it did work, I preferred to use a different program instead. You can read about that here.

This time, I wanted to see al the tools and things it can do, so I started experimenting with the options it has. The flip and flop options were good, the crop option was predictable, but the chop option was really fun. It’s the first time I have ever seen that option. I don’t really see the functionality of it, but it is very nice. The shear option is also good. The roll option is nice, and could probably be helpful to verify if patterns or textures are seamless. I don’t understand what the trim edges option does.

Overall, I think it’s a good program to do basic things to images. The option to save to many image formats is also very good.

That’s it for 2d raster software. My program of choice is still Photoshop, but MyPaint seems very nice to create images that look hand drawn.

Starting on 2d vector software:

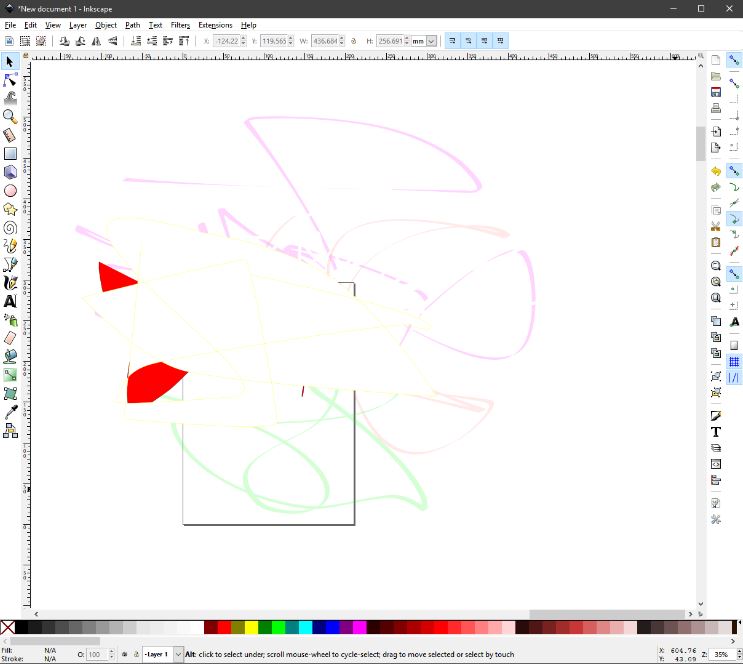

As an initial impression, Inkspace has a nice interface with plenty of working space and a nice array of tools on both sides of the screen. It is nice to have the color palette at the bottom of the screen. This program seems to work very similarly to illustrator, with options to select and move paths individually. I like the path tools, especially the calligraphy one. It seems to be harder to set the colors, especially changing the fill and stroke settings from the paths. Also, the perspective tool has a nice functionality and is interesting to use.

Overall, I prefer Adobe Illustrator for vector drawing for design projects.

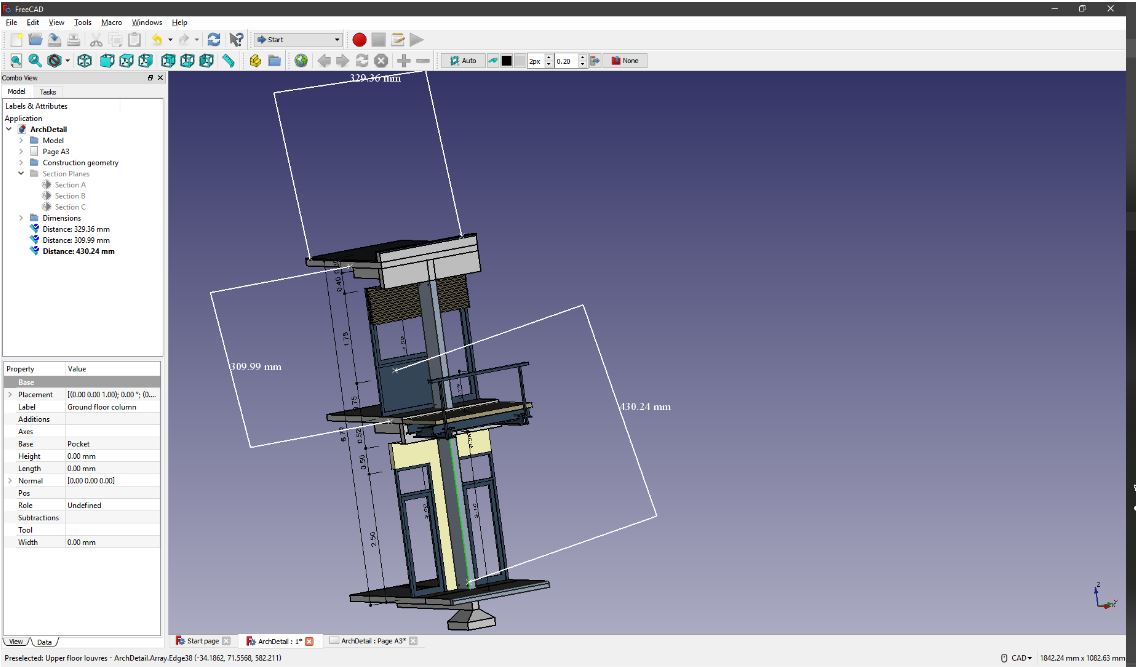

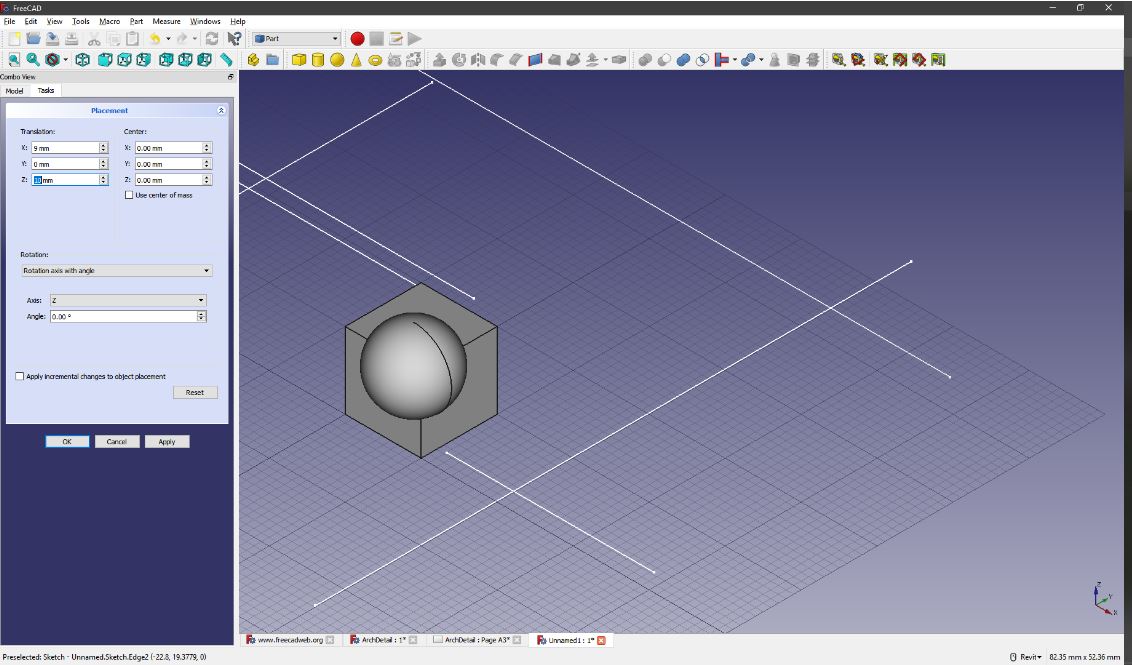

Starting out with freecad, I decided to use a sample architecture model. This let me see how the tools work on a model without having to create the model myself. I did not like the way the orbit tool works in comparison to other programs that I have used, such as sketchup and revit, as these allow you to orbit the model without losing the orientation (z vector stays the same) of it, or allow you to go back to this easily. However, I did like that this orbit tool gives you the option of making the model continue rotating after you are done clicking it, whish is good to analyze it better. I like how freecad gives you information about each element and allows you to change it in properties, but I did not like that it isn’t easy to configure commands to use with it, like I can in AutoCAD. I’m sure that there is an easier way to use it, but until now I find the buttons and controls hard to find, and messy in comparison to what I am used to in cad. Also, I miss the command line that I have seen in other programs, which gives you more information about certain tools. I like the constraint options that are given between lines, that seems to be very useful when creating objects.

Overall, I like the constraint options in FreeCad, but for line vector drawing, in both 2d and 3d I prefer AutoCAD, at least until I learn how to use this program better.

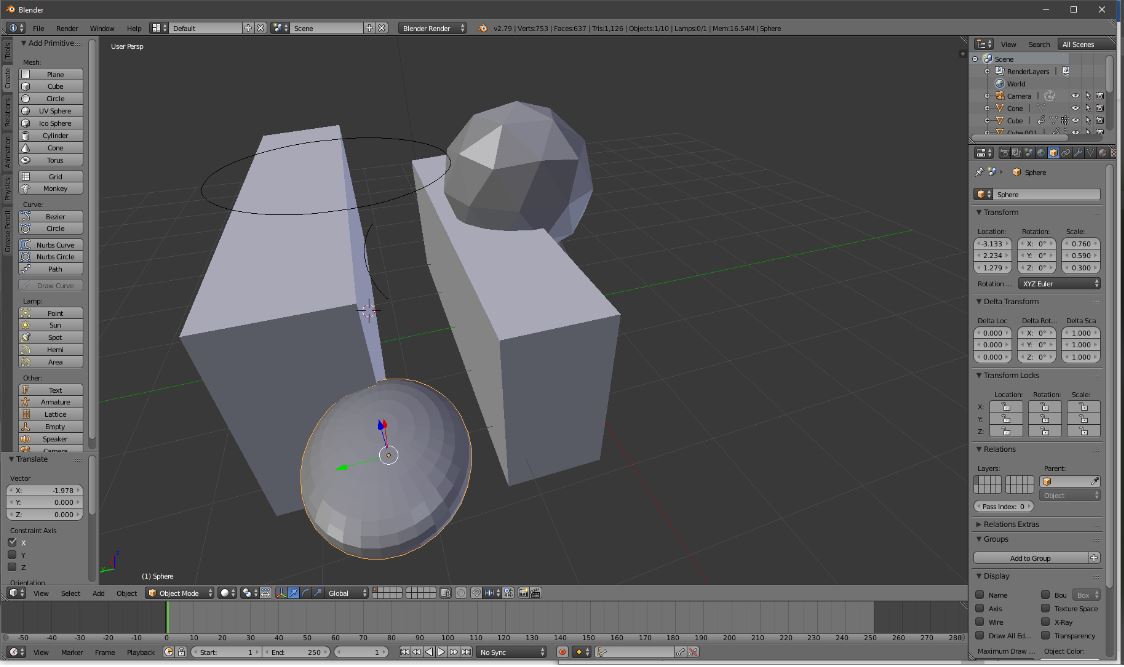

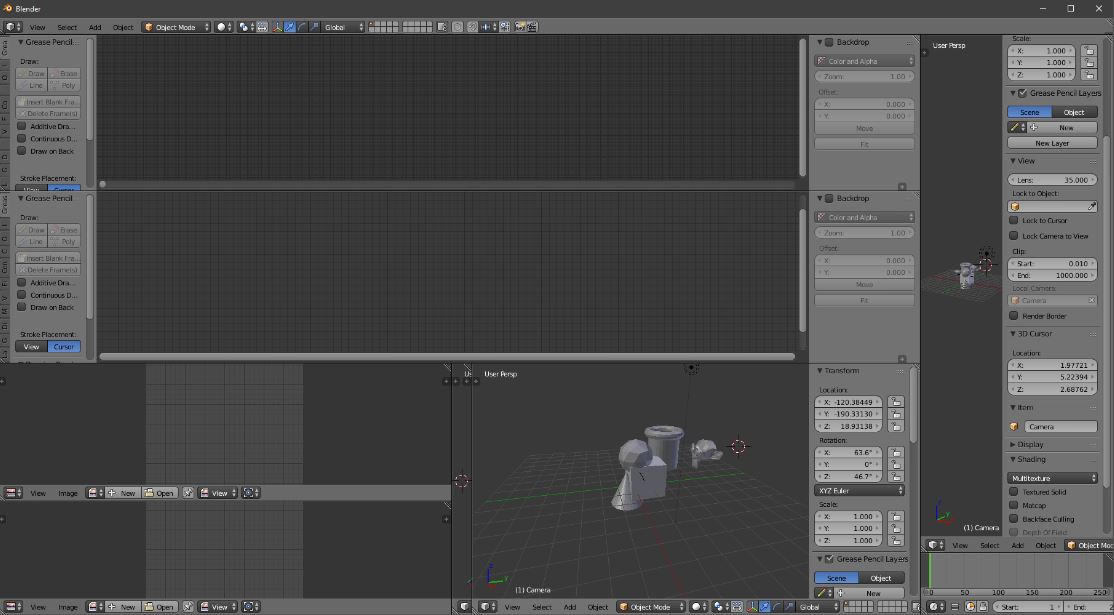

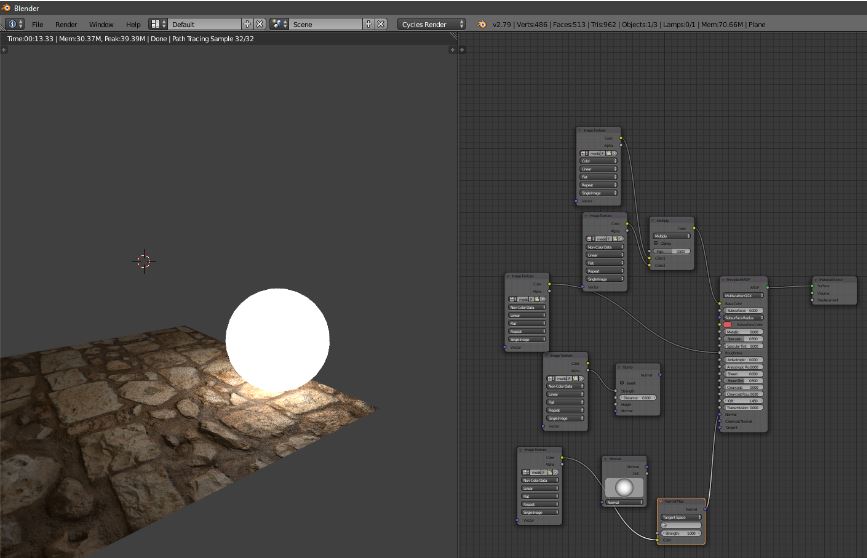

From the beginning, I like the way blender works. It is easy to understand how to move objects, pan and orbit. Also, the orbit tool by default keeps the Z vector vertical, so it is how I am accustomed. I also like the different options that are given, such as painting objects. There is also the tool for inserting objects, which seemed to be easy, as well as modifying the inserted objects to change their size and dimensions. However, while playing around with the program soon I started to have trouble with the panels and gave up on it.

Overall, I think it is a very interesting program, I’ve heard that it is very good for creating renders, and I would like to learn how to use it better.

--edit

An architect friend from my university was teaching me a little of how to use blender for rendering. Now I am really interested in learning how to use it better, seeing all the characteristics and the amazing effects that can be achieved with this program. Also, my friend told me that there are more tutorials and forums regarding this program, as it is open source, therefore it is easier to learn. --

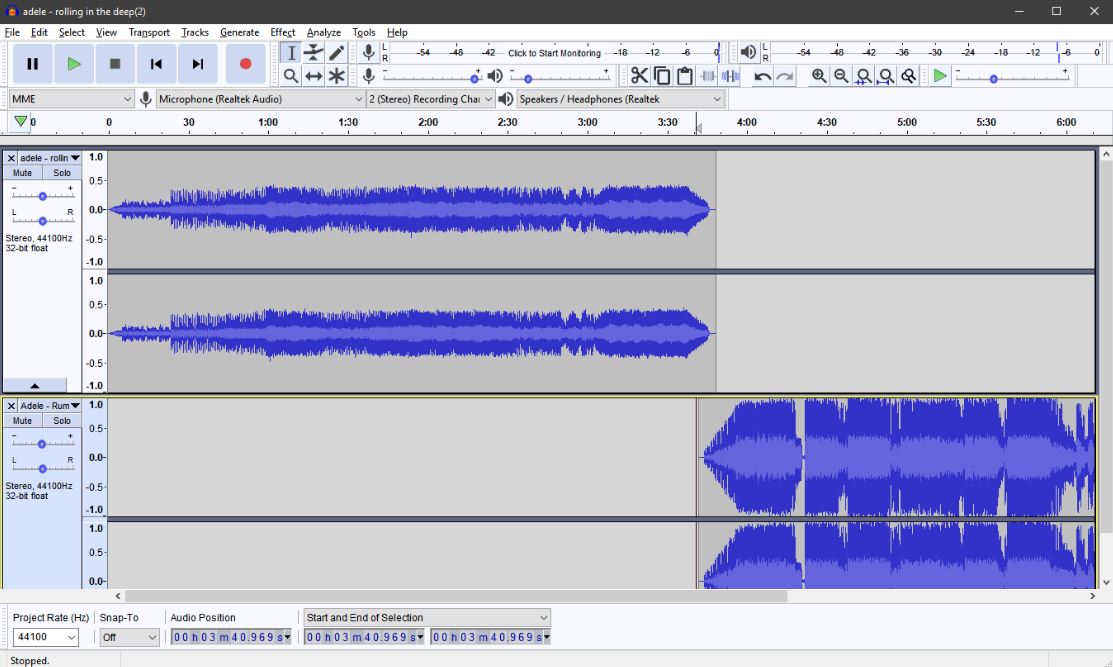

I tried out audacity as I was told it was going to be very important to edit audio for the videos in the final project. I opened the program and first imported two Adele songs and started playing around with the effects and the tools. I liked that it seemed easy to use and has nice effects. Also, I like the option of being able to load many different tracks.

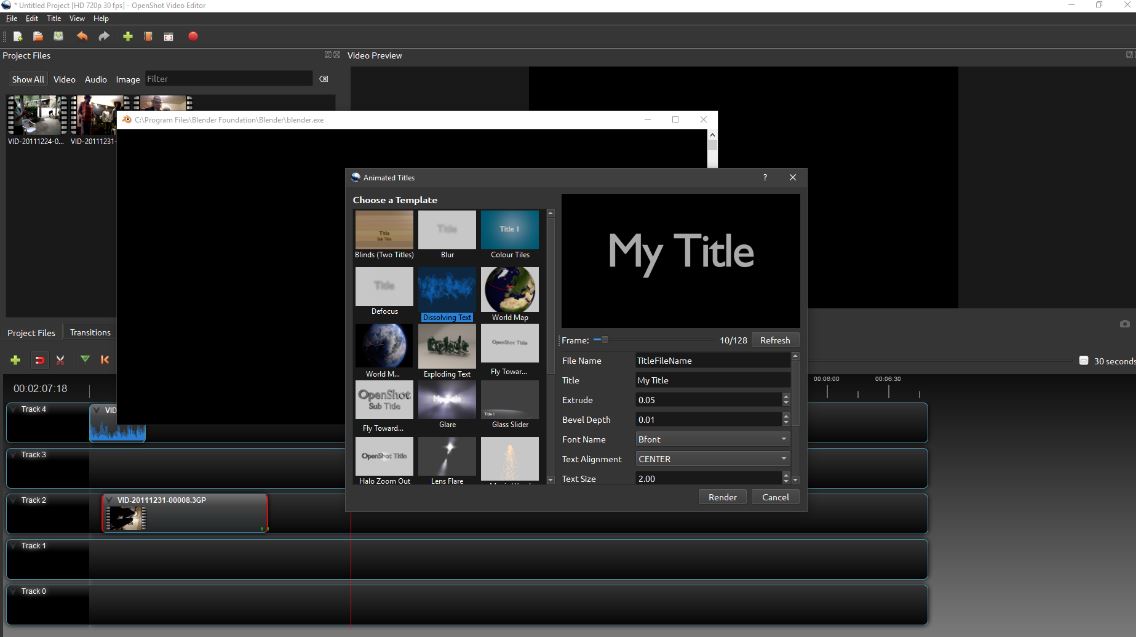

I have used a few programs for editing videos before, such as Windows Movie Maker, Apple’s iMovie, and Camtasia Studio. All of these have had a similar interface, therefore I understood quickly how Openshot worked. So far, from what I tried it worked well and it was easy to use. I like that there are 5 track options, because that gives you a lot of flexibility.

For animated texts, I like that there is the option to create lots of interesting texts effects by using Blender, just by adjusting the path to the blender executable. However, it does take a while to render the title, although it is worth it for the effects.

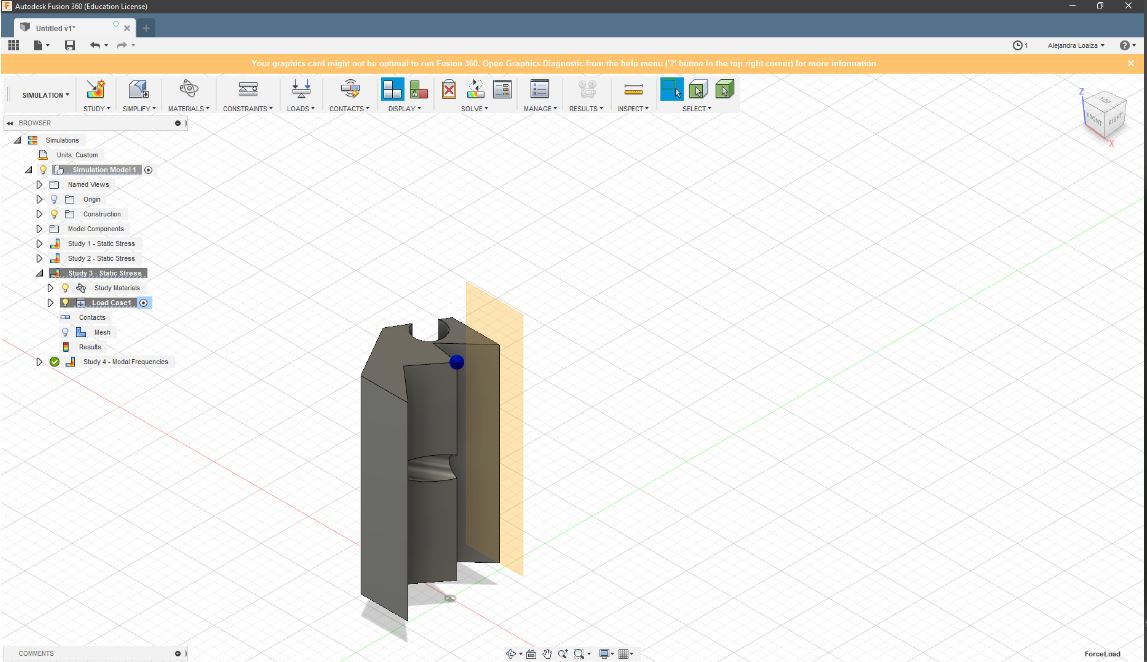

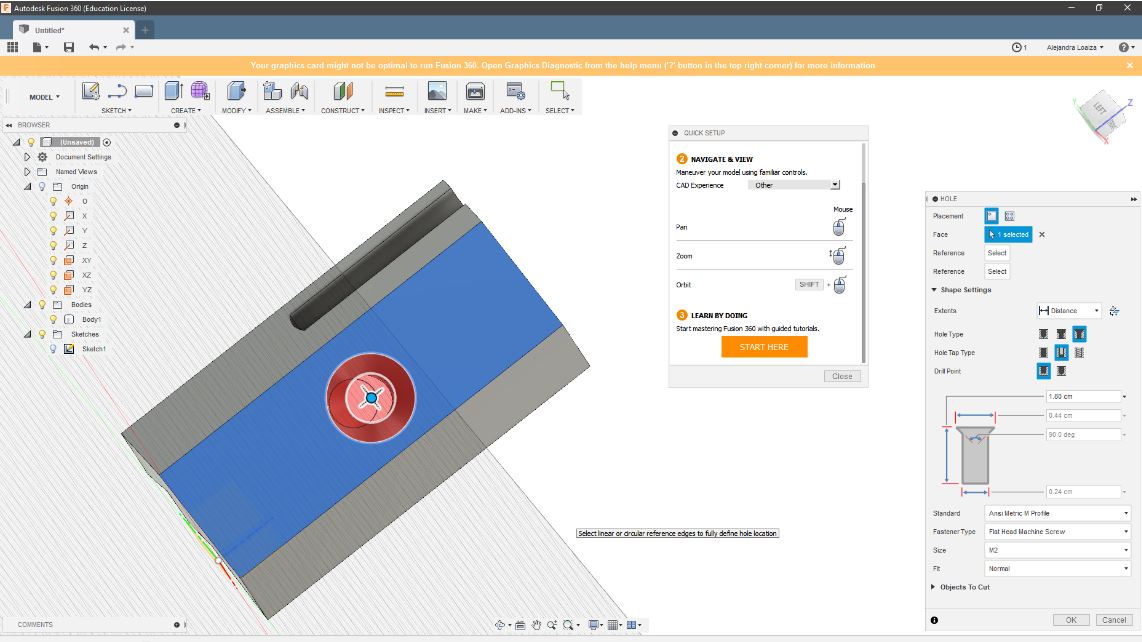

I like Fusion’s interface. It reminds me of SketchUp interface as it has drawings of what each tool does. Also, when I first opened the software it gave me the option of watching different tutorials to understand how to use the software properly. I tried a few options for creating an object and then making holes in this object, changing the initial sketch and watching the subsequent object change as well. I like the options that fusion has and the very friendly interface. I also tried to use the simulation option but with few results, I’ll have to watch a few tutorials to understand how that works. Overall, I did like the software a lot and it seems to be friendly enough to learn the basics quickly.

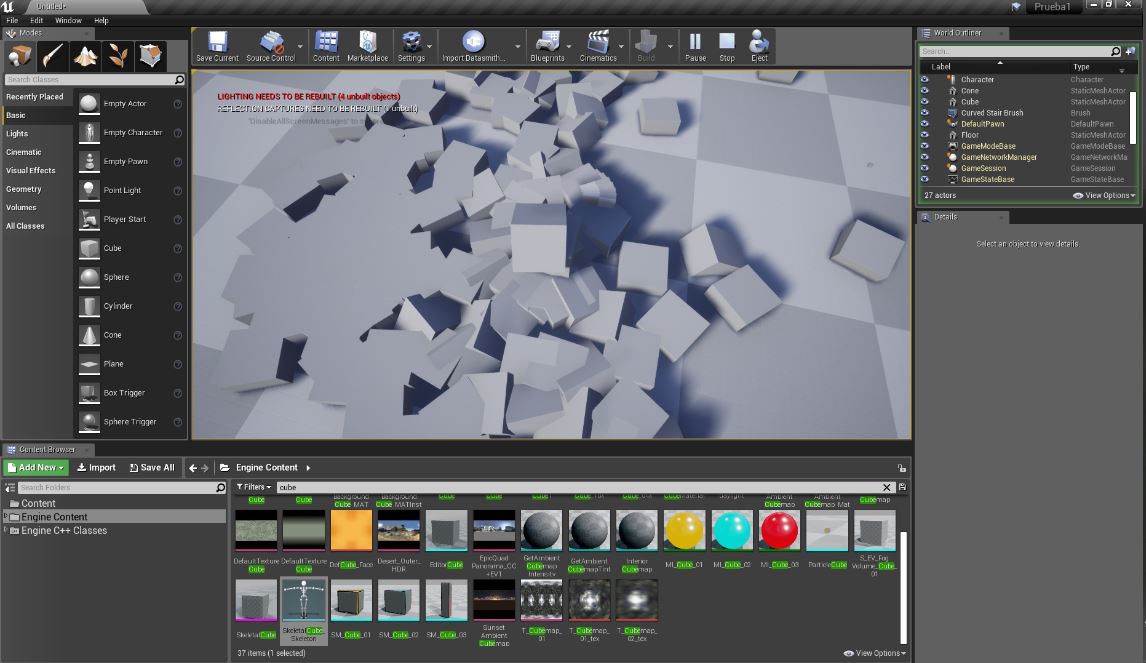

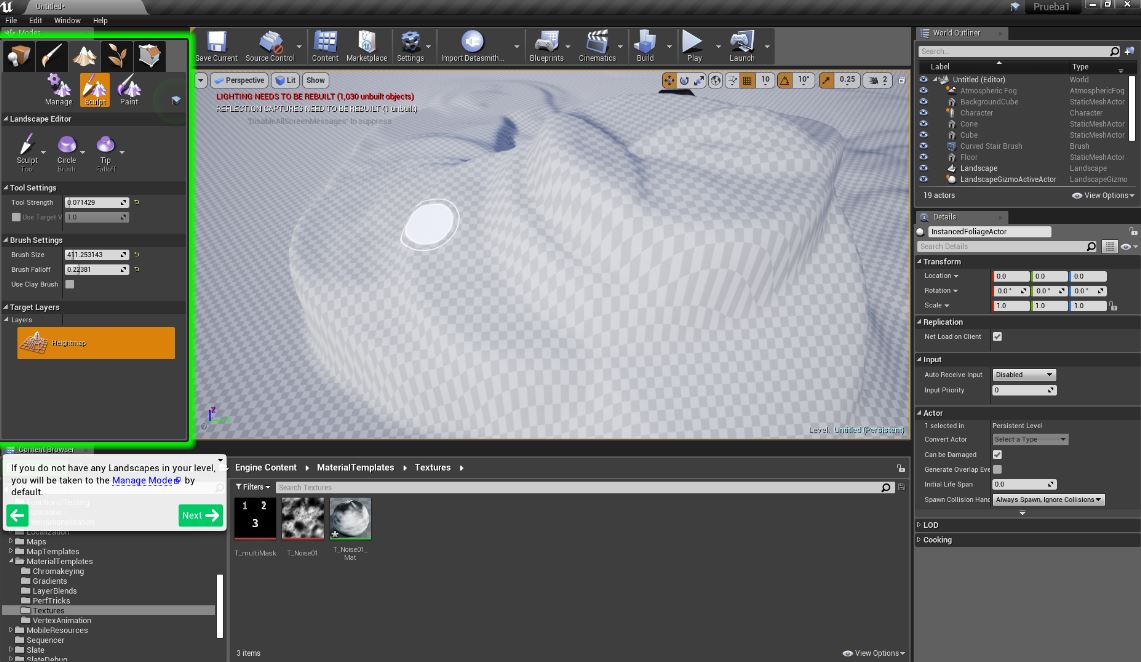

I tried the software Unreal Engine, mostly because it was mentioned during class and I thought it sounded very interesting. It’s a very large software as it weighs around 6 gb. It has a lot of options and functions, and I liked how there is the play mode option so you can walk around the area as if you were a character in the game. I don’t think it will help me very much in creating project models, but it looks very interesting in rendering and creating landscapes.

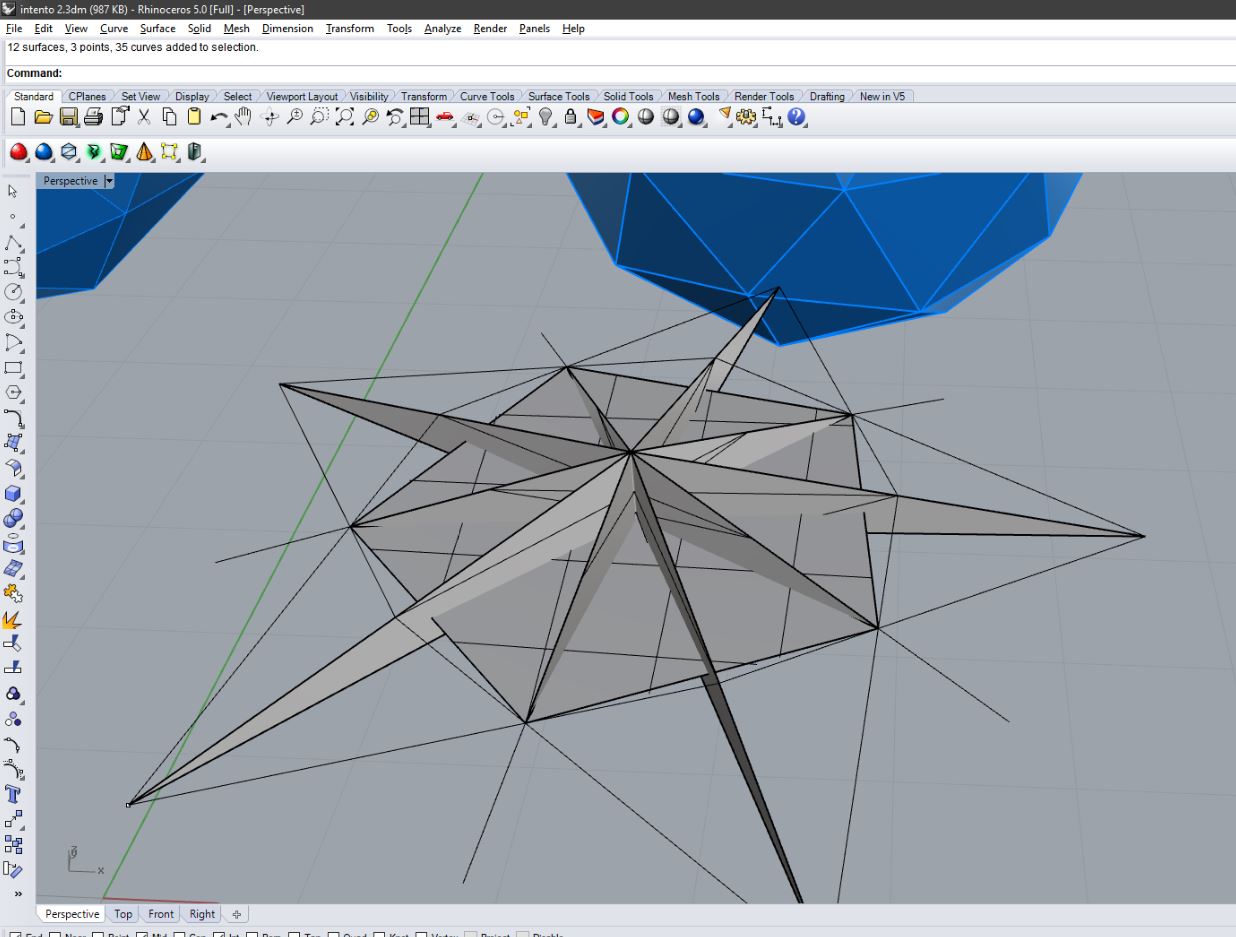

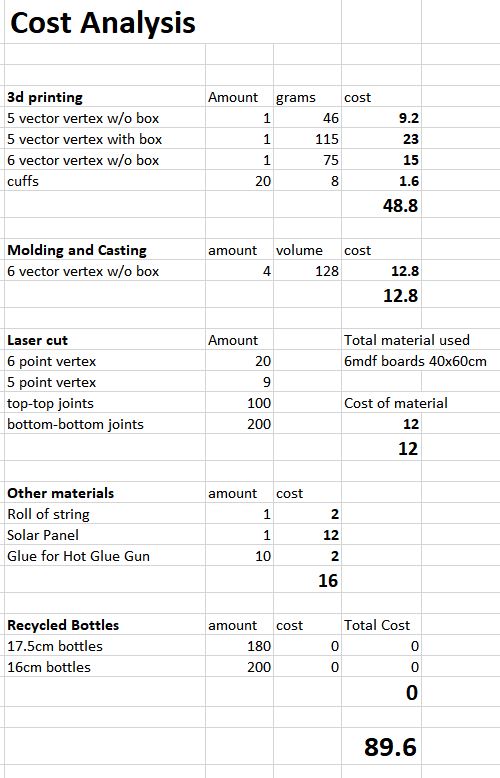

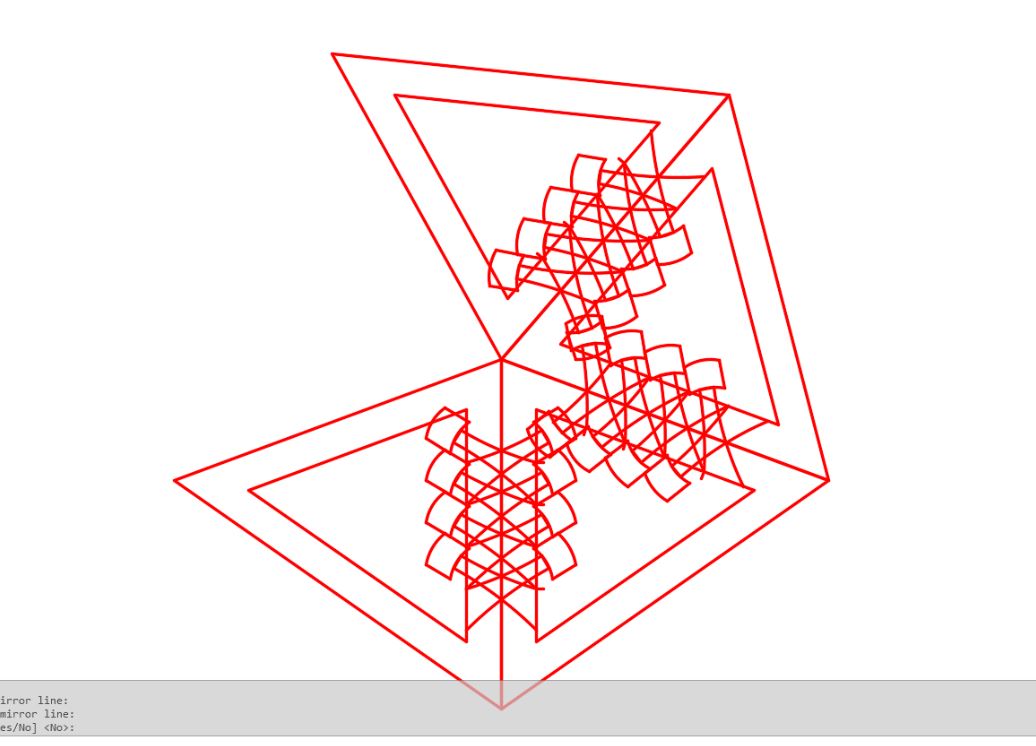

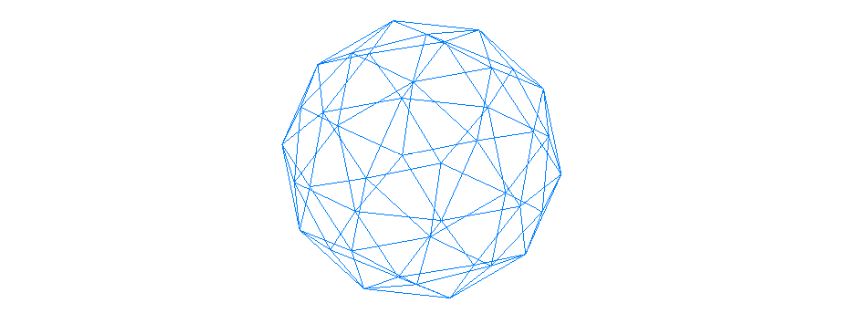

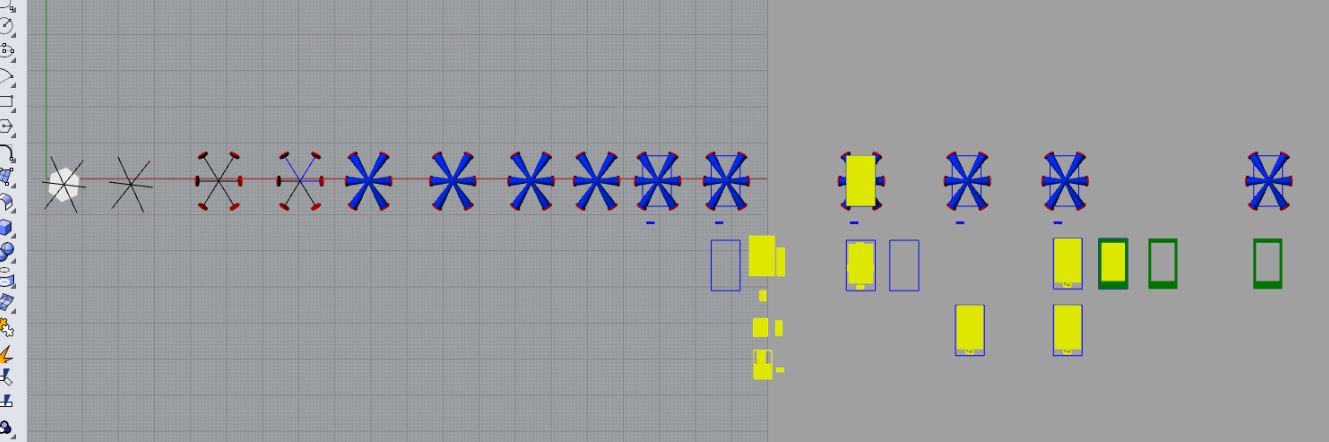

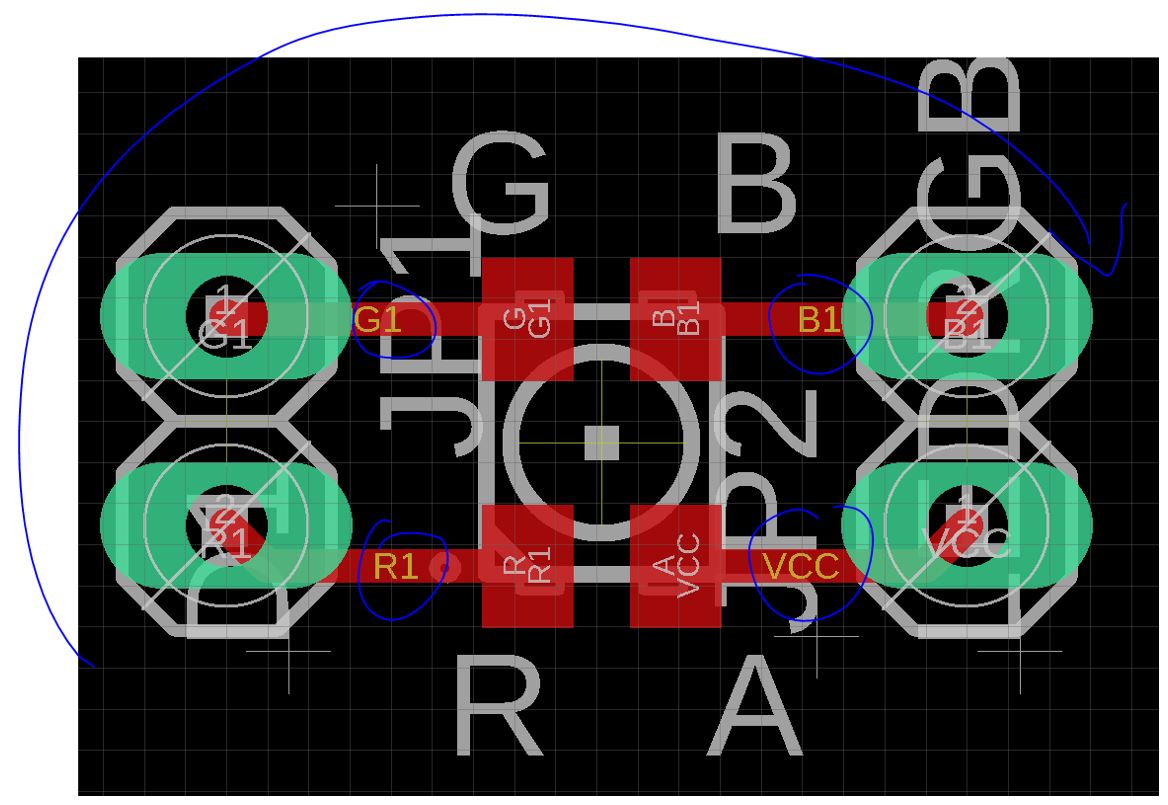

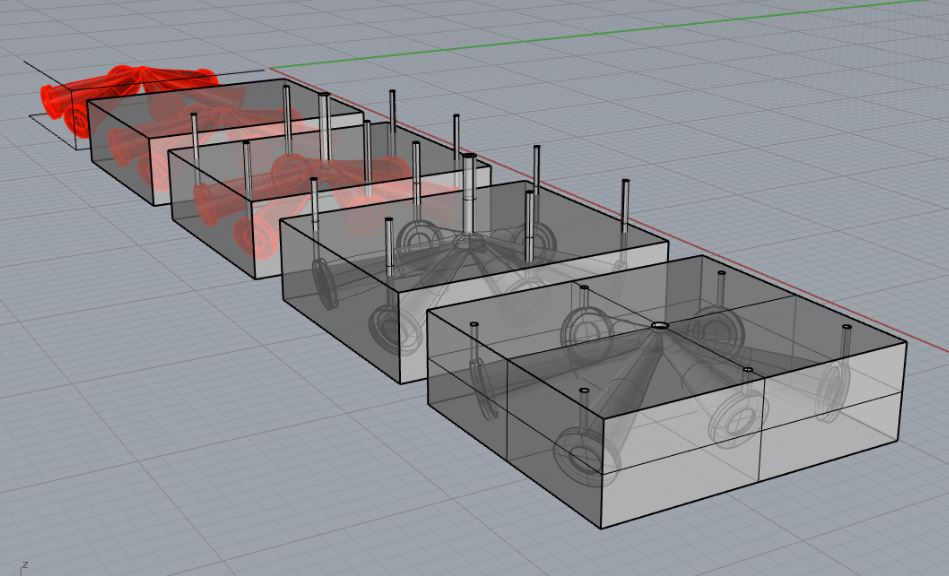

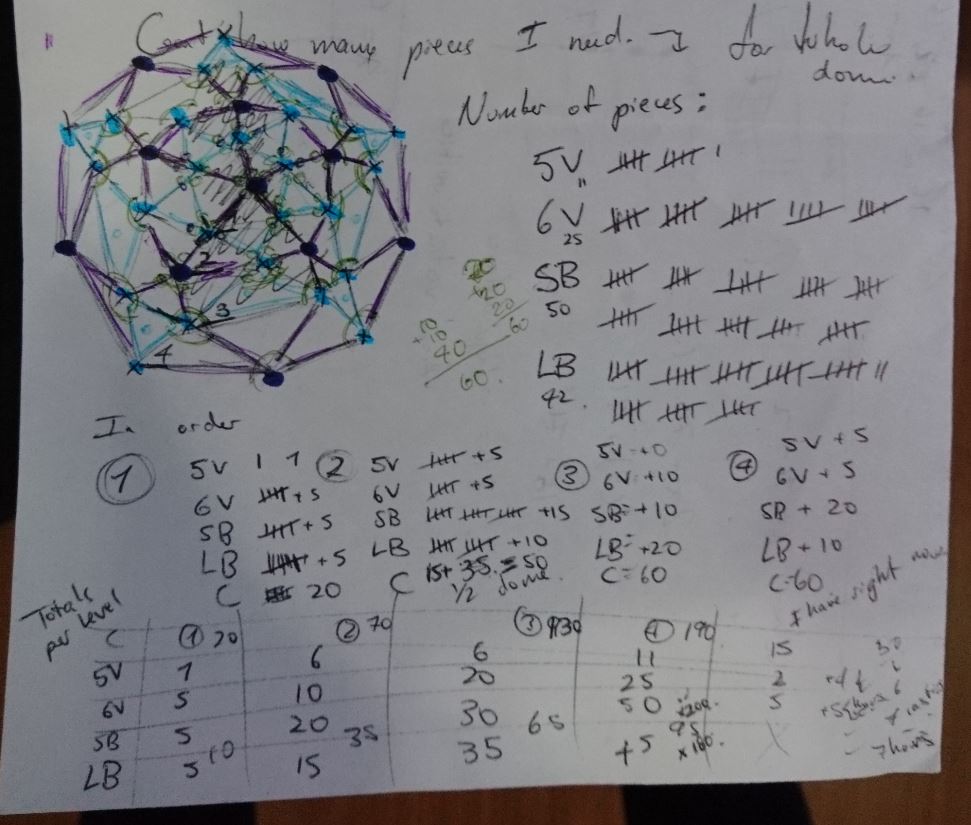

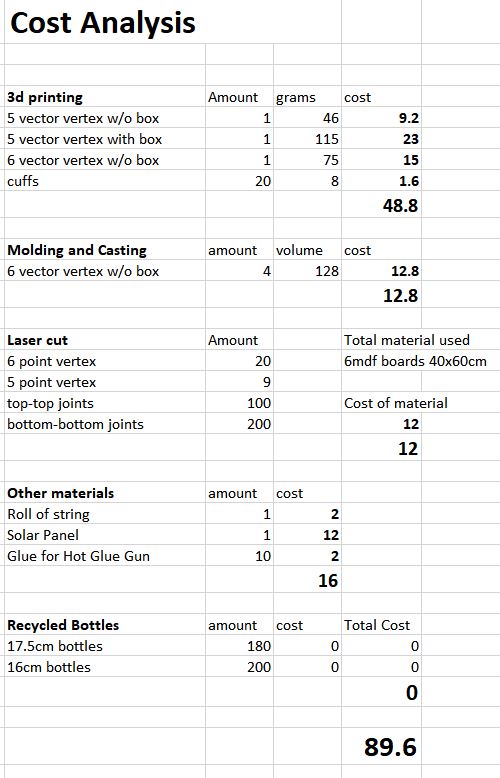

As a final project, my intention is to create a geodesic dome using recycled bottles and 3d printed joints as the vertices. In order to do this, first I had to understand the shape and be able to calculate the angles and lengths of the beams.

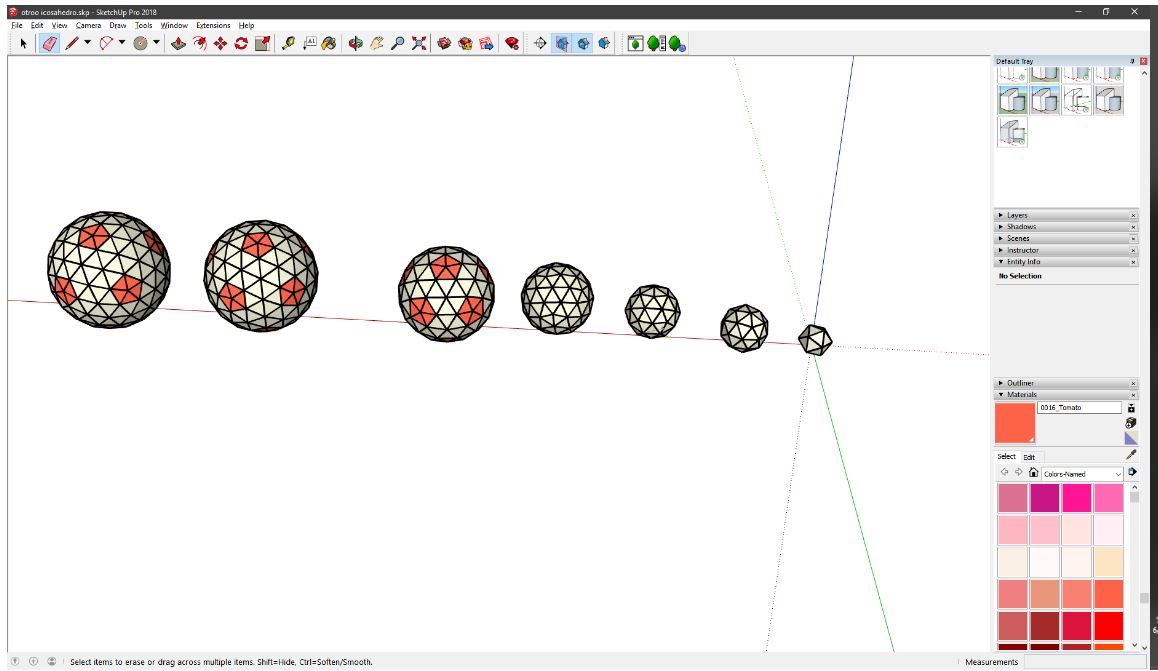

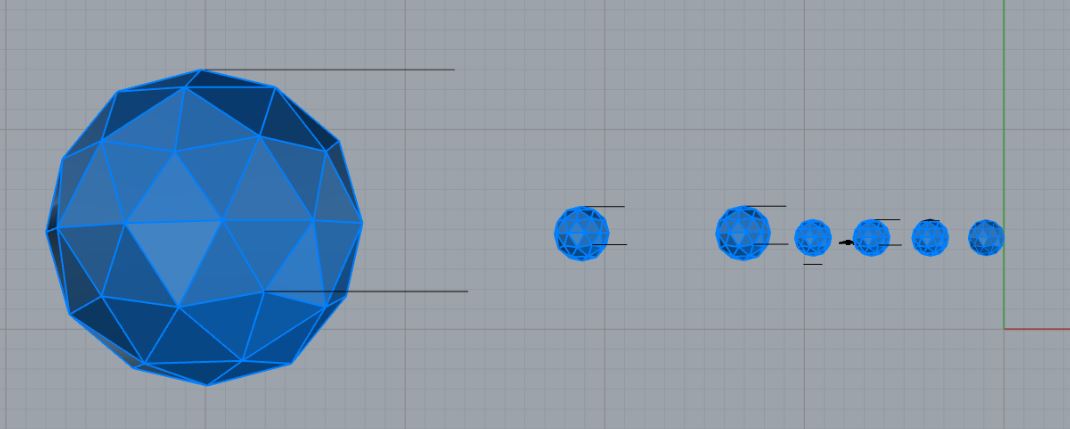

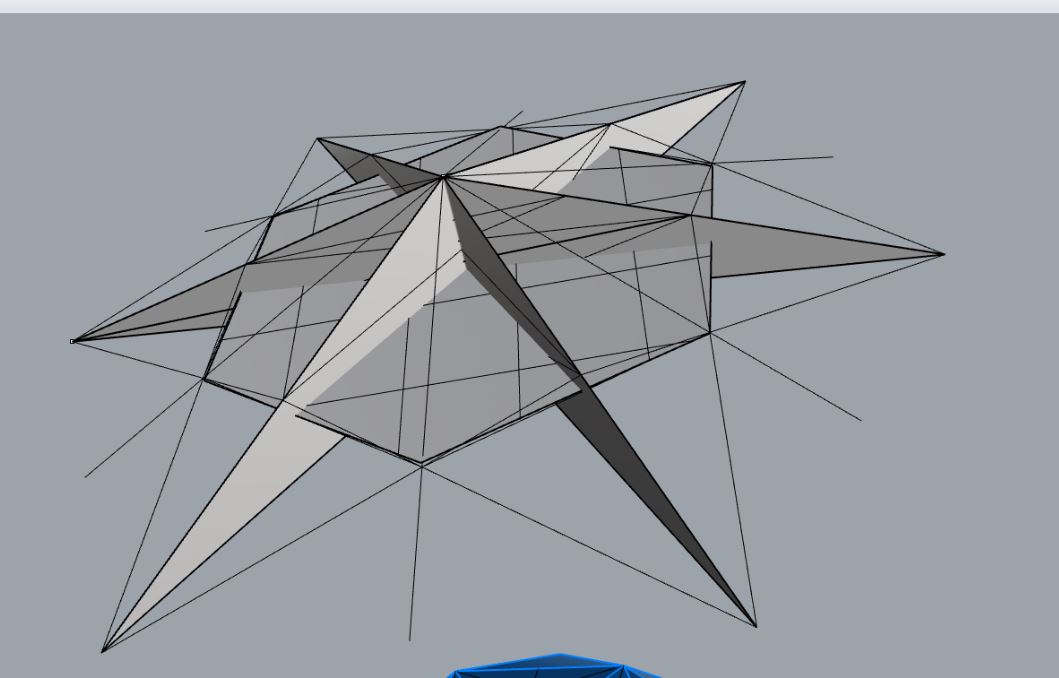

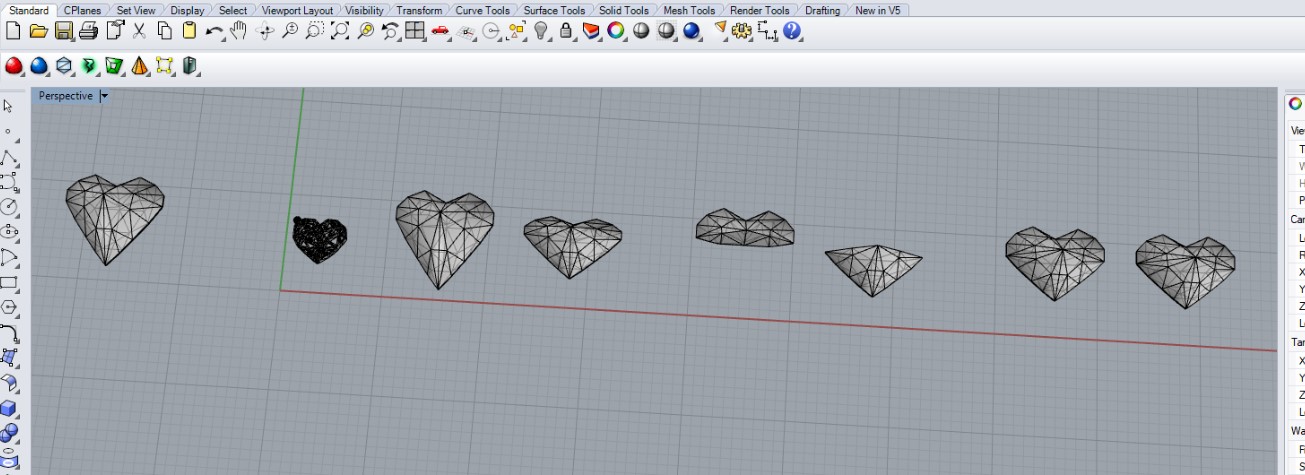

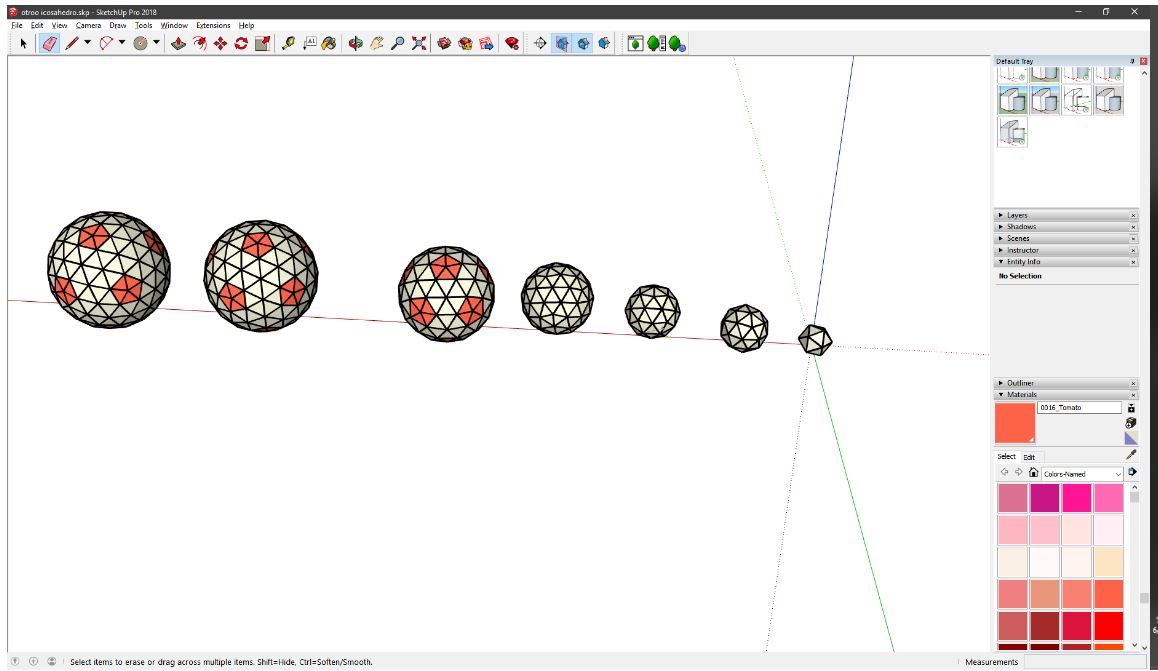

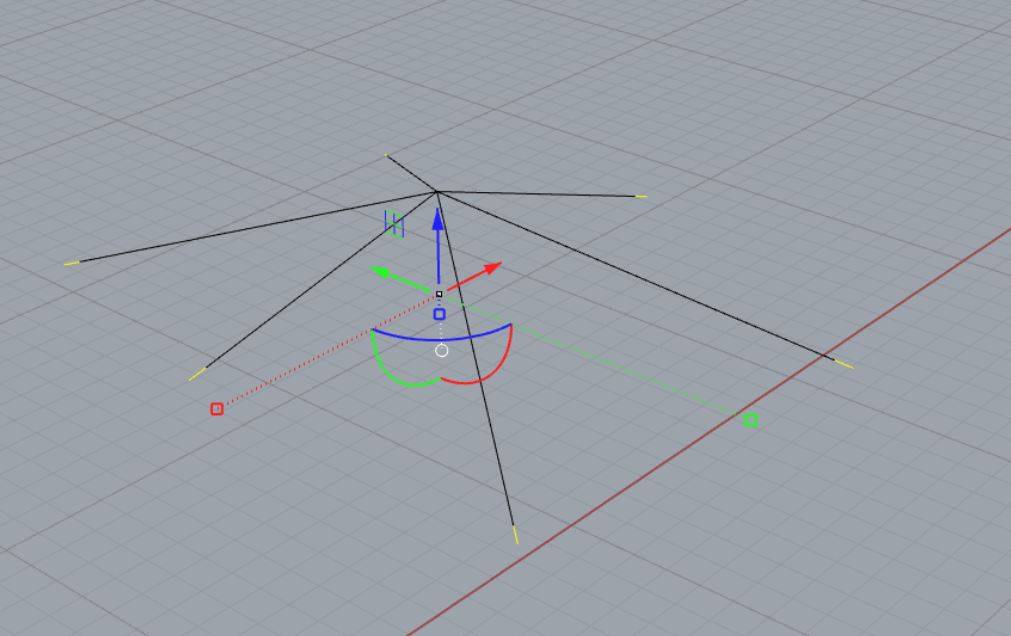

In order to do that, first I used rhino (specifically a plugin in rhino that has many polyhedron volumes) to visualize different types of geodesic shapes. I used the icosahedron as a basis, and then saw the different types of icosahedrons that were available in this plugin.

Seeing as I found these shapes particularly interesting and I wanted to understand them better, I did a little bit of research and this is the information that I found:

Also, I found a lot of very interesting information about the benefits of geodesic domes in Buckminster Fuller Institute webpage (Fuller was awarded the US patent for geodesic domes, and is the one credited for popularizing this type of structure)

At first I found it very difficult to understand these shapes, something that was definitely needed in order to deconstruct it and be able to make out the pieces. Therefore, I exported the shapes and imported them into SketchUp (a program I am more familiarized with) and then began “painting” the faces in order to understand the logic behind them.

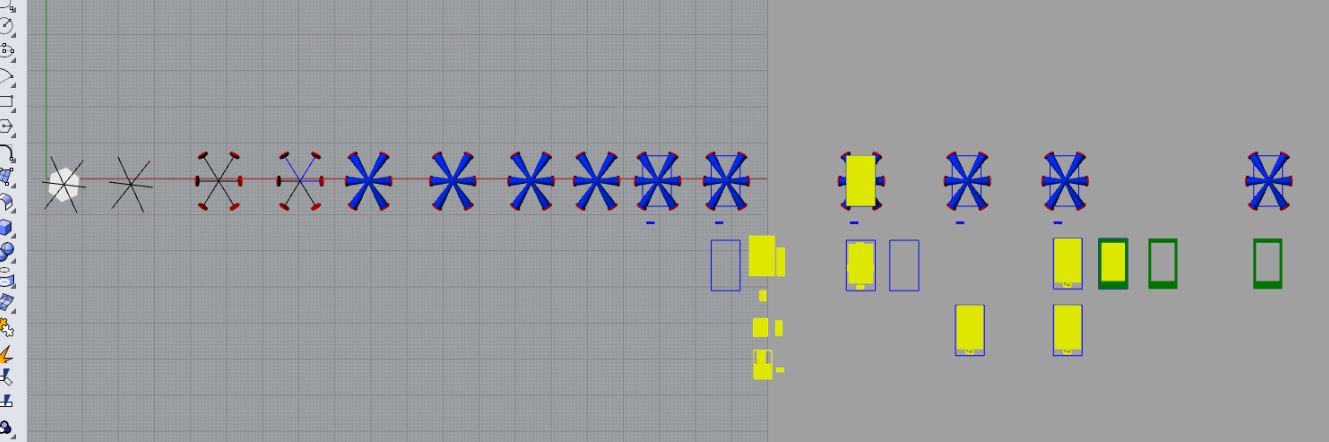

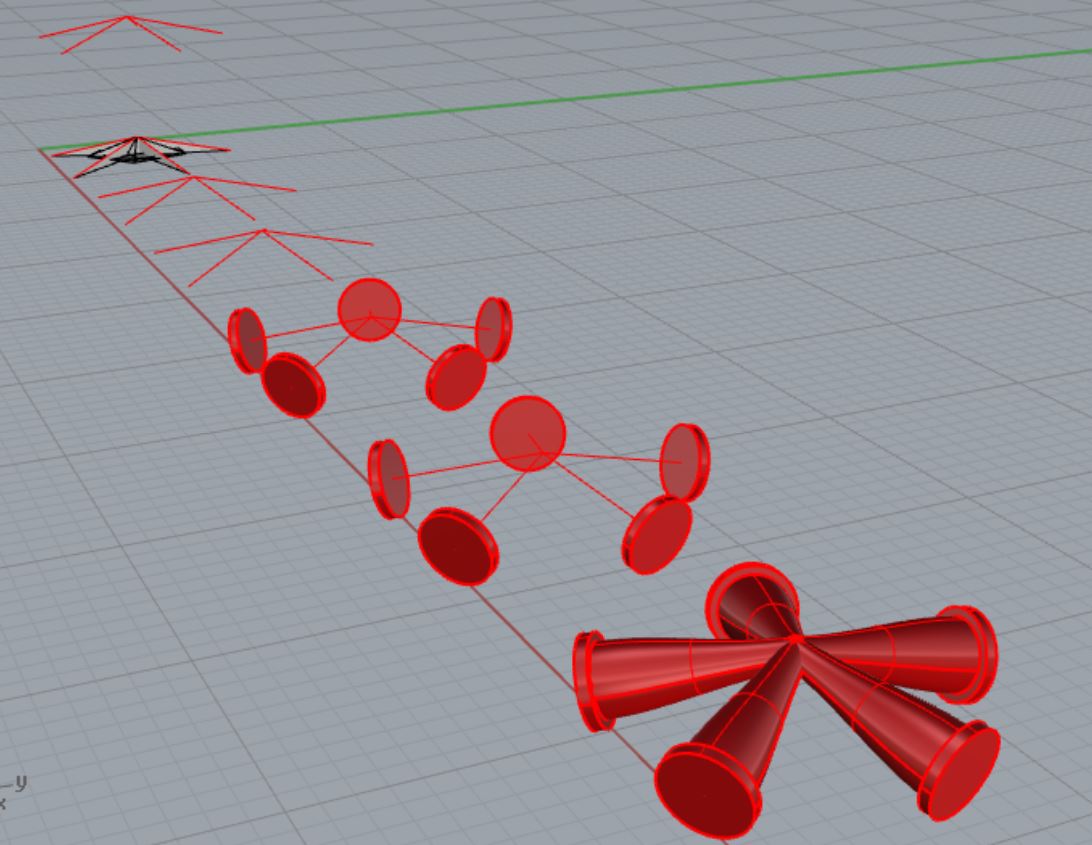

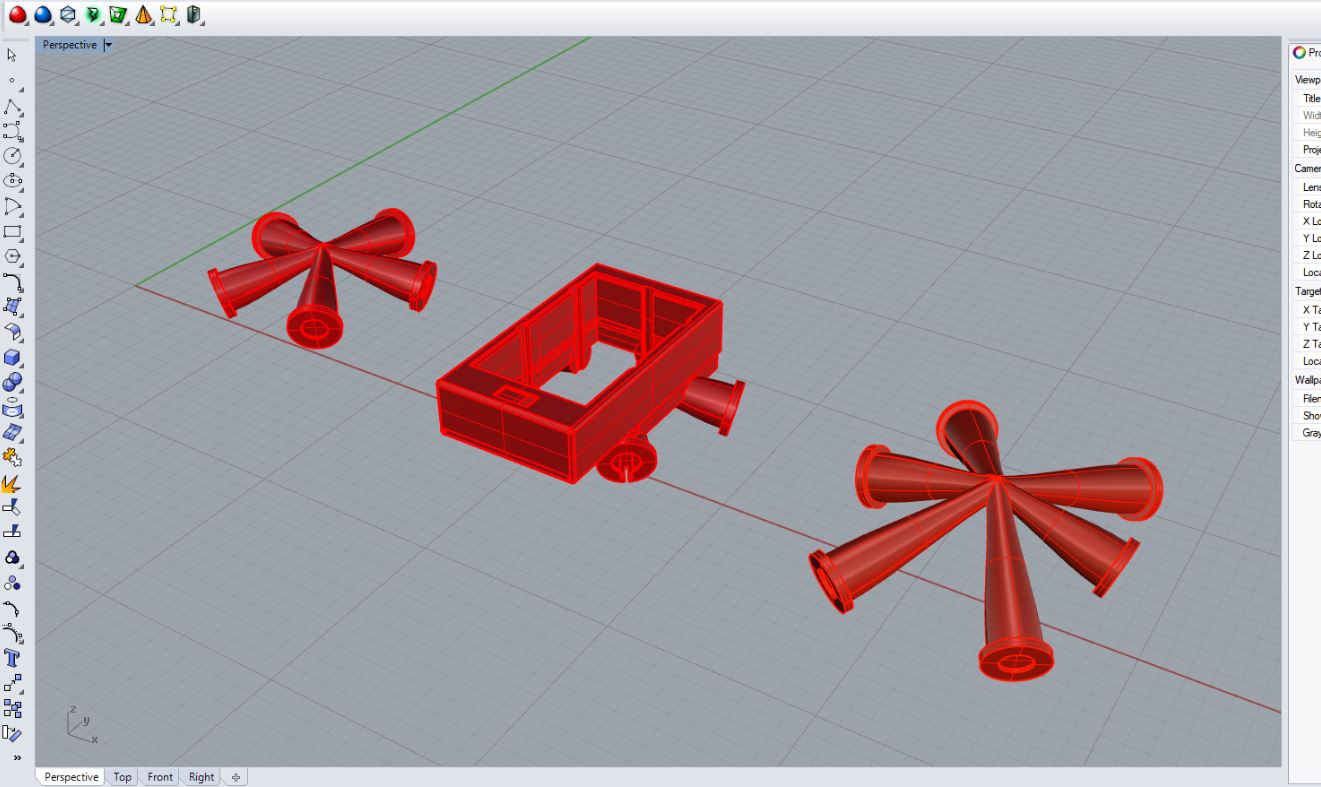

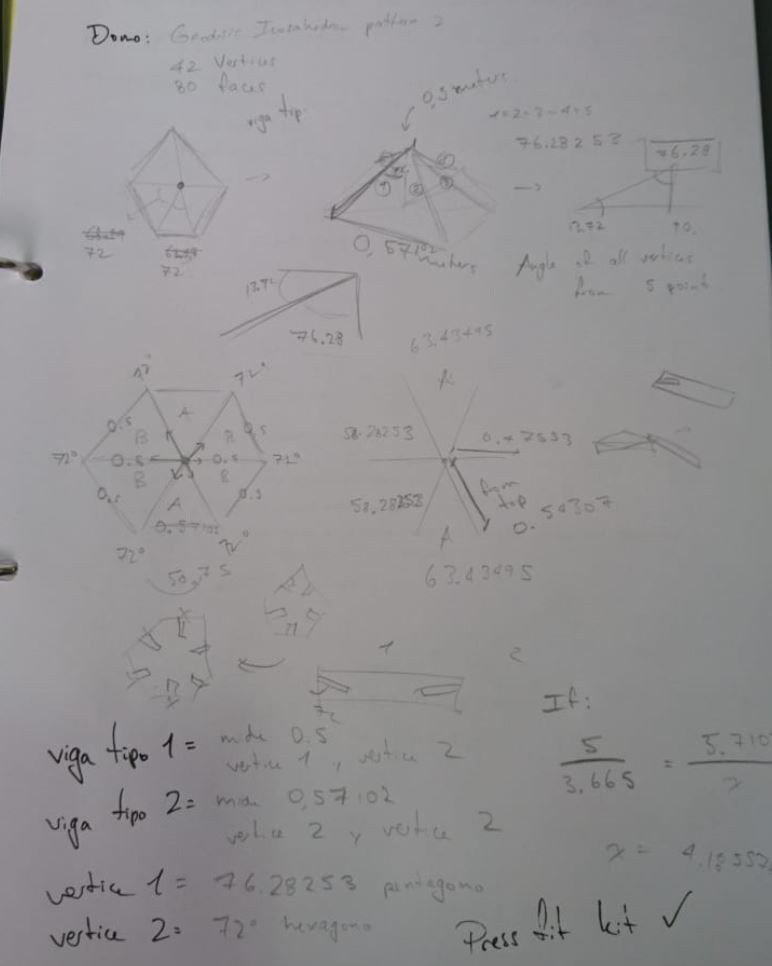

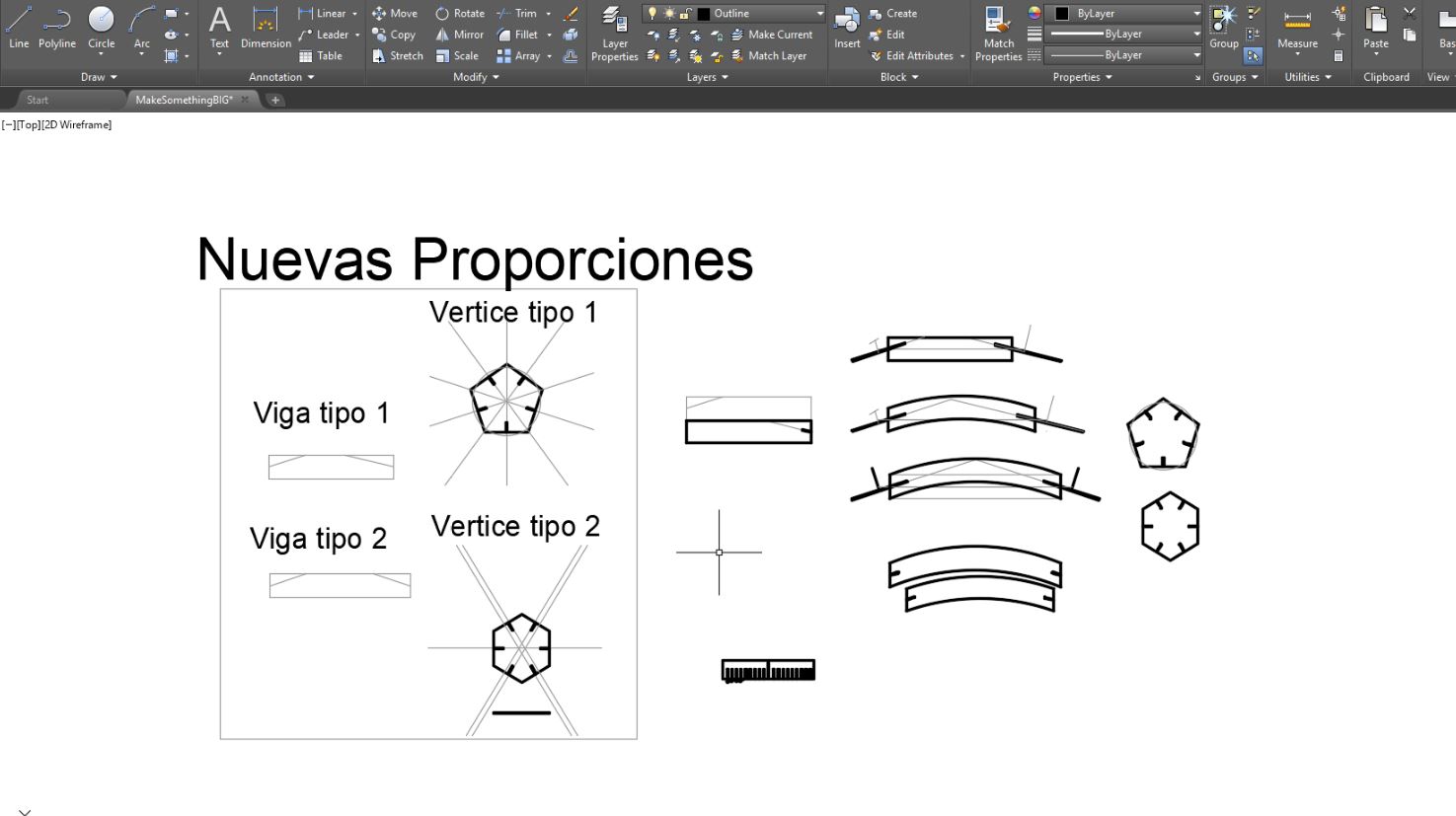

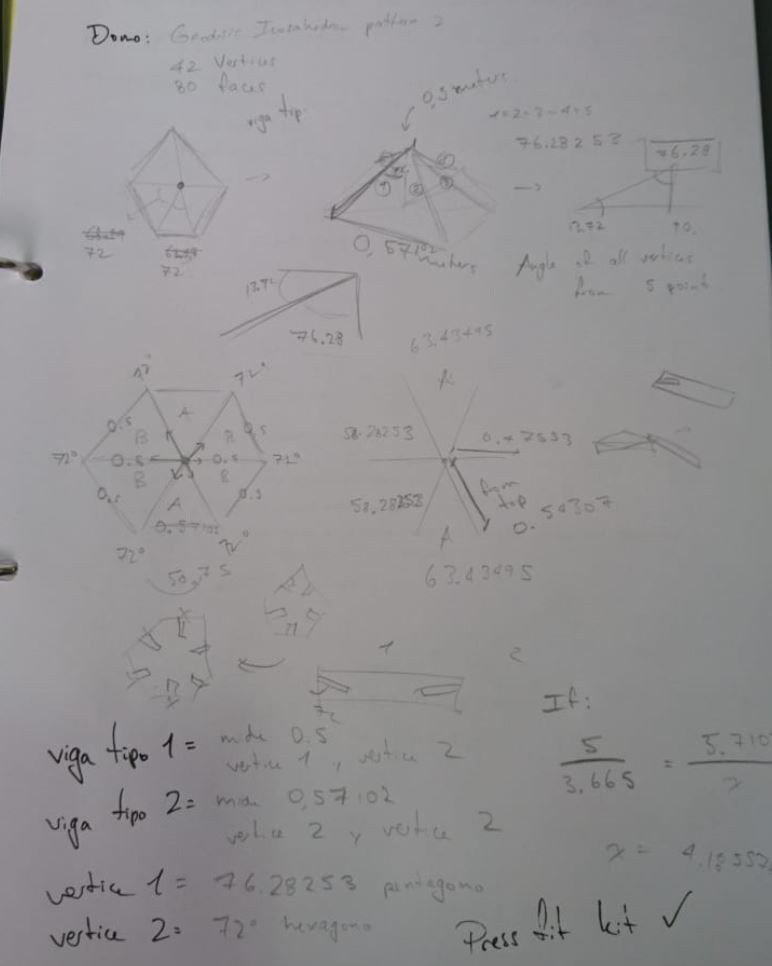

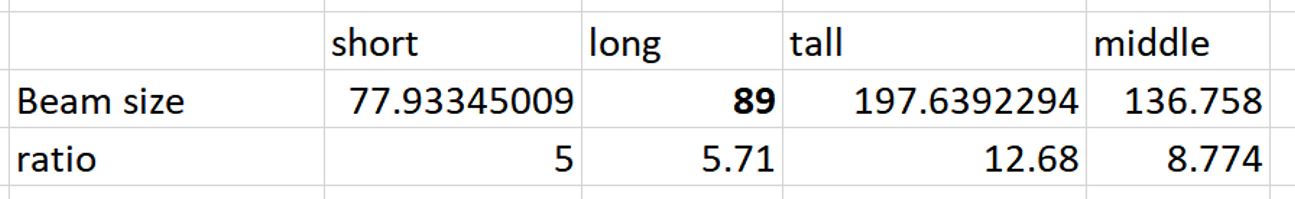

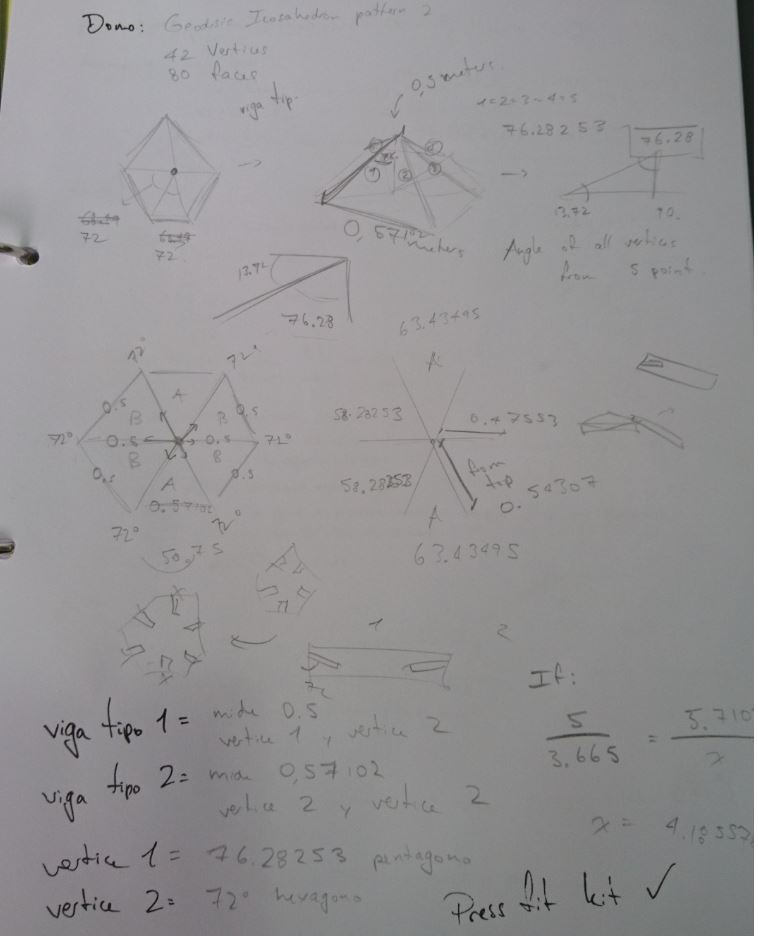

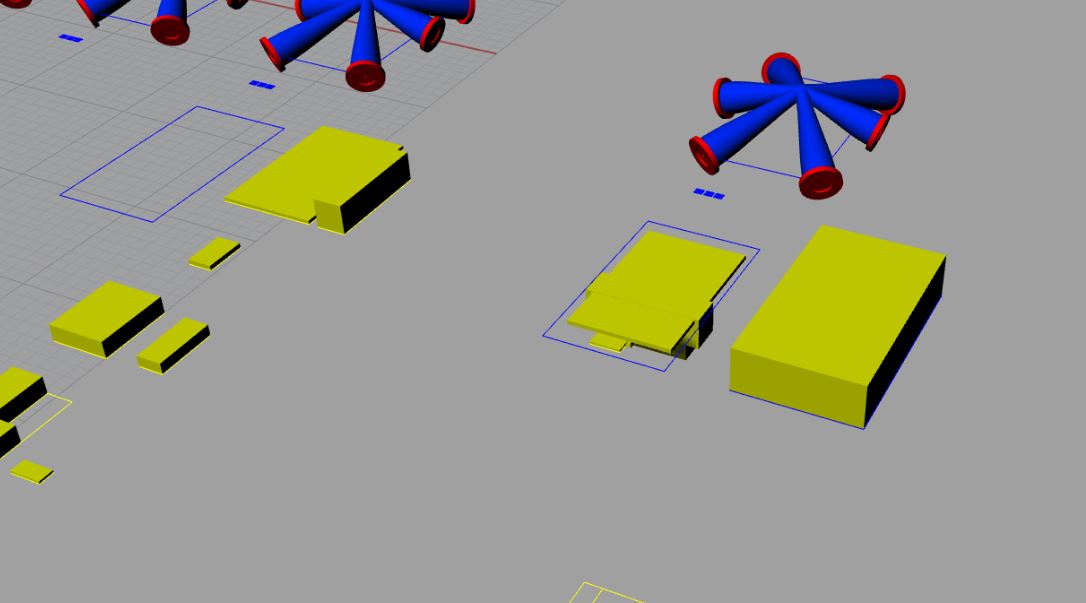

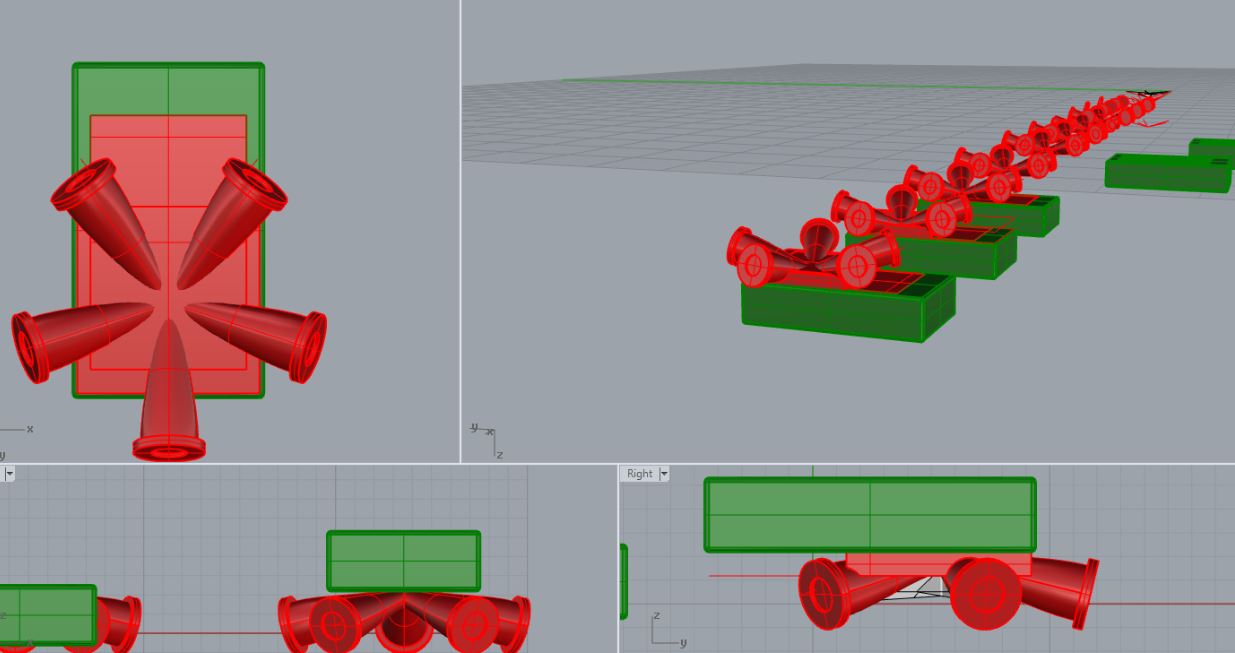

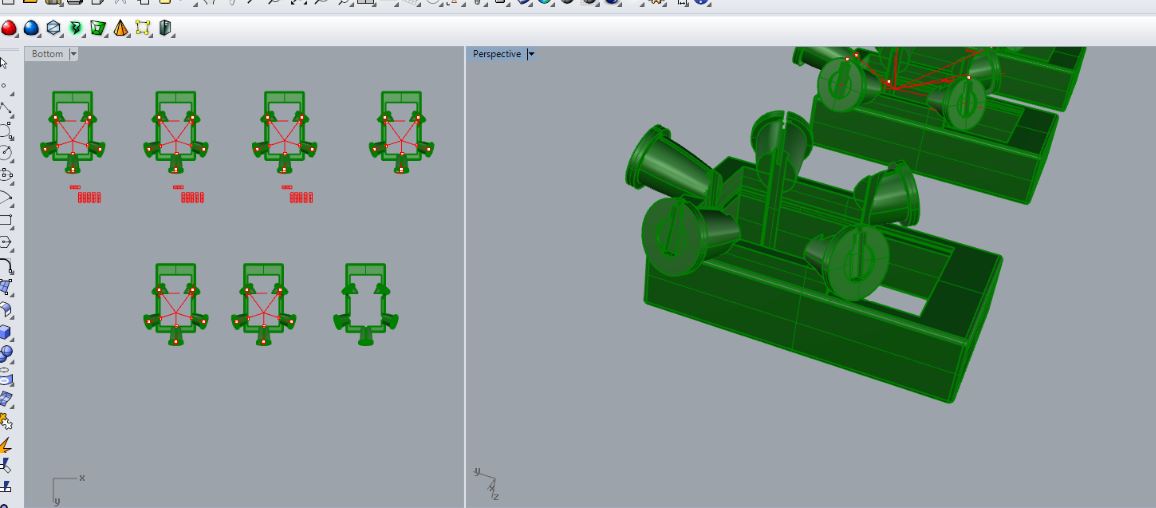

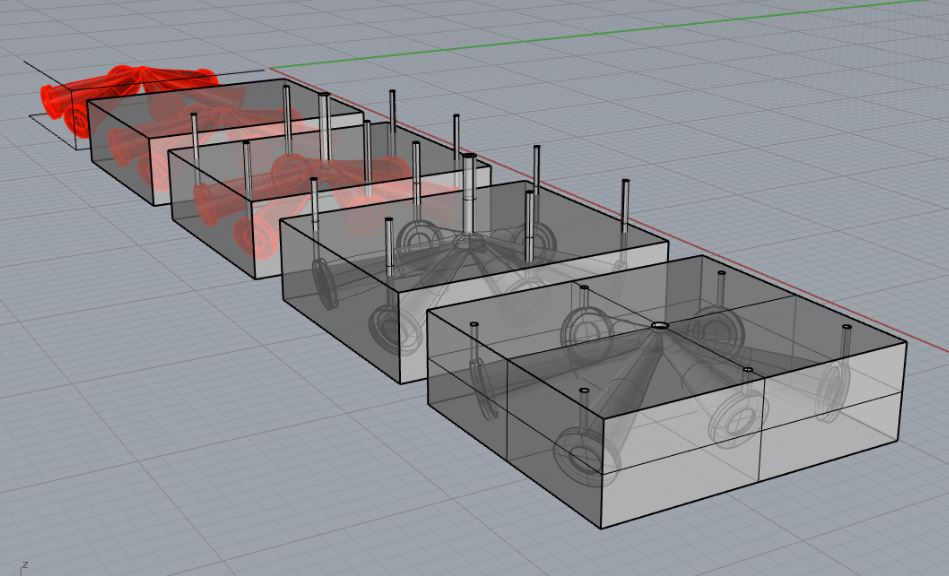

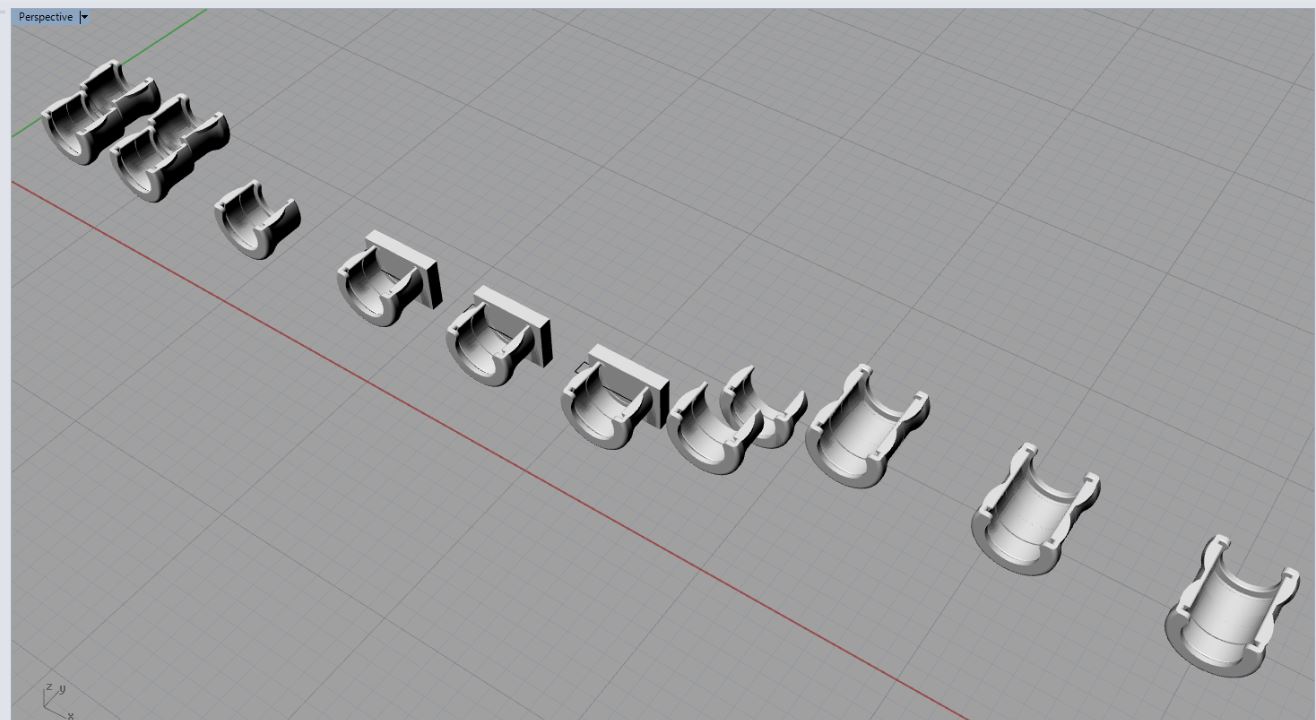

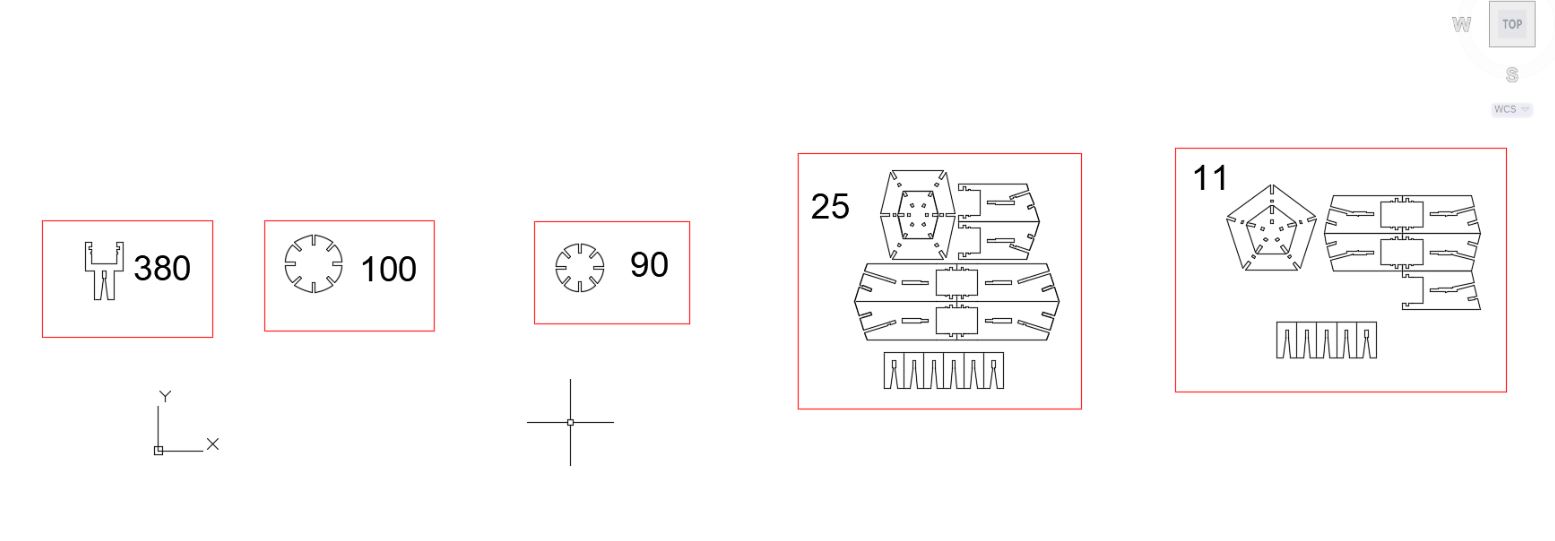

After experimenting with different lengths for the beams and seeing the height of the resulting shape, I decided upon a specific one for my final project. It is the Geodesic Icosahedron (pattern 2 in the rhino plugin), and it has 42 vertices and 80 faces. Upon deconstructing the figure into pieces (as I will have to do for the final project) I discovered it has two types of vertices; 12 vertices where 5 beams meet, and 30 vertices where 6 beams meet. Also, there are two types of beams, 60 beams that connect vertices type 1 (pentagonal) with vertices type 2 (hexagonal), and 60 beams that connect vertices type 2 with other vertices type 2.

That was the modeling and analyzing the shape for my final project using CAD. Go to the week 4 assignment to see how I turned this shape into the pieces needed in order to lasercut and test the shape.

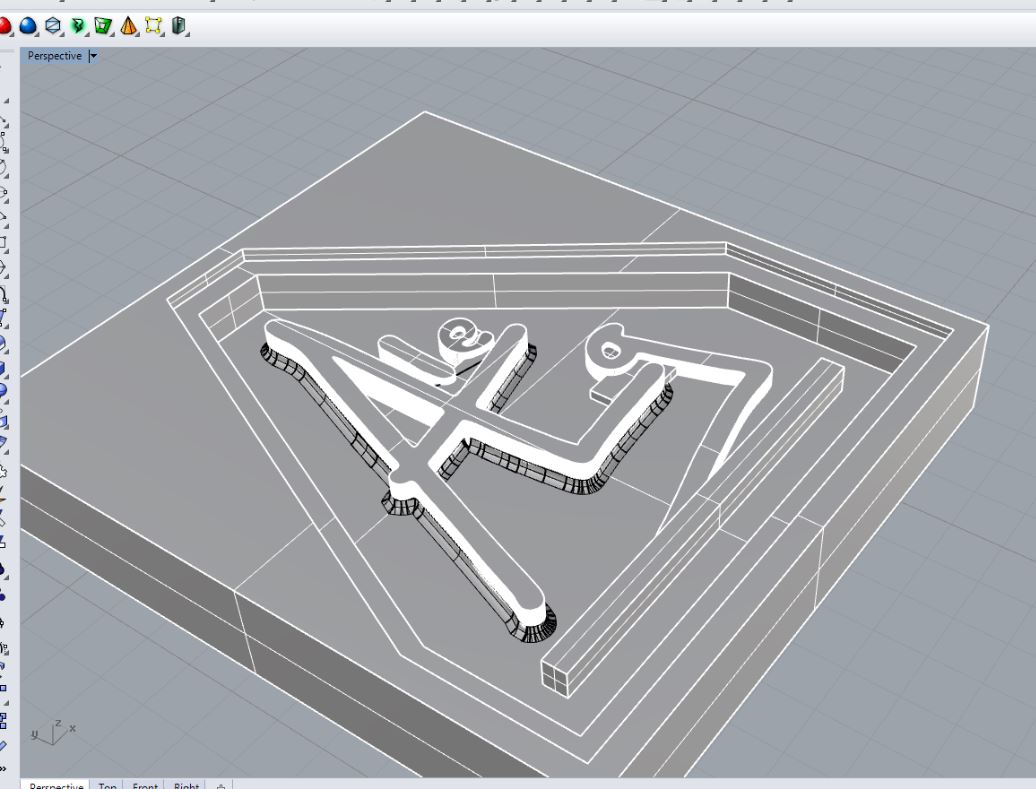

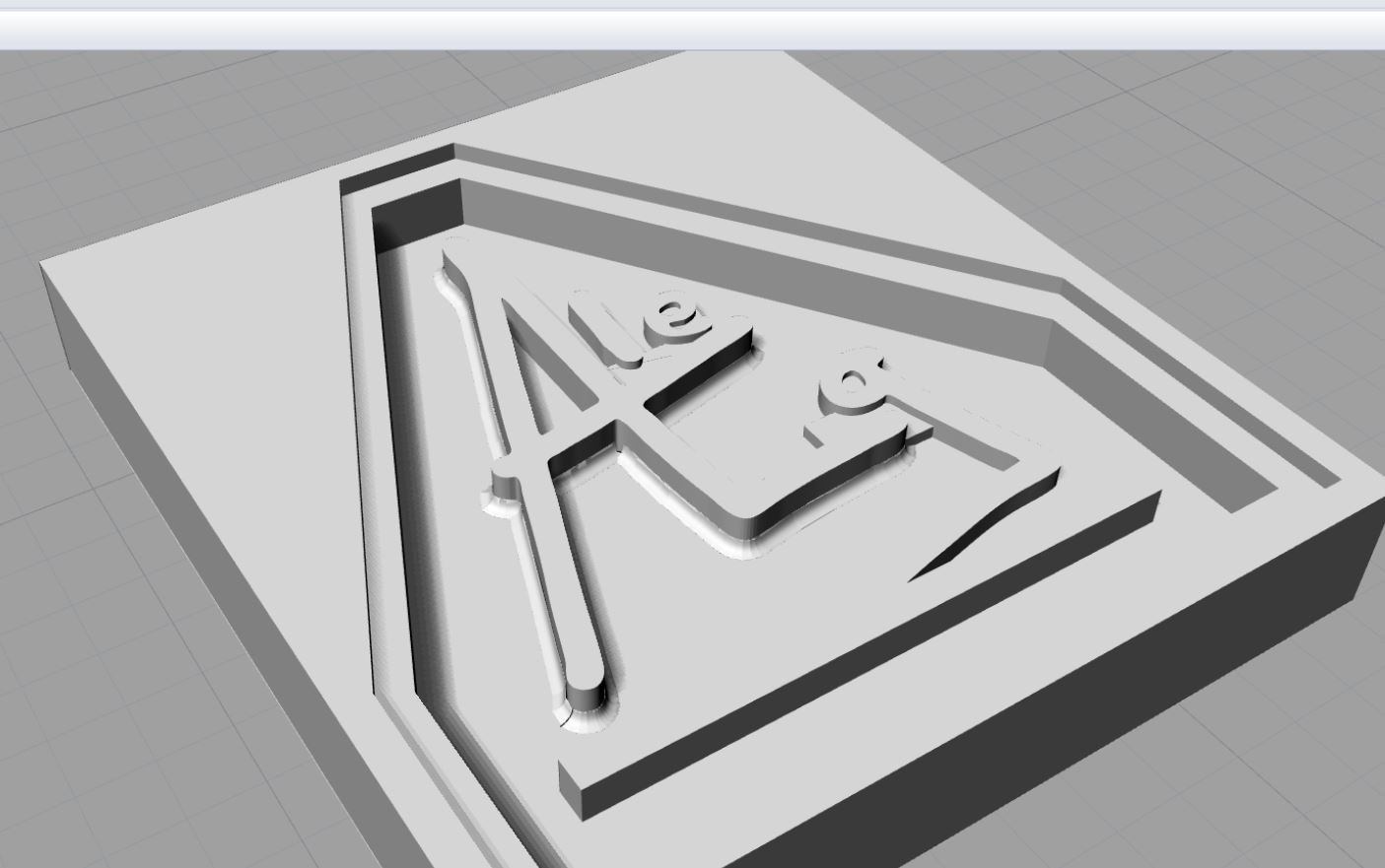

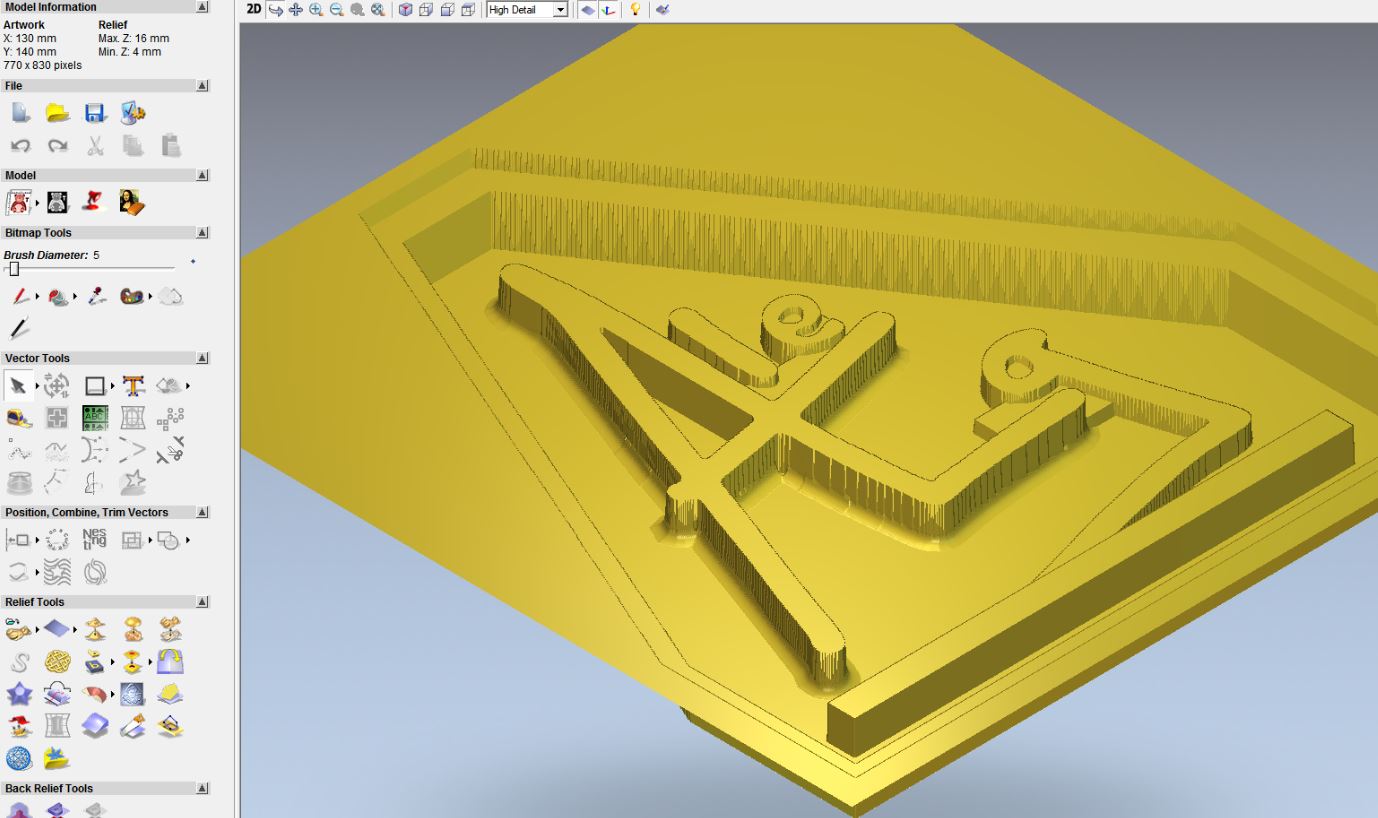

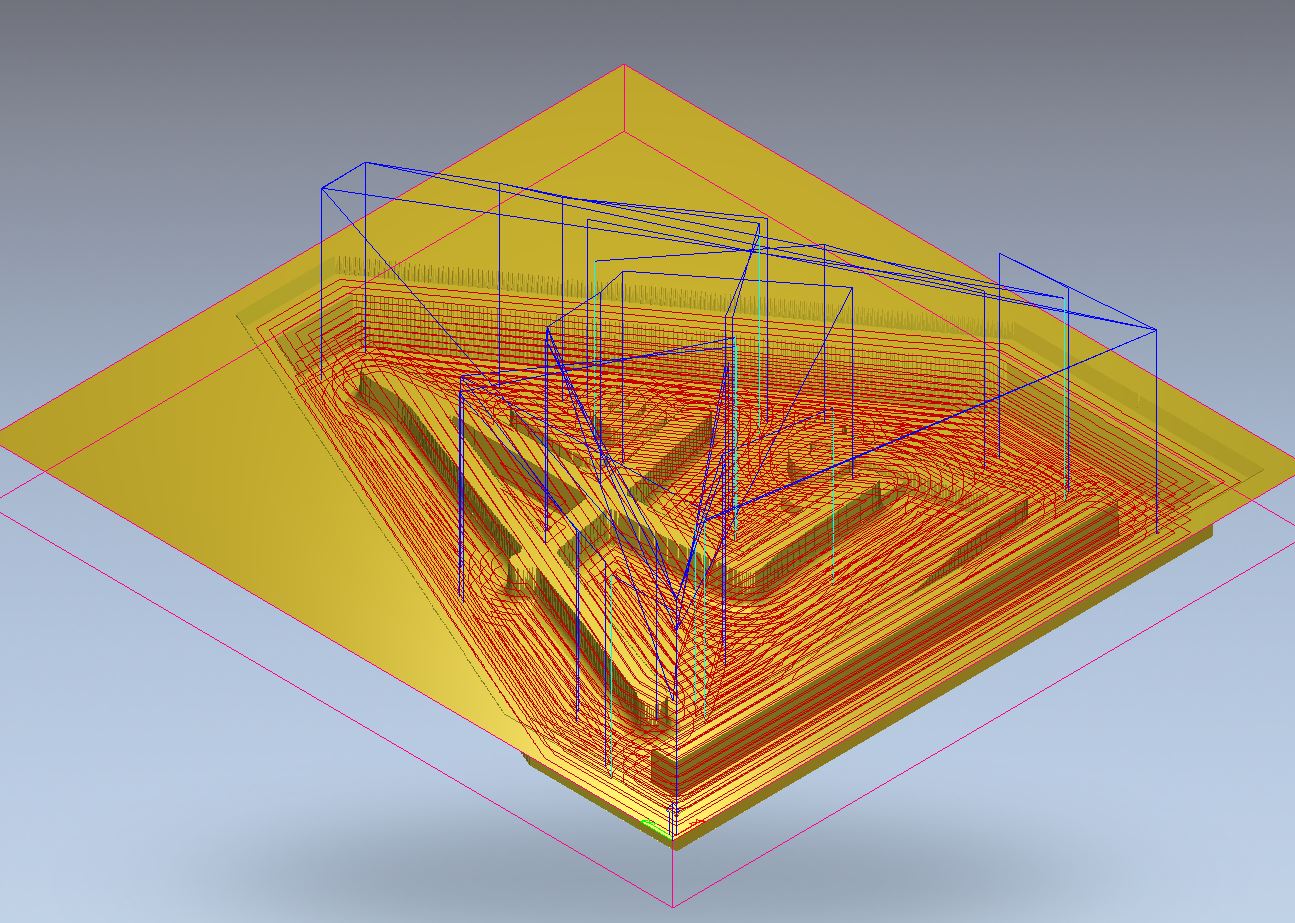

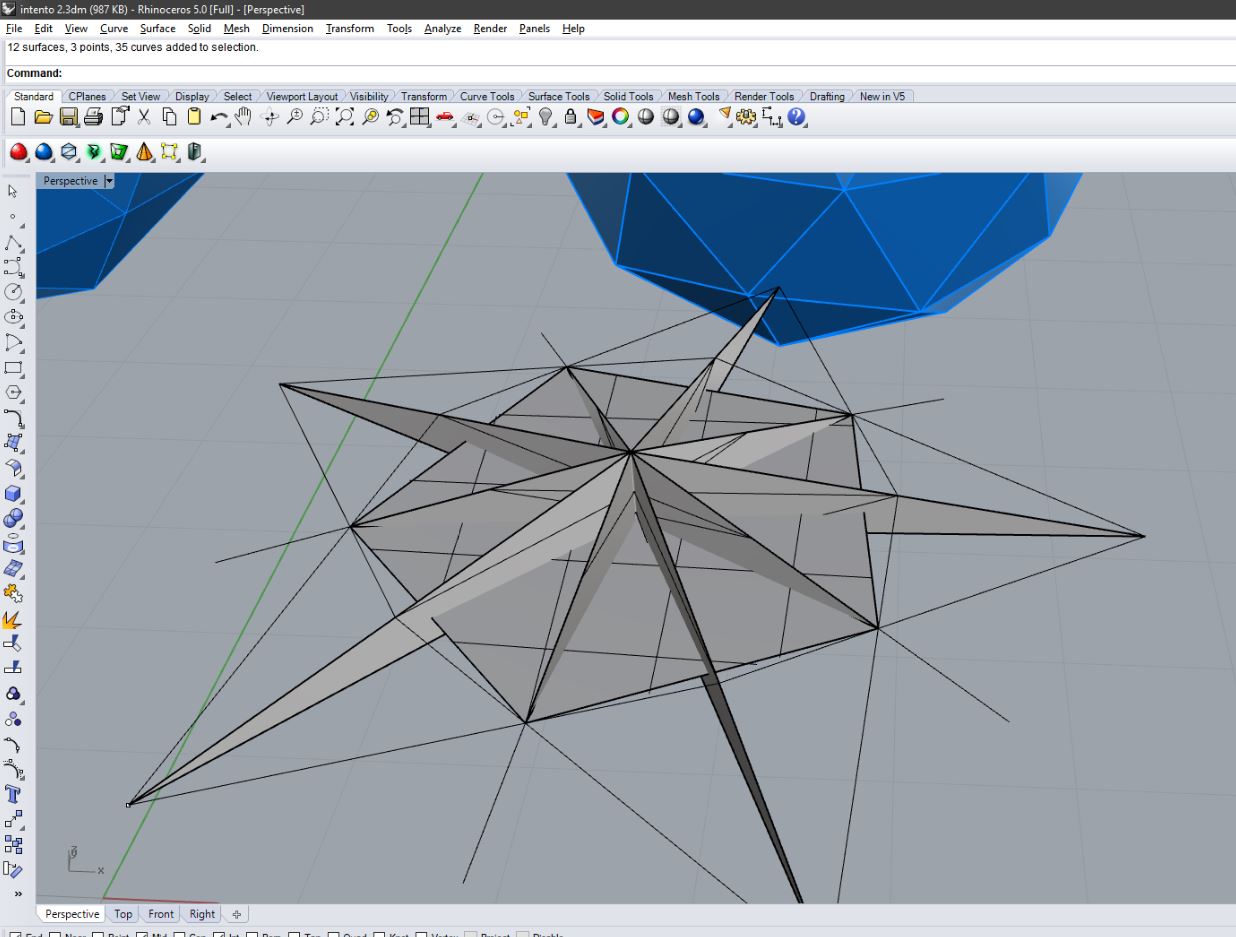

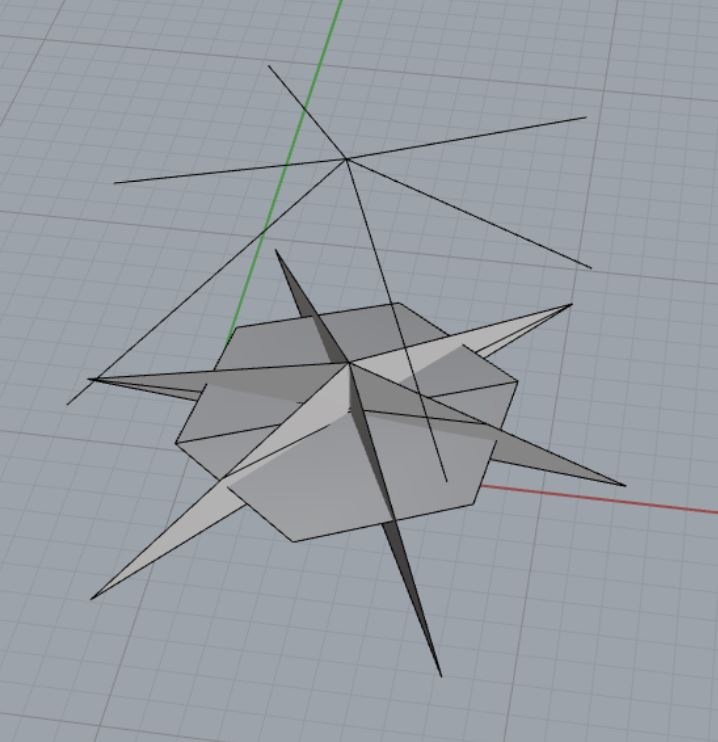

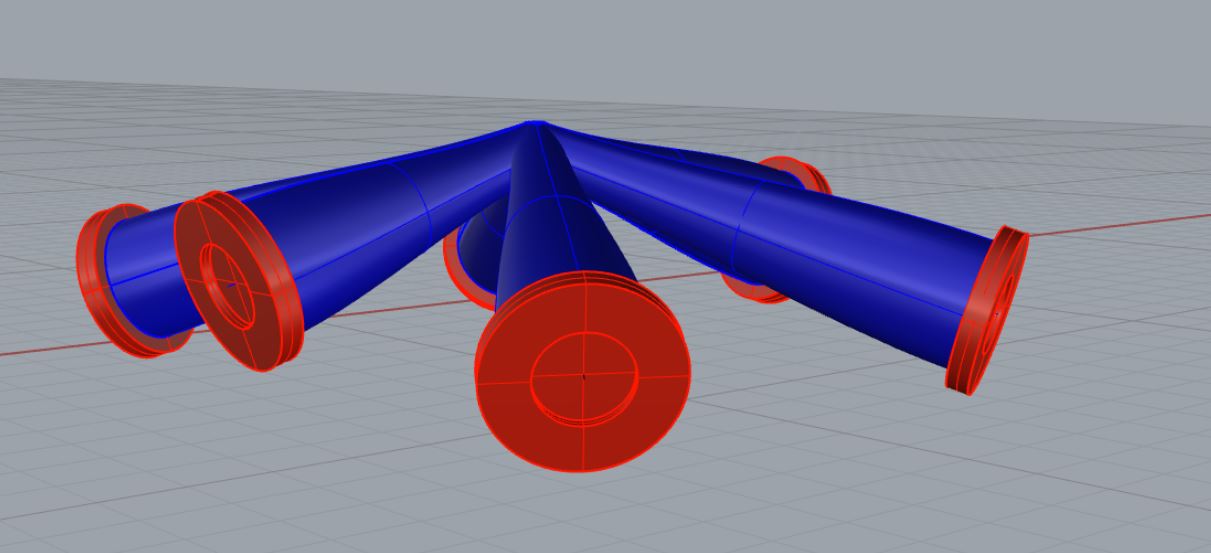

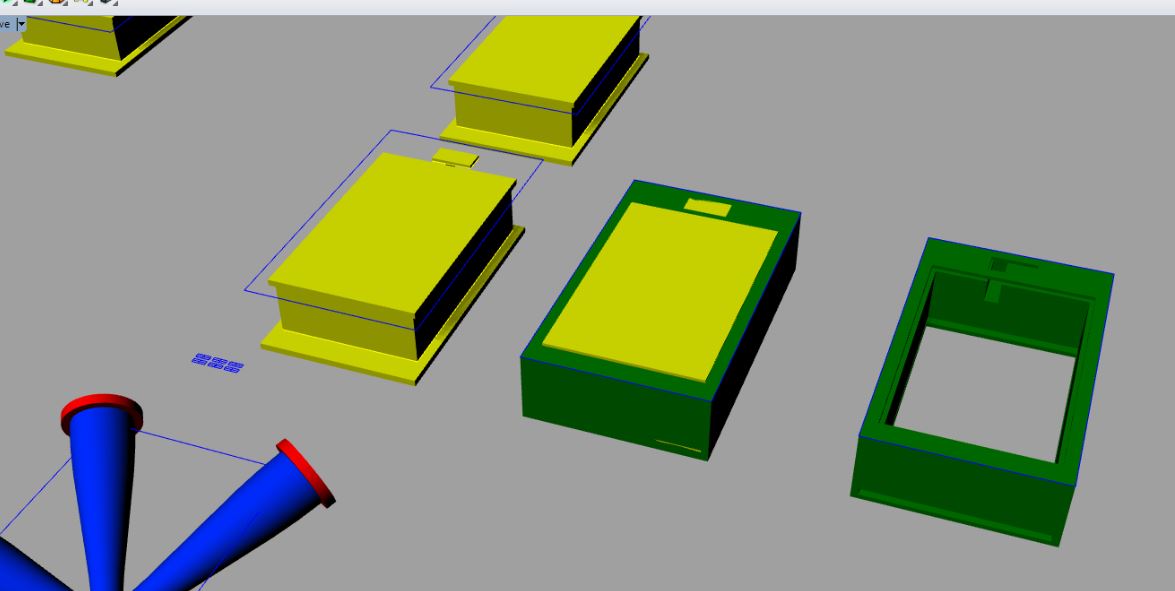

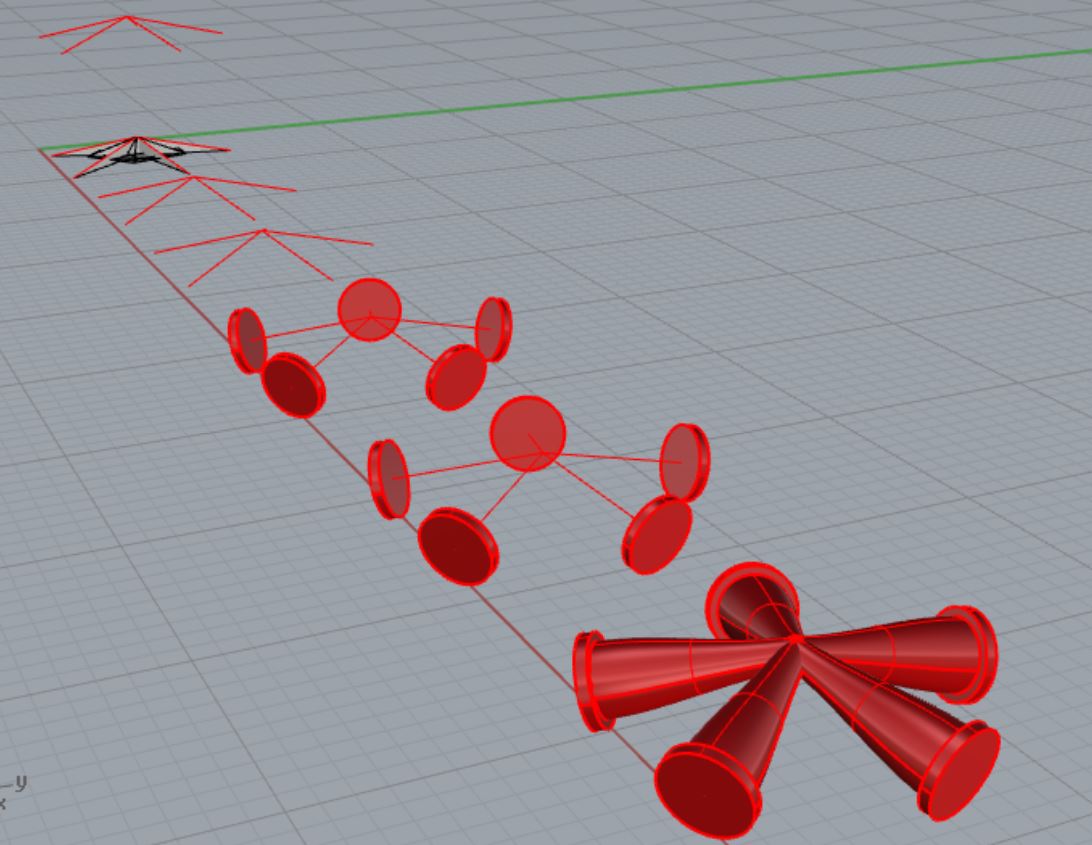

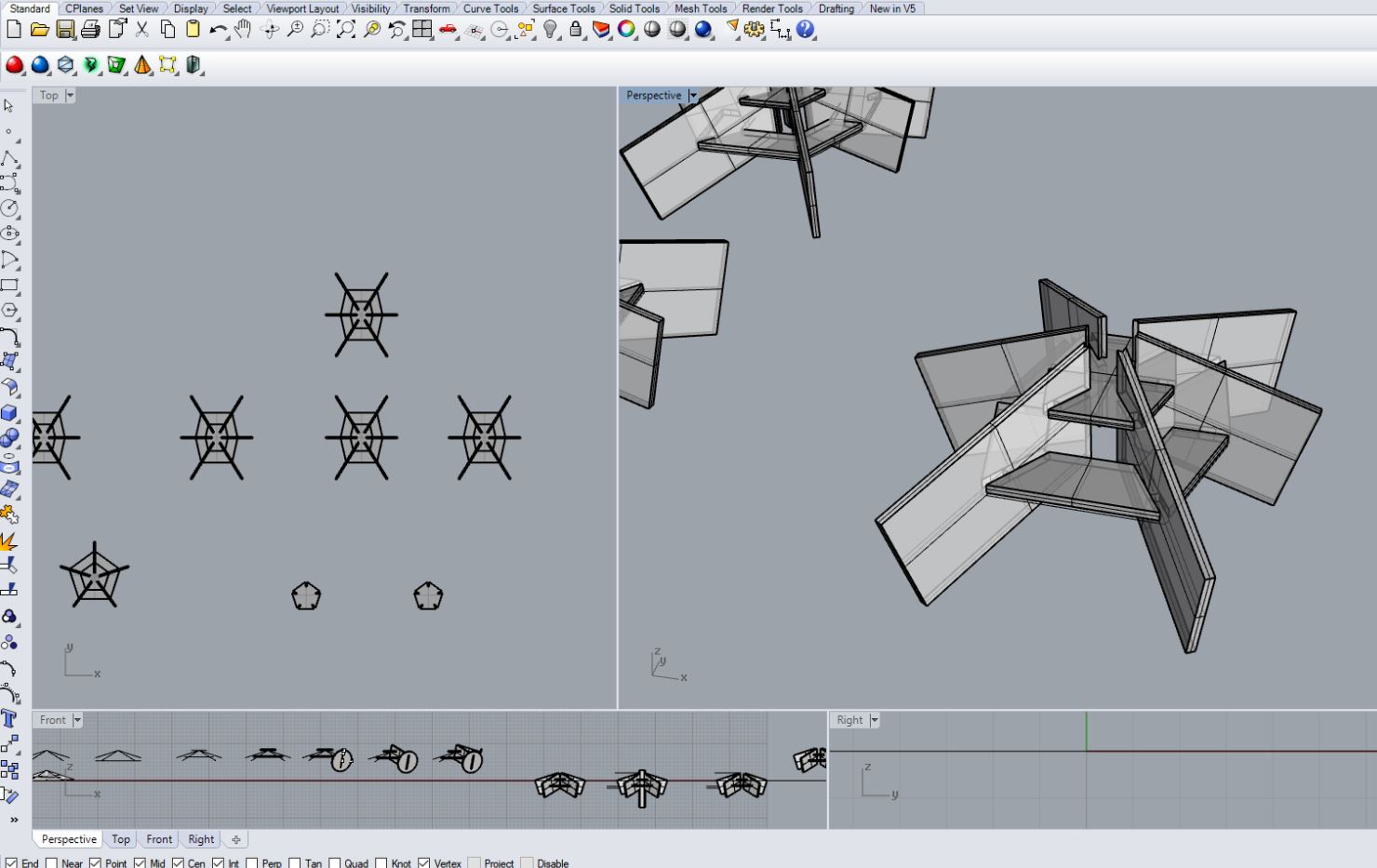

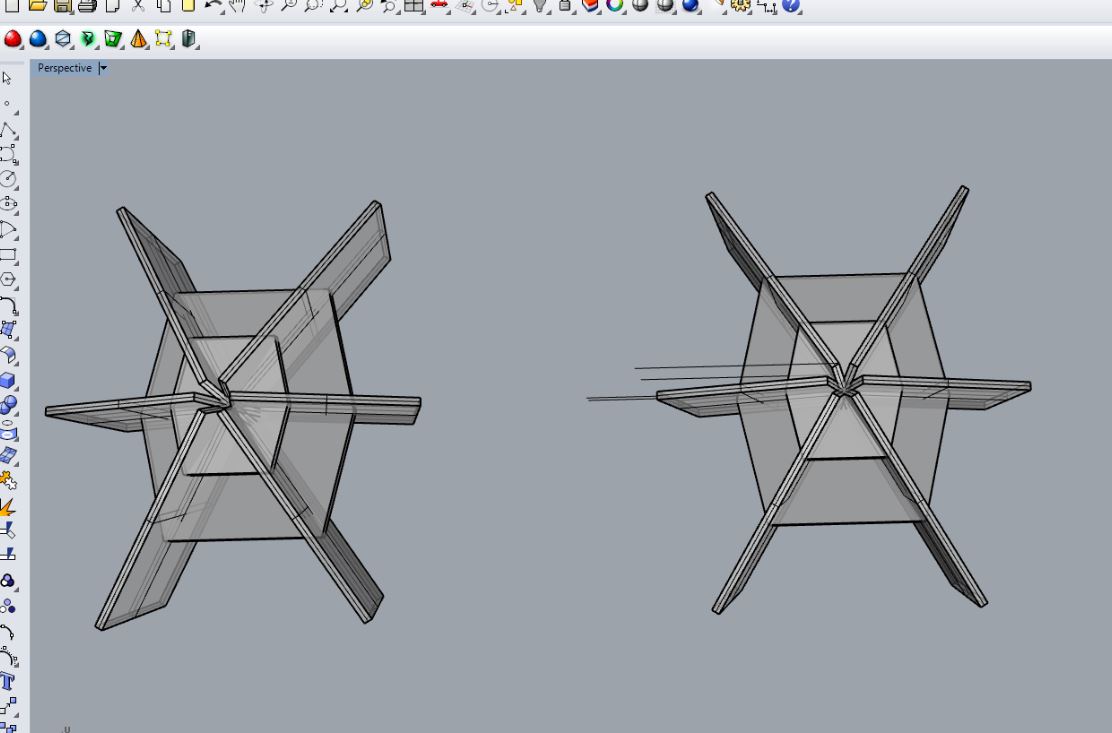

I realize that the model described above is not an actual modeling of the project. It did, however, help me to decide upon the shape. Now (having presented the final project) I can post the modeling I did for the joints of the shape above, and the process of creating them.

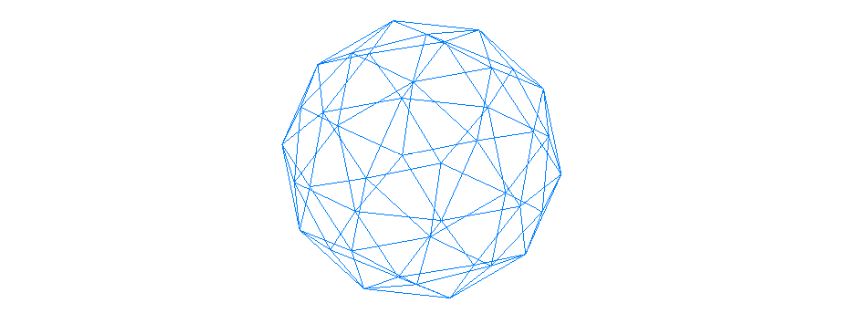

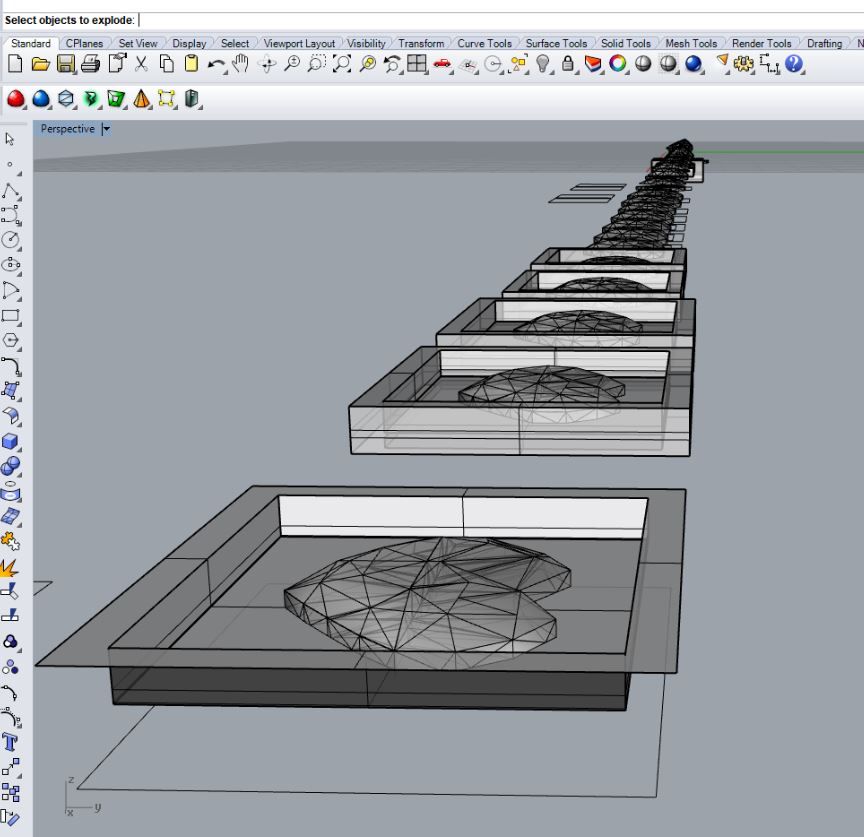

The modeling was done using rhino (which I now like more than sketchup) and using the vectors taken from the shape described above.

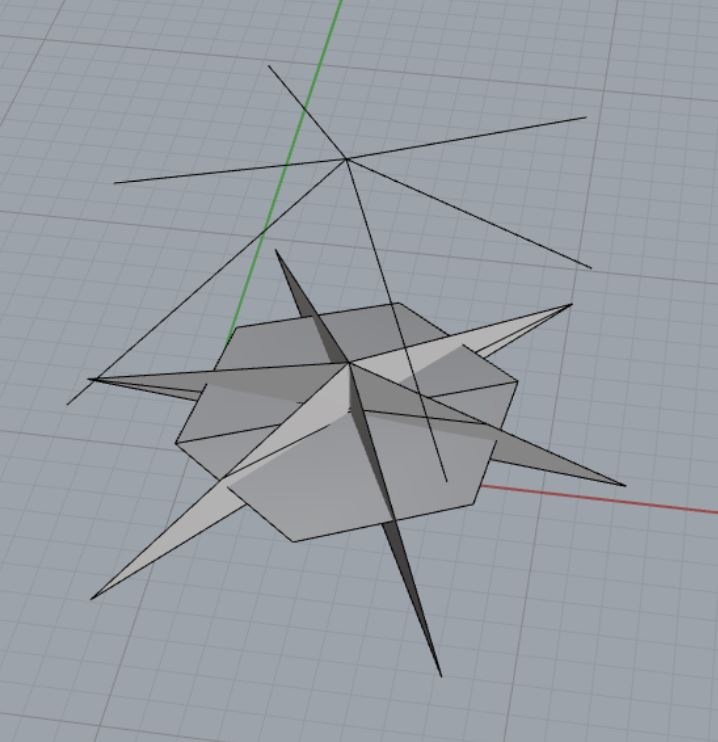

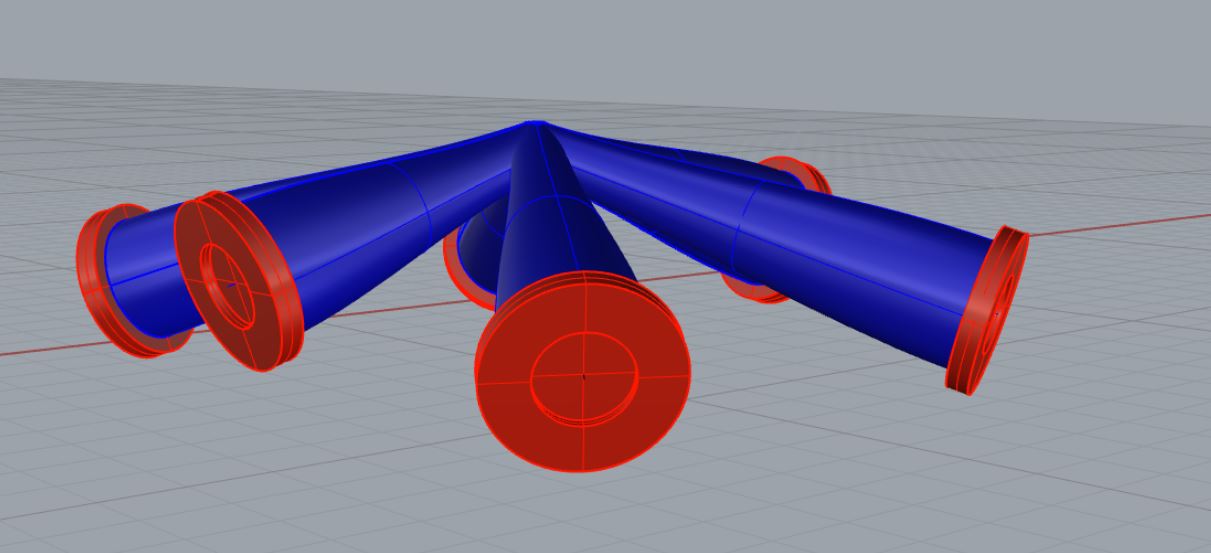

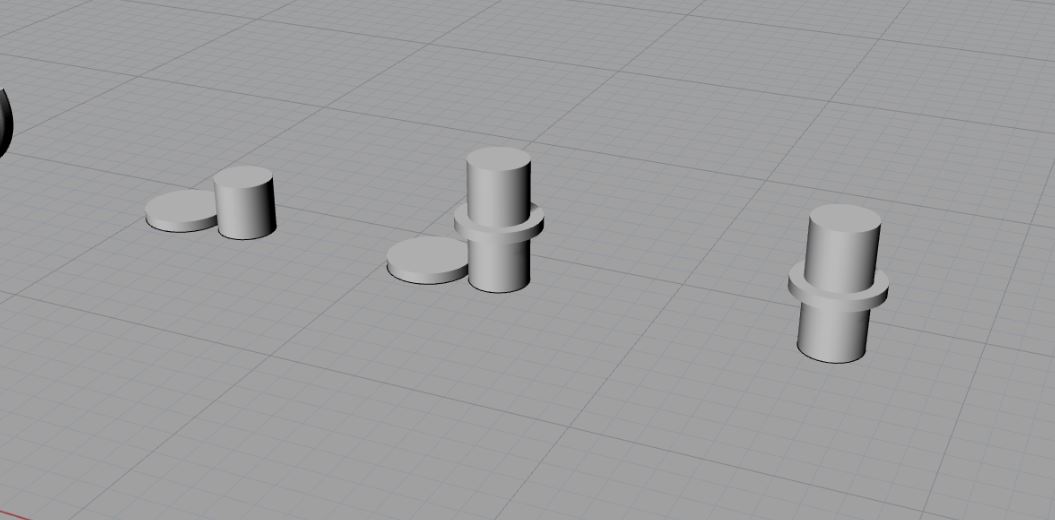

Here are some pictures of the process of modelling (which are also present in my final project development page), and at the end there is the picture of the 3 objects which I used to create the dome (the joints). The beams of the dome that connect these joints are recycled plastic bottles. The process of how I created the objects is also quoted, as it is present in my project development page.

When creating the file in rhino, first I imported just the 6 point vertex. I created the lines with the measurements that resulted from the analysis above, and proceeded using the pipe command to create the shape, keeping the same 4mm thick 3cm diameter circles through which the bottles will be joined.

Then I created the pipes that connect to the vertex. For this, they are 2.4mm in the end that joins with the circle that joins with the bottle, and the “top” part where they all meet is 1cm in diameter.

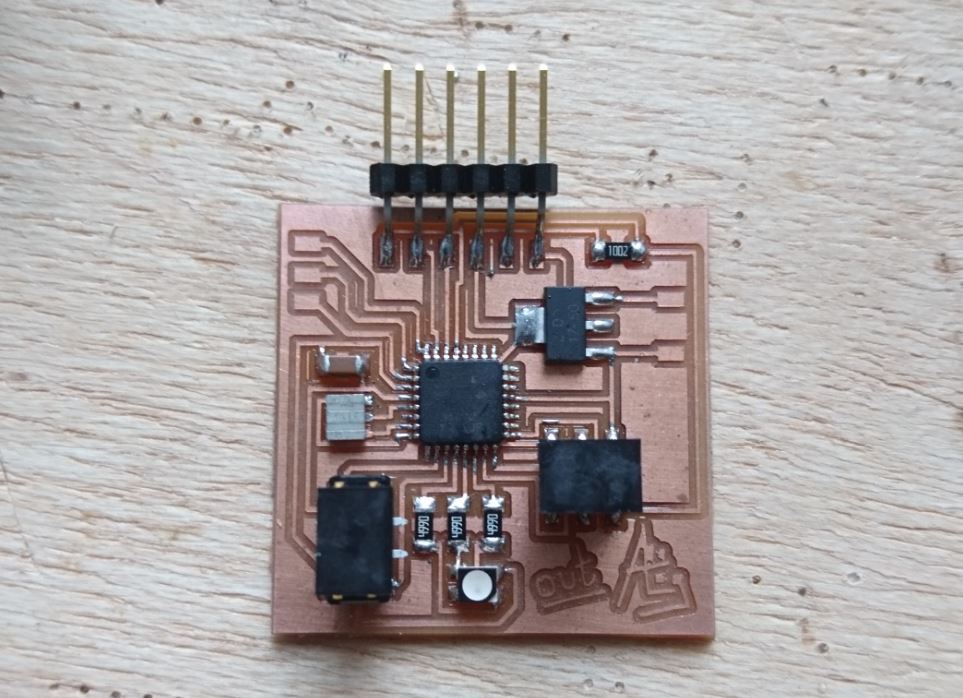

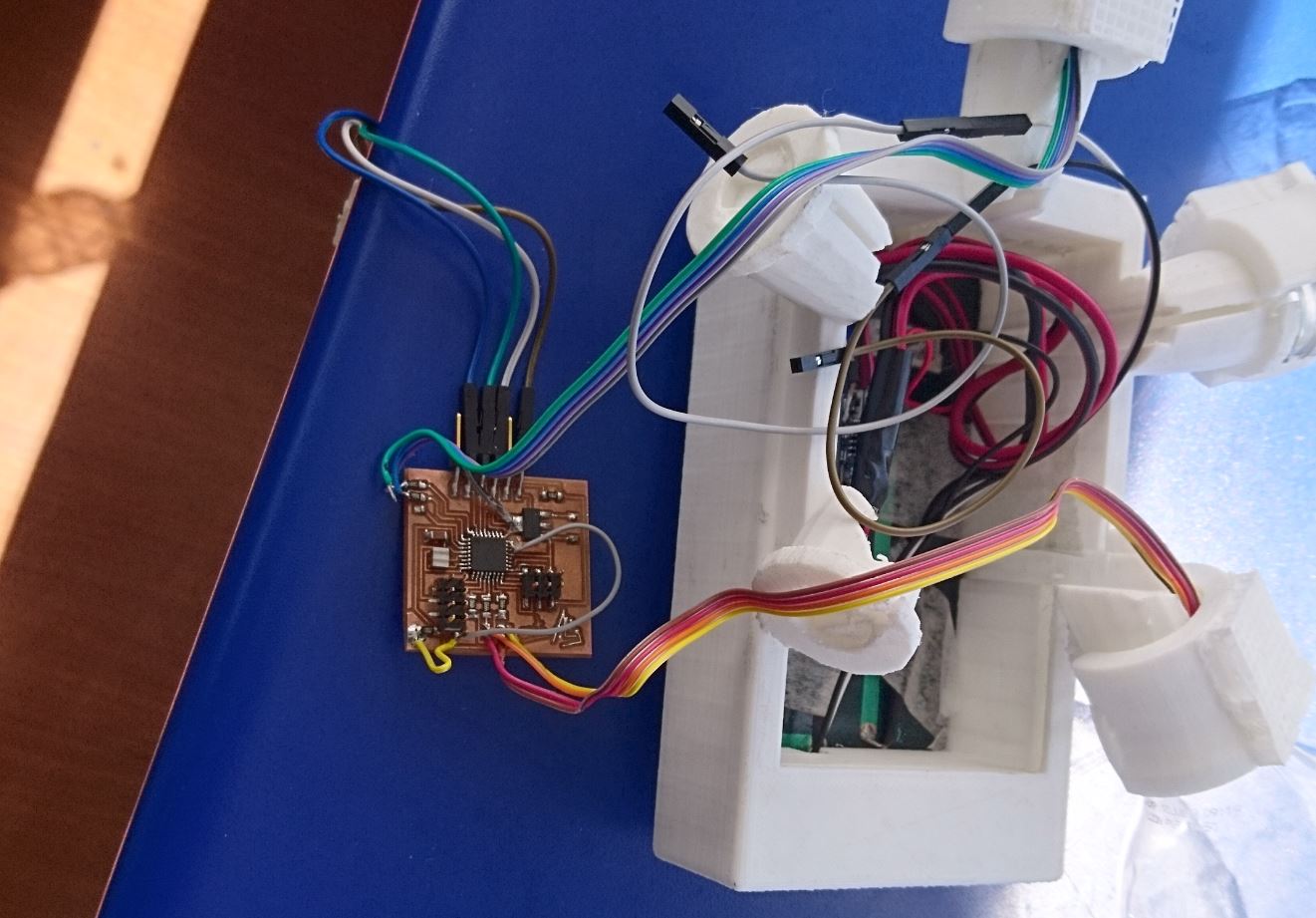

I cut out the volumes of the PCBs of the RGBs. They are 1.6mm thick, so I will cut a 1.7mm thick hole in the joint part, so the light goes right in the middle of the bottle. I used the command BooleanDifference for that and it turned out nicely

For an in-depth description of how these shapes were created, visit Final Project Development.

Also, here are the files for the 3 final objects (the ones shown in the last picture) in stl format.

As most of the programs that I tried work for different things, it is hard to compare them. However, in the following table there is a general overview of my thoughts of each program, with four main criteria that I believe to be important:

I omitted a general score for the programs as that would imply that they are somehow competing, which isn’t the case as each program does something different.

This week was very good as it allowed us to try out many, many different programs without having the pressure of having to master them. I enjoyed trying out the different 3D modeling programs, especially the rendering aspect of blender. However, having a background in architecture and having used many CAD programs before, although I did like some of the new programs, I will continue using the ones I am more familiar with (AutoCAD, Sketchup, Photoshop, Illustrator) for most of the assignments as it will allow me to work faster.

February 6-12

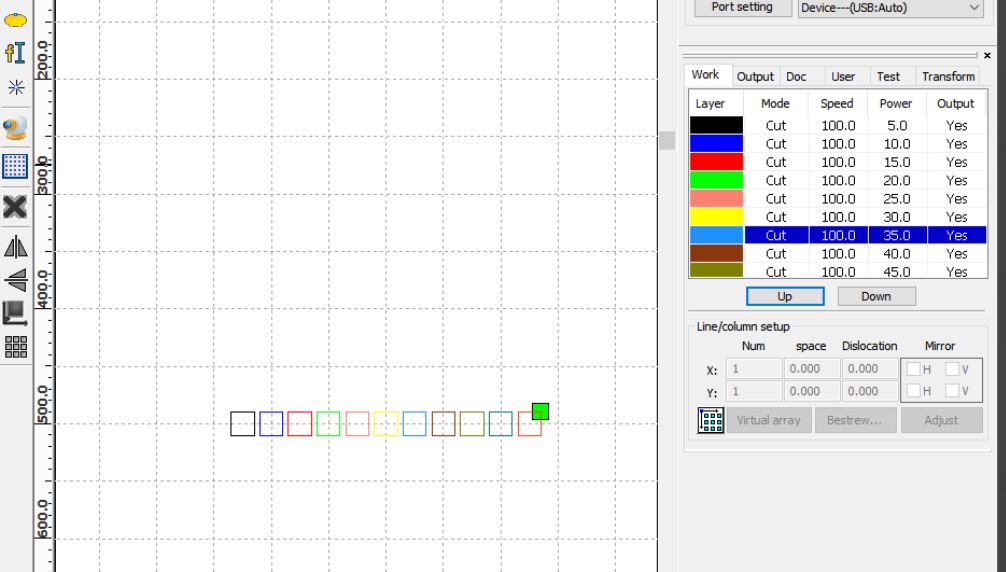

For this week, we are going to learn how to use the laser and vinyl cutter, with their corresponding softwares. We are also going to create a press fit kit through parametric modelling. I’ve had experience before with laser cutting and very basic parametric modelling, but not with vinyl cutting. With that in mind, we begin the assignment.

In Fablab ZOI, there are three students who are working in person in the fablab: Jorge, Danny and me.

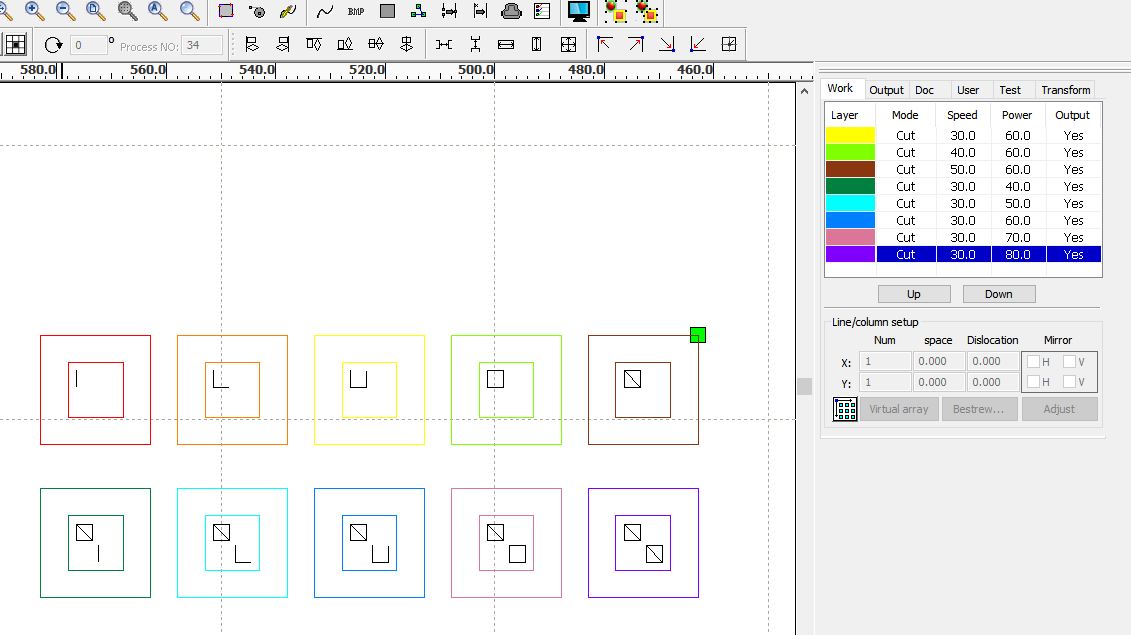

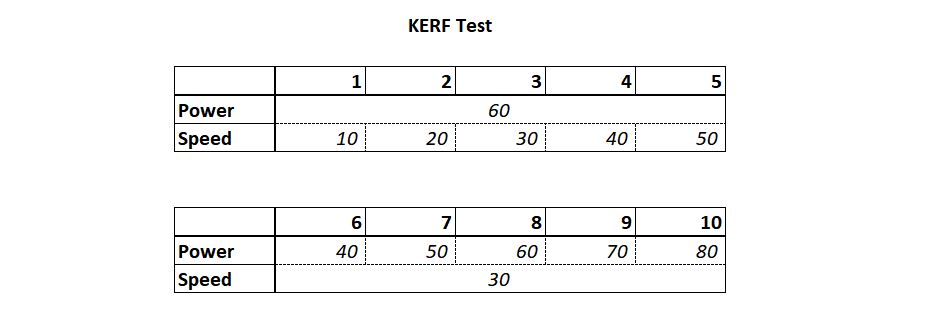

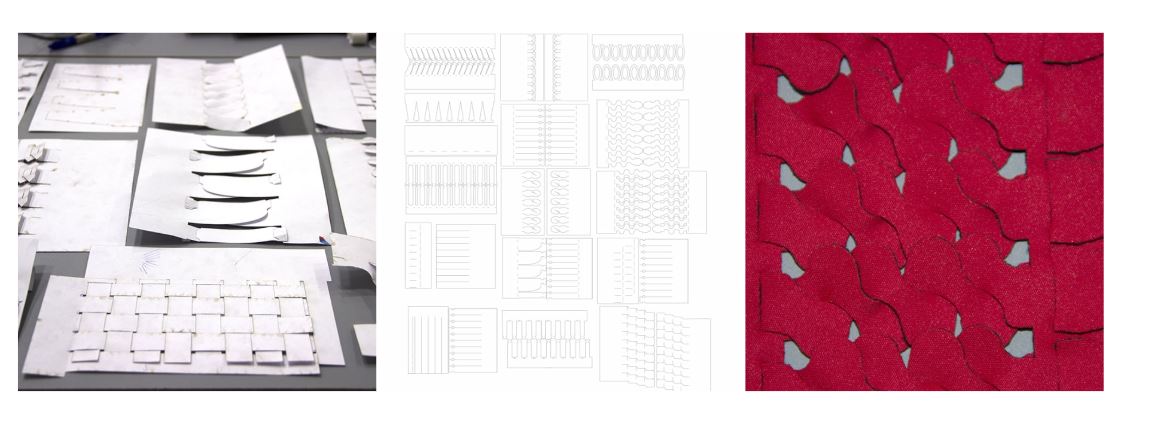

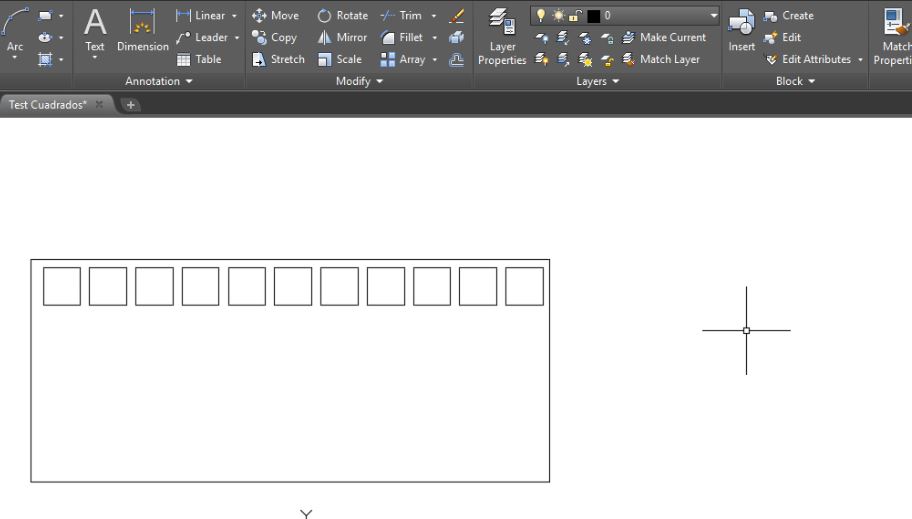

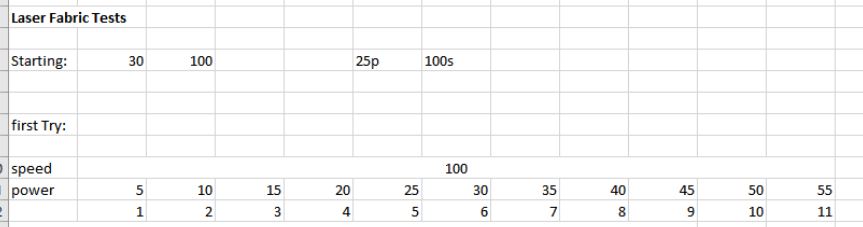

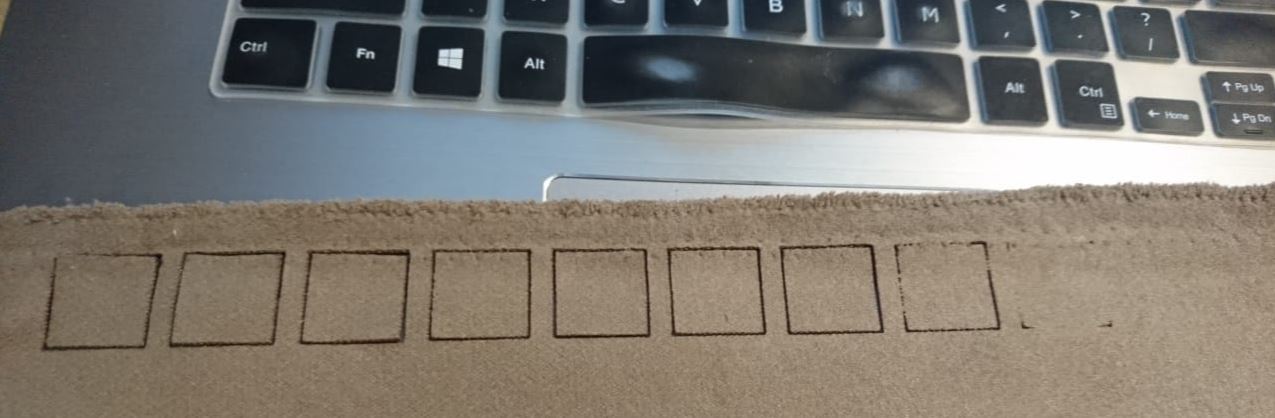

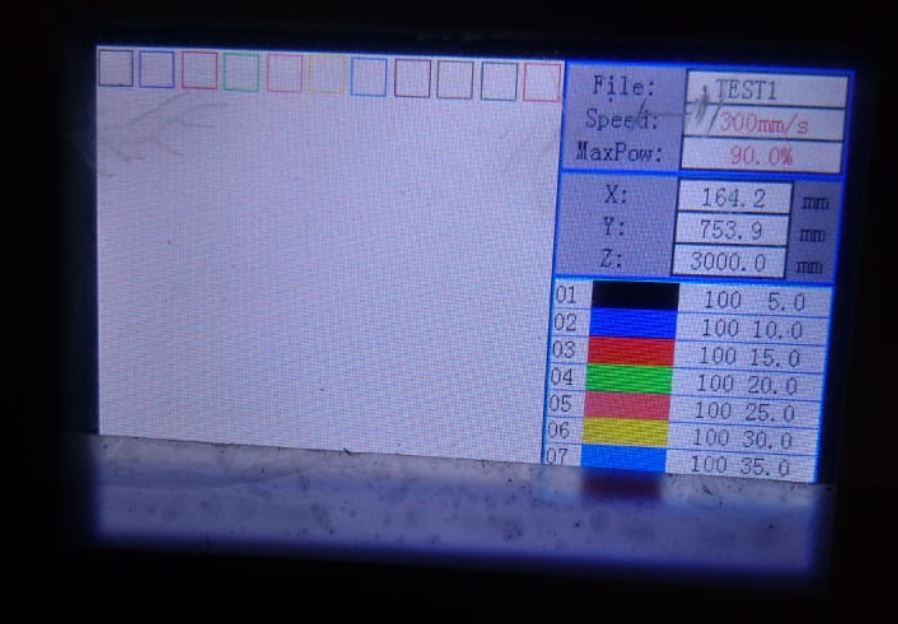

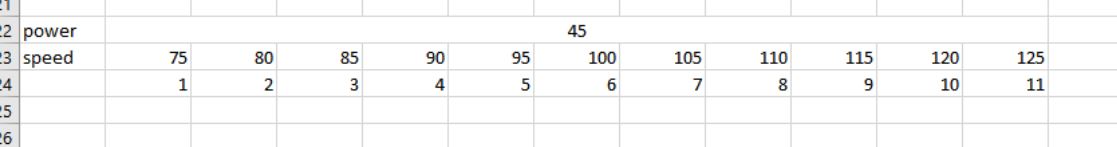

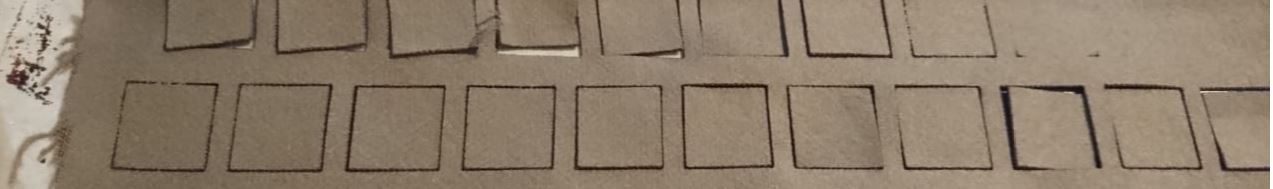

For this group assignment, we divided the laser cutter tasks between us, so I did the drawing and lasercutting of acrylic in order to find the KERF of the machine we use at the lab (Kerf being the “width” of the laser, so to speak). In order to do this, I made an array of squares with a square inside, and changed the settings in the program so each pair of squares would be cut with a different speed and power.

For the first row, the power remained constant while the speed changed in steps of 10. For the second row, the speed remained constant while the power changed, again in steps of 10. The center square is the one with the speed and power settings that our lab suggested (speed 30, power 60) for this material at this thickness.

While I was doing this, my lab mates were working on the parametric design of the “combs” which will vary thickness in order to establish the proper measure for creating joints.

After doing the tests, we found the best power and speed for cutting acrylic 2mm thick. From the test we also found the kerf for the parameters which best cut the acrylic without burning it.

In the computer, I had designed squares that were 2cm wide with a 1cm square right in the center of them. Therefore, the edge of the resulting square should be 0.5cm wide and the inner square should be 1cm. however, while measuring it, we noticed that the inner square was not 1cm, but .98cm, which indicated that the laser had cut 0.01 cm more on each side, resulting in the laser kerf (or the thickness of the laser so to speak) being 0.02cm wide.

This also correlated with the findings of my friends with the comb. They had done various widths for the holes of the comb, around 1.9mm, 2mm, 2.1mm, 2.2mm and so on. *

Also, before this we had done some experiments with the laser cutter, cutting and engraving textures, as well as understanding how the laser works and the order that had to be followed to turn it on and off, as well as the different parts of the machine. There I did a few tests on different materials with some designs.

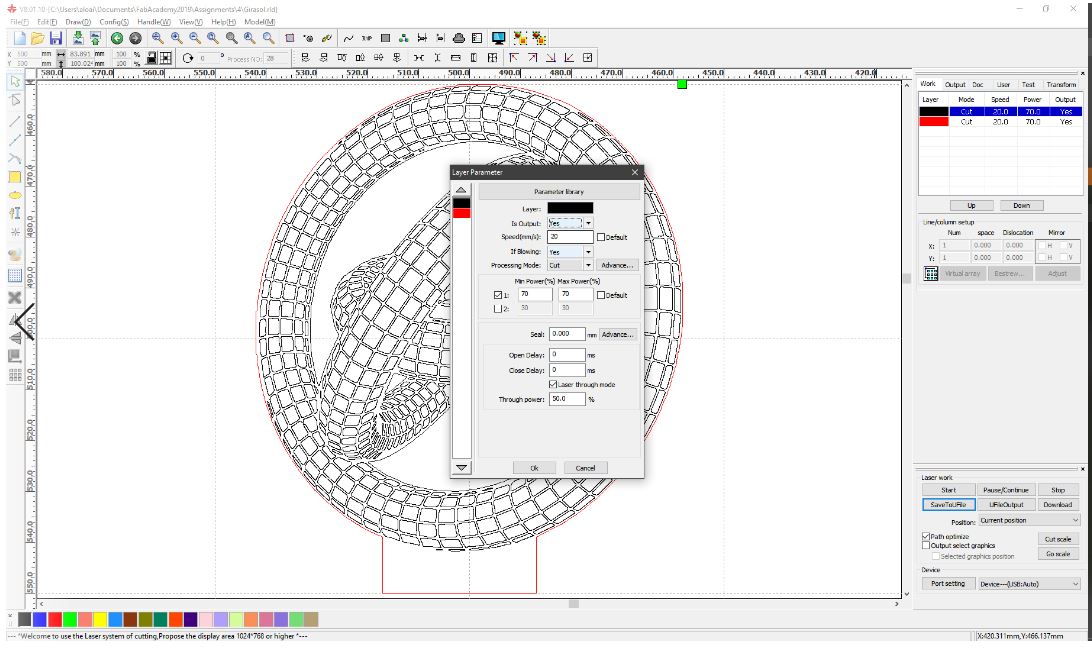

For these designs the software that I used was Illustrator to create the design (or in the case of the 3d ring design, to make a mask of an image), then exported it in dxf to cad, fixed the size and some of the lines, and then passed it to RDWorks software to prepare it for the lasercutter, with different layers to cut, engrave, or scan.

The order in which the laser cutter is used:

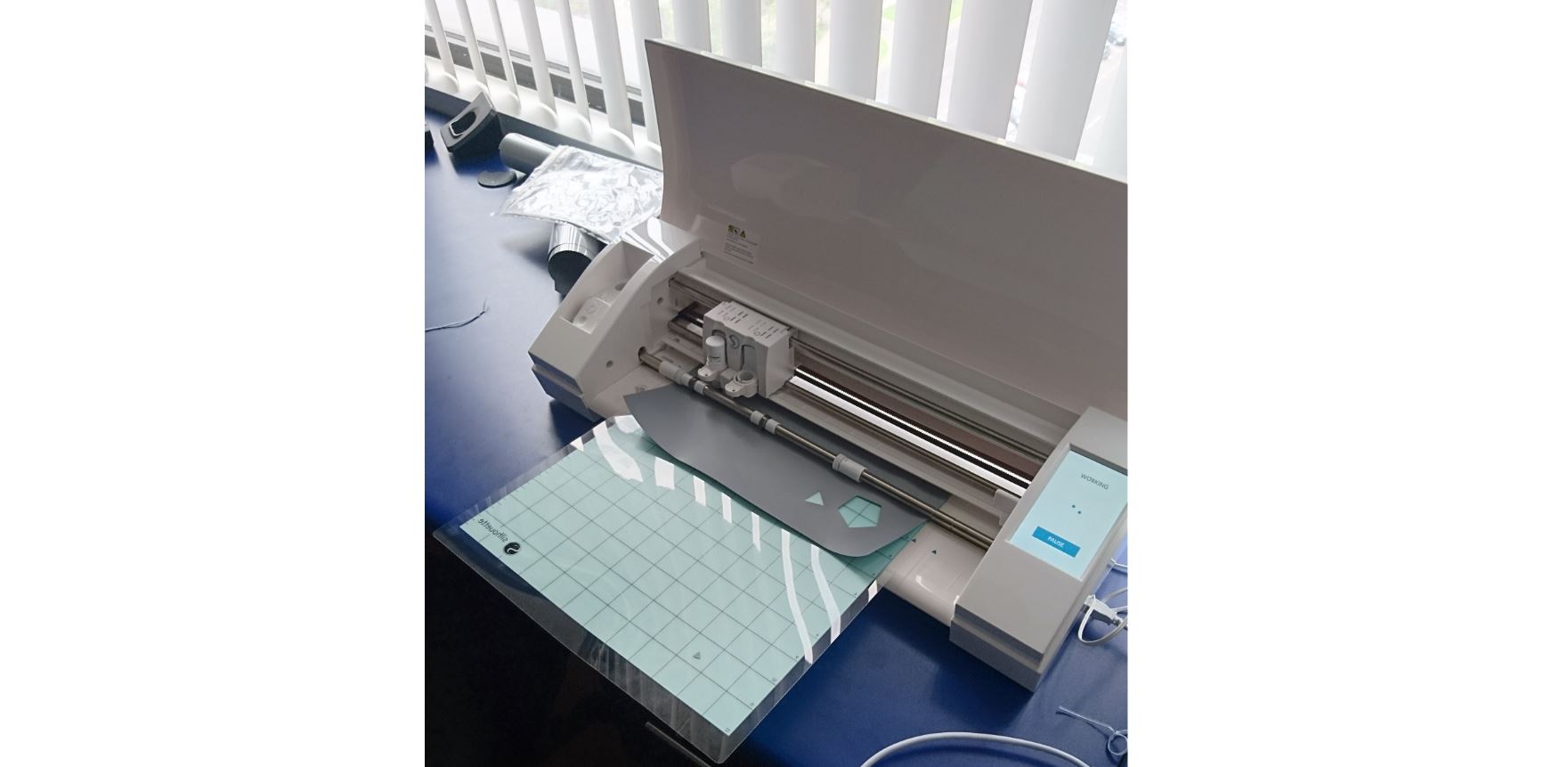

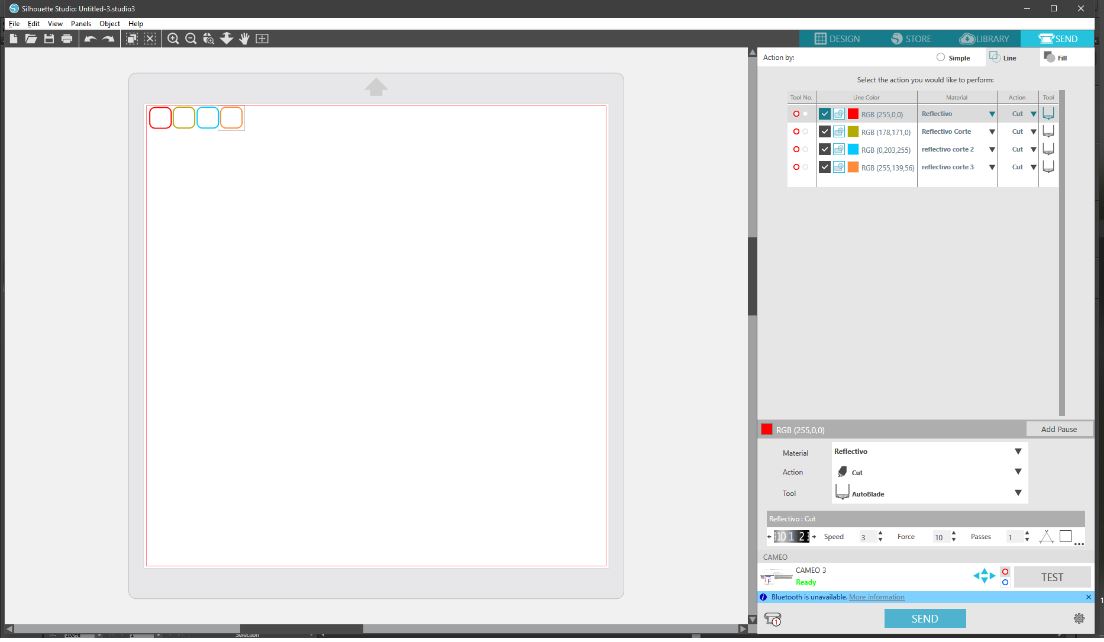

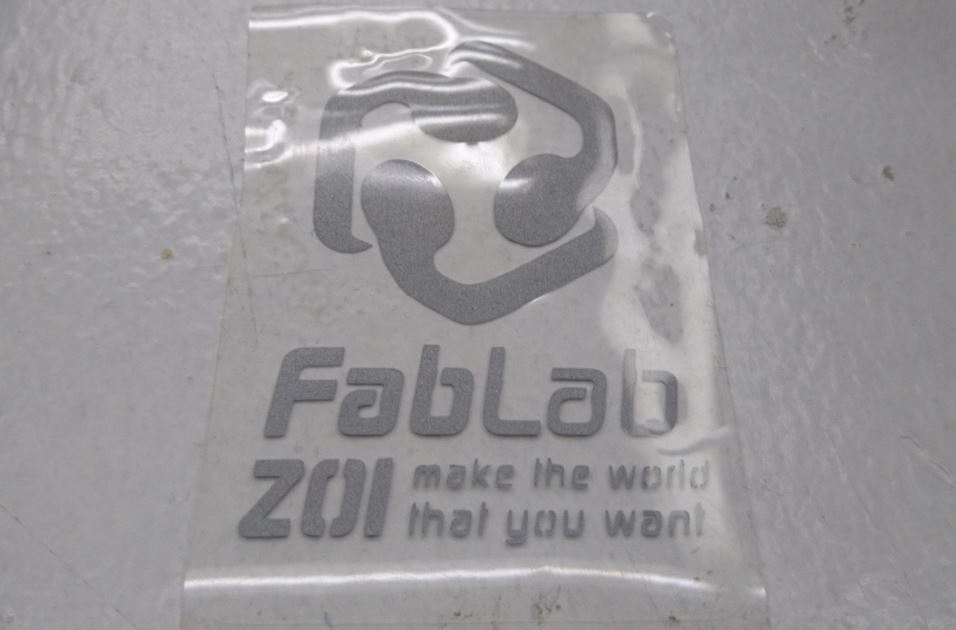

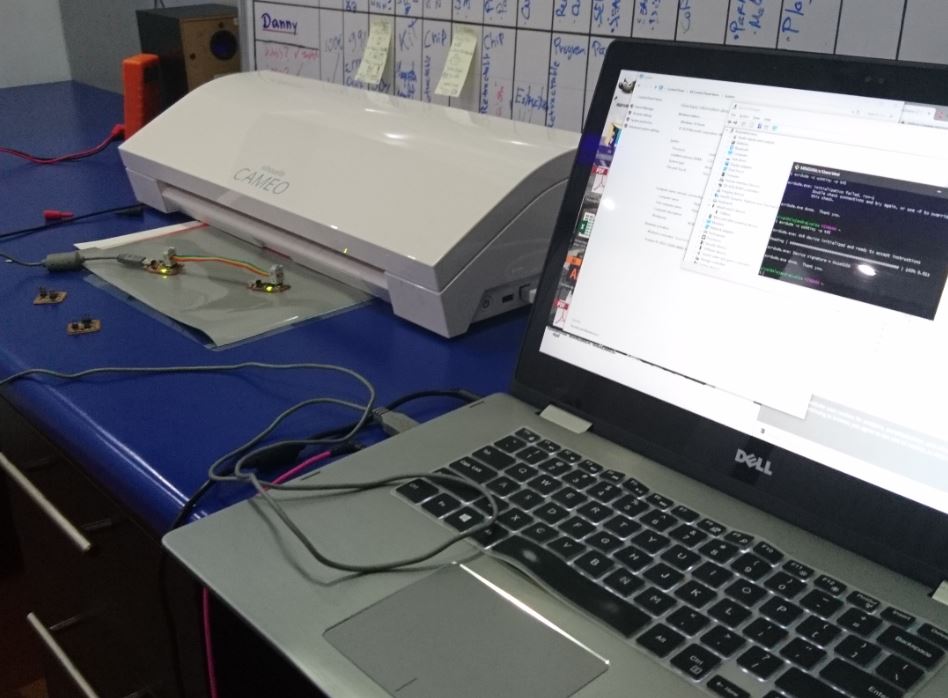

As part of the vinyl cutting assignment, my lab decided to work as a group. We would design stickers for t-shirts, so that we could all have our own fab academy shirts. We decided to keep a few things from the design constant, while varying others. We wanted to create two different vinyl cutouts which we would stamp to a t-shirt, one would be a FabAcademy 2019 cutout and the other would be the FabLab ZOI logo. I vectorized these two cutouts in illustrator taking an image and tracing it with the mask option. Then I exported the resulting vectors into silhouette studio software, as it is the program for the vinyl cutter we have available in the lab, the CAMEO.

After doing a few tests with the strength, passes, and speed, we arrived at the correct parameters for the material we were using.

After that, I sent a test with the FabLab ZOI logo, and it worked very well. I will soon iron it on a surface to verify the usefulness of the material when trying to transfer it to a t-shirt. Click on the button to download the files in dxf and studio3 format.

The process for cutting something on the vinyl cutter is:

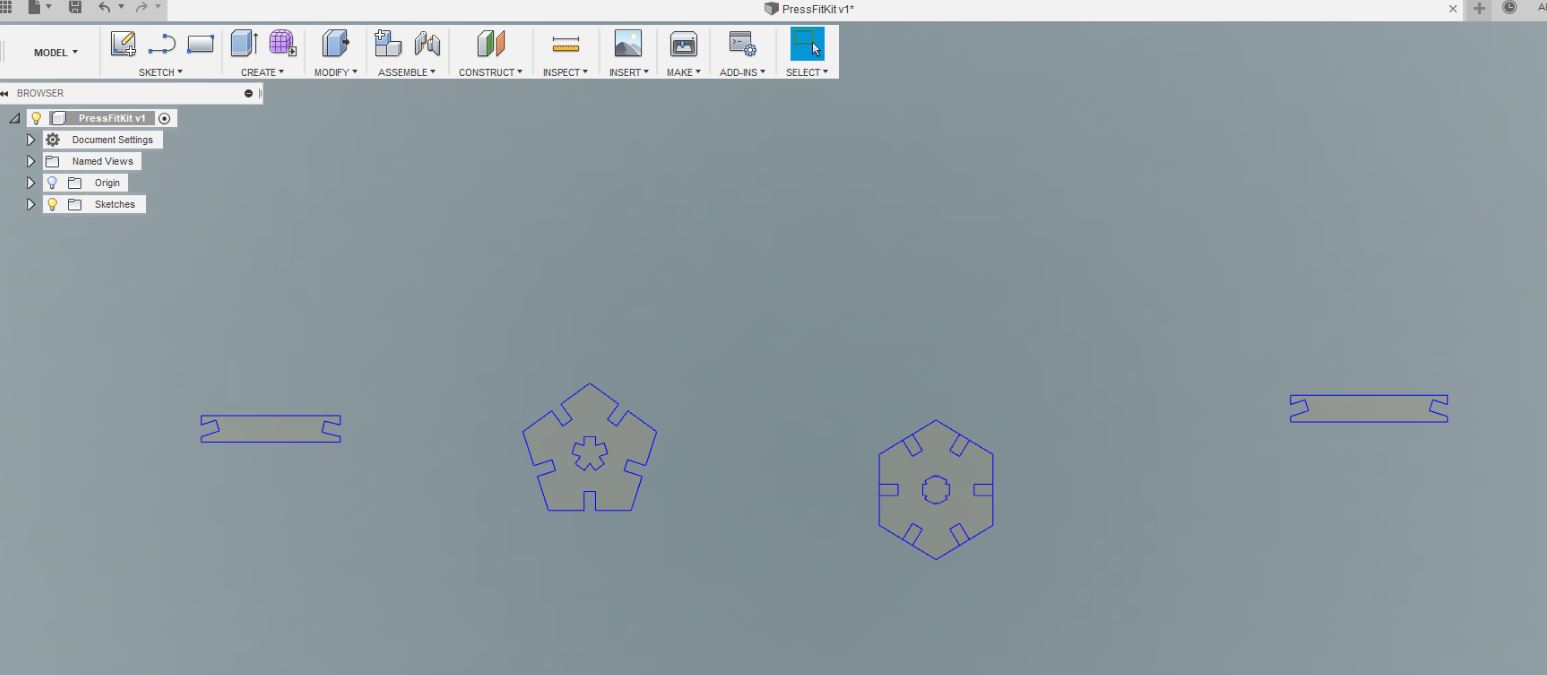

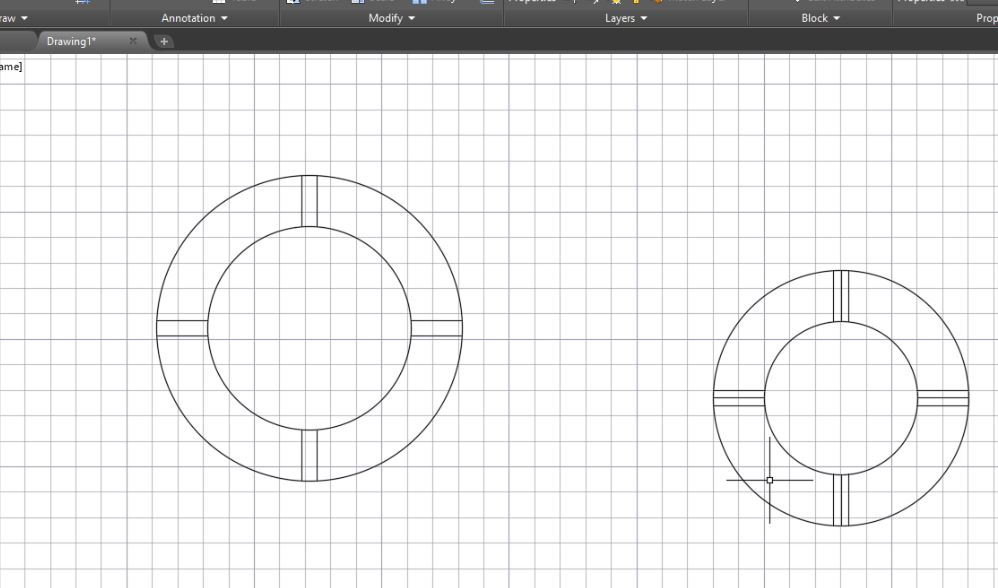

So, I’ve been postponing doing this kit, mainly because it is mandatory to do it using parametric software (which AutoCAD, my choice of software, isn’t), and also FreeCad scared me a little the last time I tried it. Also, I wanted to create a dome-like figure so that it would also help me get started on my final project, but when I saw the Geodesic Icosahedron figures in rhino (see week 3) I did not know where to start.

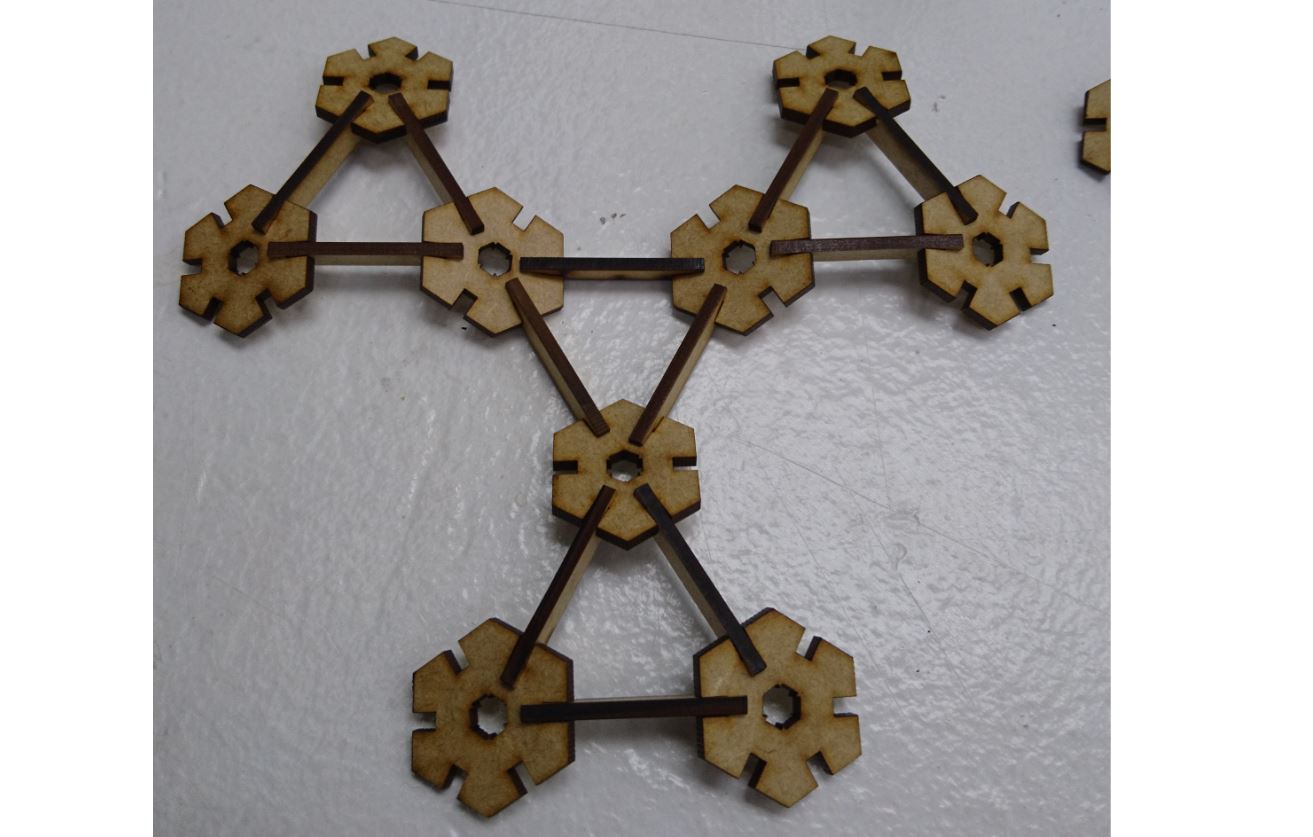

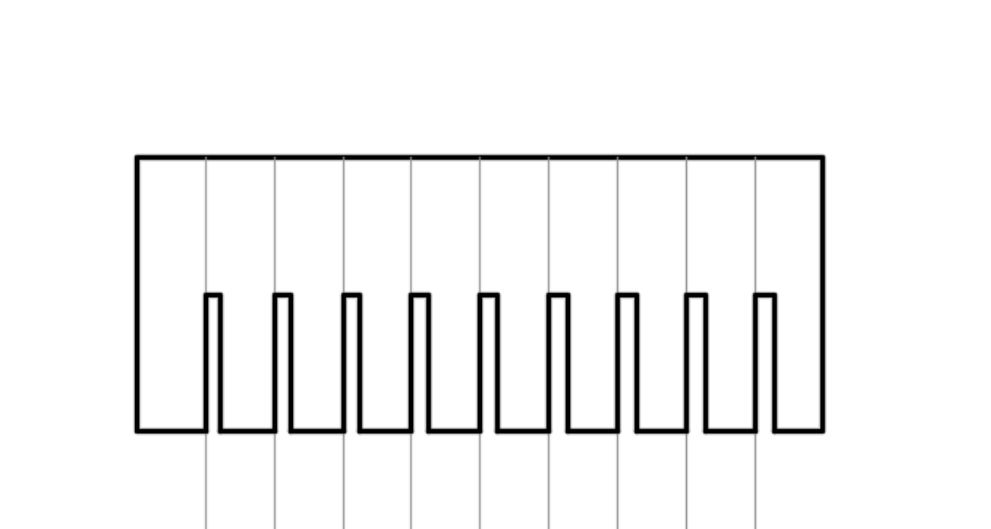

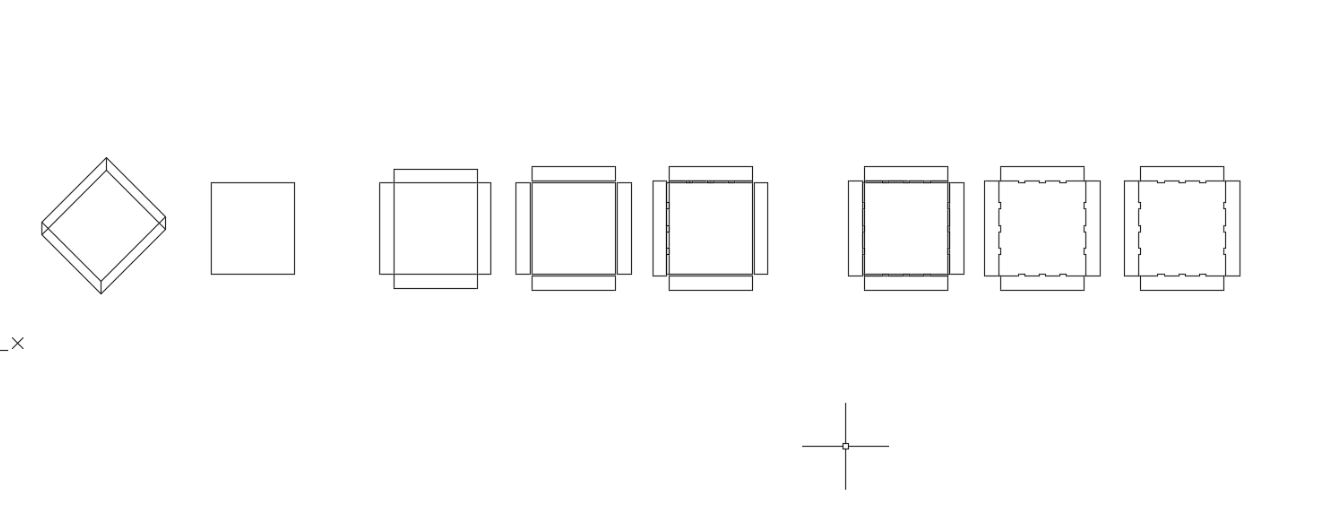

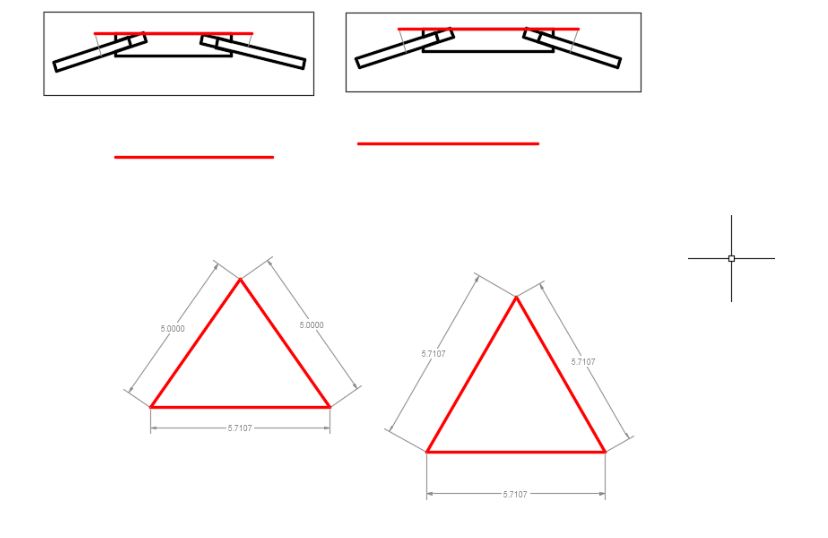

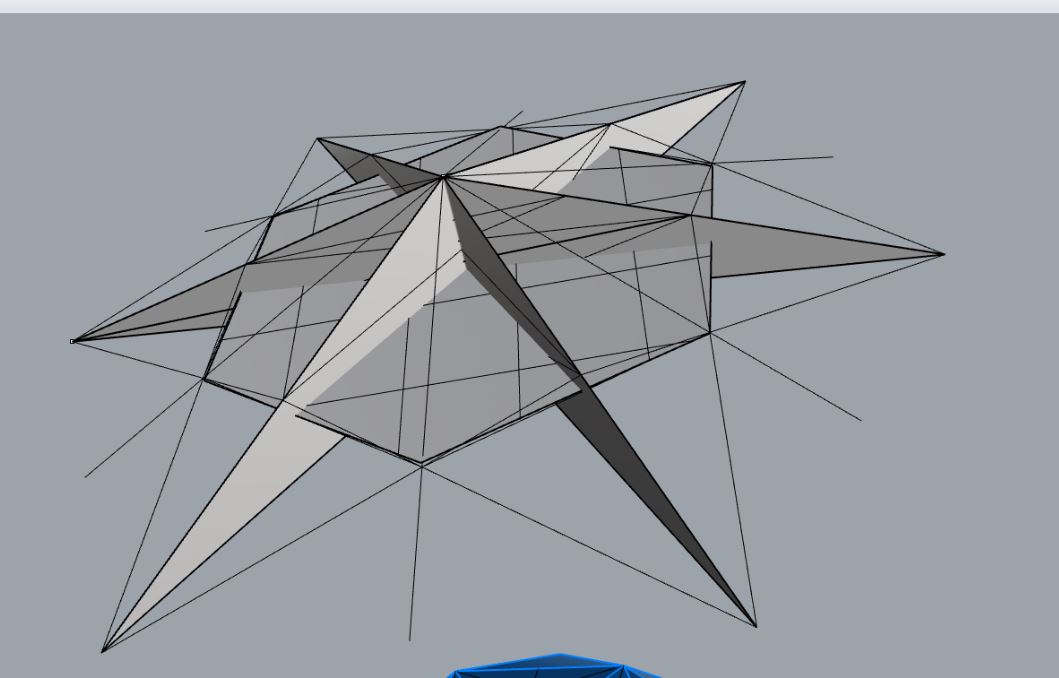

I used the figure I had seen last time in Rhino (using the Geodesic Icosahedron pattern 2) of which I had already analyzed the beams and vertices. I knew that to create the pieces I would have to analyze the angles and replicate them using 2D pieces.

It turned out to be a lot harder to check the angles than I had first expected. I searched for a command in Rhino that would let me check the angle between two faces, didn’t find one, and realized that even if I had it was not that angle that I was looking for. After some thought, I redrew the vertices with just the lines, and extended some of the lines so that I would be able to create a triangle, of which it was much easier to verify the angle.

After verifying the angles of the 5-joint vertex, I did the same thing with the 6-joint vertex. For the 5-joint vertex, the angle was 76.28253°, and for the 6 joint one the angle was 72°.

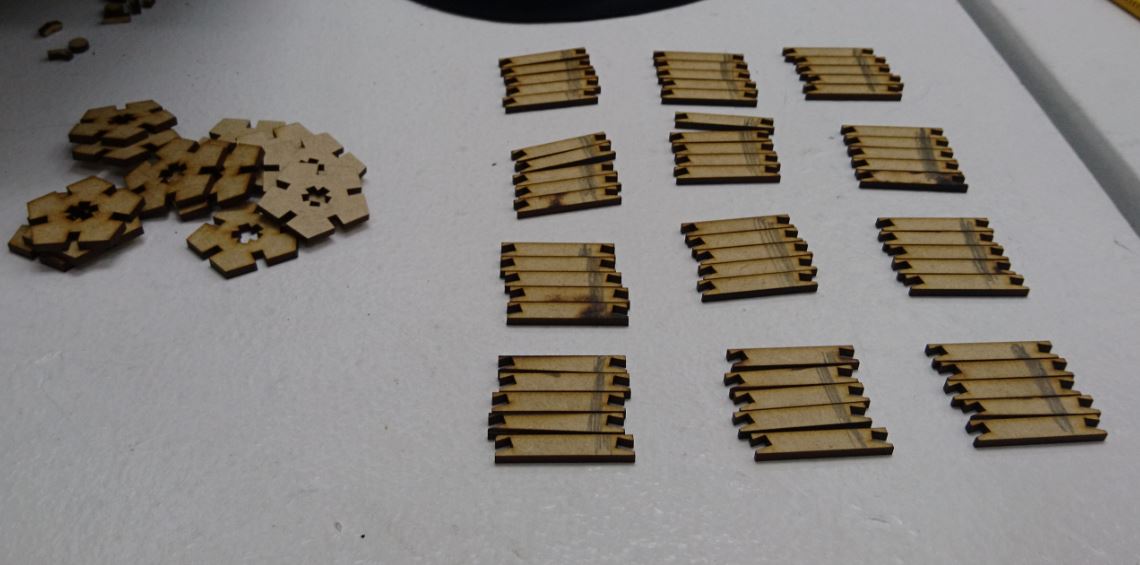

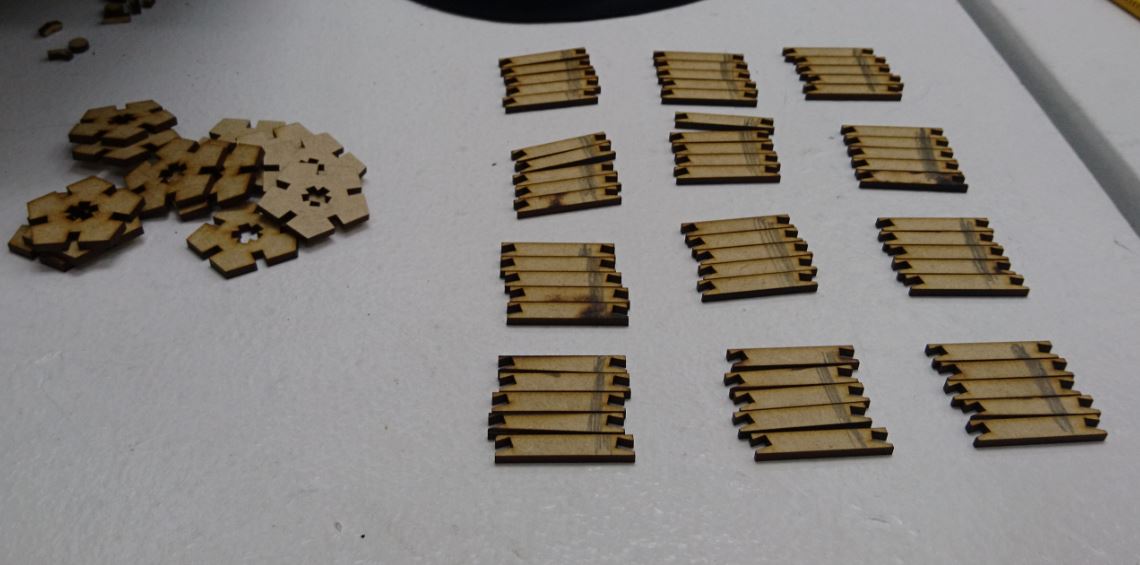

With this, I figured out the pieces needed to create the dome, and noticed that there were just 4 pieces:

With this in mind, I began drawing the shapes of the pieces to cut them.

The little experience with freecad that I had, I did not enjoy. I found it to be a complicated and confusing program, despite knowing all the benefits it could bring me. However, in my lab it is highly encouraged – if not mandatory- to use this software, therefore I realized I needed to give it another try. So, I started with a few short tutorials in youtube.

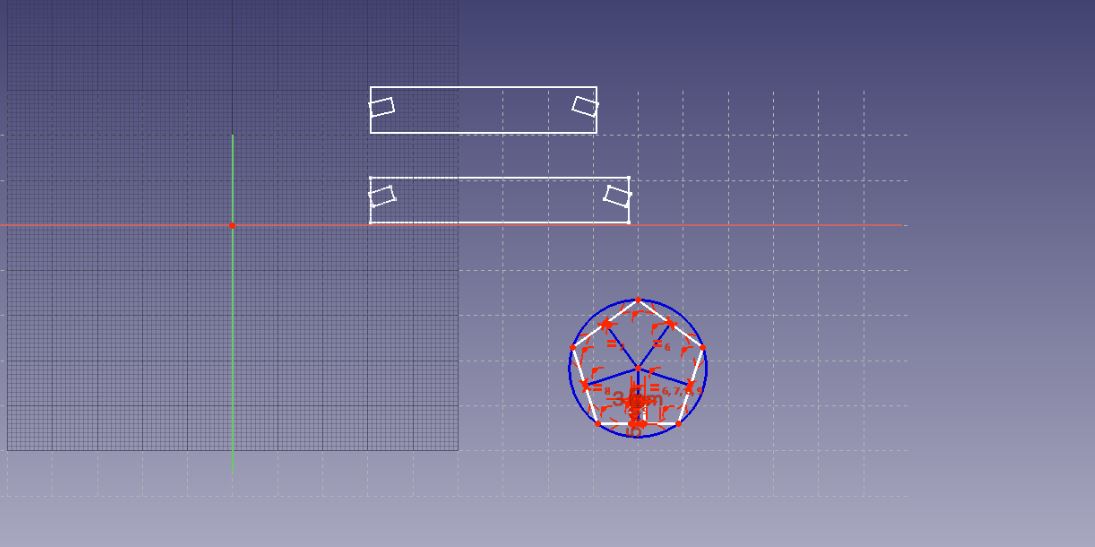

I began modelling the pieces in FreeCAD, with constraints and parameters. I managed to model and parametrize the beams without much trouble after a few attempts, however, the pentagon gave me many problems. Eventually, I decided to change software as I really didn’t understand how to use FreeCAD properly.

After my frustration with FreeCAD, I used AutoCAD to try and understand the shape better, as I noticed that the beam sizes that I was using did not account for the vertex (pentagon/hexagon) size. After doing some designs of the pieces in cad, I got the final shapes. However, seeing that AutoCAD is not a parametric program, I had to redraw the pieces (using the information acquired) in another software.

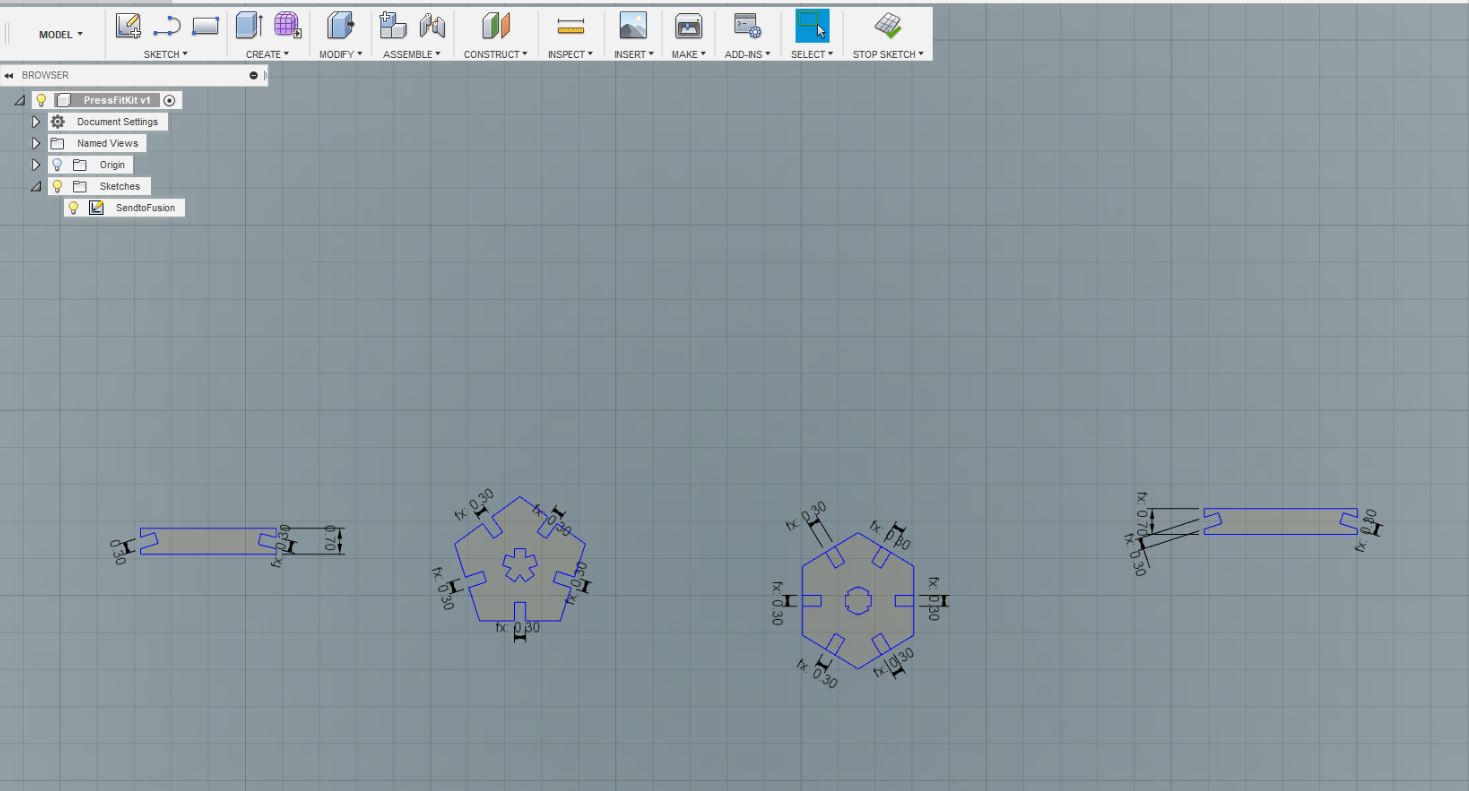

After not understanding FreeCad (I didn’t follow a proper tutorial), I didn’t want to make the same mistake with fusion 360. I followed a tutorial suggested by Roberto from this page and understood how to use parameters. Finally I was ready to create the pieces using parameters.

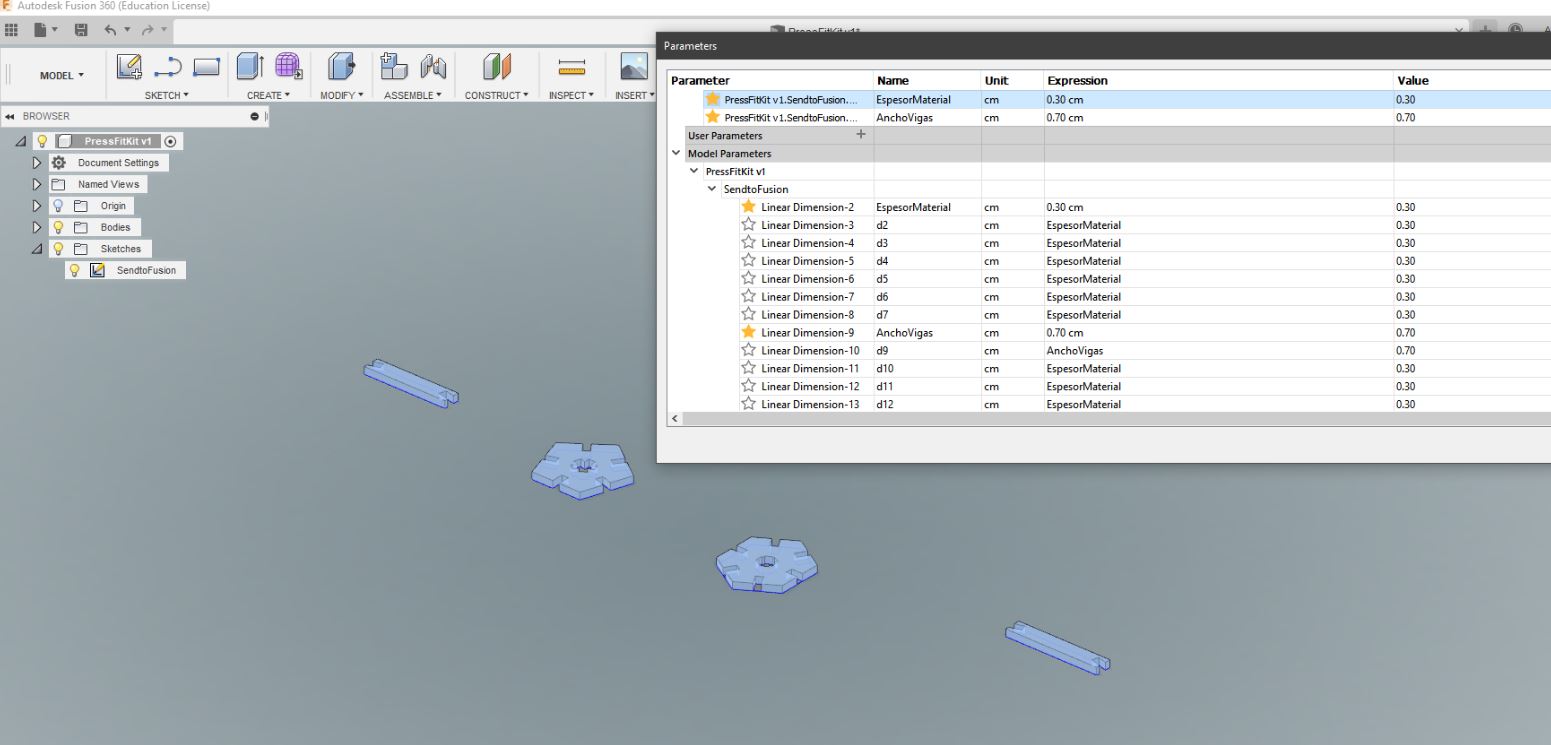

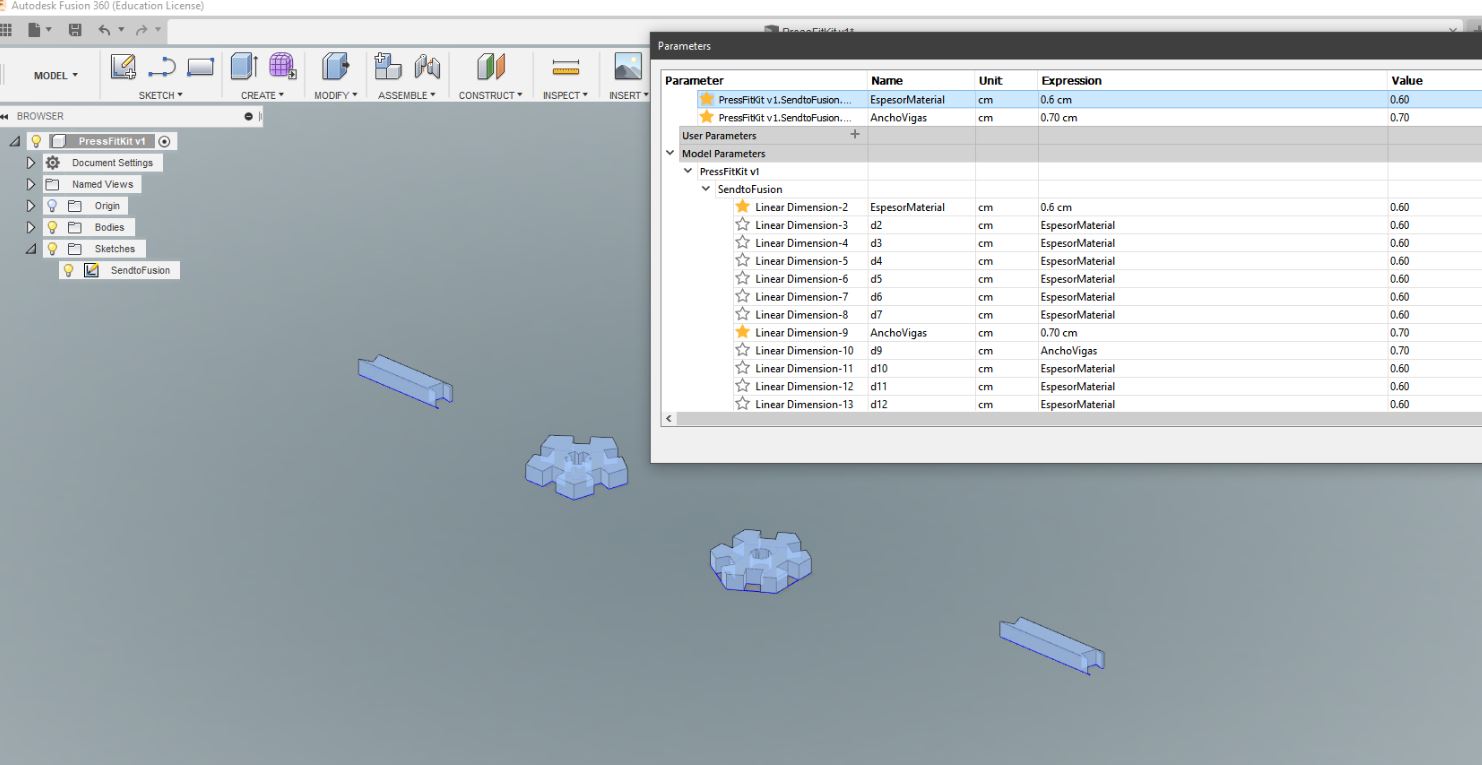

I inserted the pieces I had drawn in cad into fusion 360 and added dimensions and parameters into the sketch so that I could modify the material thickness without any problem. After a few tries I managed to do that, and I tested it by changing some of the parameters and seeing how the extrusion pieces were modified.

The process for parametric modelling is the following:

first draw the sketch (using general dimensions, these will be modified later); add the dimensions and create parameters

first draw the sketch (using general dimensions, these will be modified later);

add the dimensions (using the “distance” command) and create parameters out of these (go to manage>parameters);

name the parameters so that they can be used generally (example: material thickness);

extrude (also using the parameter material thickness).

After having the names of certain parameters configured, you no longer have to put a distance or a number when creating a line, you can just put the name of the parameter and this will be configured automatically.

The amazing thing about this is that when you want to change something (such as the thickness of the material), you just change the distance of the corresponding parameter and everything that is linked to that will change as well.

This is a very basic way to use parameters, which I used for my press fit kit.

The resulting files can be downloaded in:

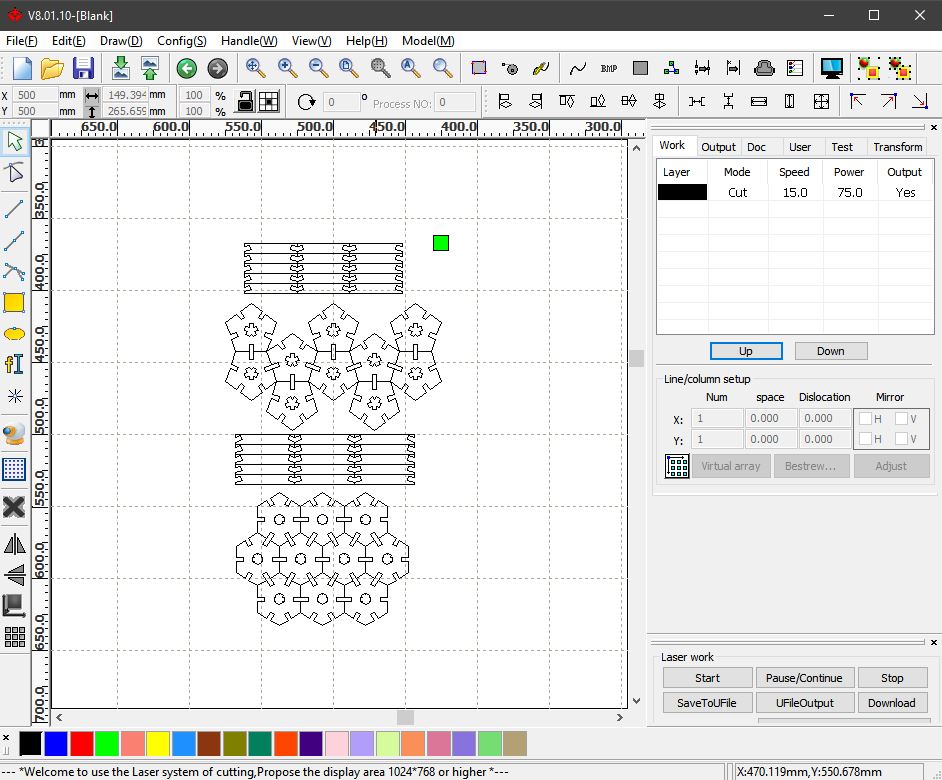

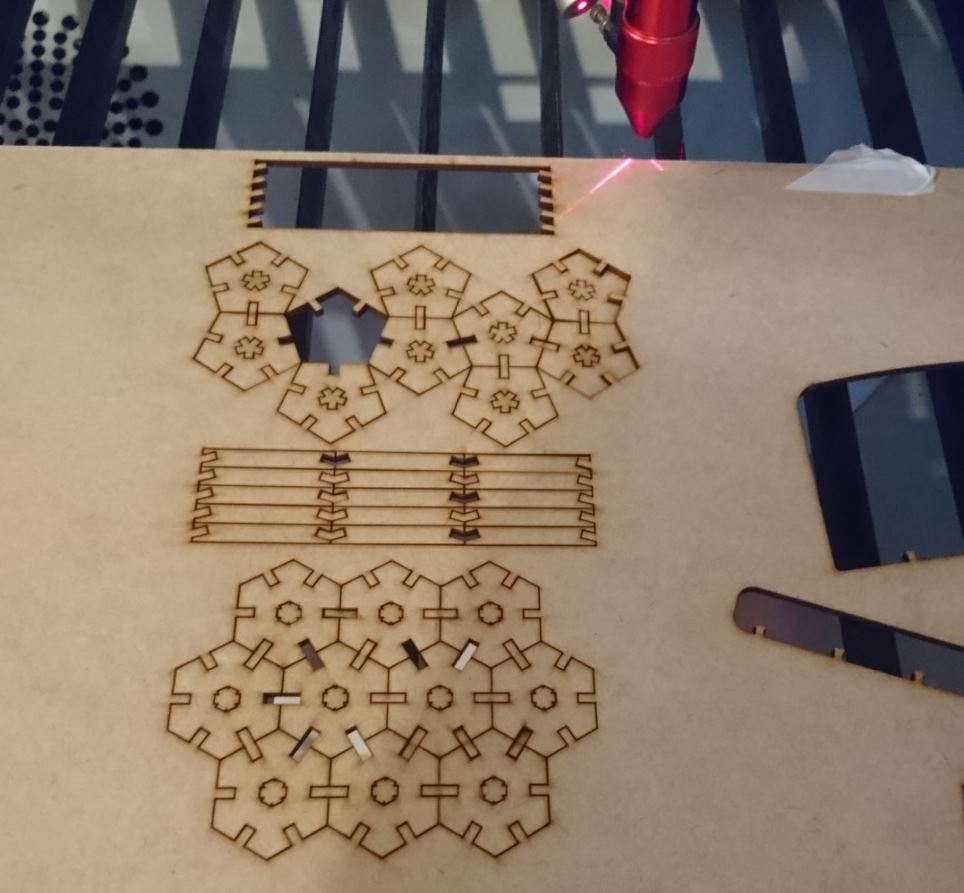

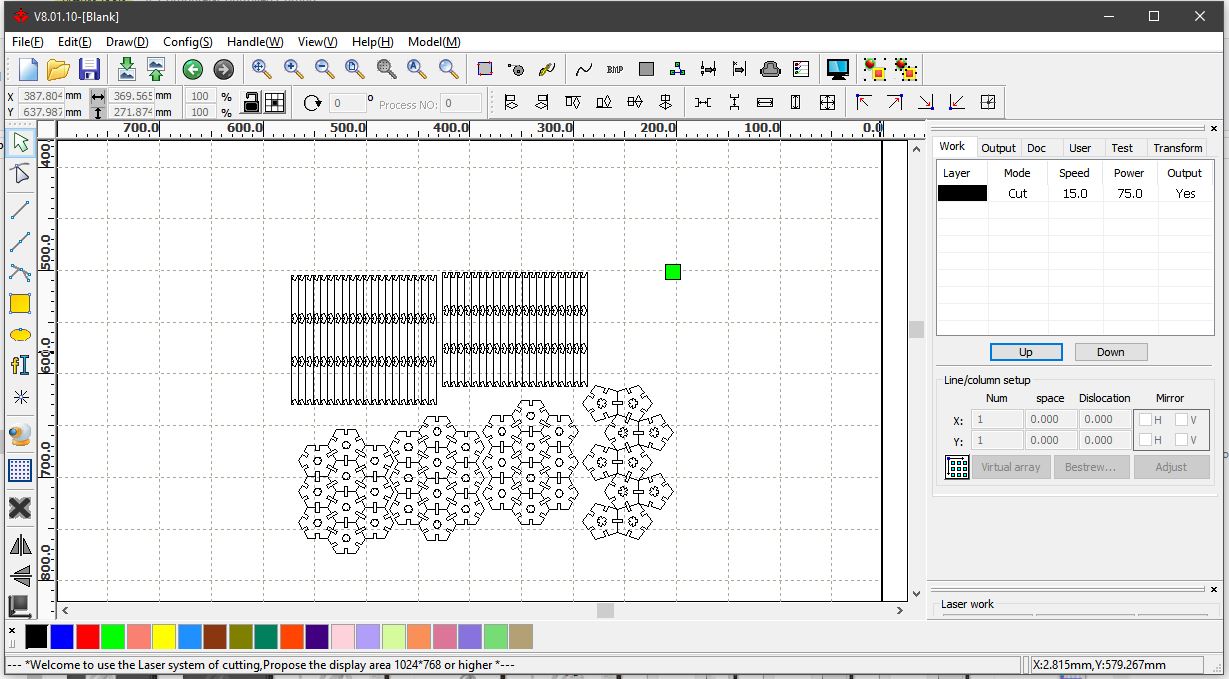

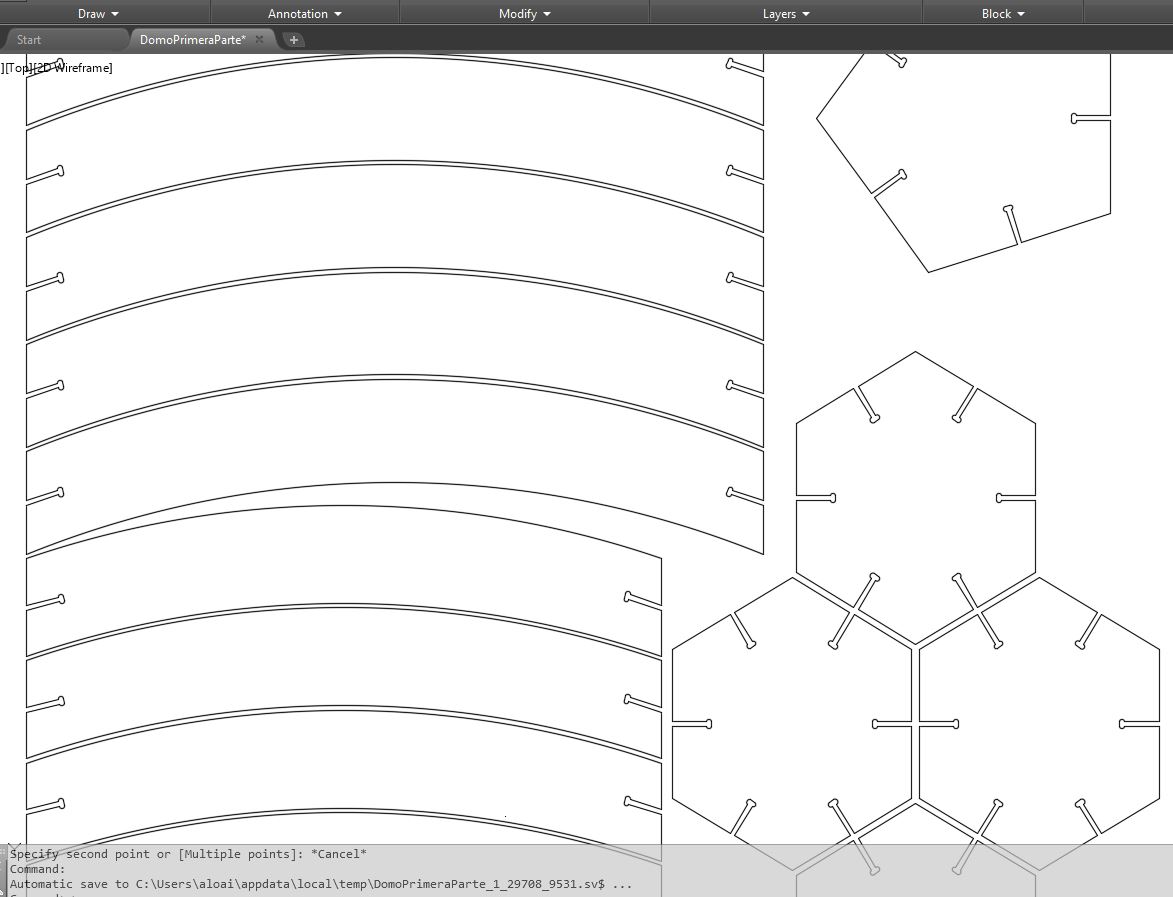

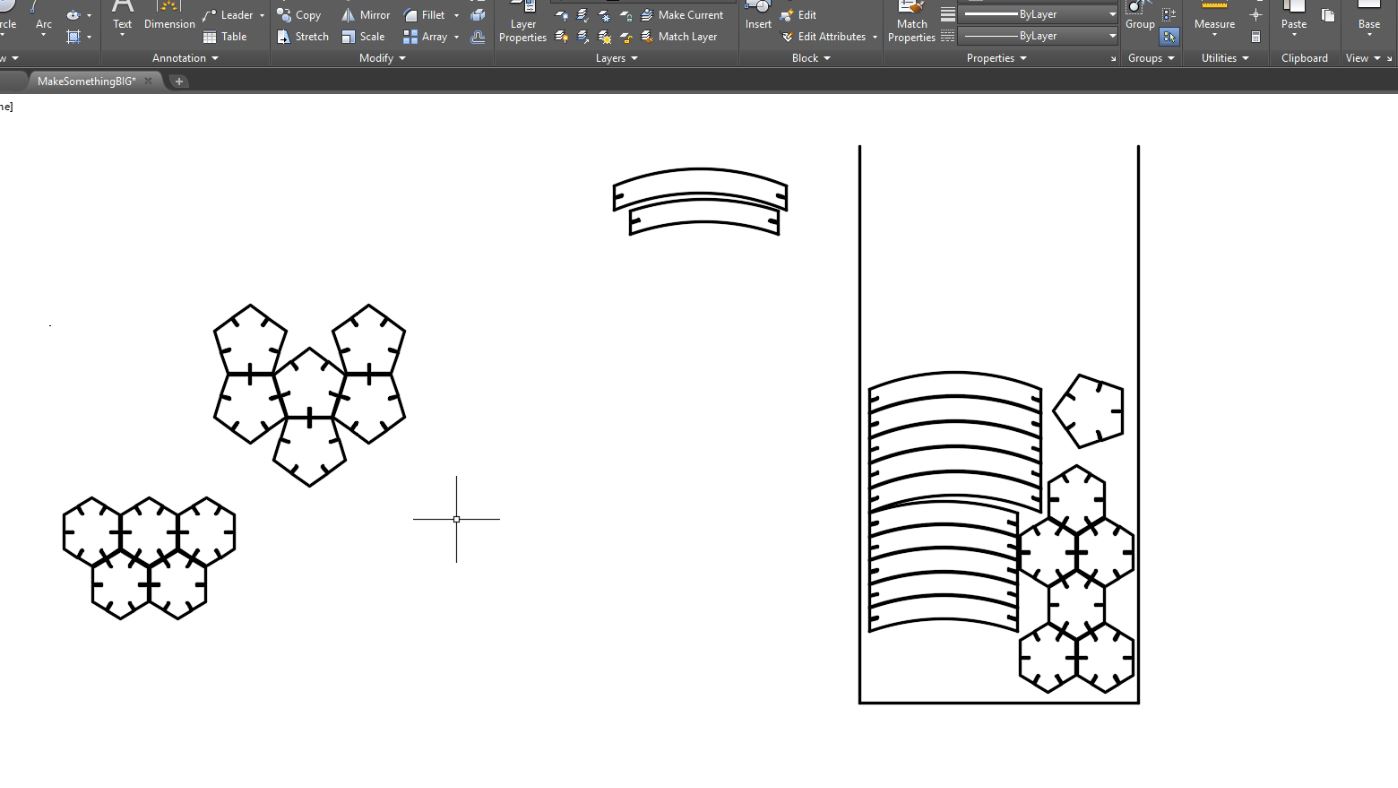

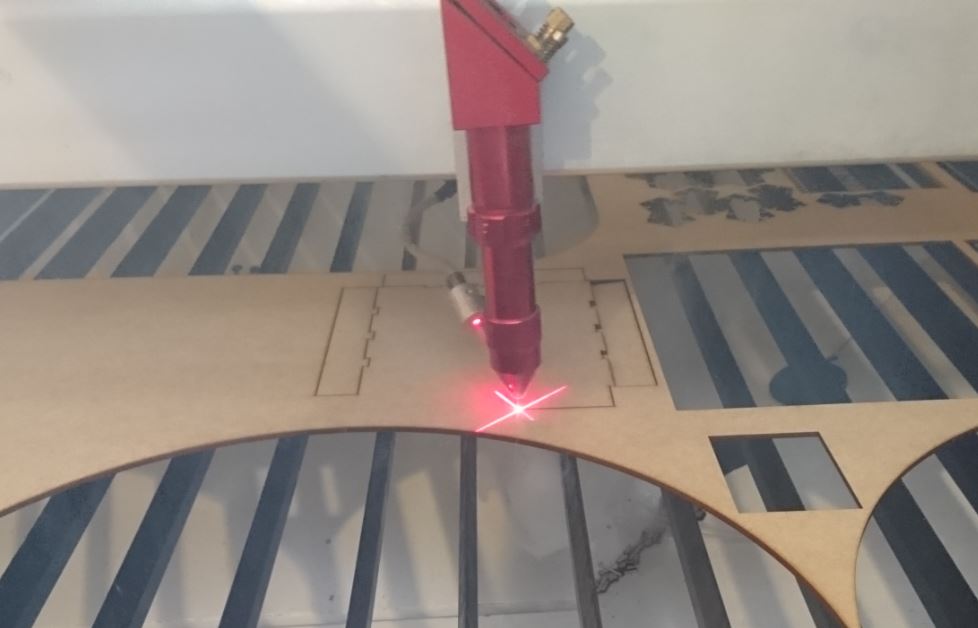

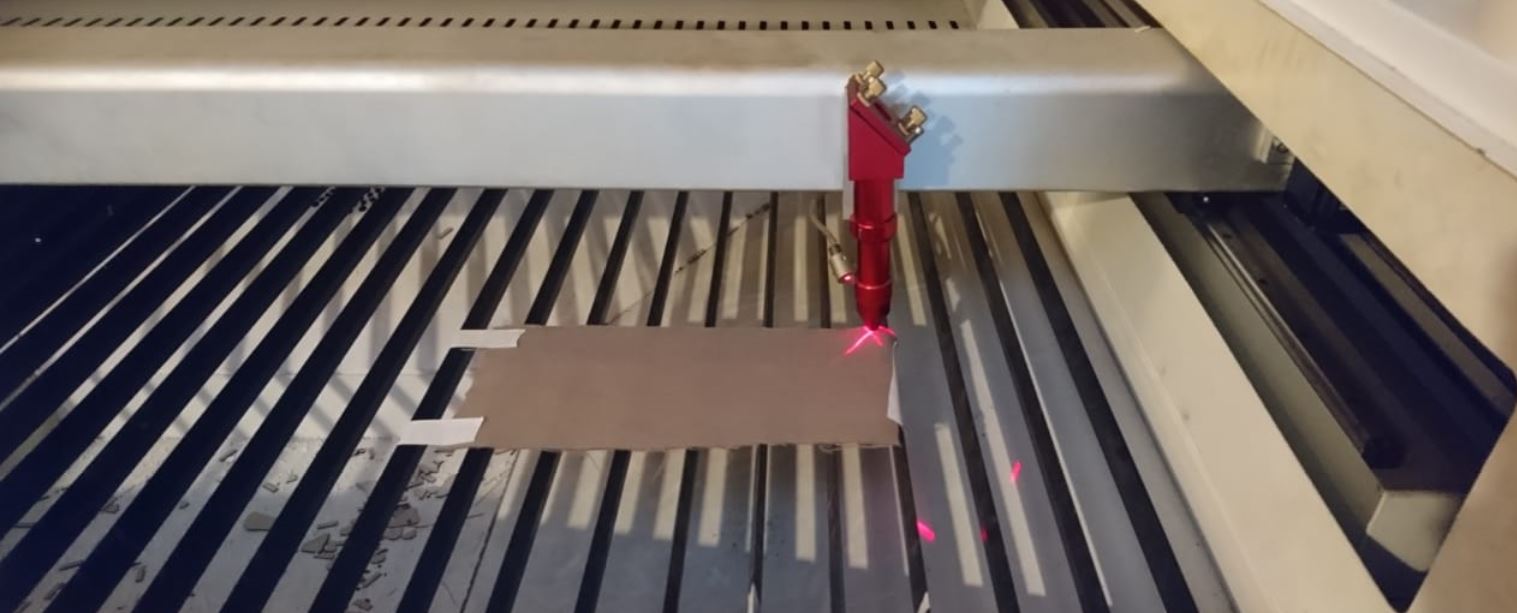

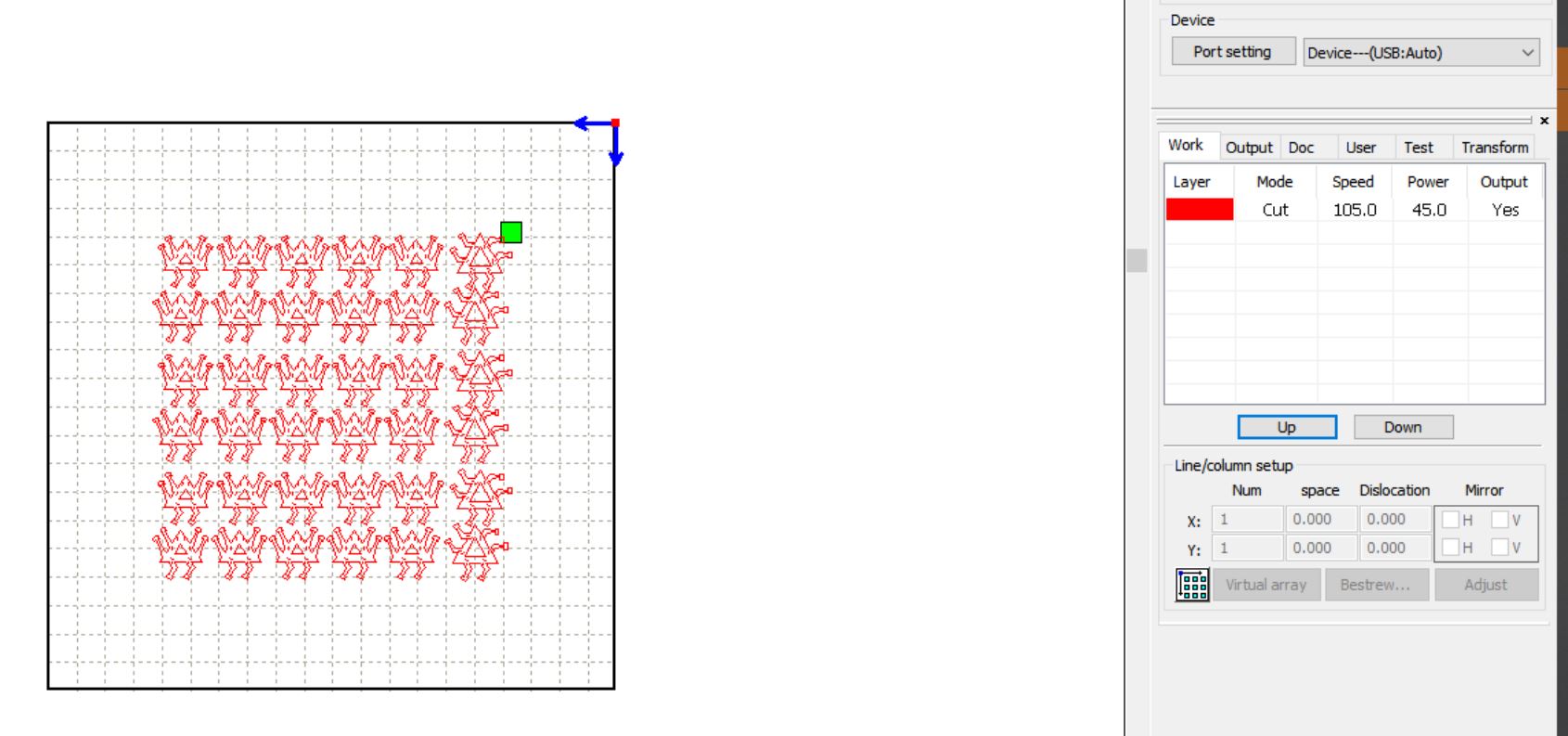

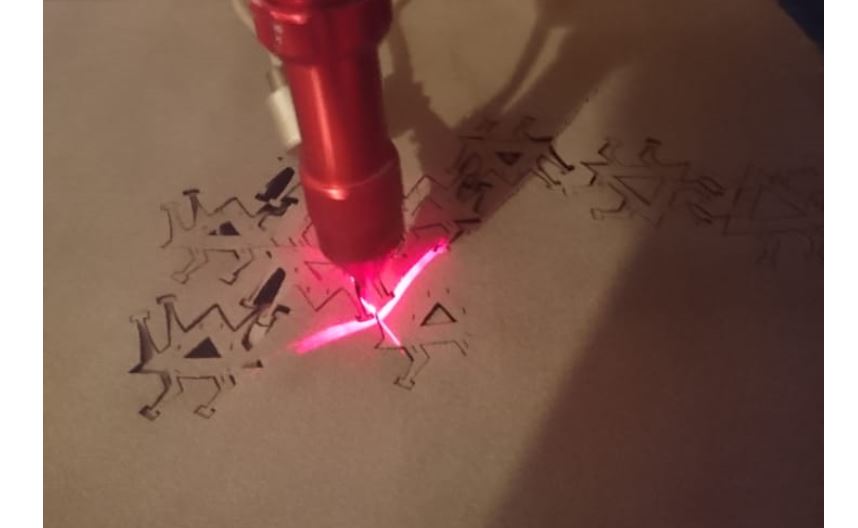

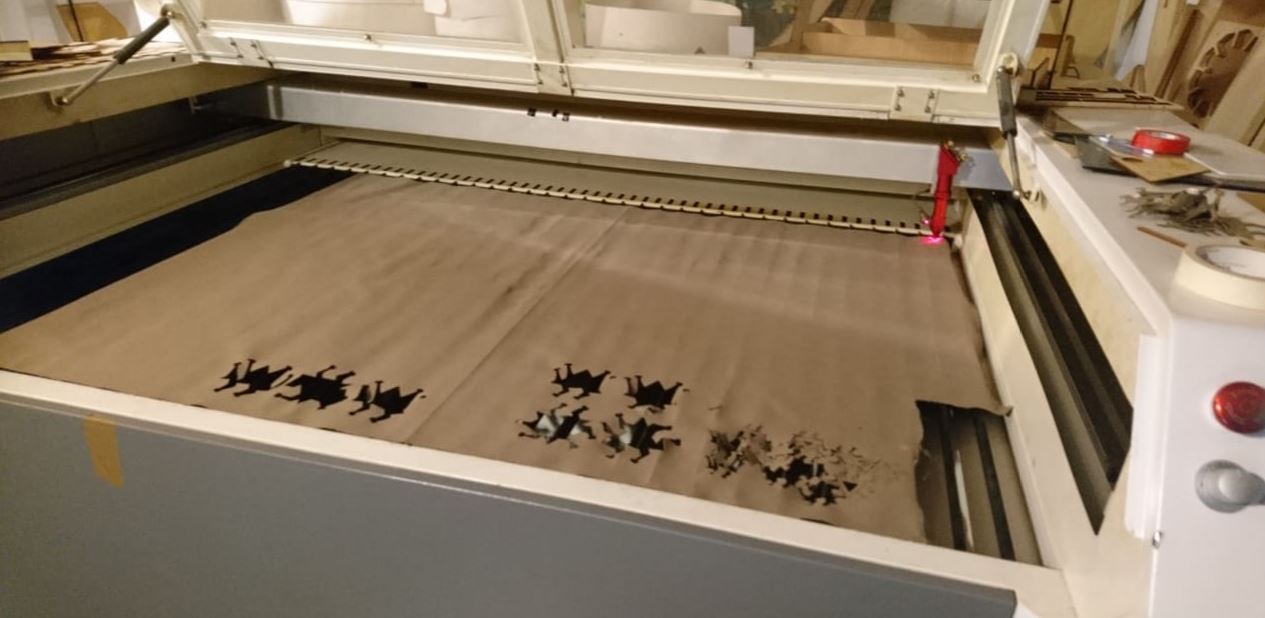

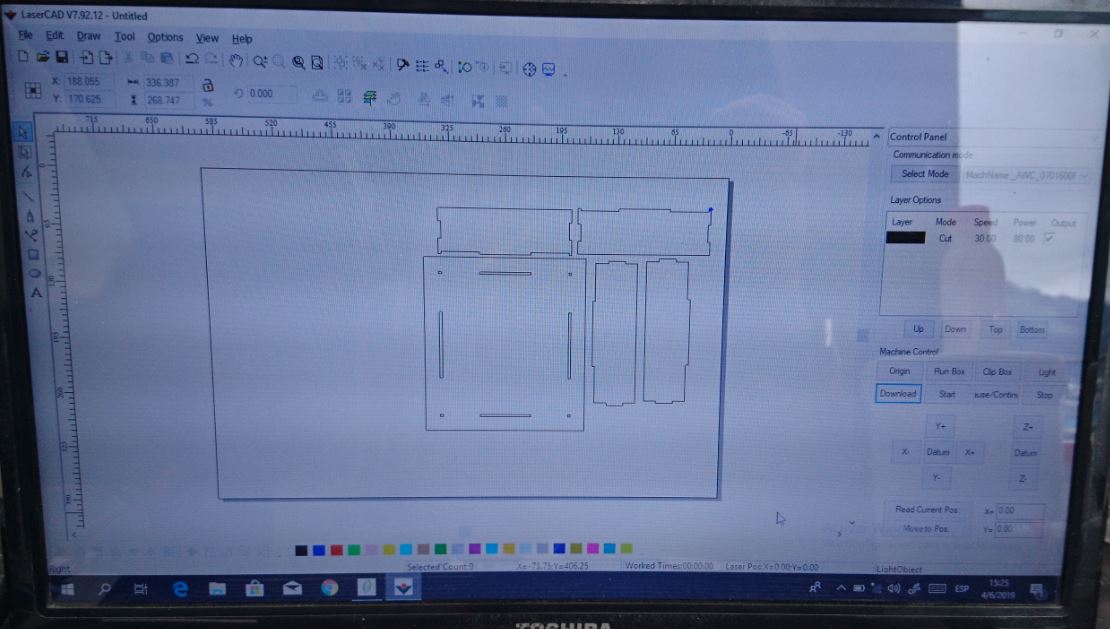

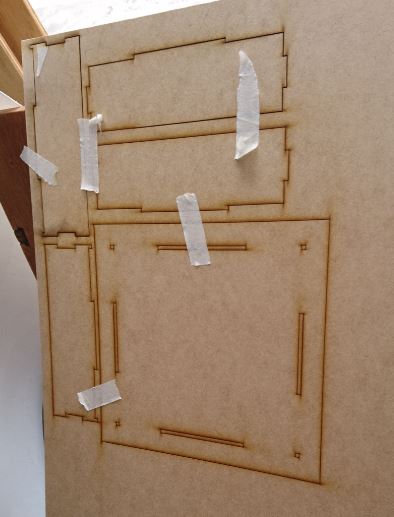

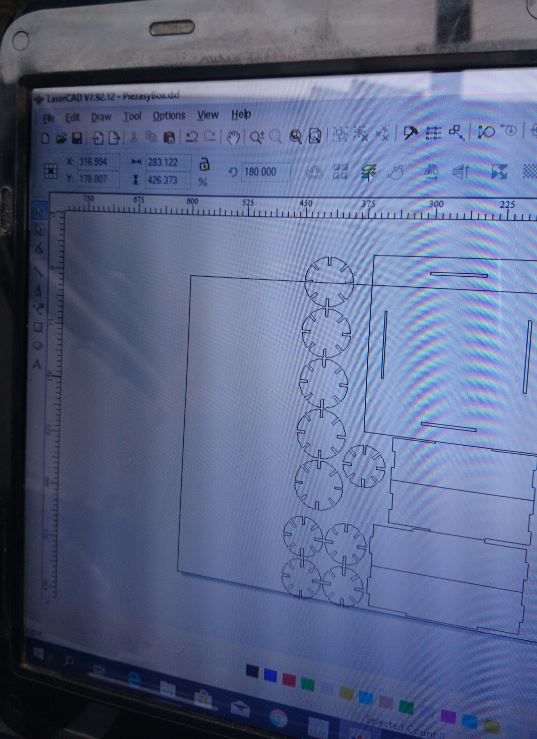

After having drawn the pieces, I had to prepare them to be laser cut. The material I chose for this was 3mm MDF, for which I set the power (75) and speed (15) in RDWorks software to generate the code. I inserted the vectors in dxf format into rd works, and then pressed the "save to u file" button to generate the code. This I then loaded into the laser to be cut, adjusted the correct height for the material, and then sent the file.

First I cut just a few pieces in order to make sure that everything fit well together (making sure I had calculated the right dimensions for the kerf) before cutting all 160 pieces.

After the first pieces had been cut (and I verified that the power and speed were correct), everything seemed to be joining nicely, so I cut the remaining pieces.

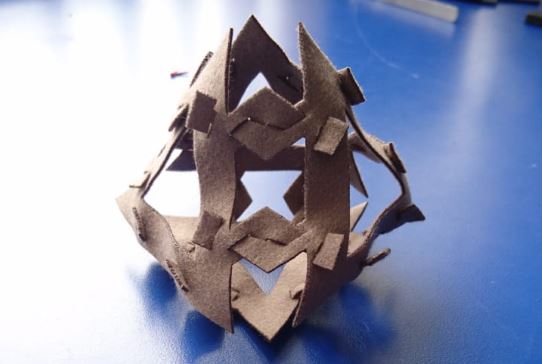

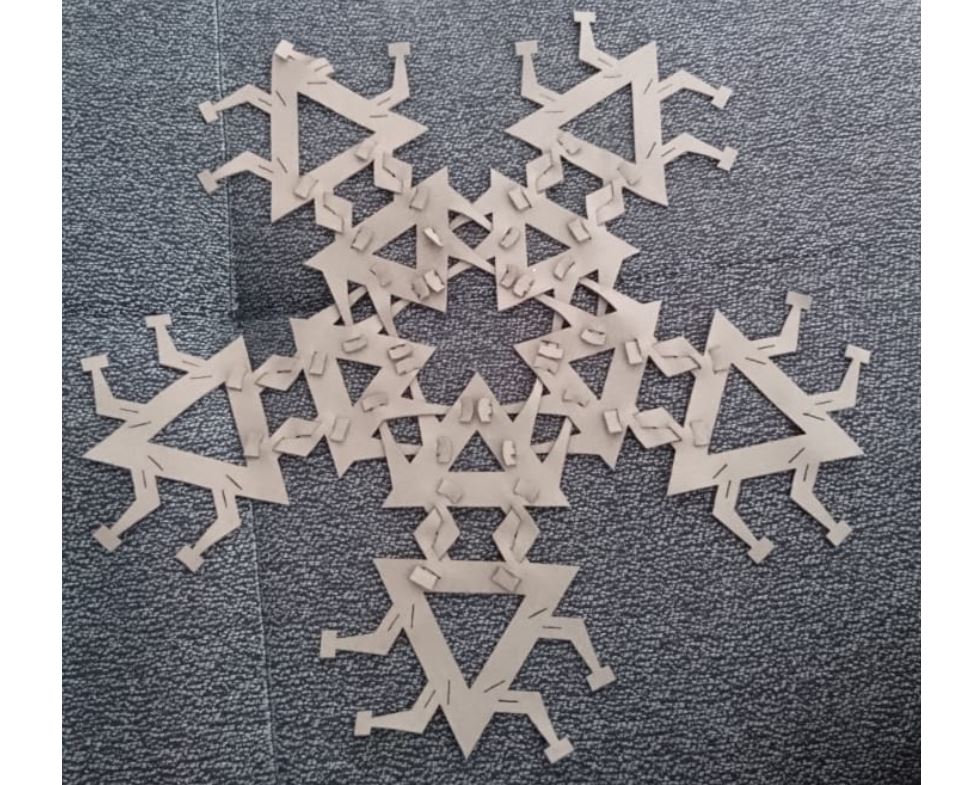

Joining them turned out to be a harder task than I had thought, because after some beams and vertices had been joined forming triangles, the structure became rigid and it was hard to fit the other pieces. After a few tries, I noticed that I had to first place the pieces very loosely and then tighten the structure evenly. Likewise, when the dome was completed and tightened, if I wanted to remove some parts I had to loosen a whole section in order to not force and break the pieces.

Also, I experimented with other shapes (as the press fit kit had to be able to join in different ways).

Overall, I am happy with how the press fit kit turned out, as it helps me have a starting point for my final project. Also, I appreciate the ease with which parametric modelling processes allow to rapidly change models and shapes and adapt them to new dimensions. Using the vinyl cutter and configuring it was very interesting, as was learning how to calculate laser kerf.

The press fit kit worked as expected, although it does not have many viable configurations to create other enclose volumes. The good is that the angles were calculated correctly and the geometry works and is ready to be tested in a larger scale. The bad (sort of) is that there are not too many other ways that the pieces can be joined together to create more volumes (which is what I wanted). However, because it worked, I consider it successful in helping me take another step towards the final project.

There is no specific project that is focused on this very useful tool. There are a range of ways you might utilise it throughout the programme, or your local instructor may set a specific project. You might make:

Ensure that you have used it in some way during this time and met the objectives below.

February 13-19

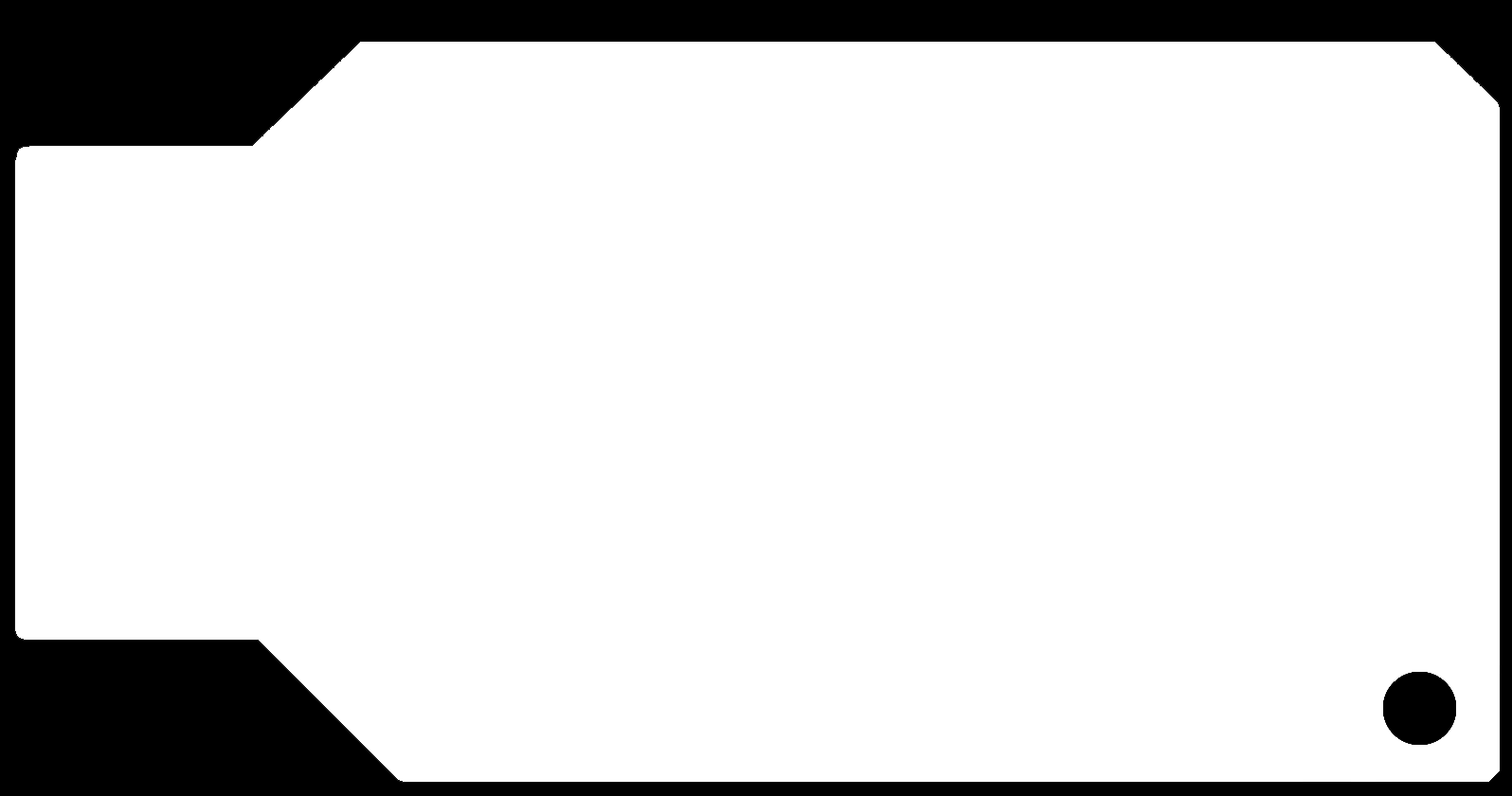

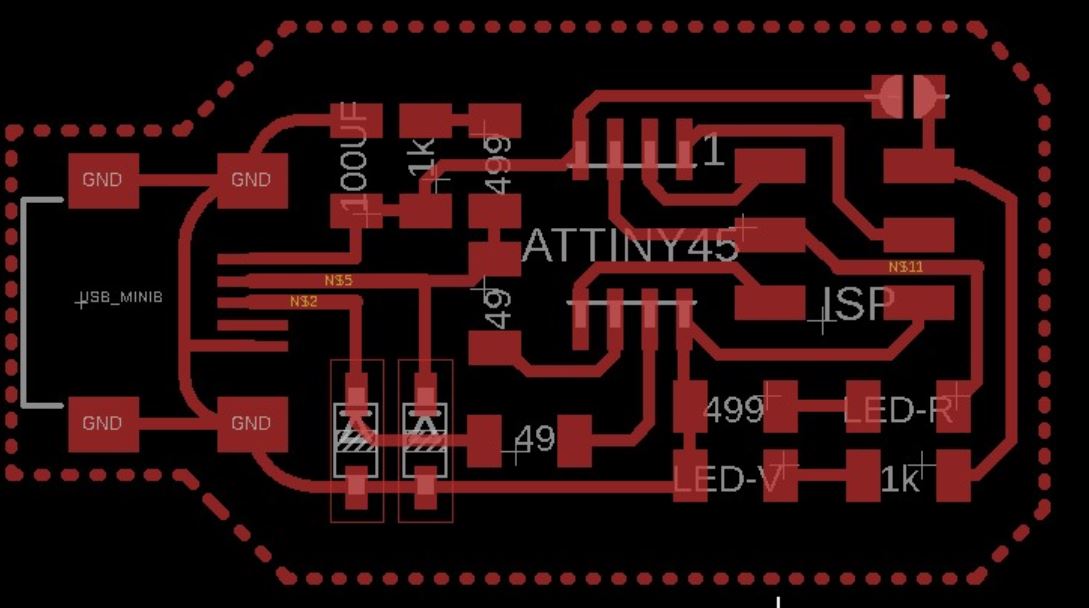

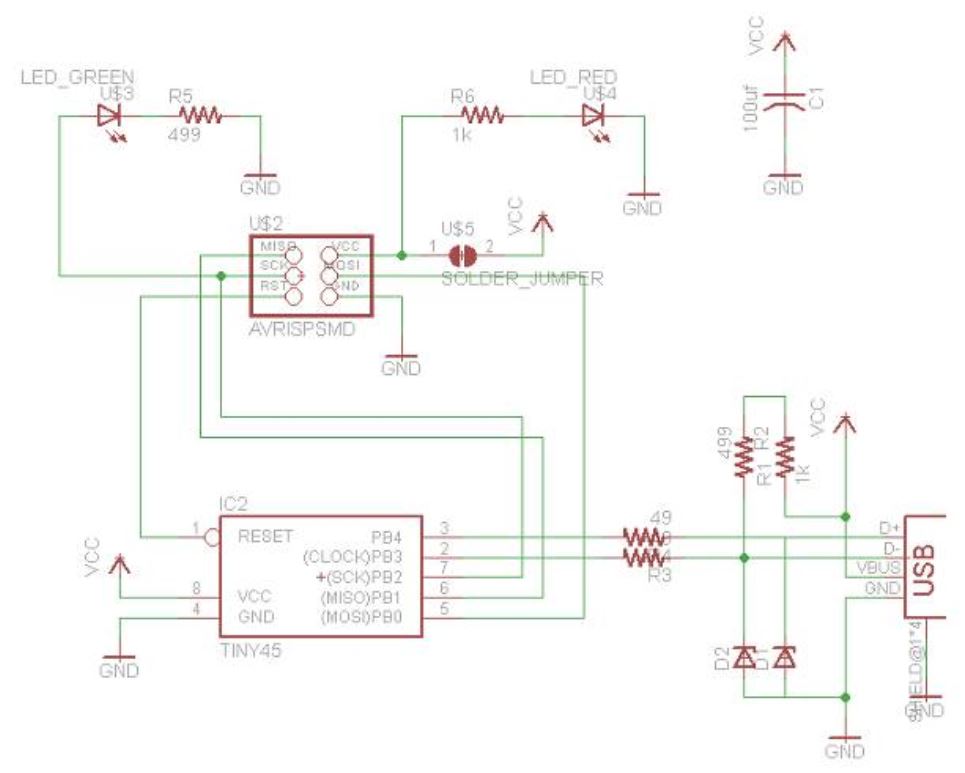

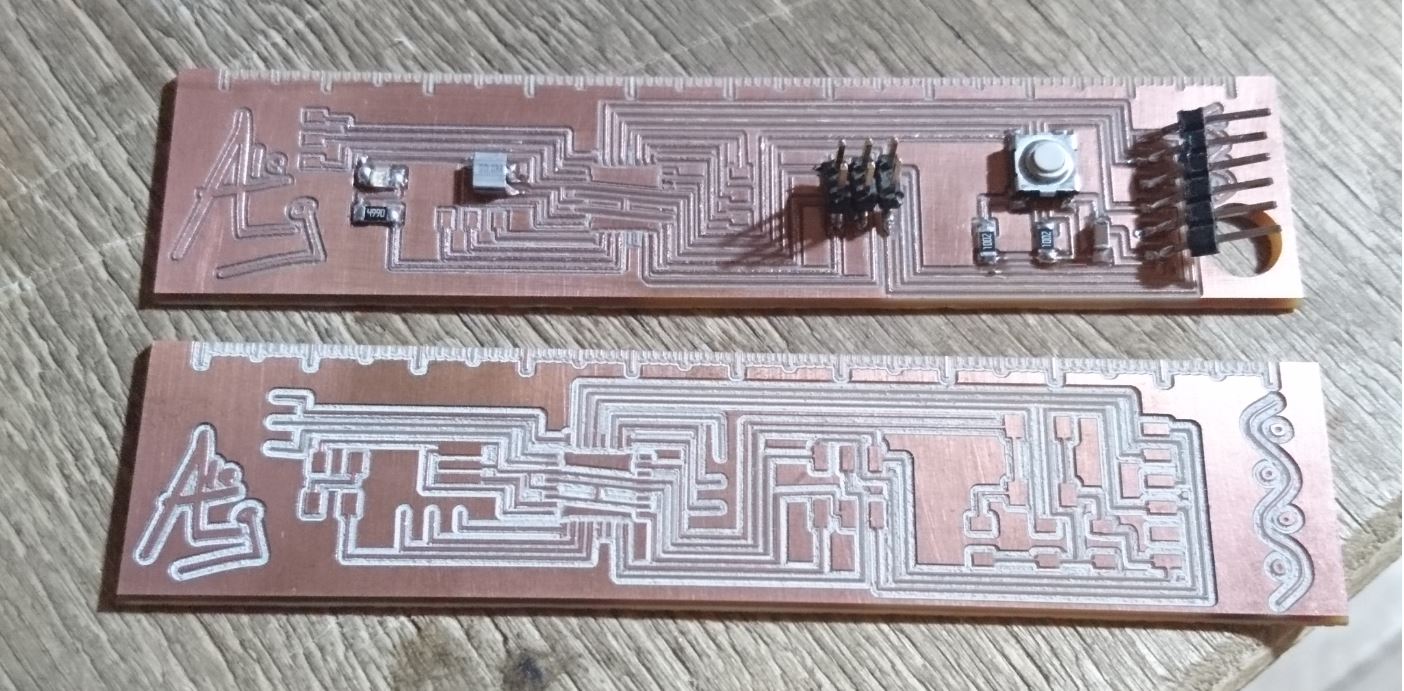

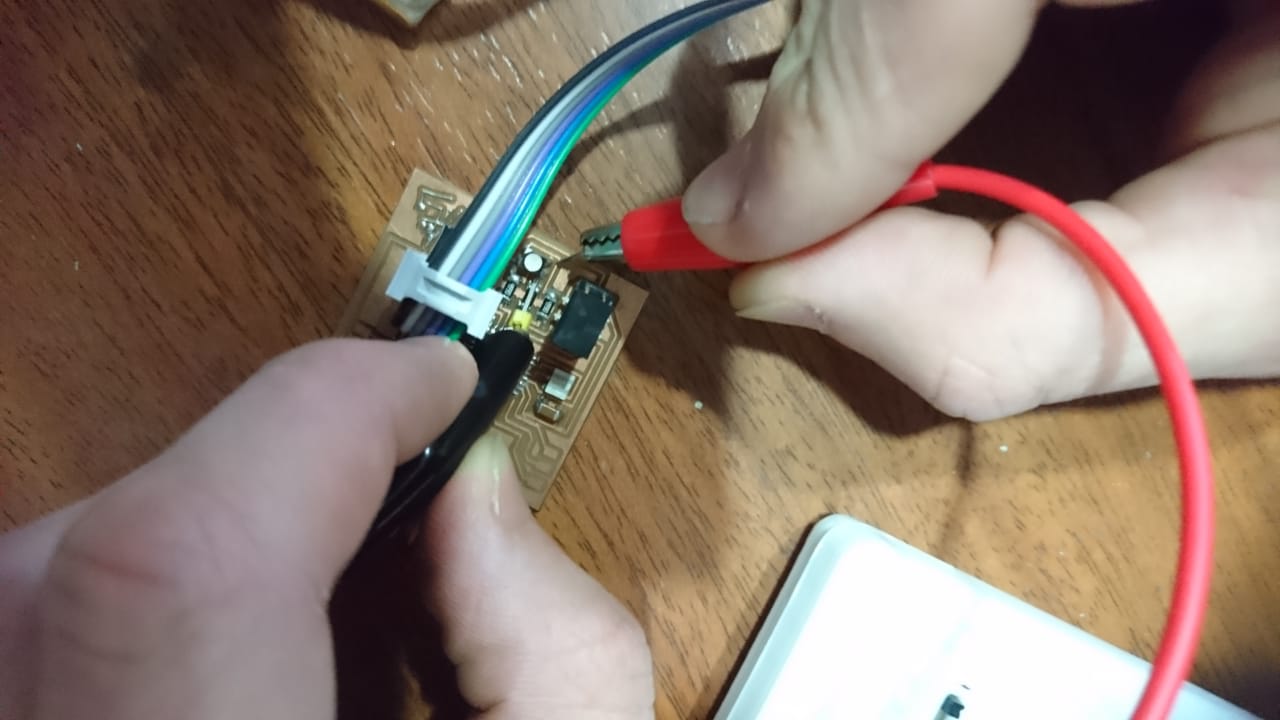

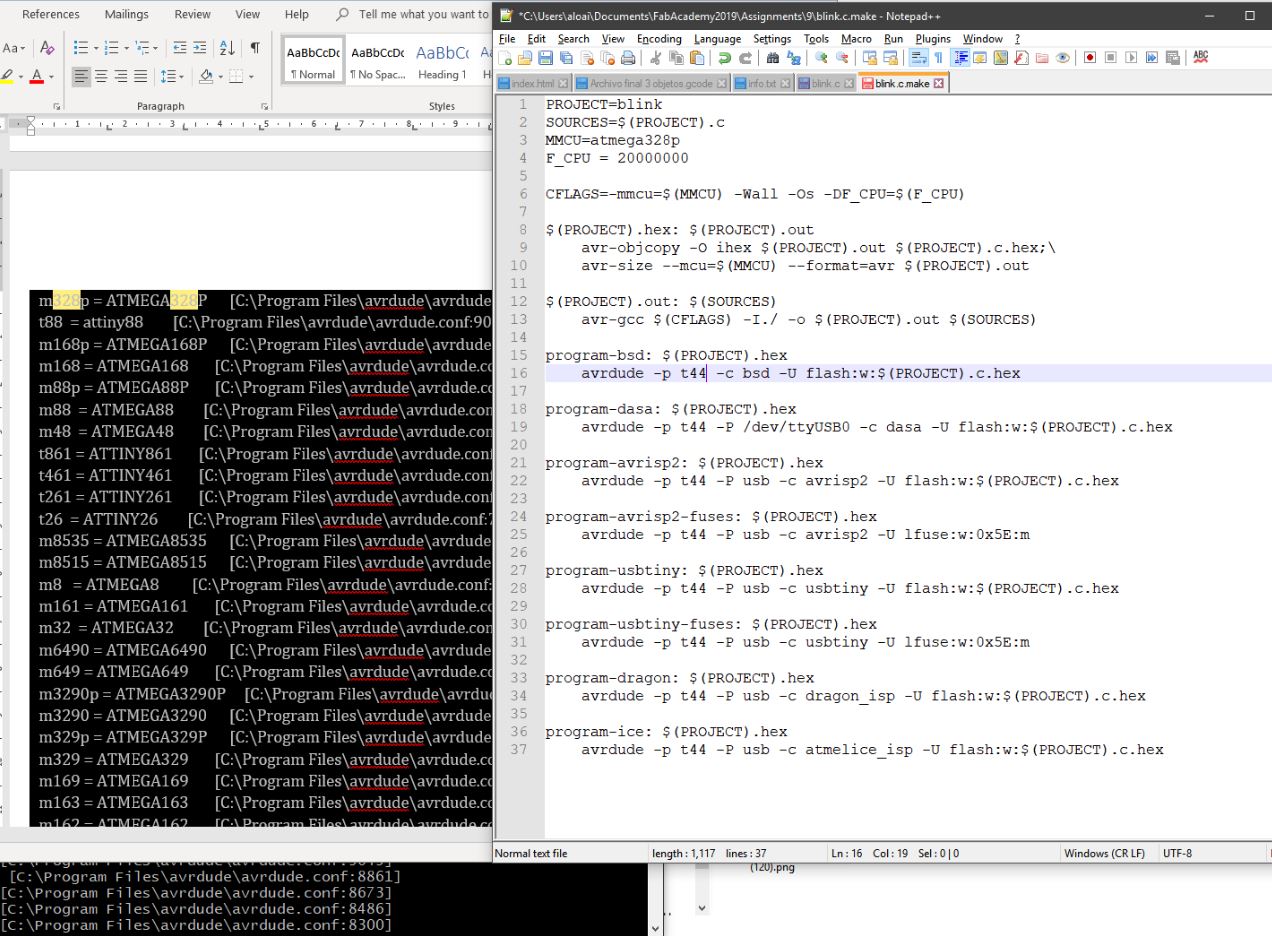

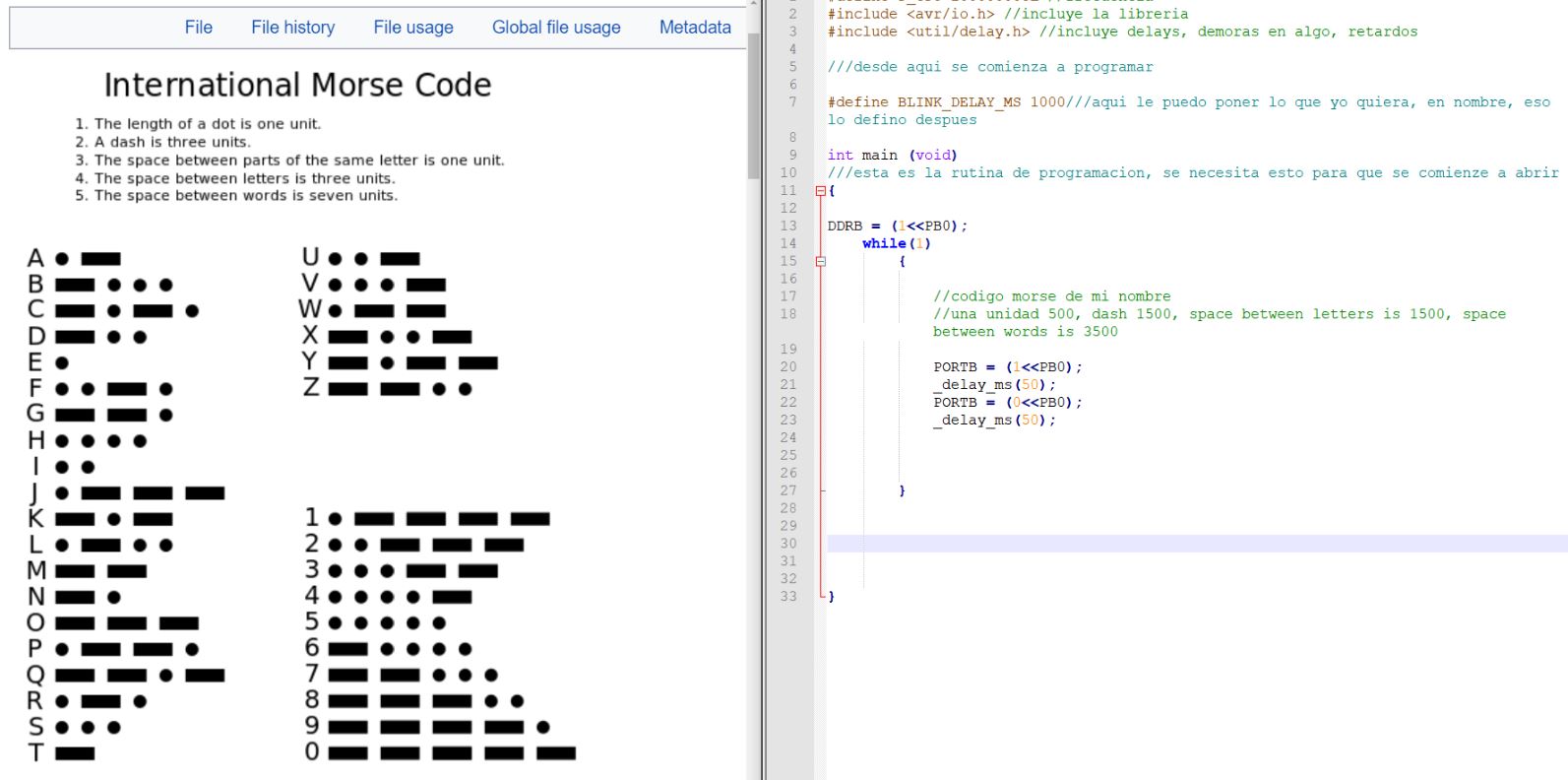

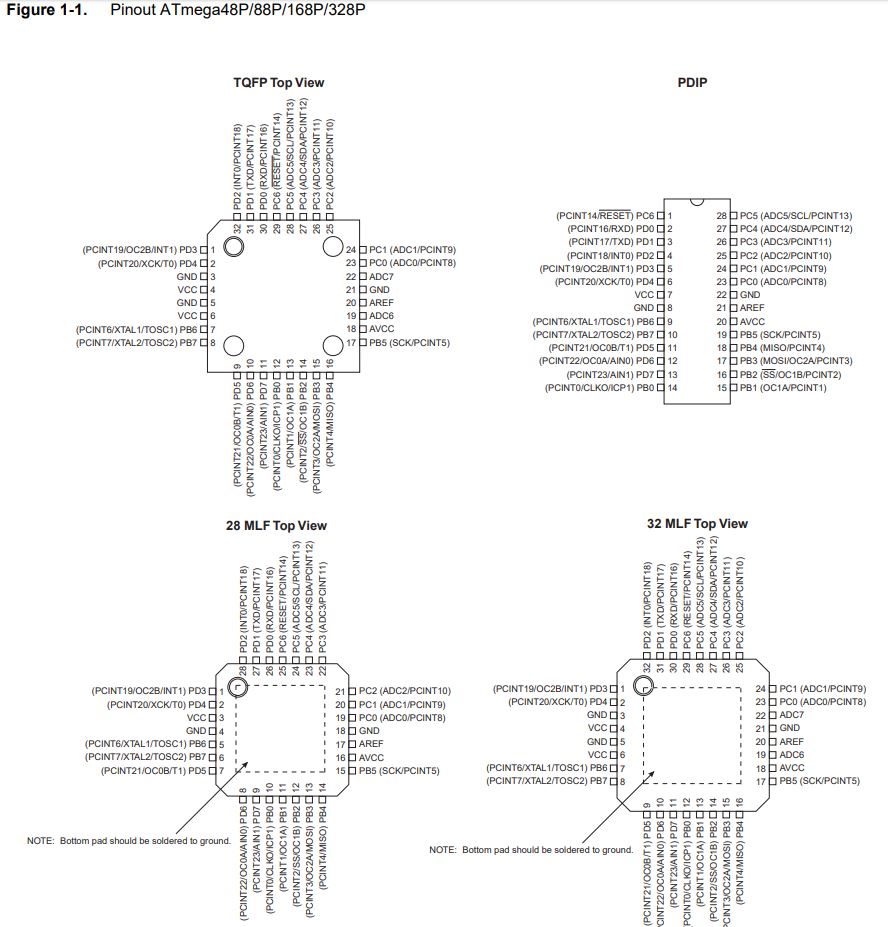

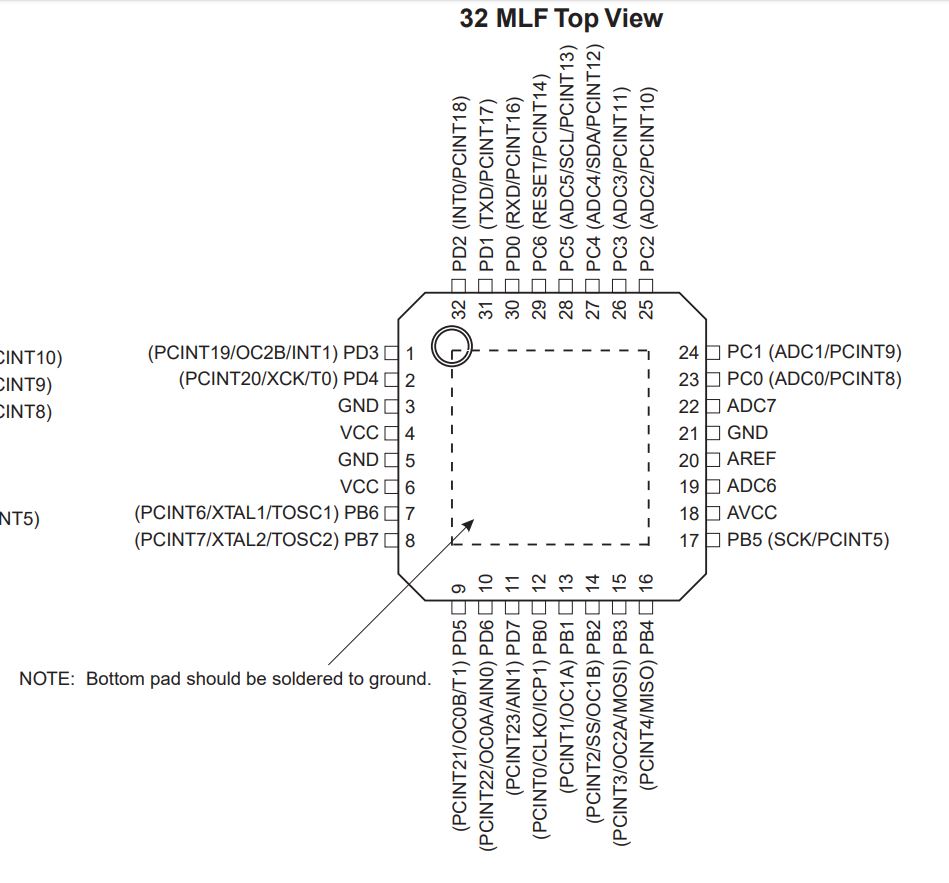

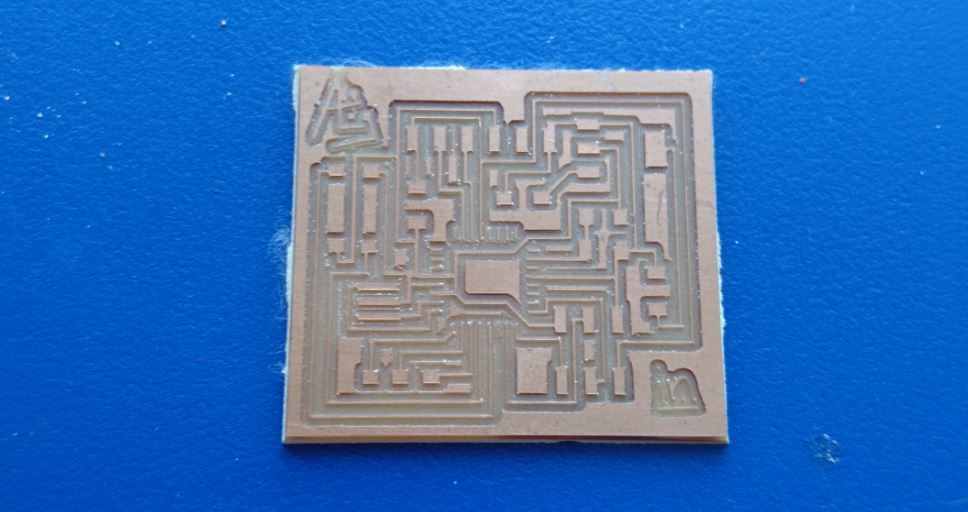

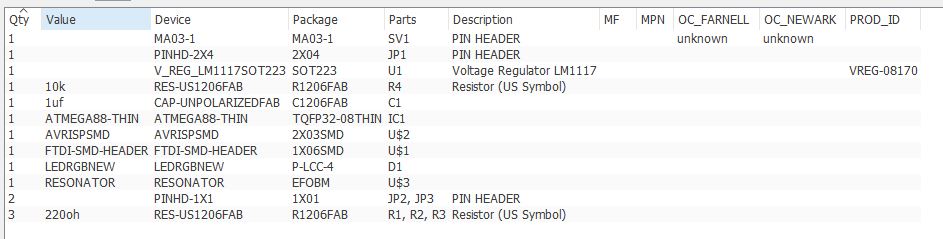

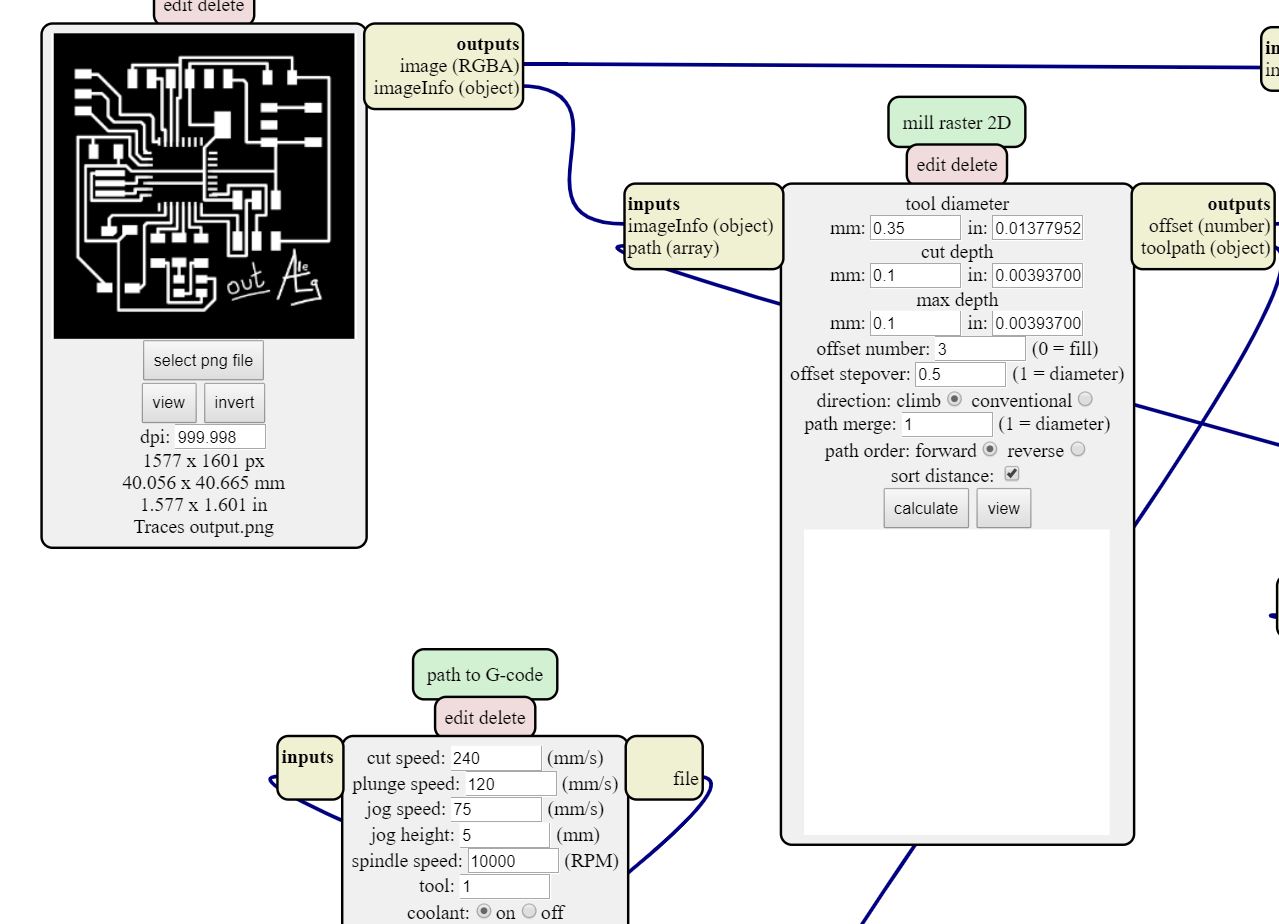

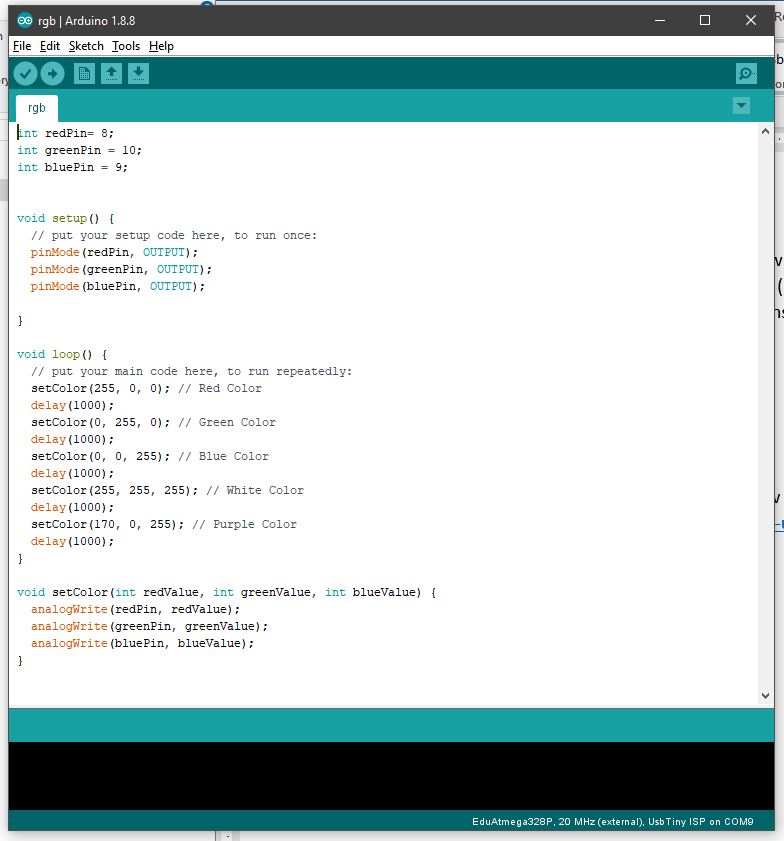

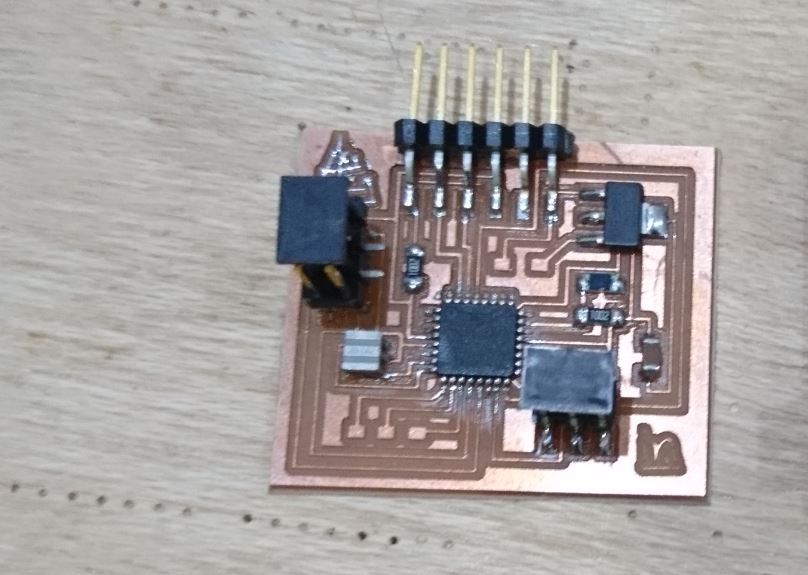

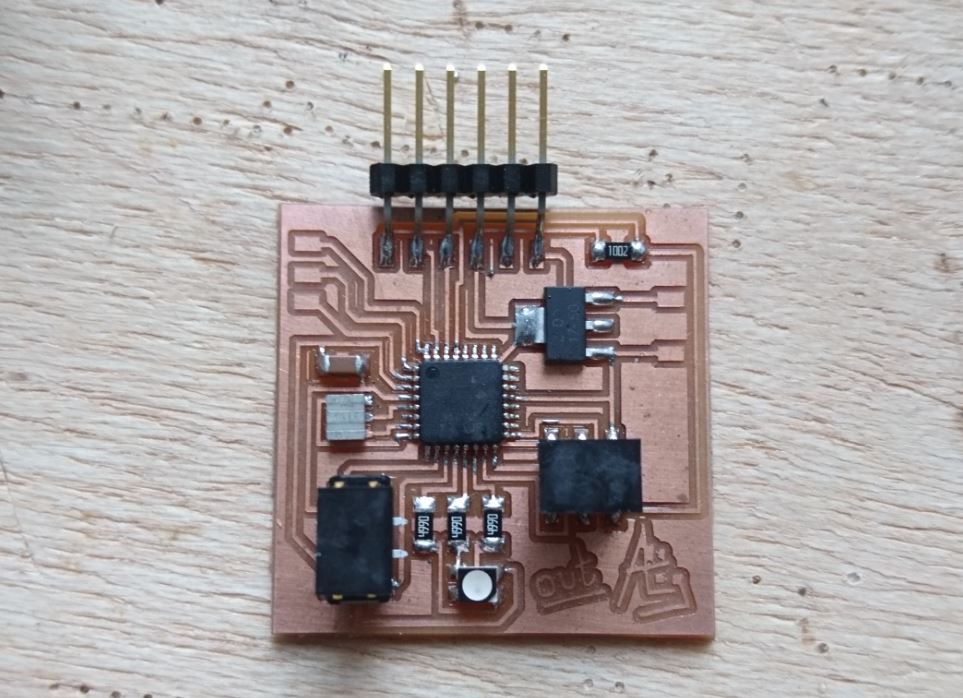

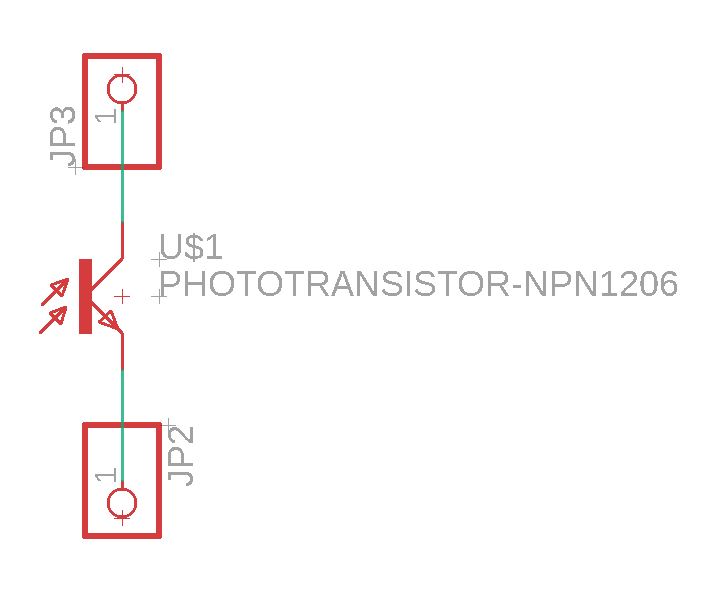

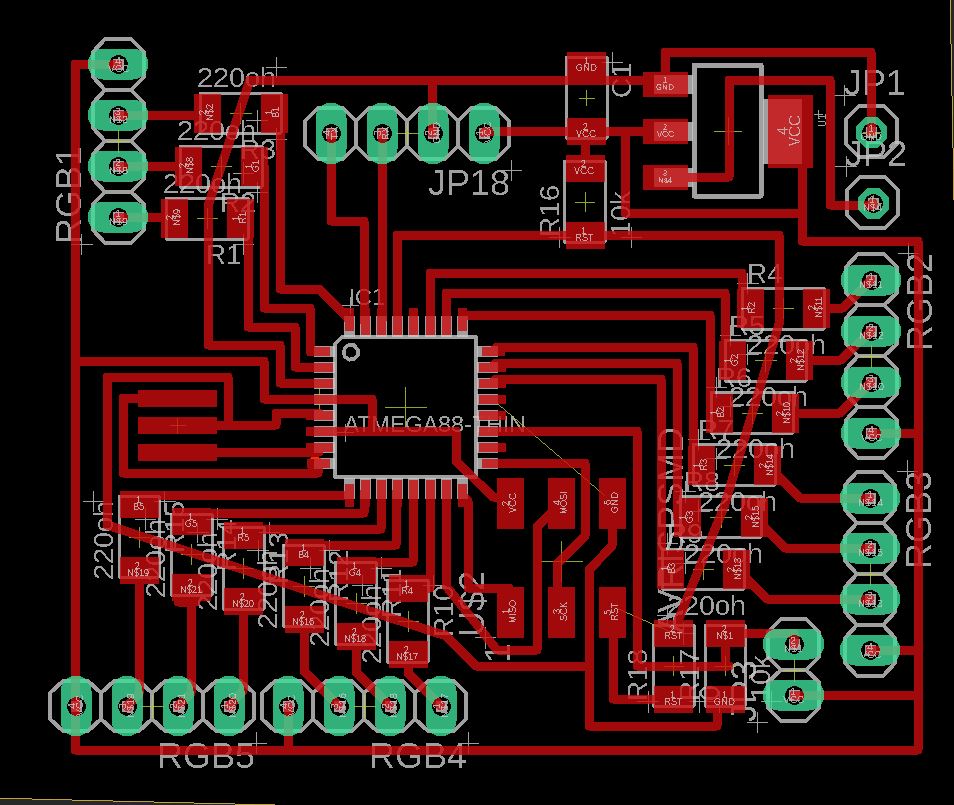

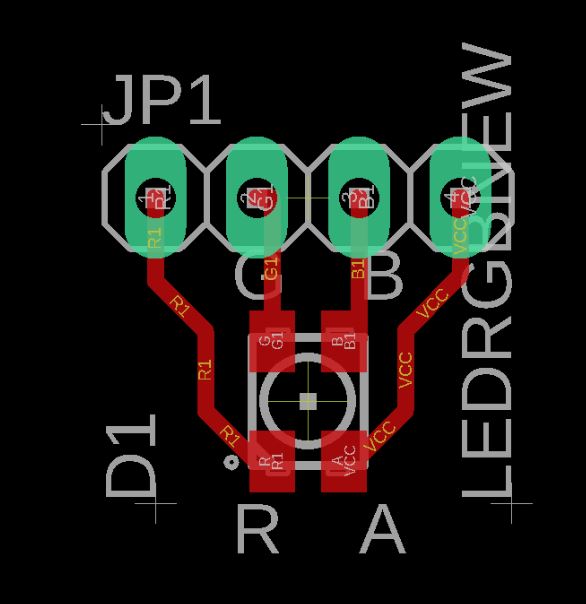

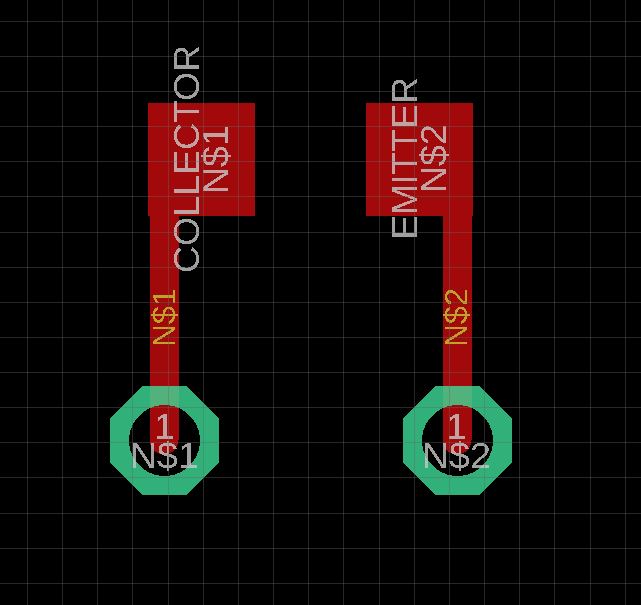

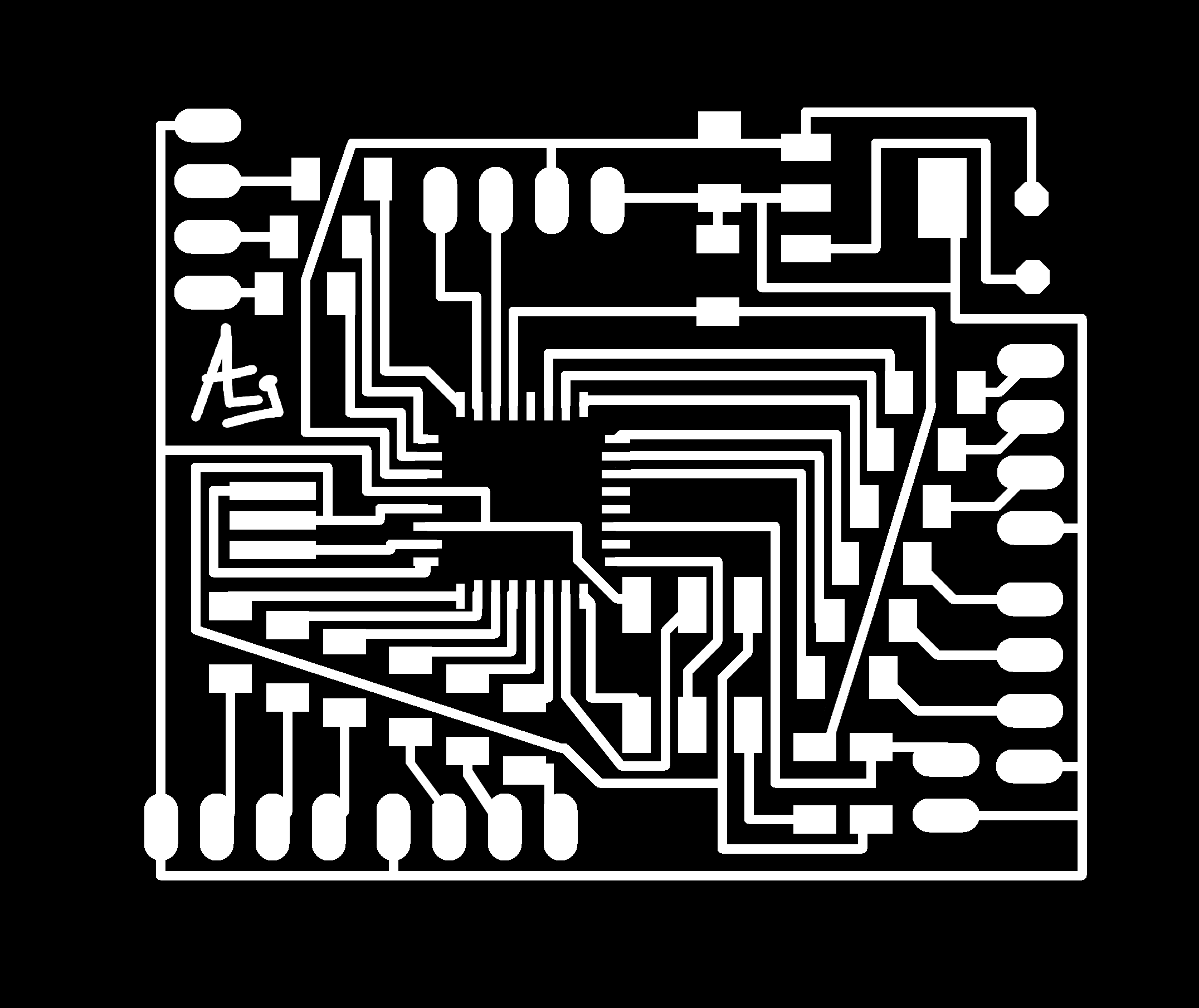

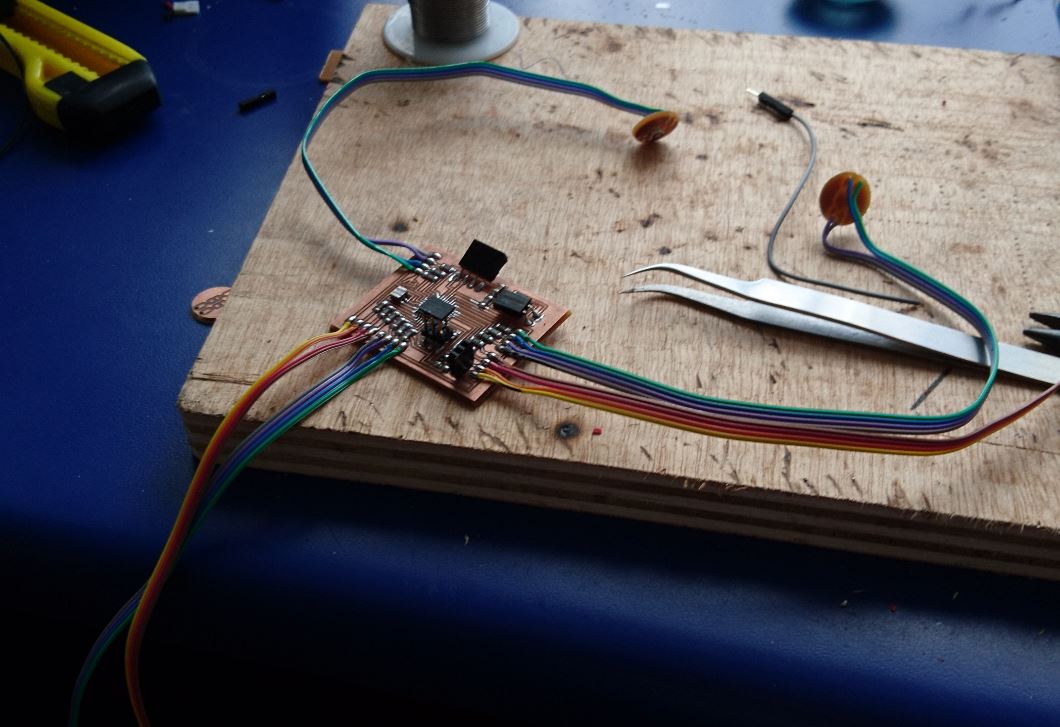

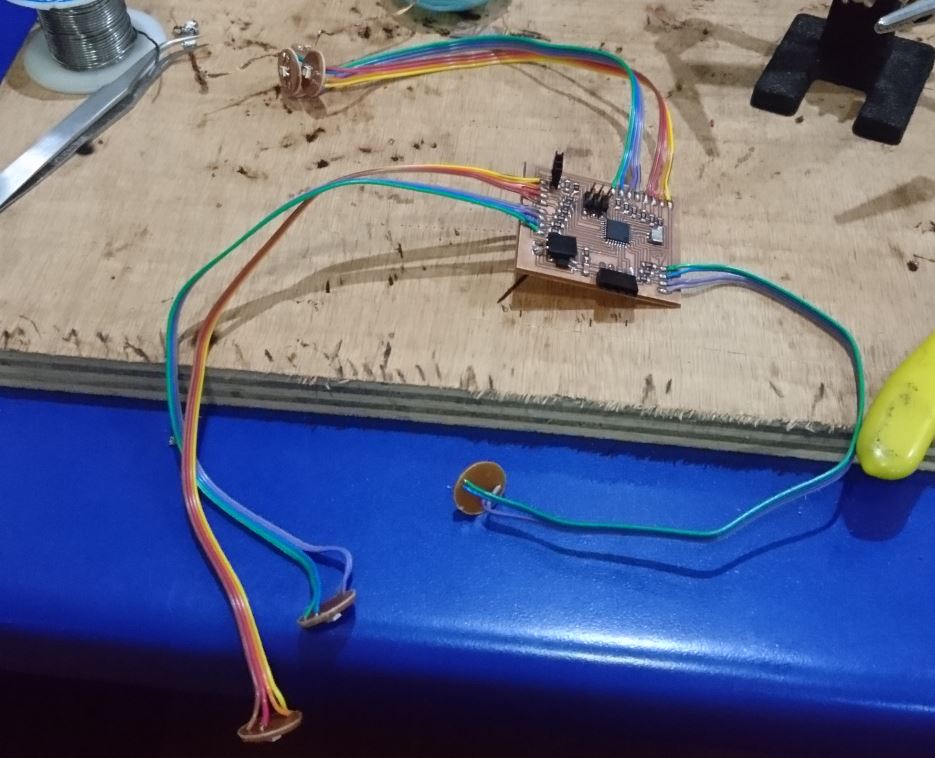

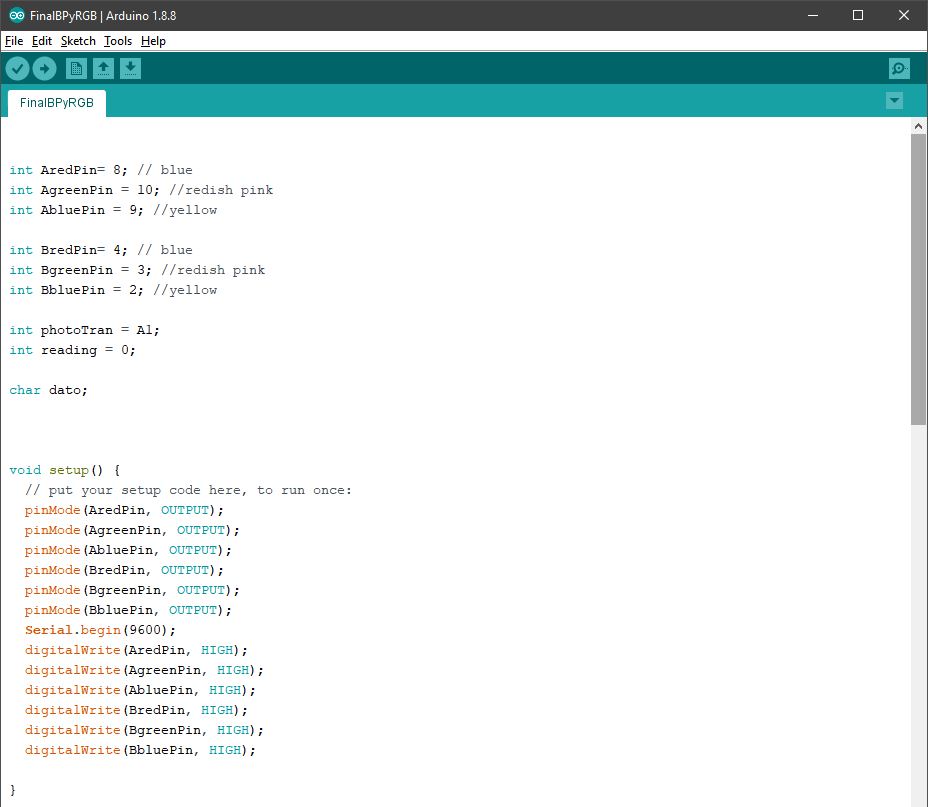

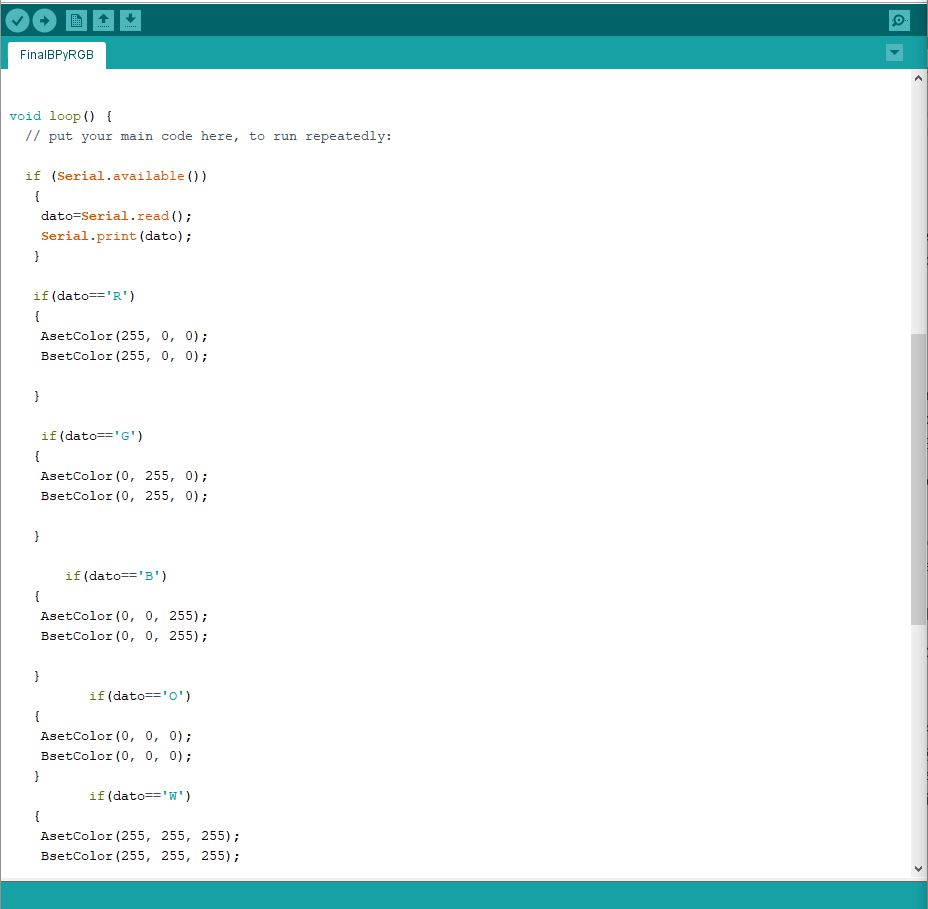

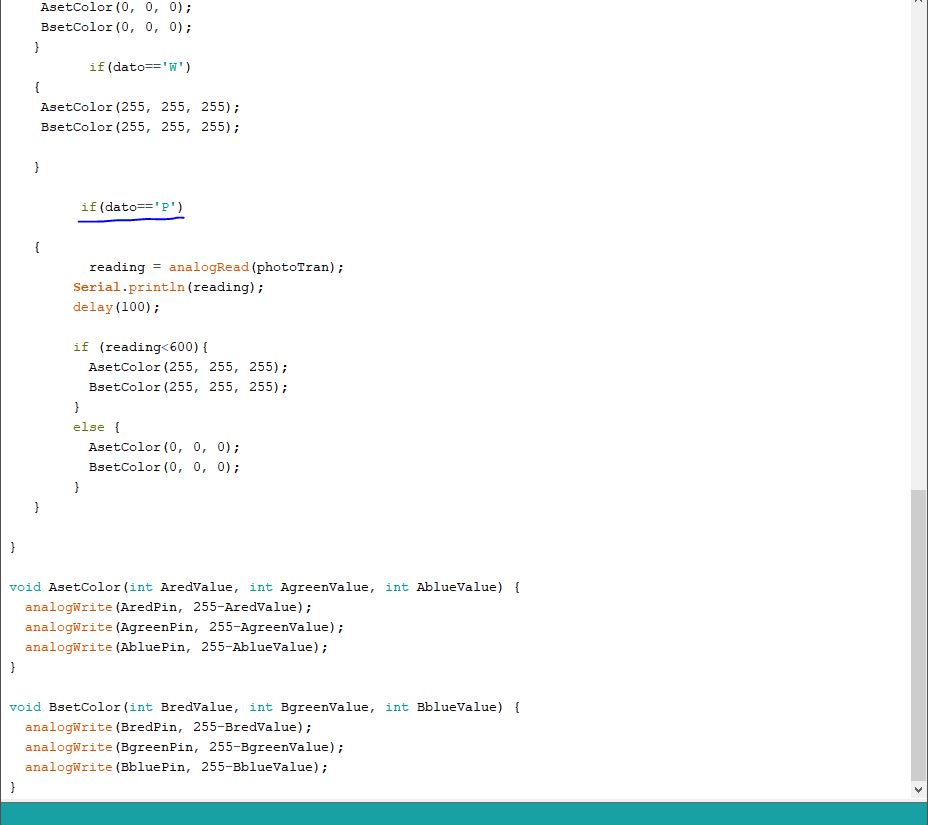

This week, the assignment is to duplicate an existing PCB, changing very few things, in order to understand the process behind making one. We must do the whole process: understanding how to pass from the design in the computer to the g-code to mill it using the CNC, then solder the components, and then program it. What we do not need to understand yet, however, is how the design is made, or specifically what the code should do or how to do it. This week is just about creating a PCB that actually works.

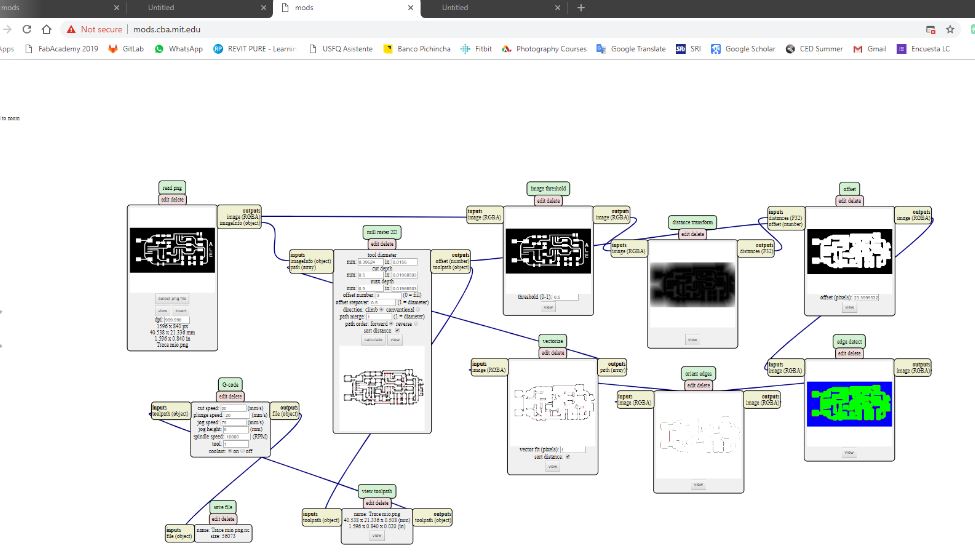

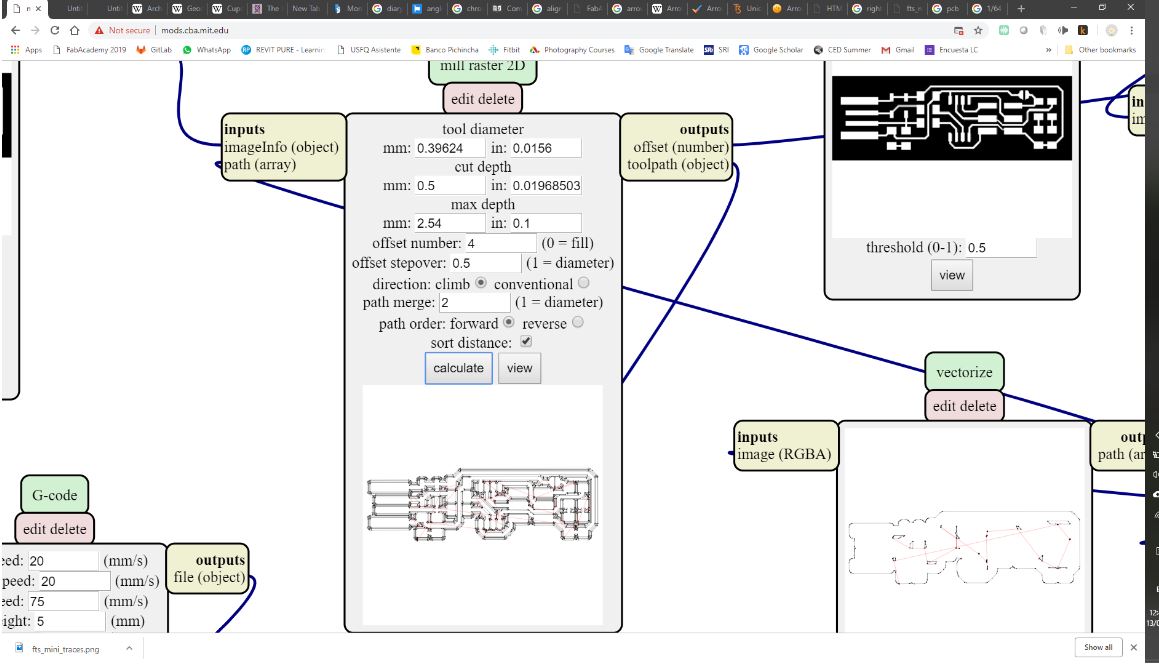

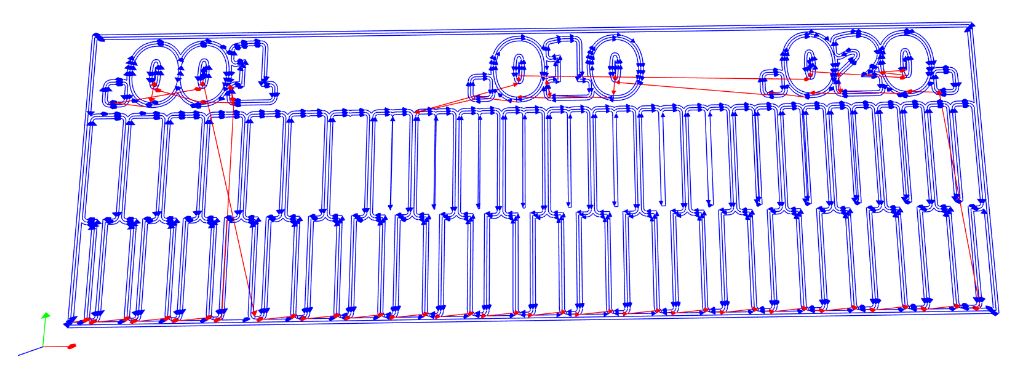

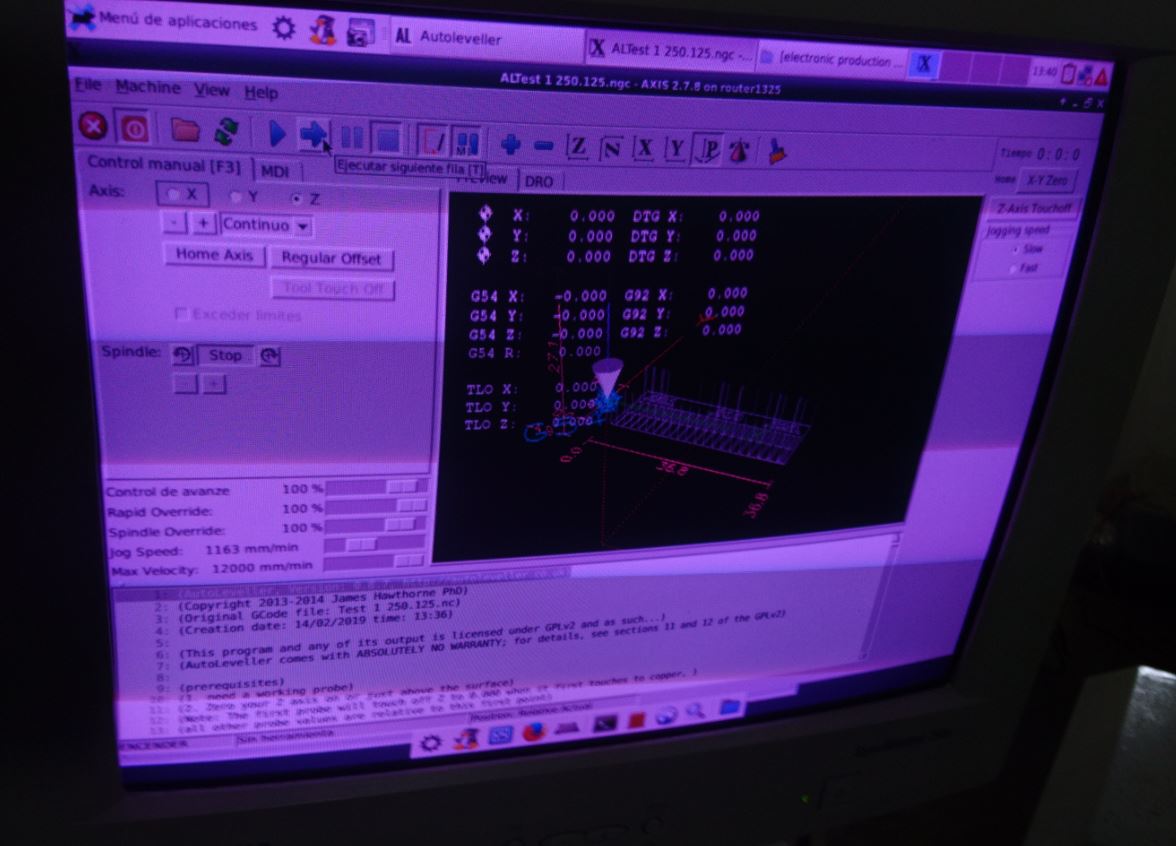

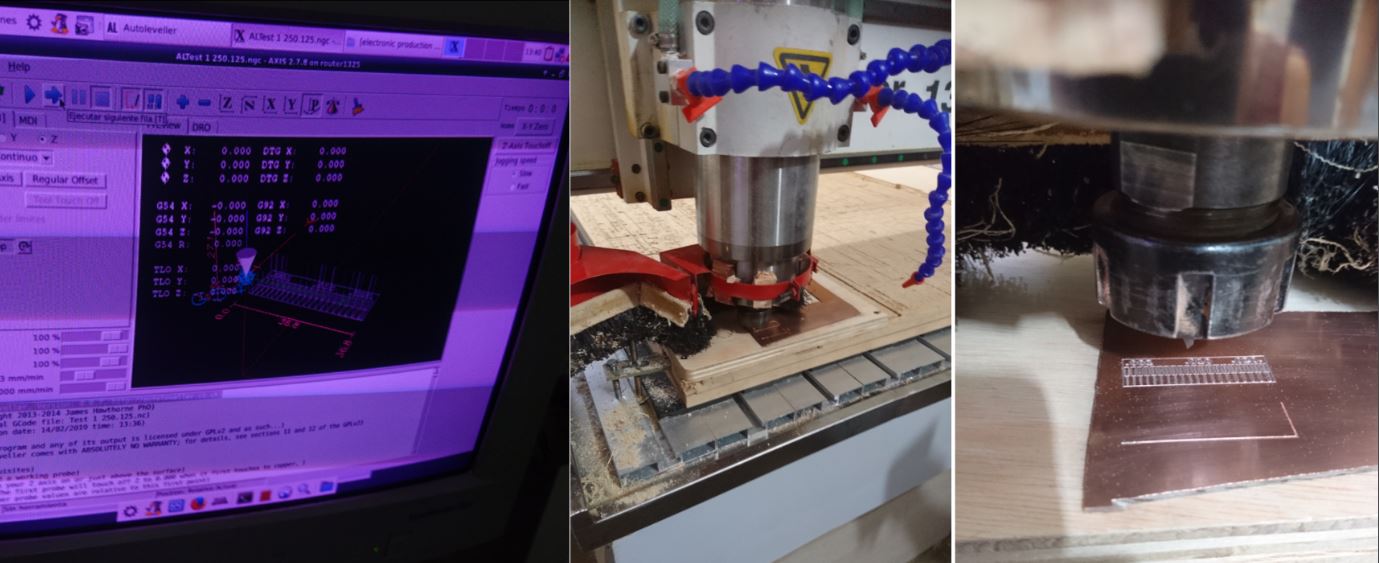

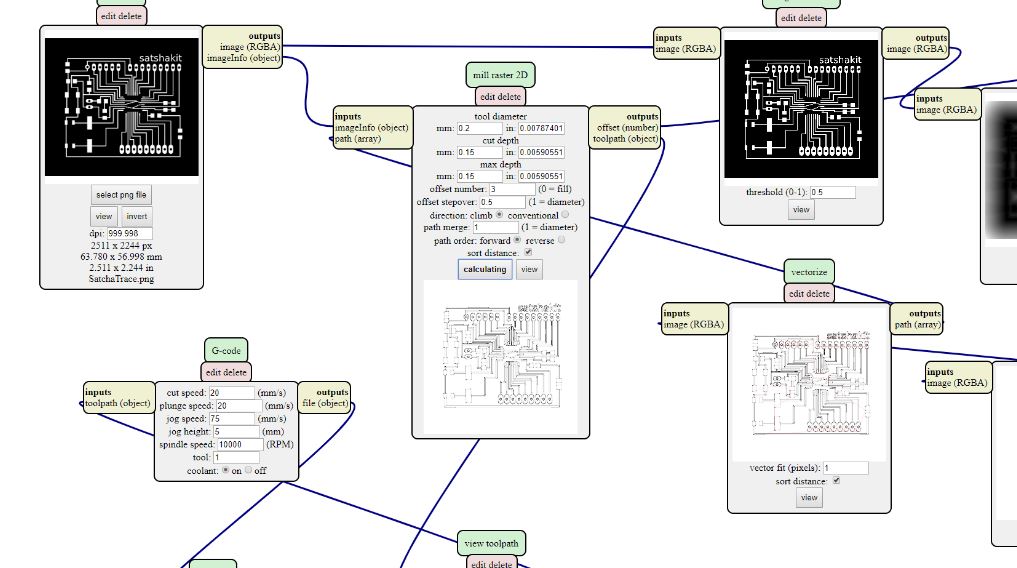

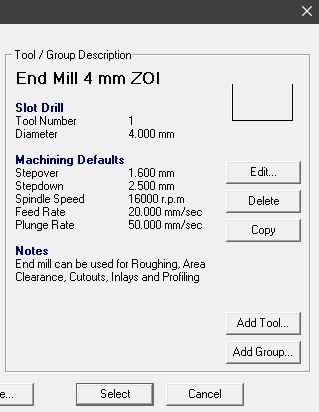

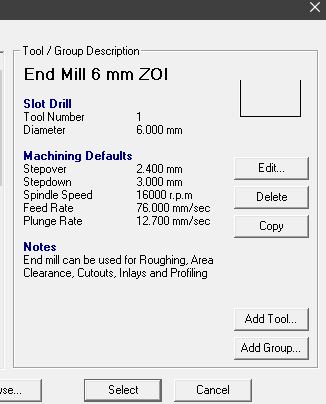

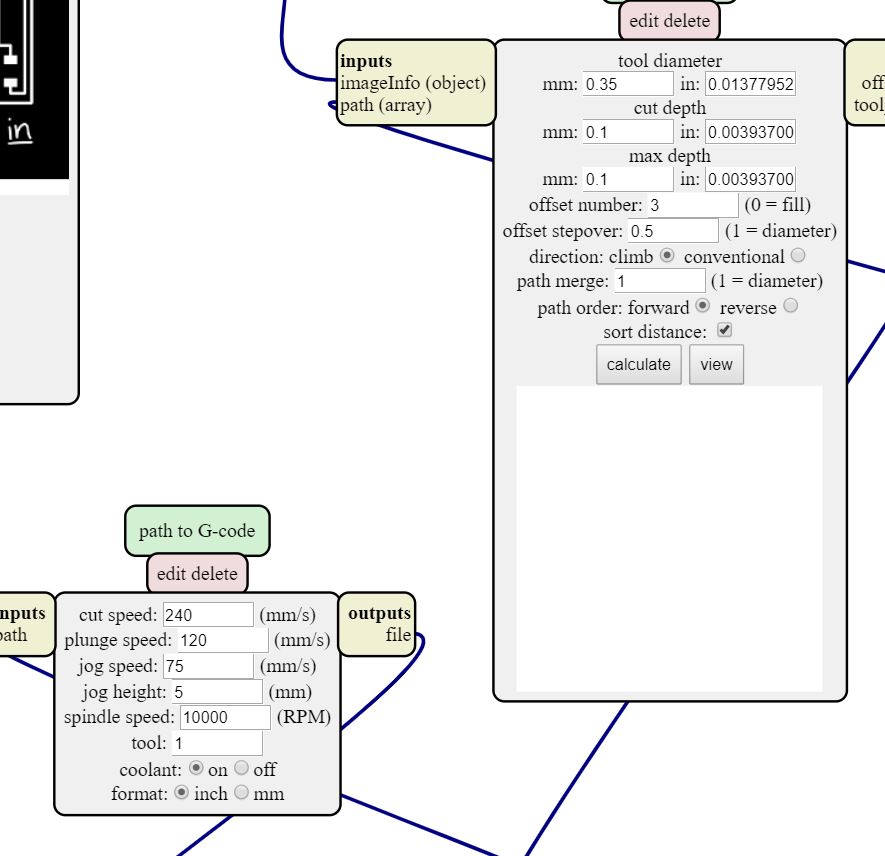

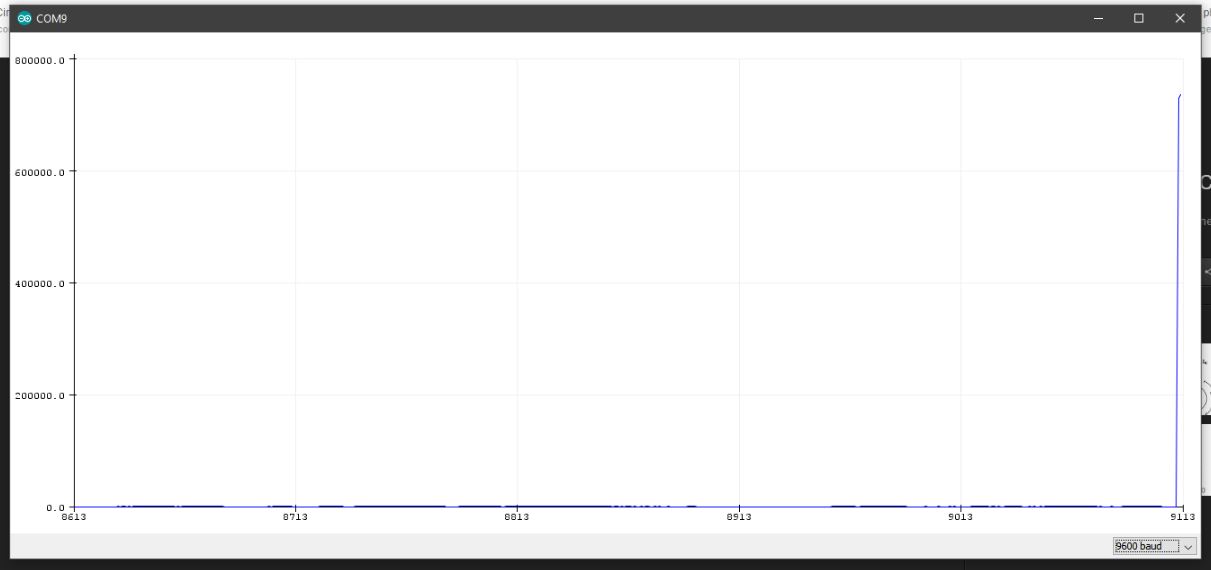

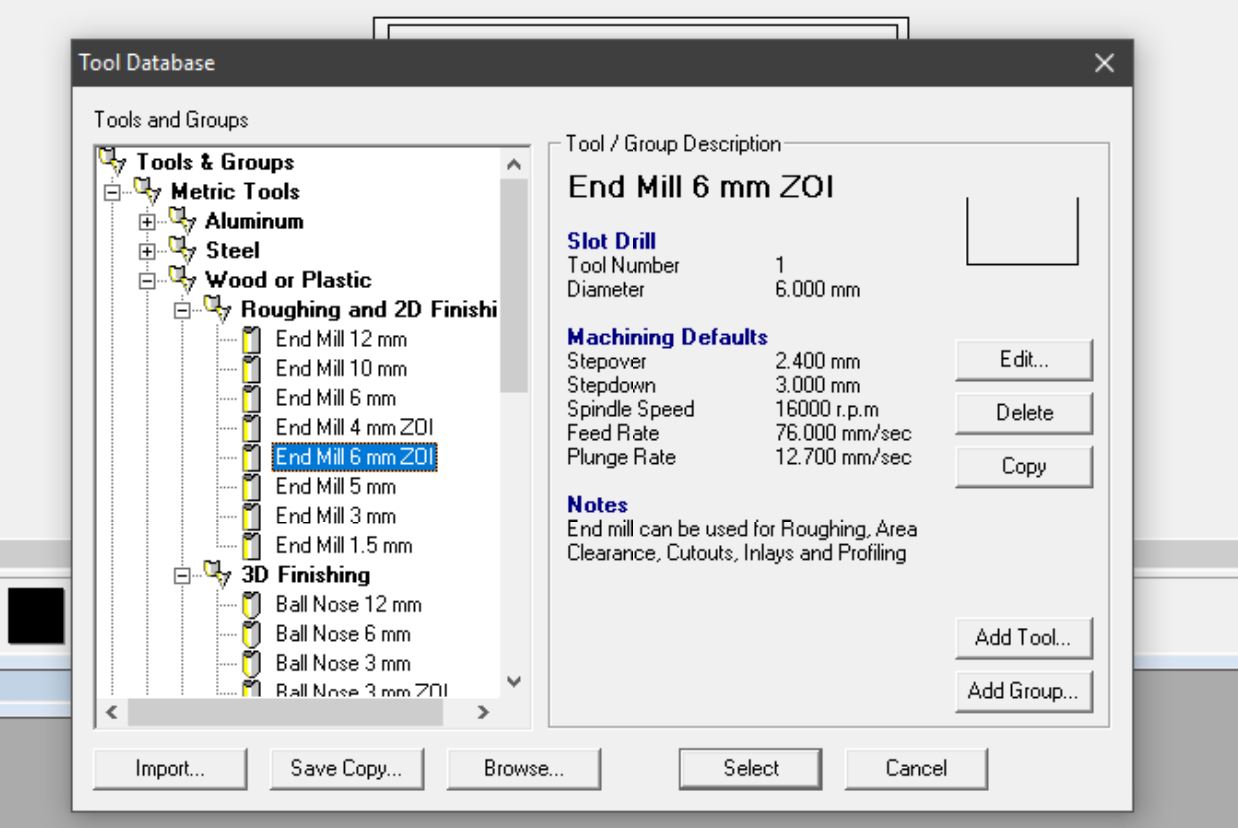

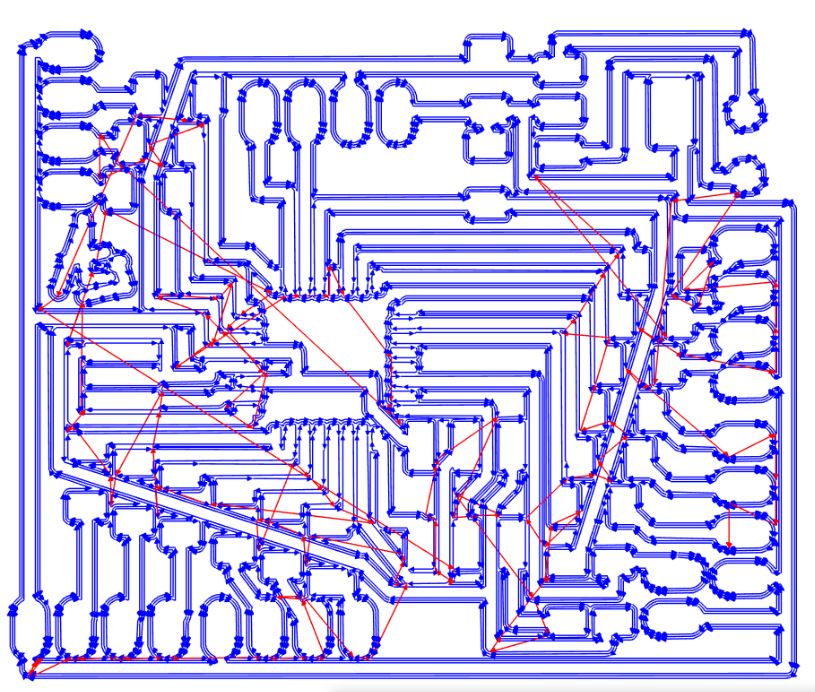

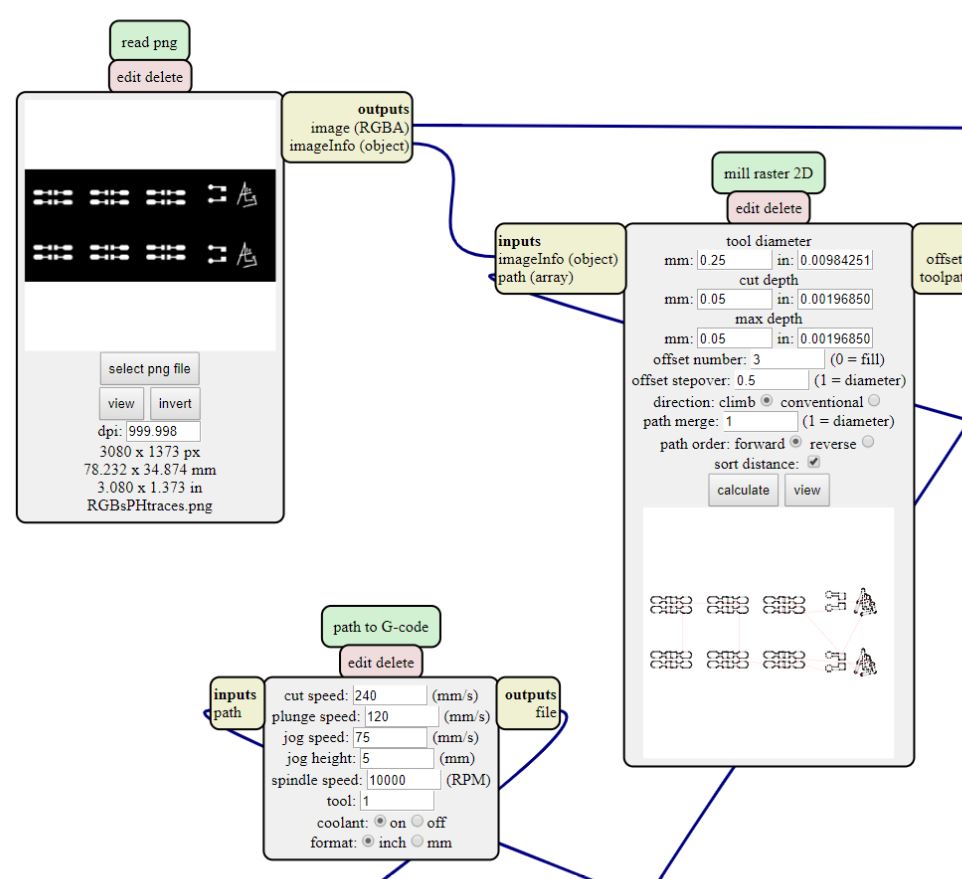

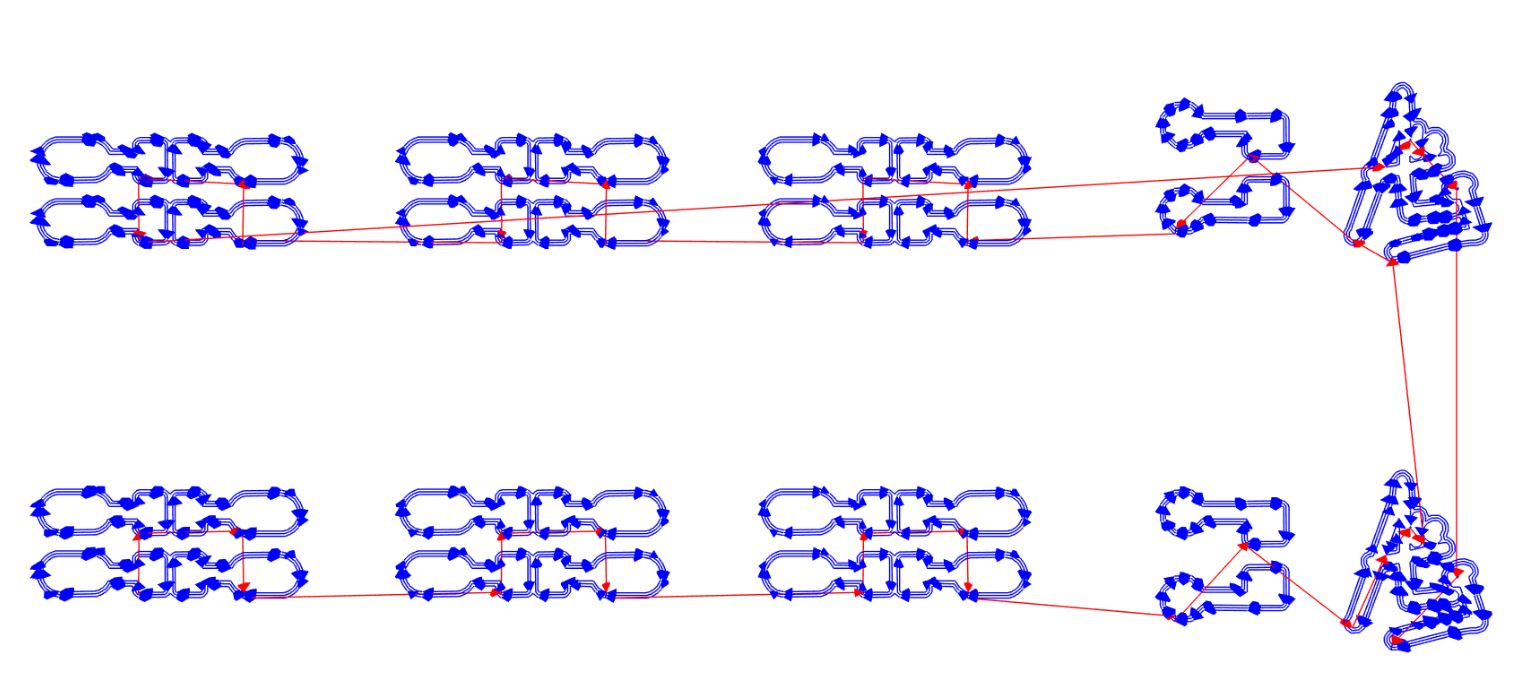

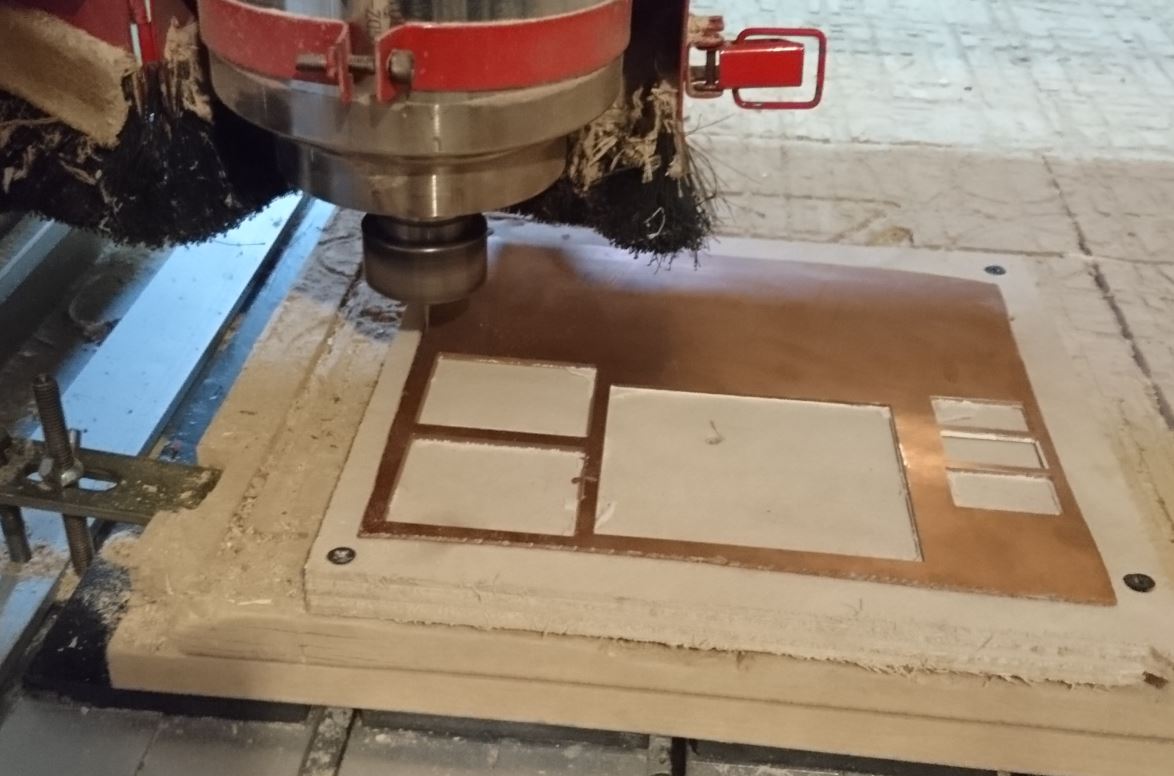

As the starting point for this week, we are going to mill a PCB. In order to do this, and in order to understand it, Roberto was teaching us how mods works, and how to use it to get the g-code from a 1000dpi png by establishing parameters for the toolpath.

The parameters we will use are:

The design rules and recommendations for PCBs can be found in this link from the University of Sevilla, (this link was also taken from Alex’s page).

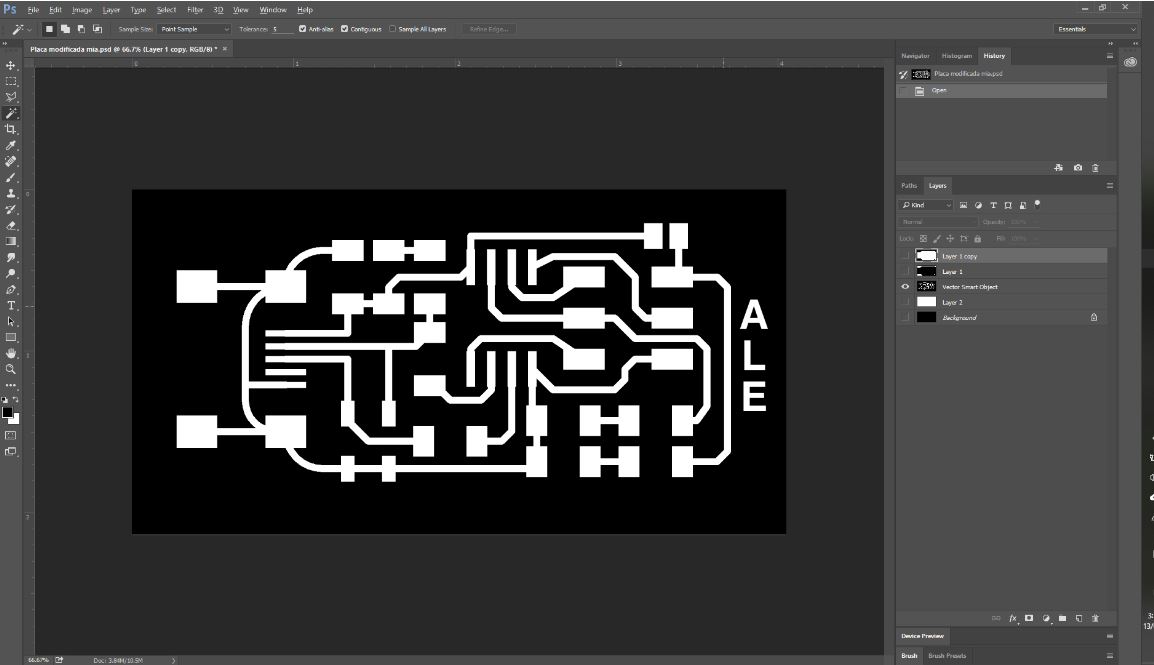

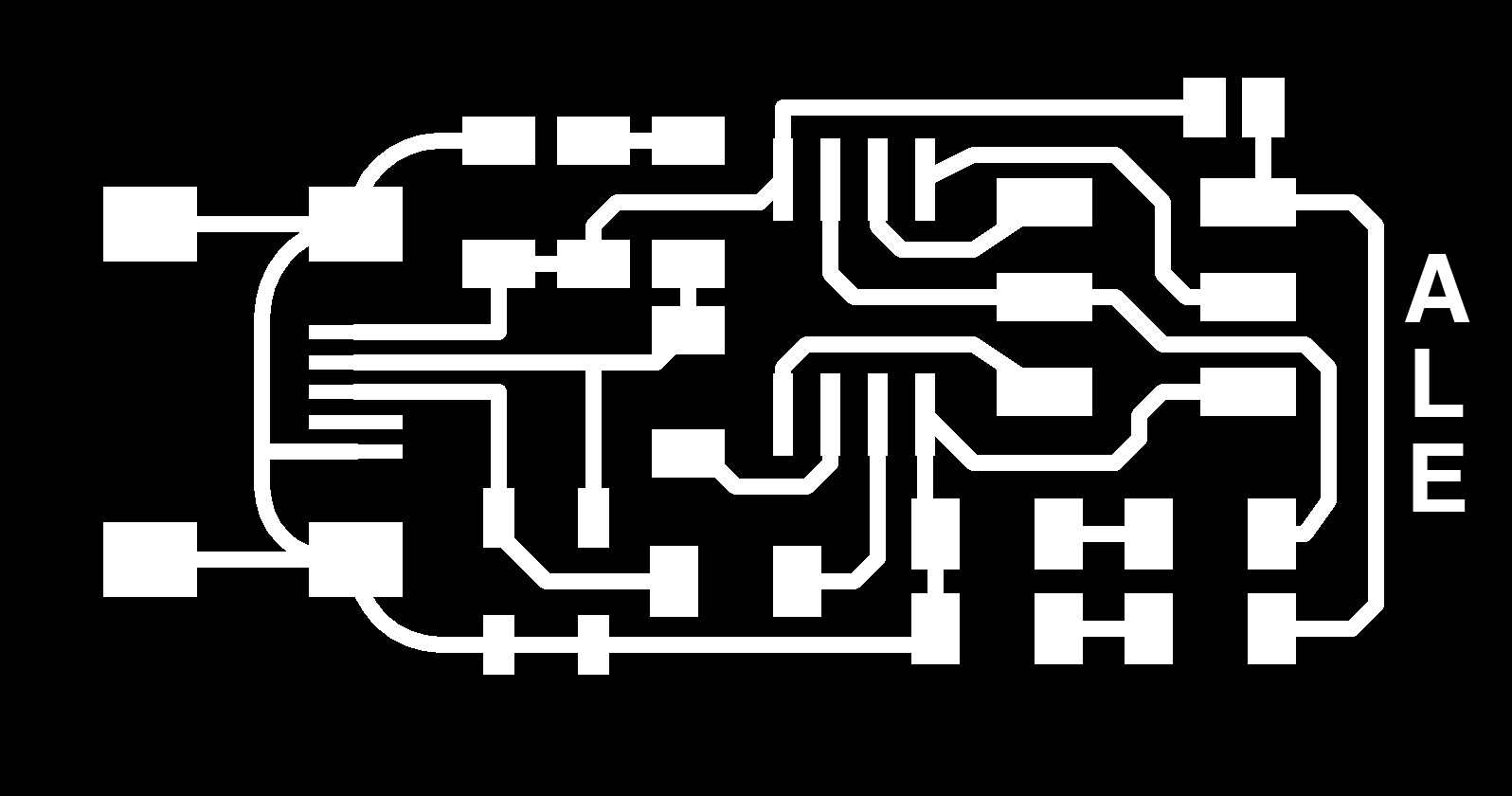

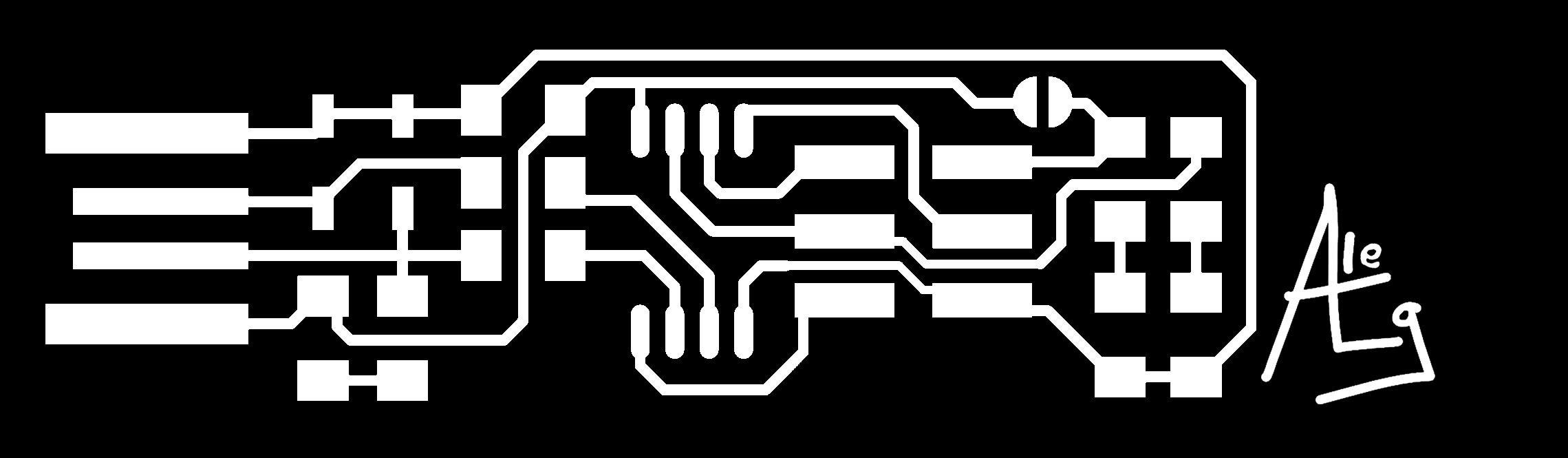

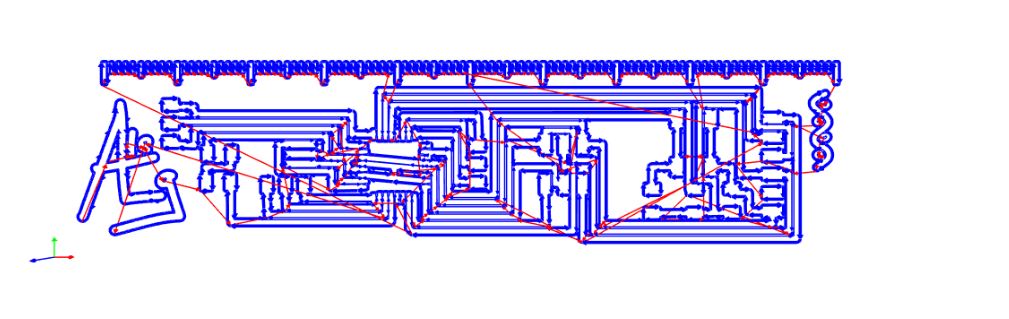

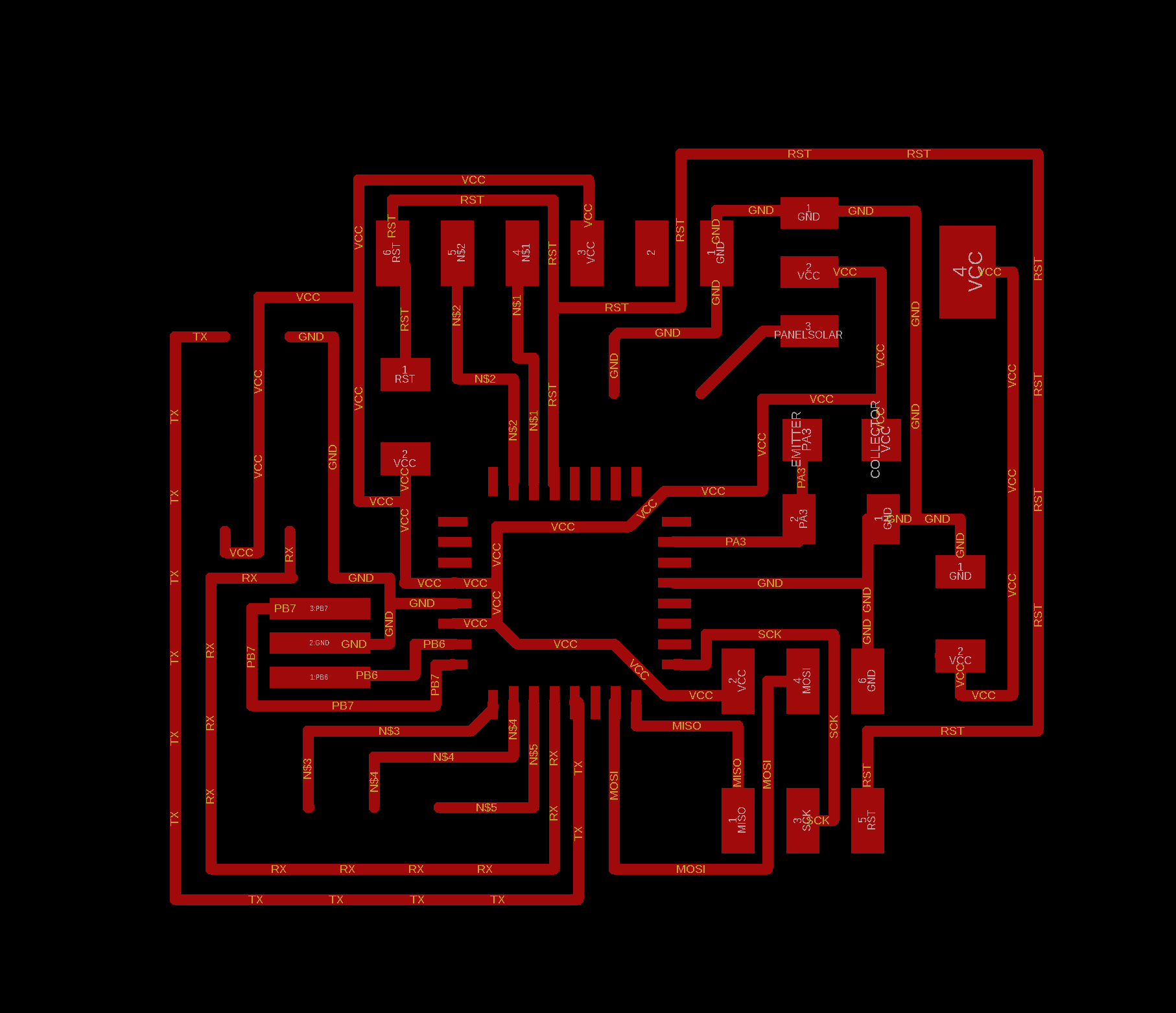

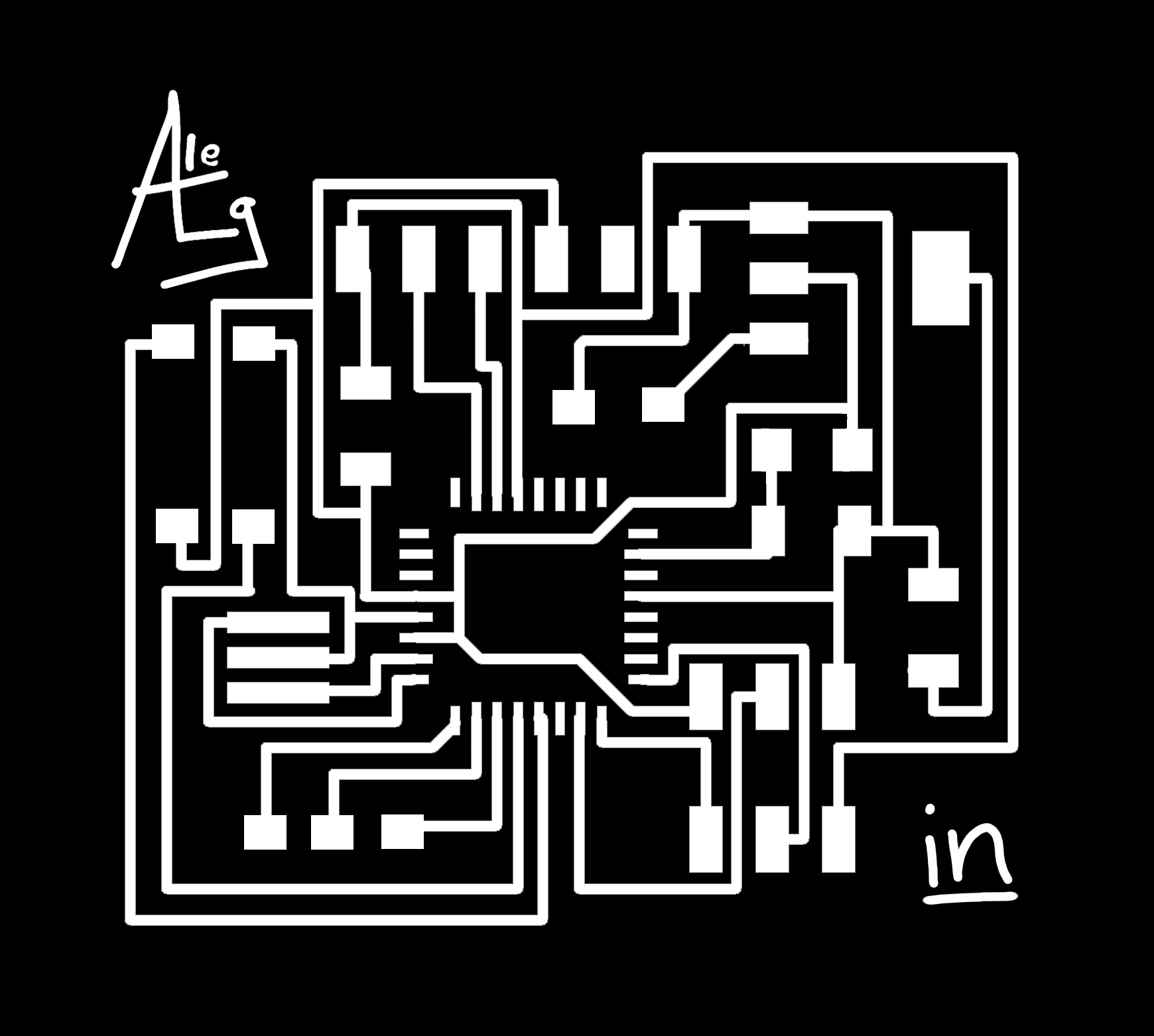

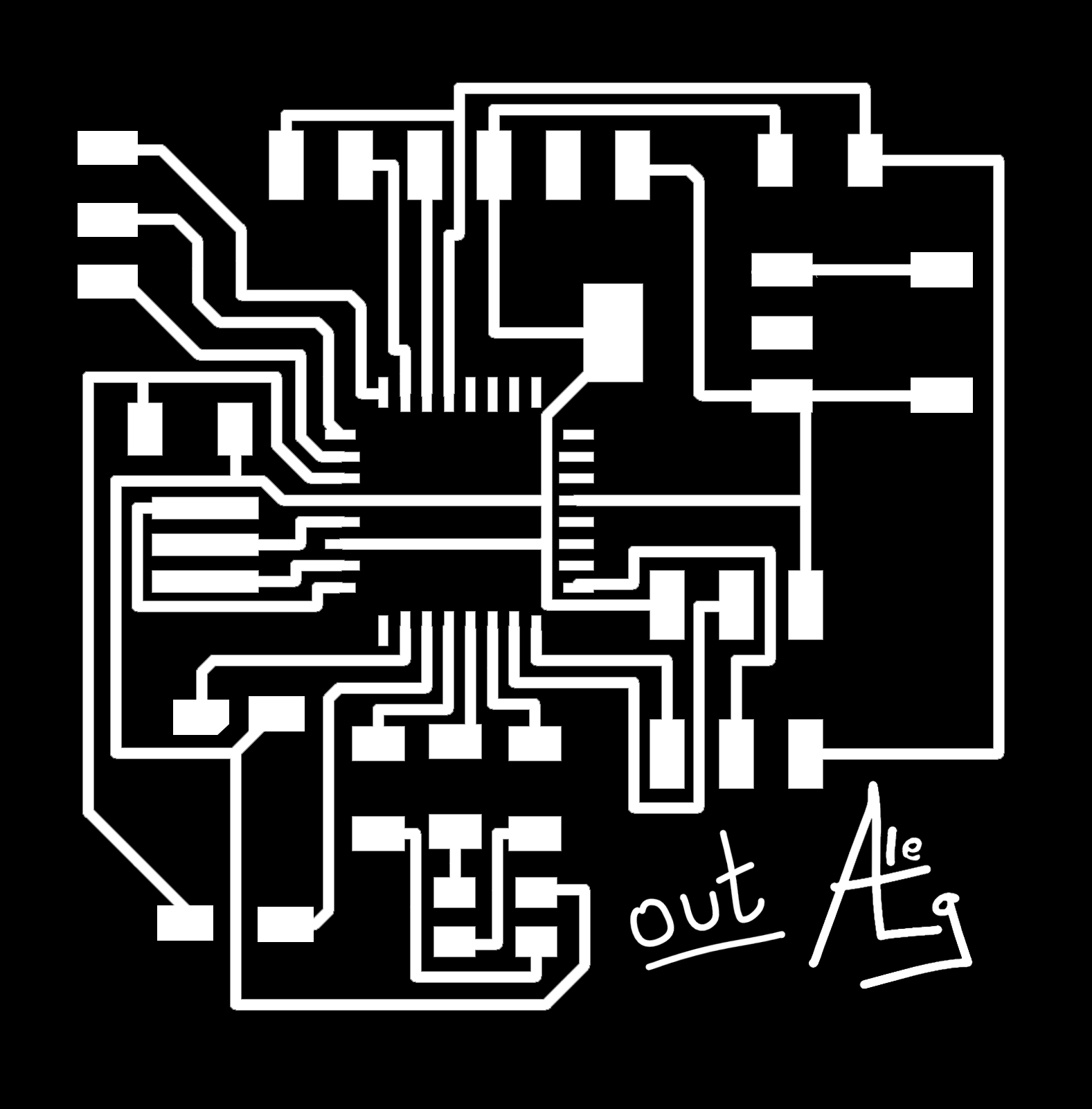

After that, we downloaded Alex’s PCB and modified it a little bit (nothing from the circuits, just the text and layout in order to make it our own) and prepared the outline and the trace. For this, I used photoshop, although I had some trouble as when I tried to open the original file and modify it, the program didn’t allow me to create any more layers. I wanted to use layers in photoshop in order to make sure that the outline and the trace went well together, as I modified the size of the board.

After trying it out a little bit, I embedded both files into a new file, and that way was able to work in layers. I added my name at the side, changed the outline just a little bit, and then saved the files in 1000 dpi and loaded them into the mods G-code mill 2d png program.

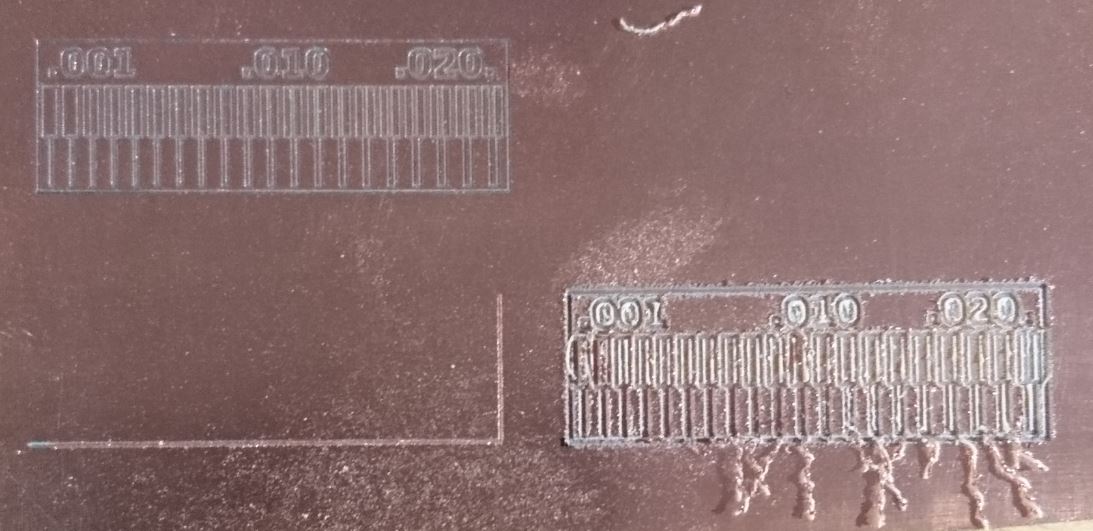

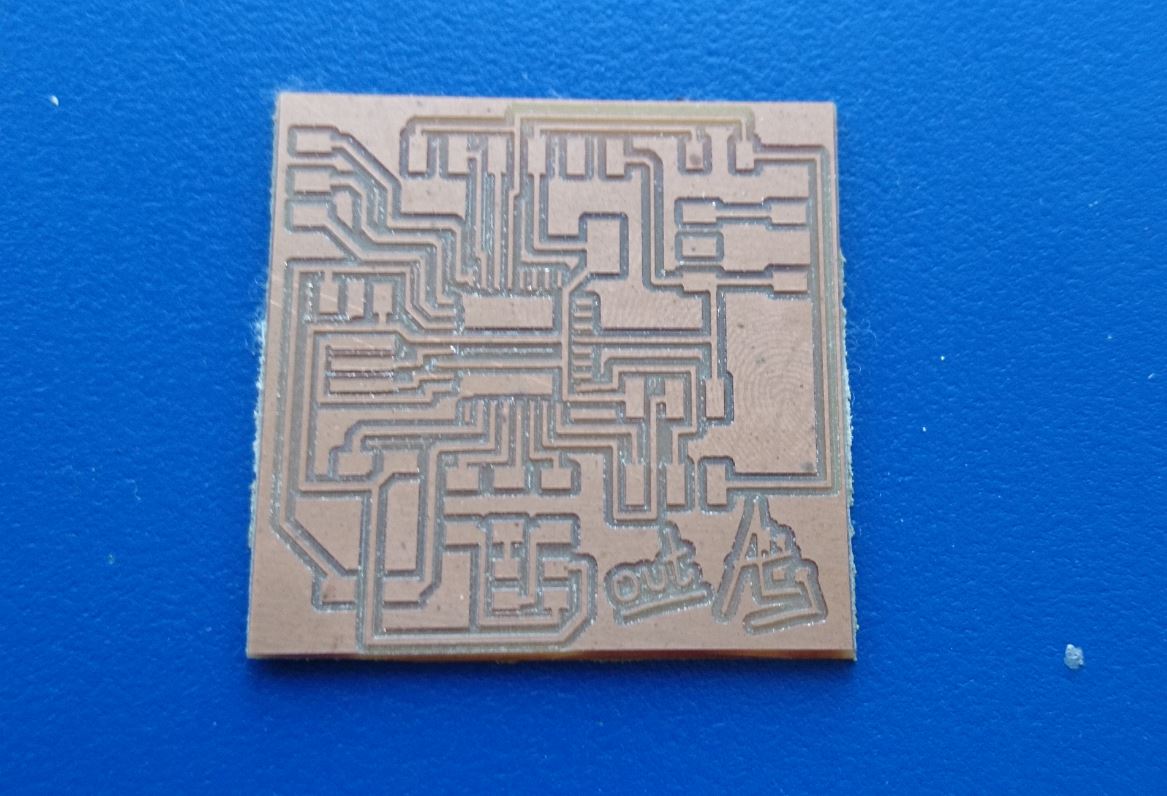

When using the CNC machine, we tried out different PCB mills which had just arrived. The one that the lab had used before (that is 60°) worked amazingly well and had great resolution when doing the test file. The new mill (30° point) was very good, however we still have to test out the distances and configurations for which this mill would work optimally, as the result was still not as good as the other one and it seemed to be cutting in too much of the material.

We use these v mills (as opposed to the flat ended ones that are the recommended ones) because the others are very hard to acquire in Ecuador. However, a new shipment to our fab lab in a few weeks will probably bring some.

Also, here are some drawings trying to understand what happens when there is a difference in the size of the mills configured in mods and the actual size of the mills used to cut. Apparently, the size we configured in mods for the g-code was a little smaller than the actual size of the mill we were using, so the paths turned out a little thinner than we expected.

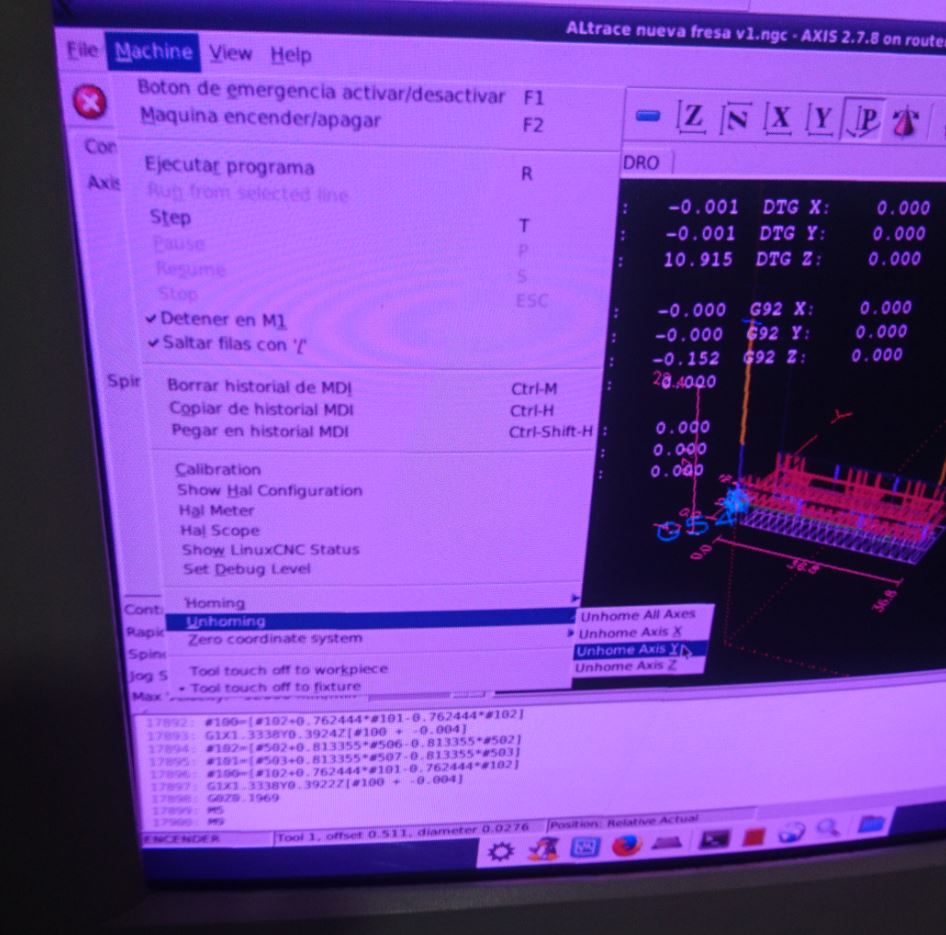

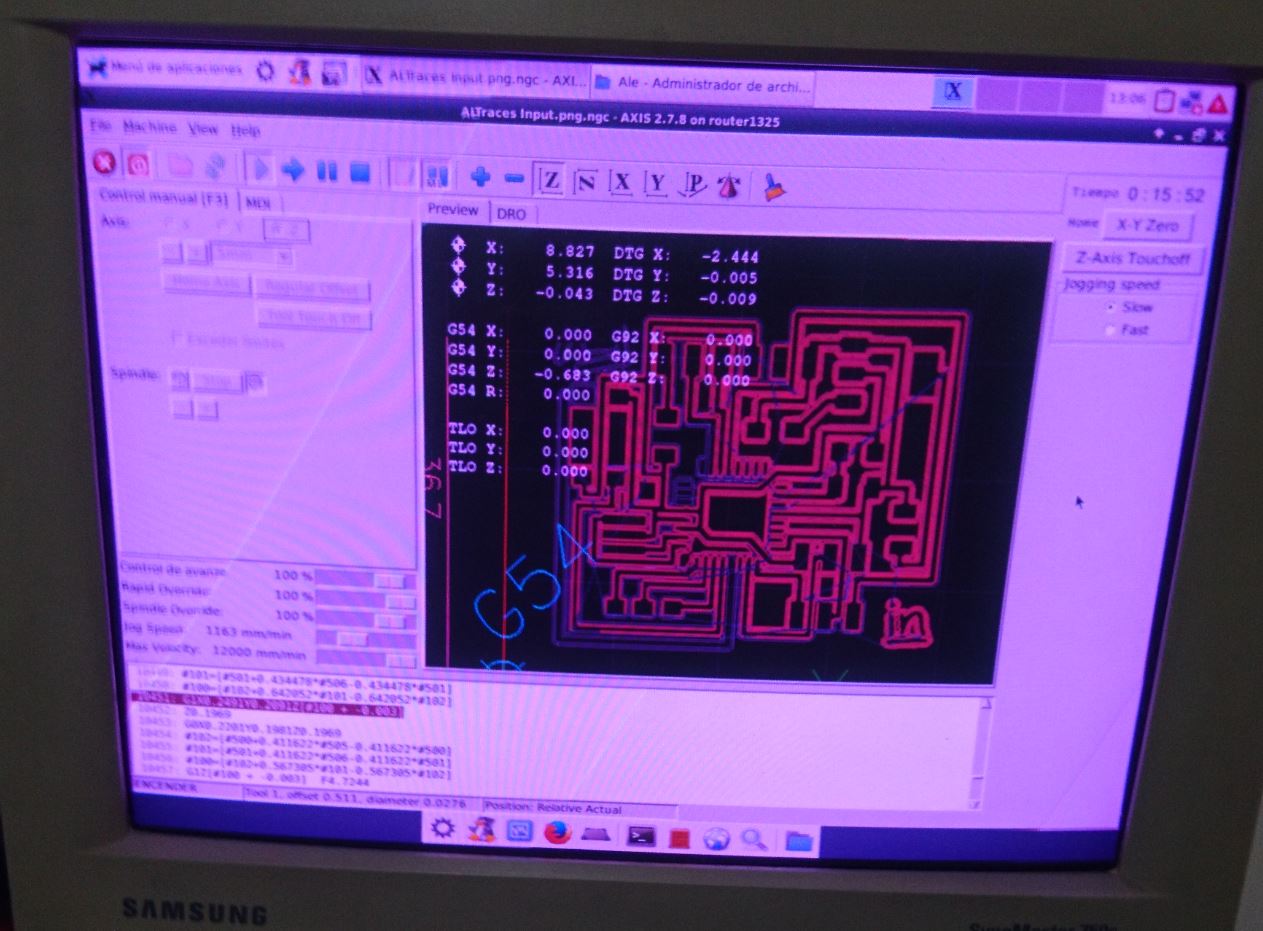

Finally, we used the CNC to cut out our PCBs, and I really liked the result of mine. Roberto and Alex taught us about the process and the steps that should be taken in order to use the CNC. They are as follows:

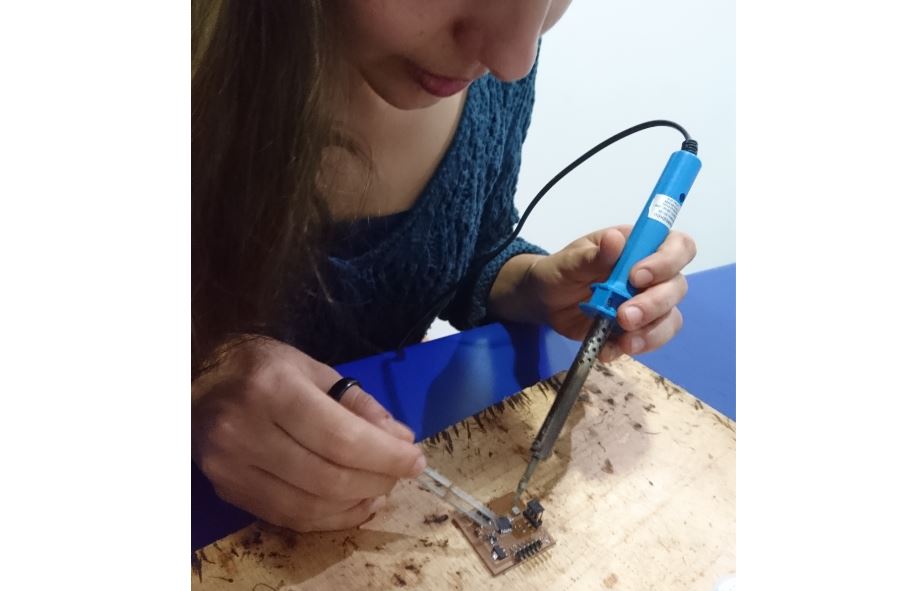

We had the rest of the afternoon after having made the png and the g-code for milling the PCBs. As the CNC machine was in another office, we decided that the remaining 2 hours we were going to start learning how to solder. Roberto and David were teaching us first the theory and then the practice of soldering, and telling us about all the necessary precautions. We used a few old PCBs and where soldering and de-soldering components on to it. They say it takes a lot a practice, and it sure looks like it as the components are so tiny and hard to work with.

The hardest part was trying to solder each of the legs (?) of the components, as it had to be done individually but the drops of tin were very large.

It was a very good practice, an I think it was very helpful to do this before actually trying to start soldering our own PCBs, as it gave us room to make mistakes and try again without damaging our boards.

Another of the exercises we were told to work on for this week was to make a Satshakit. I still don’t know exactly how that works, but I will soon read up on that. For now, we downloaded the files that Daniele Ingrassia loaded on this page and after verifying they were 1000dpis we loaded them on the mods program and got the g-code.

I prepared the g-code files and saved them, however, we first must finish the first PCBs before making the sashakit, therefore this exercise may be completed later.

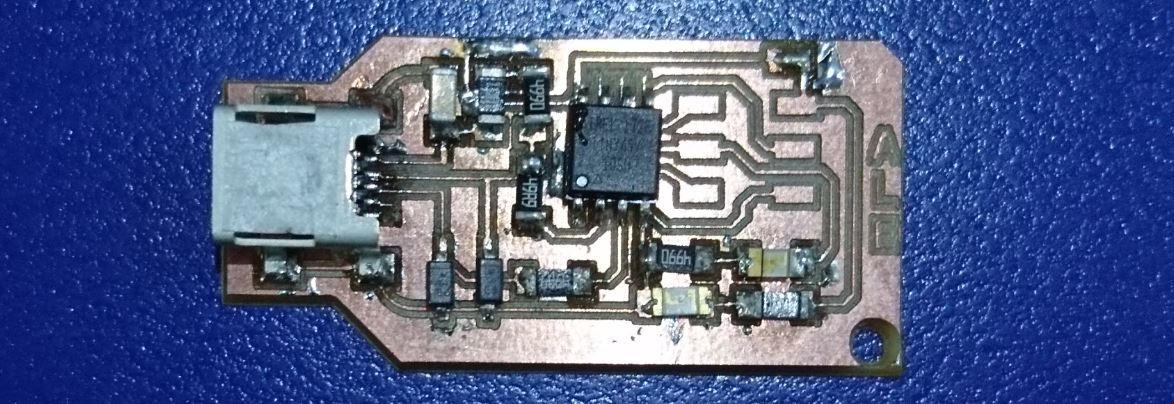

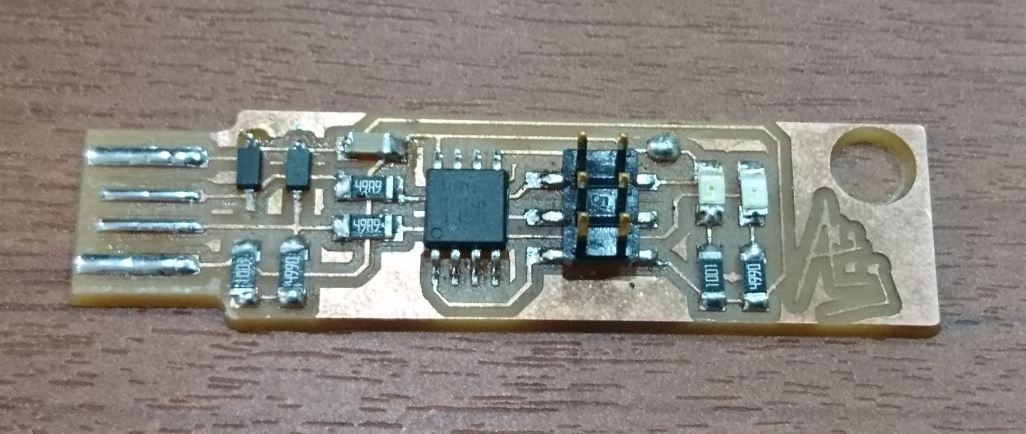

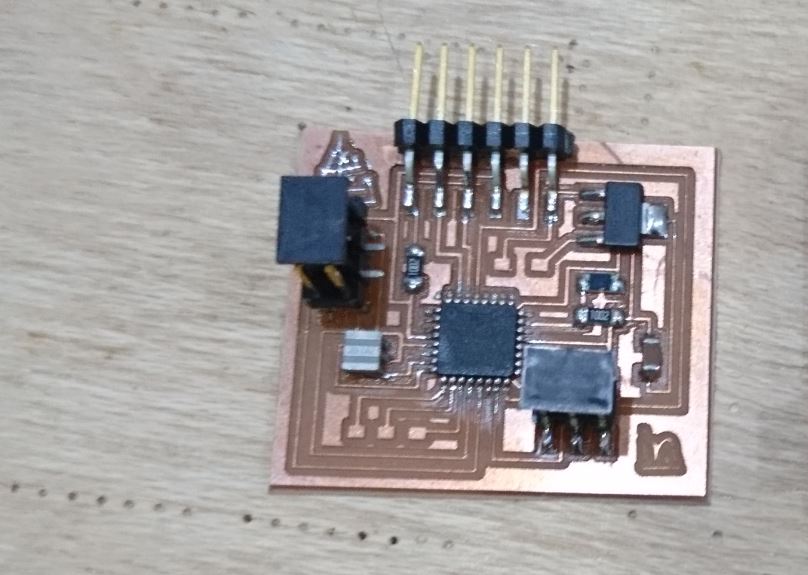

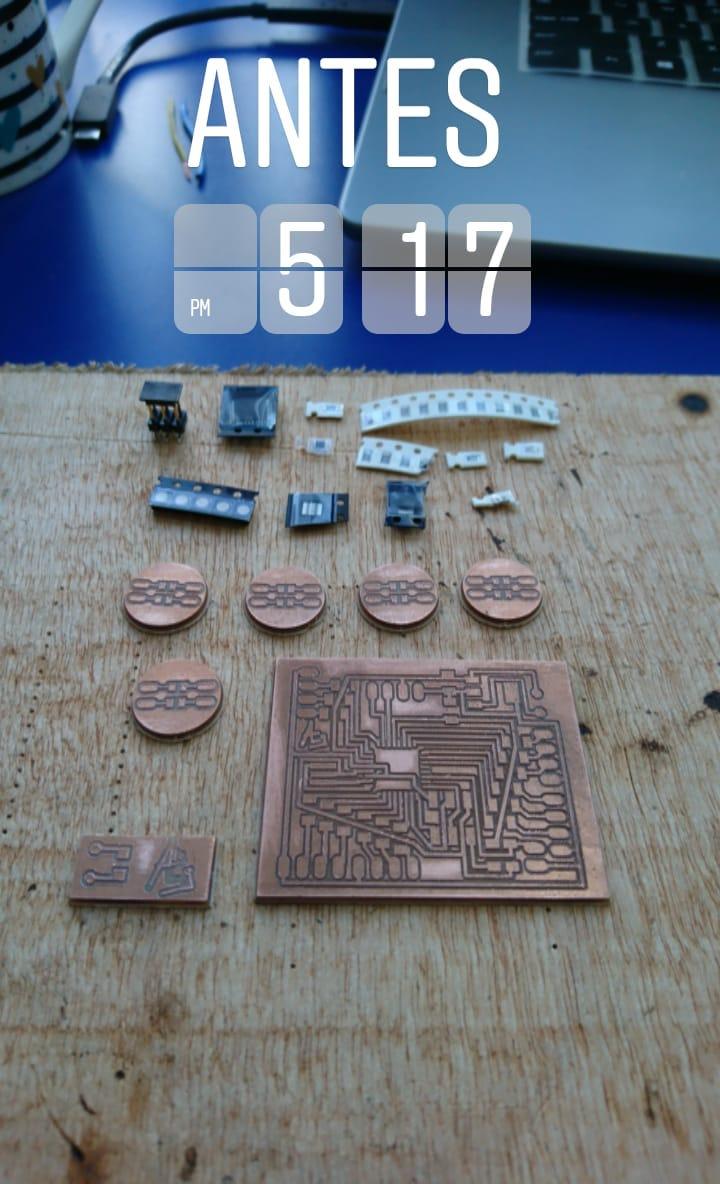

The soldering process was harder than I had imagined. First, we laid out the components in order following the list on Alex’s page. Once that had been done, we followed the instructions and tried to make sense of the circuits on the page to see where each component should go. Luckily, Alex was more than happy to help us, otherwise that seemed like a really hard puzzle.

I started soldering the components one by one and had many problems such as the tin running around and messing up the paths, the components not wanting to stay in the place, and the microprocessor refusing to line up agreeably. However, after a little more than an hour of trying to make all the components stay in their place, they did and I had my very own PCB which may (or may not) work. Problem: part of the copper in on of the paths peeled off. Solution: Alex helped me, by teaching me how to use a tiny piece of copper to connect it using tin, and created a sort of bridge which helped solve the problem.

The materials (components) used (taken from Alex’s PCB page):

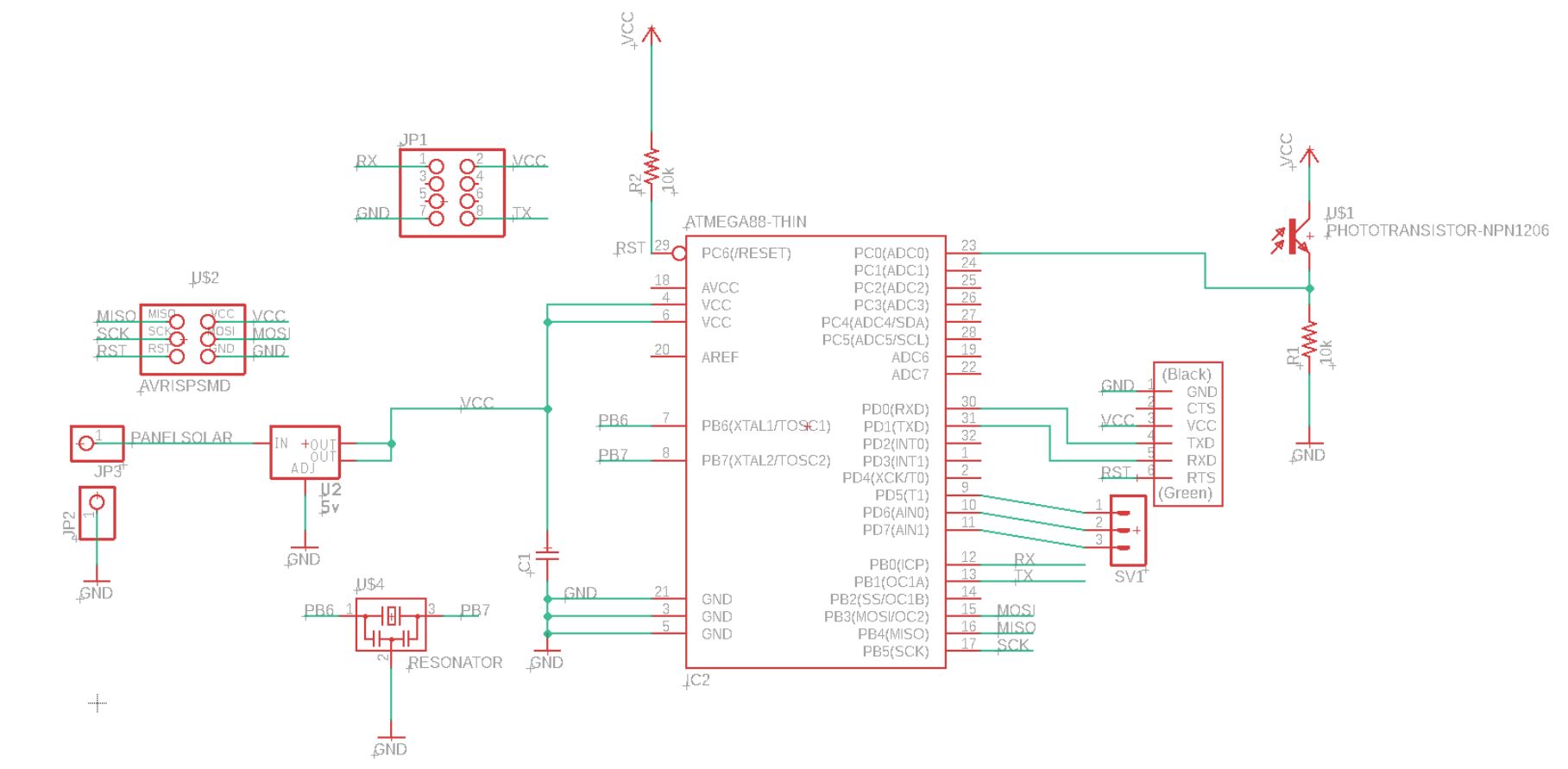

The way they were soldered is according to this diagram:

and this circuit:

The diagram was sent to us by Alex, and the circuit image was taken from his page. I understand very little of how this works… but hopefully during the next weeks I will understand better.

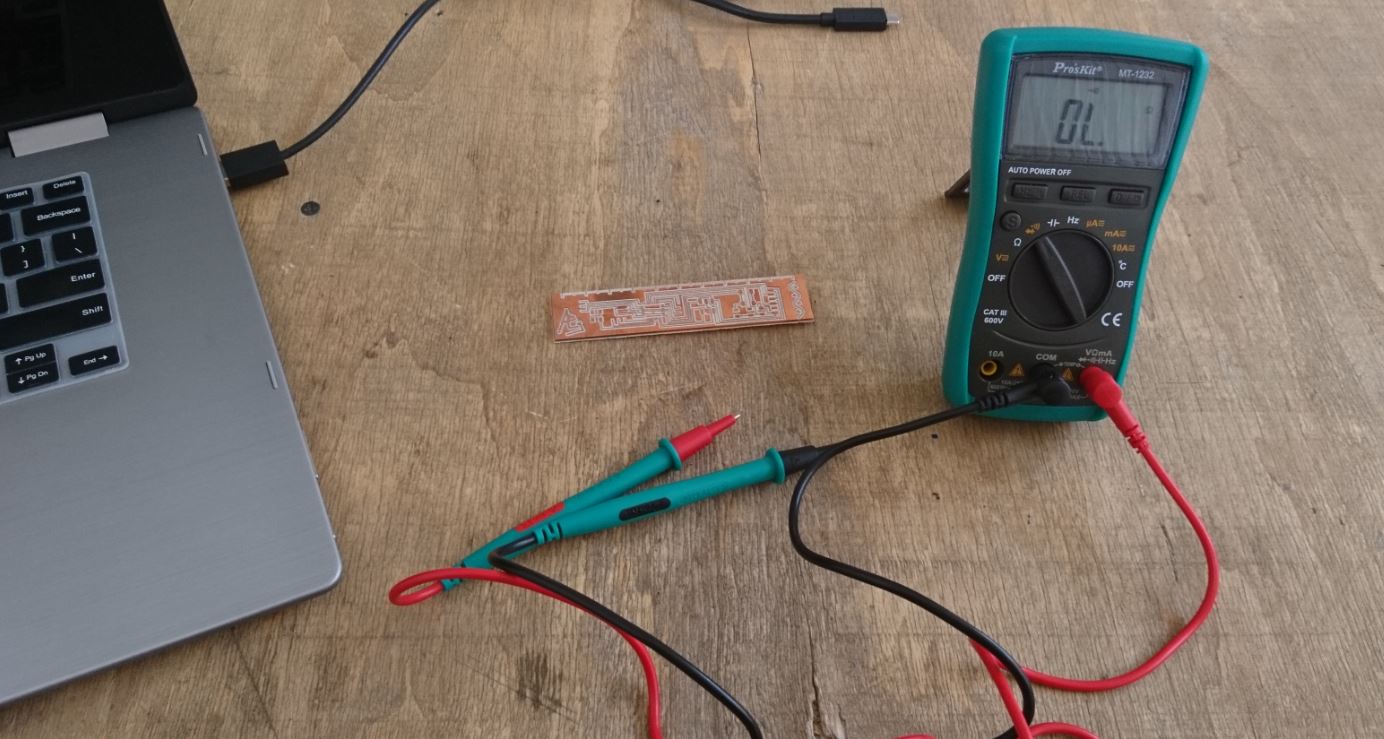

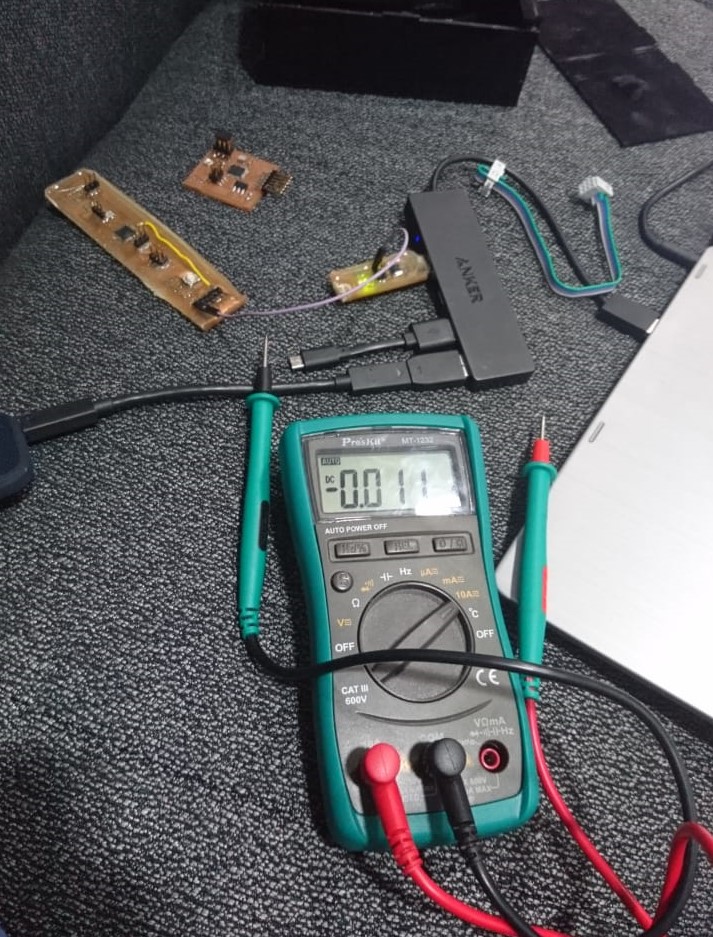

Now onto the next steps: verifying that everything is connected right and seeing if it works!

After having soldered everything, it was time to make sure that everything was soldered correctly. I started checking the circuits, and by Roberto’s recommendation followed the diagram of the circuit and started painting (in photoshop) over the circuits that where working correctly, to not get confused. By doing this, I noticed that some of the circuits that led to the microprocessor weren’t attached properly, so I fixed them, which wasn’t that difficult.

However, the problem began when I checked the circuits leading to the micro usb adapter. That was one big headache, as some of the circuits seemed to be right at the bottom of the USB but when checking to the top part of the “leg” of it, there was no connection. Trying to remedy that, I added more tin, which proved to be a very bad decision as that made all the legs stick together in one big mess. There was nothing left to do but de-solder it and try soldering it again, and it was even more complicated this time considering that some of the copper of the circuits peeled off. However, with a lot of patience and by making tiny bridges with copper wire, everything seems to be properly connected now, as verified by the electric current meter.

The next step: programming the board.

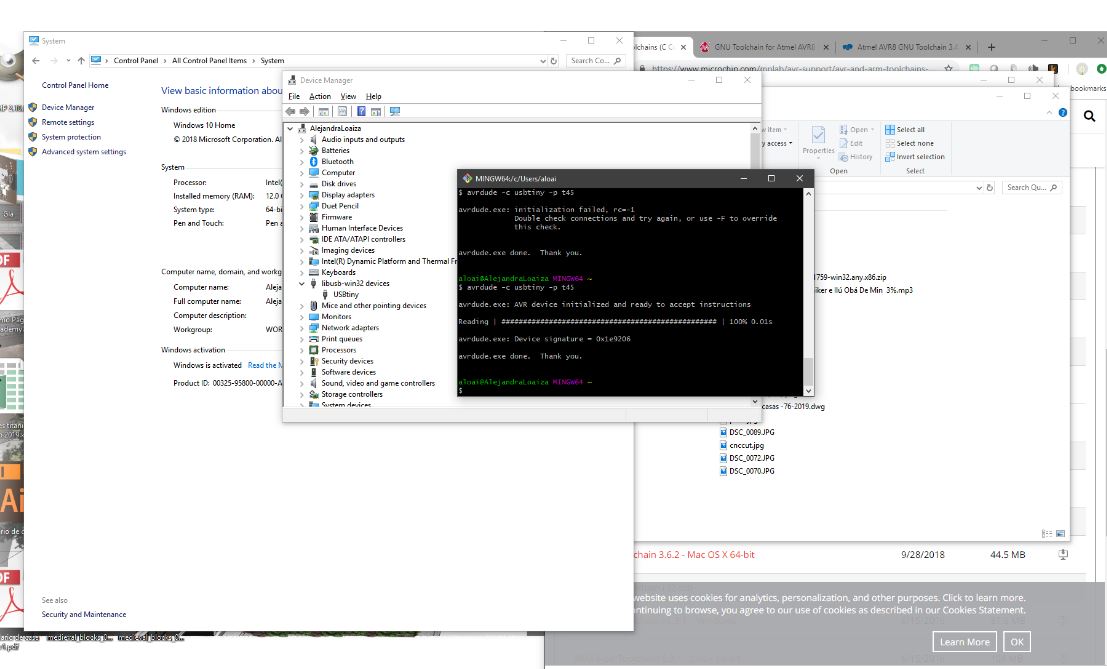

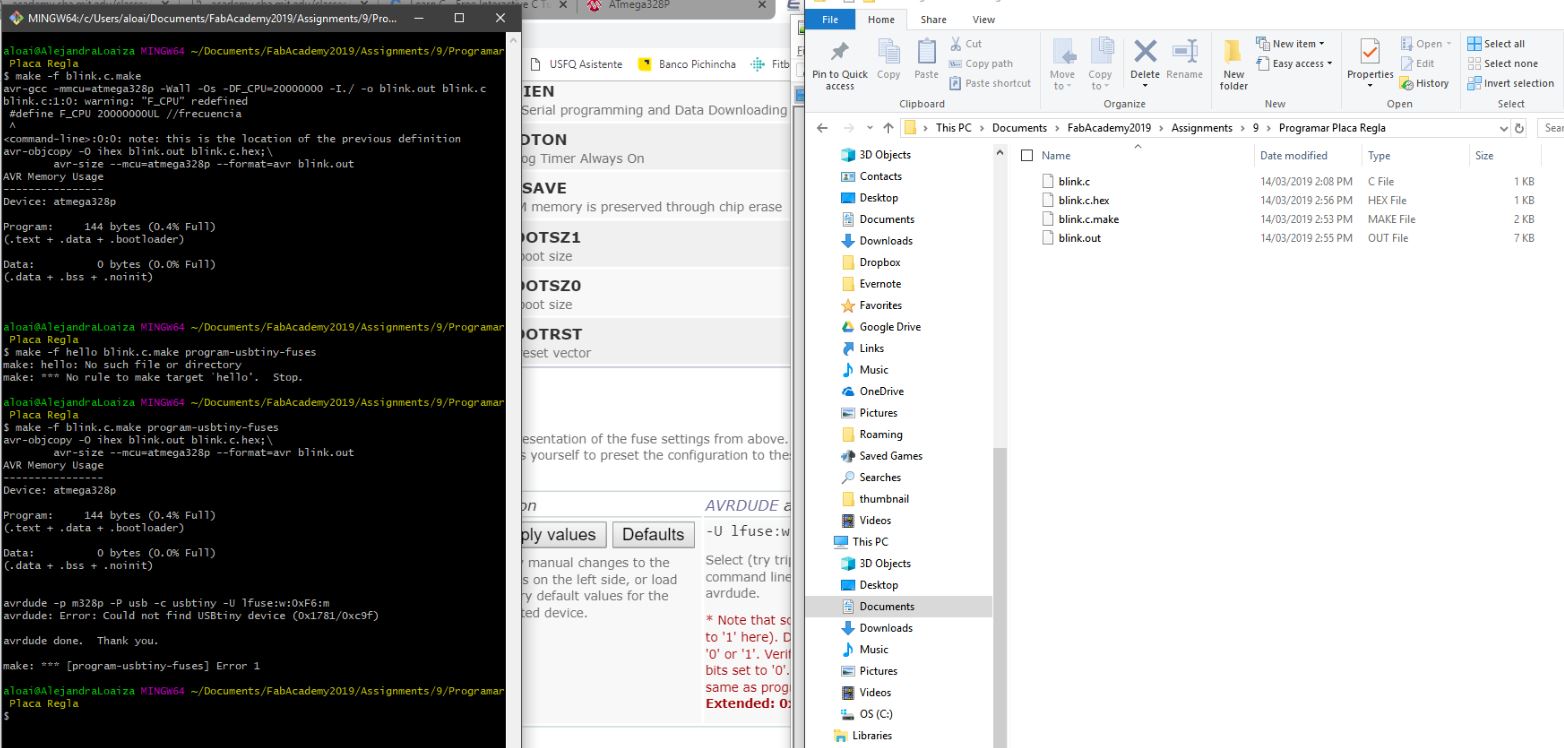

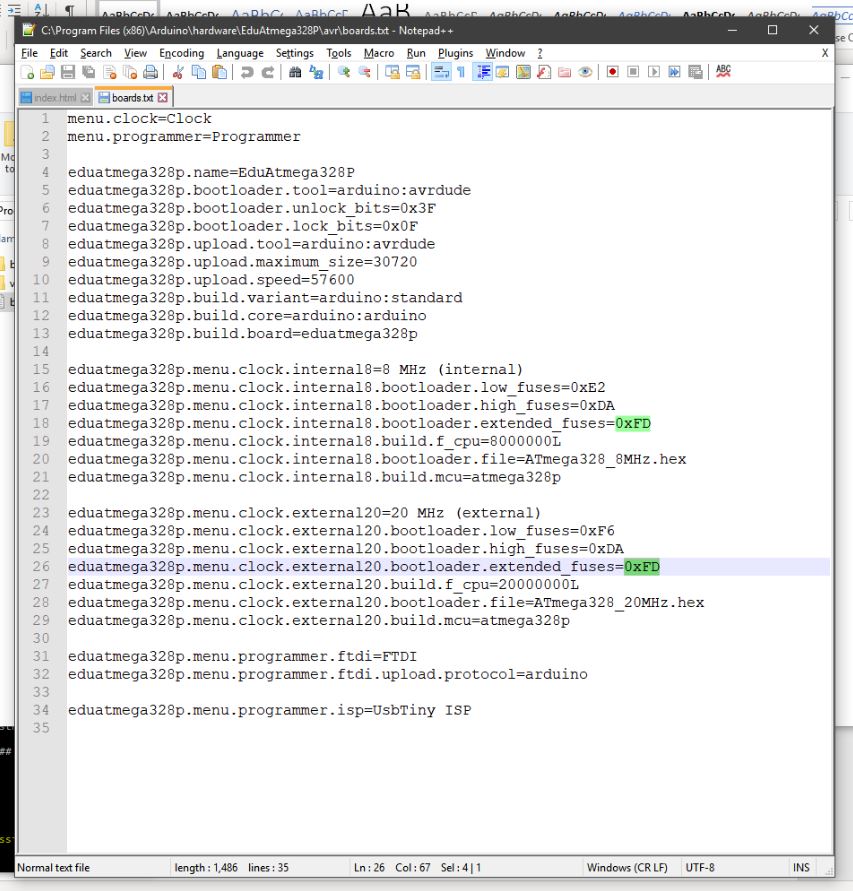

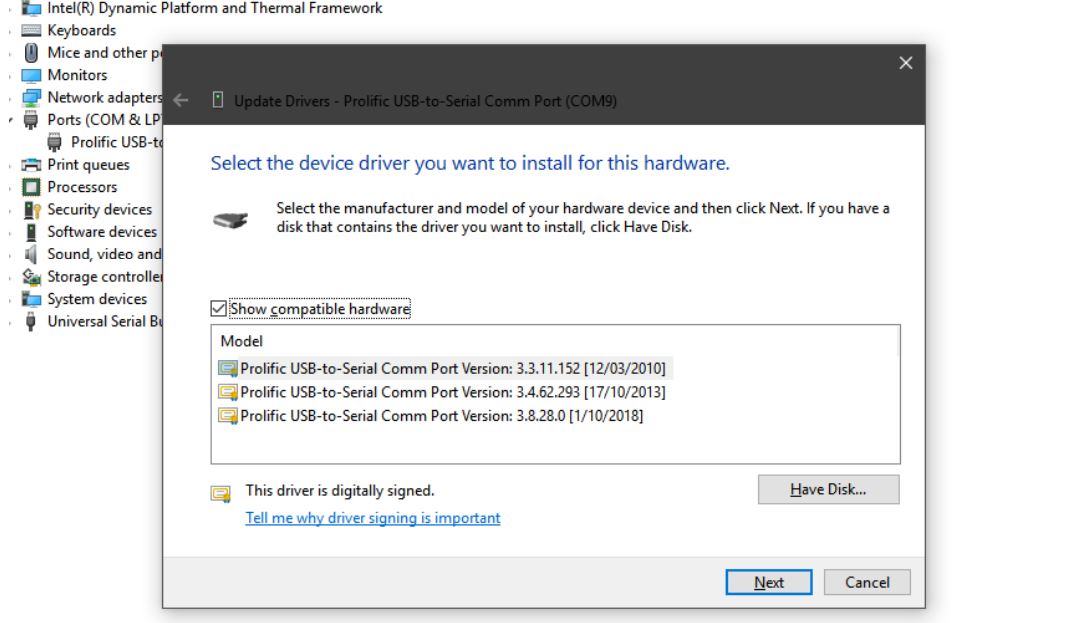

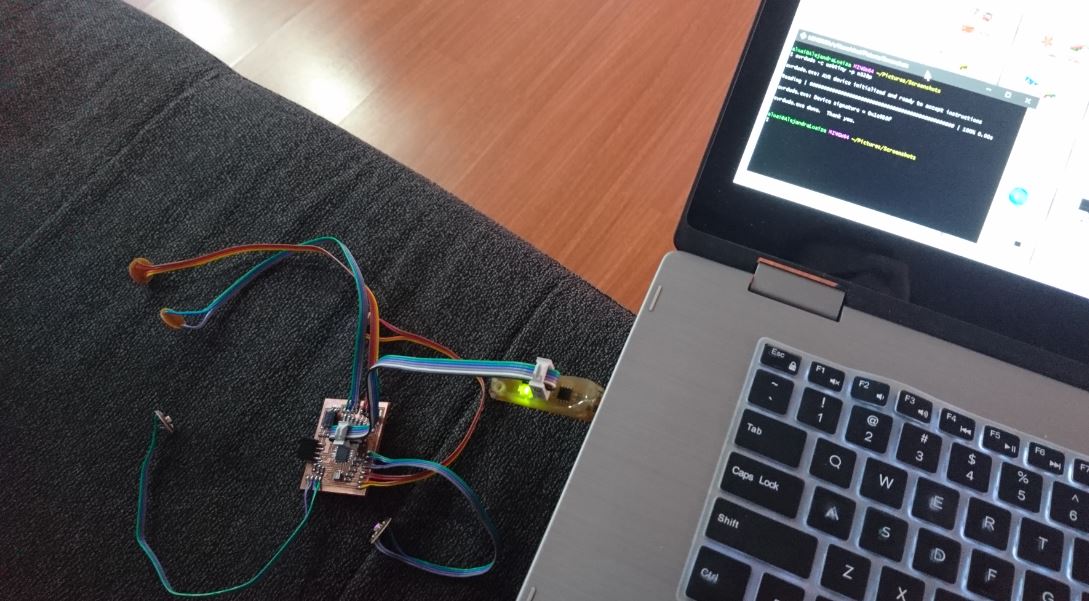

Now on to the final test: programming the board.

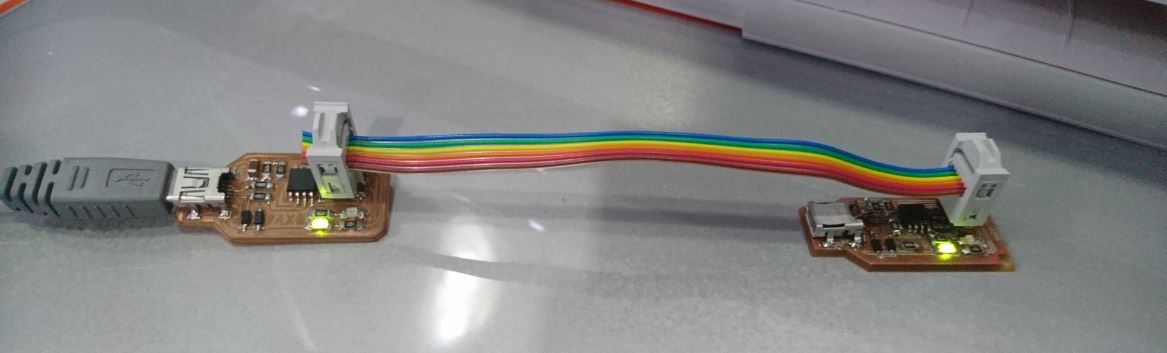

We used Alex’s board which was already configured and had the same design as ours to program our boards.

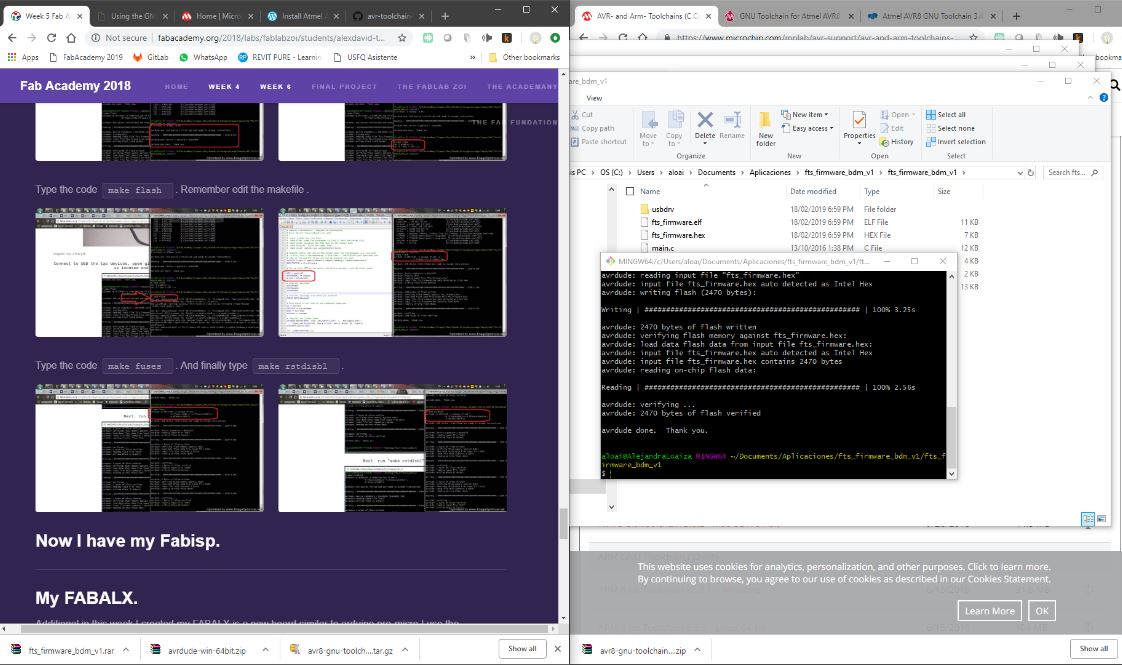

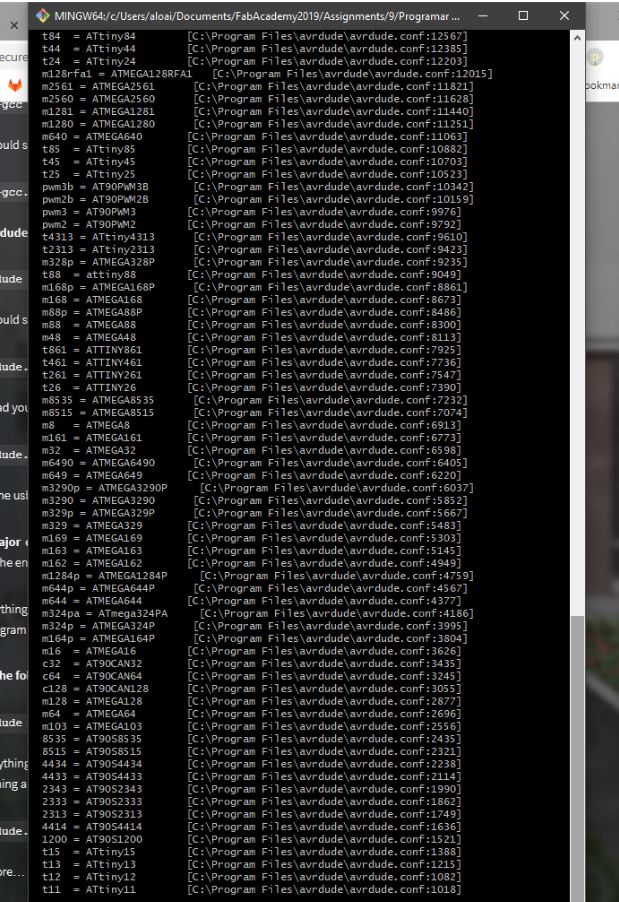

However, before doing all of this, we had to download and install some files in our computers, and change some settings. His was done following Alex’s guide which in turn was done following this guide.

The steps are as follows:

Then, inside start menu > control panel > system > advanced system settings > advanced tab > environment variables > edit the PATH variable, both in the user variables and in the system variables.

Add the following variables (paths) :

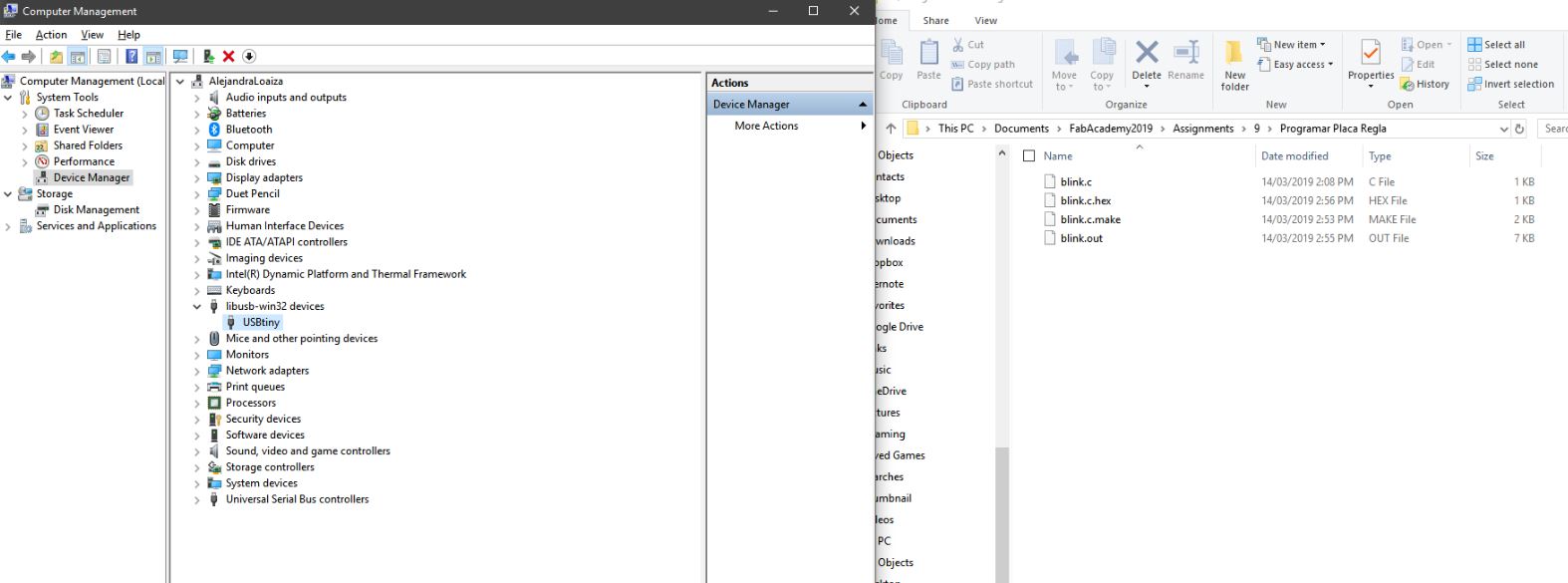

C:\Program Files\avr8-gnu-toolchain\binC:\Program Files (x86)\GnuWin32\binC:\Program Files\avrdude*Then, I installed the driver, which was done using a file that Alex sent us.

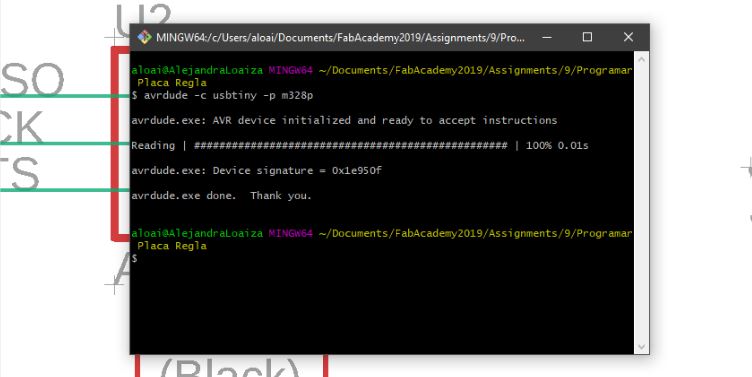

Then, I did a check through git bash to verify that everything was working accordingly, by entering the following codes.

For make enter:

make -vYou should see

GNU Make 3.81

Copyright (C) 2006 Free Software Foundation, Inc.For avr-gcc enter:

avr-gcc --version You should see:

avr-gcc.exe (AVR_8_bit_GNU_Toolchain_3.5.4_1709) 4.9.2For avrdude enter:

avrdude -c usbtiny -p t45You should see:

avrdude.exe: initialization failed, rc=-1If instead you see:

avrdude.exe: Error: Could not find USBtiny device (0x1781/0xc9f)when the usb programmer is connected, check the usb driver installation.

Any major differences to the above codes and responses indicate problems, and you must check the environment variable settings.

If everything seems ok until now, you can follow the next steps, when your board is connected to the programmer board and the programmer board connected via cable to the computer.

Write the following code to start:

avrdude -c usbtiny -p t45This code helps you communicate with the micro. If everything is right in your board (the connections, the programmer board, and the code), something along the following lines should appear:

Avrdude.exe: AVR device initialized and ready to accept instructionsand more…

If you get this far, the board, the code, and the programmer seem to be working properly!

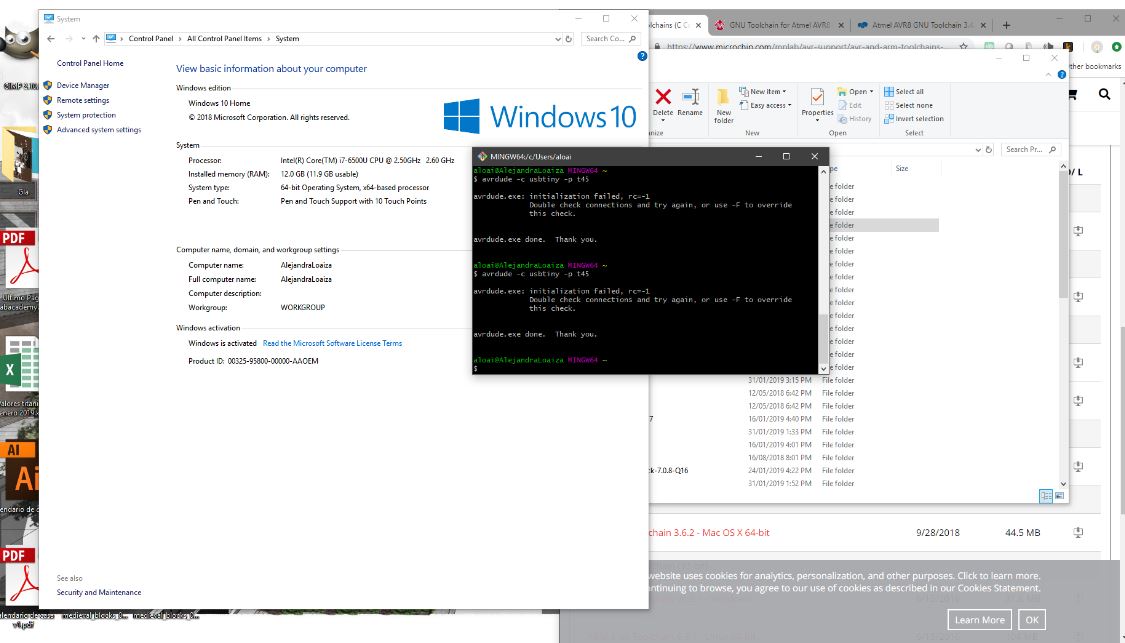

In my case, it took a long time to be able to do this. The first mistakes were that I couldn’t find where to download the files, so that took excessively long. Then, when finally downloaded, the environment variables (and therefore checking in git bash) didn’t work, as I had only changed the paths in user variables and not in system variables as well. Then, when connecting my board to the programmer board, it refused to recognize it, as there was a connection problem somewhere in it and I had no idea where. After checking it, de soldering and then soldering some things again, we found a connectivity problem between the microusb port and the rest of the board, so we removed some of the surrounding copper and then, finally, it recognized it and worked.

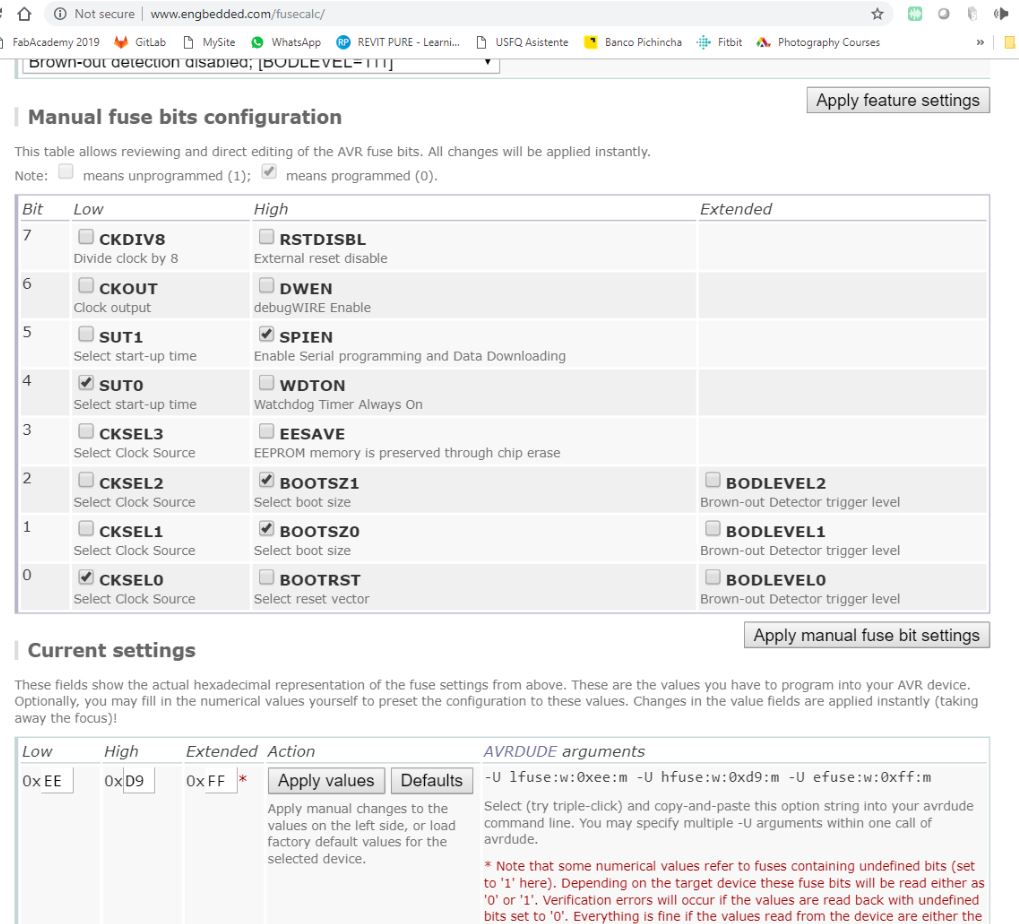

So, once that is all set and ready, enter the following commands and let them run in order (as long as everything seems to be working correctly):

make cleanmake flashmake fusesmake rstdisbl*Make clean is to clean the board of any previous information it may have had, make flash is to be able to write things on it, make fuses sets the initial configuration of the board, and make rstdisbl is the command that makes it unable to be configured further, so it will always be a programmer.

If everything has worked correctly up until then, congratulations, as you have your very own programming board!

My board worked well and accepted all the instructions. Both lights flashed on it as the information was being transferred. All was going well and worked. Of course, until it just stopped working, and that was it.

As in, it simply didn’t recognize it anymore (because of the make rstdisbl command), but it wasn’t recognized as a usb tiny device. That was very disappointing.

However, seeing as the assignment was done, and the board was programmed, and it worked properly (almost), it was a good assignment.

But that did leave me questioning what exactly it was that didn’t allow it to be recognized as a device. Was it the lack of changing the makefile from usbtiny to usbasp? Was the driver we used not appropriate for this type of programmer?

Alex tells us that it was probably the last command, the “make rstdisbl” as this command is apparently not compatible in some way to this circuit board (which he designed). I tried desoldering the microprocessor and soldering a different one, but that didn’t do the trick, as apparently the other one had been programmed in the same manner.

All that is left to do is to create another PCB (probably with a design that is easier to solder), and try the same process again, being more careful with the coding steps. However, for the time being, I will work on catching up with the previous assignments (especially the parametric modeling) which I have yet to do.

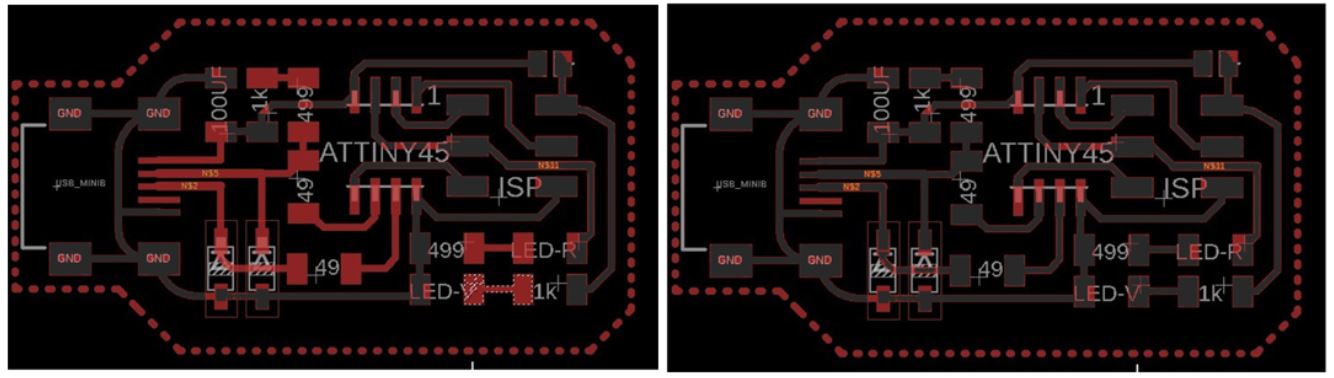

Seeing as the assignment had been done (as the board had been made successfully and it had been programmed), but I was still left without a programmer, I had to create a different one.

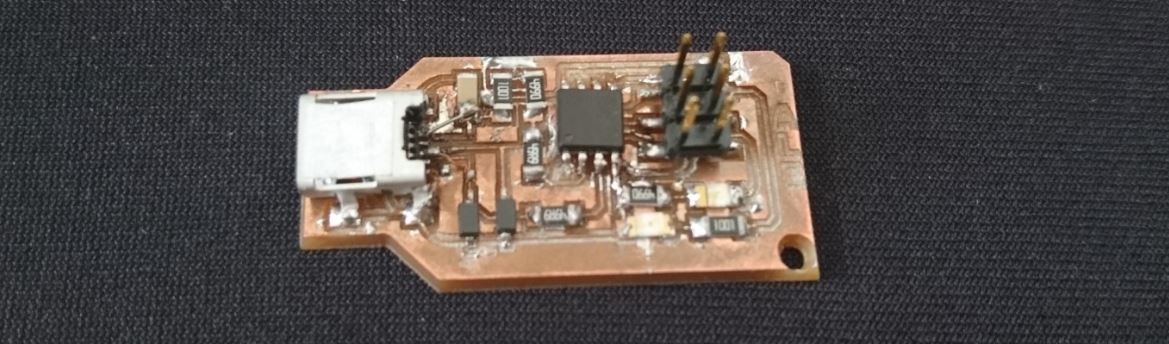

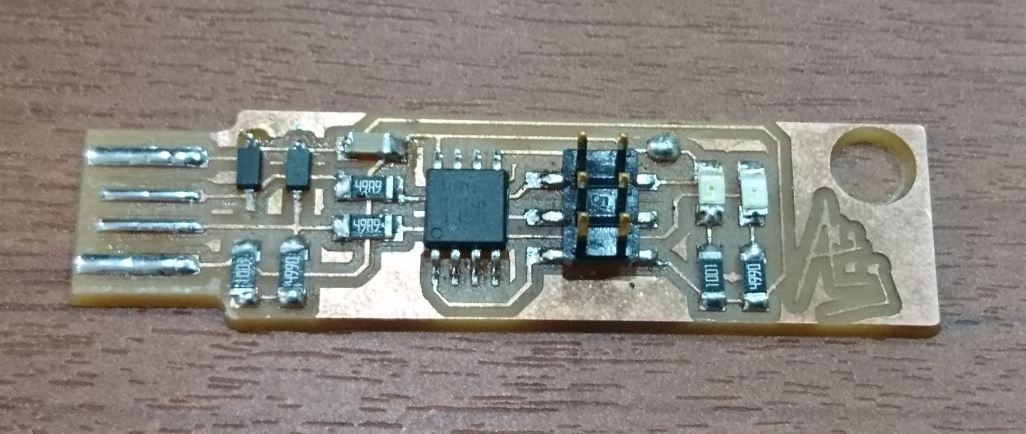

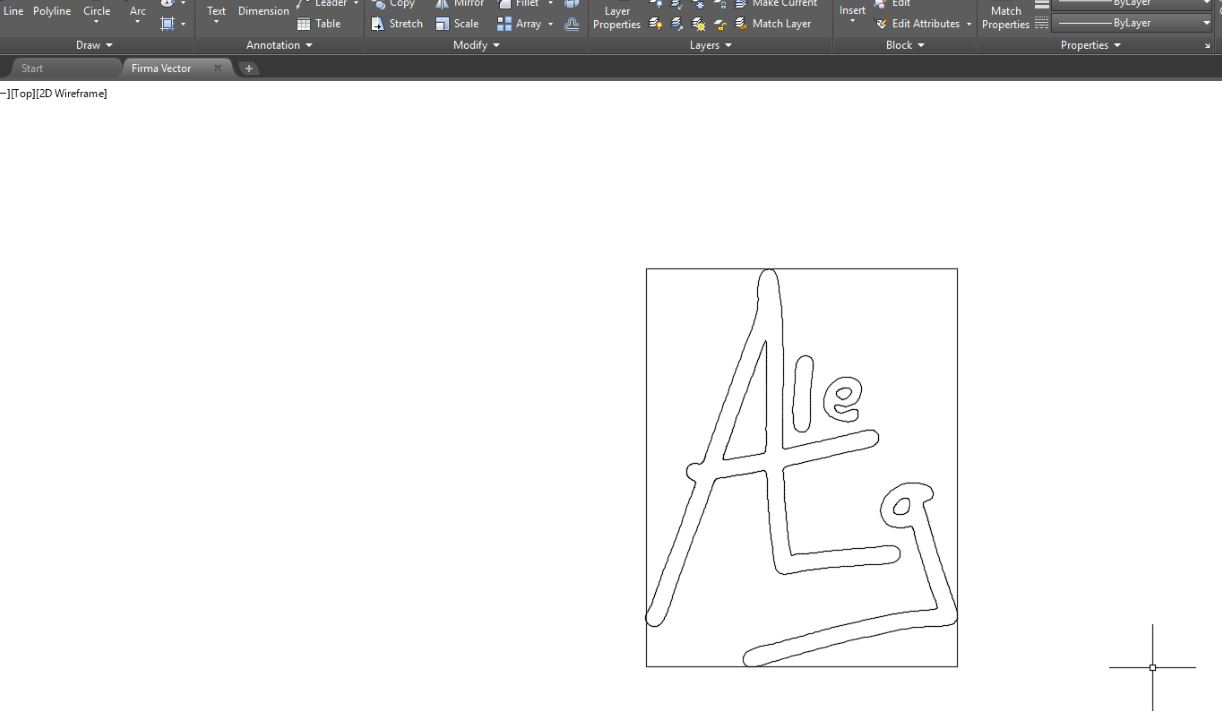

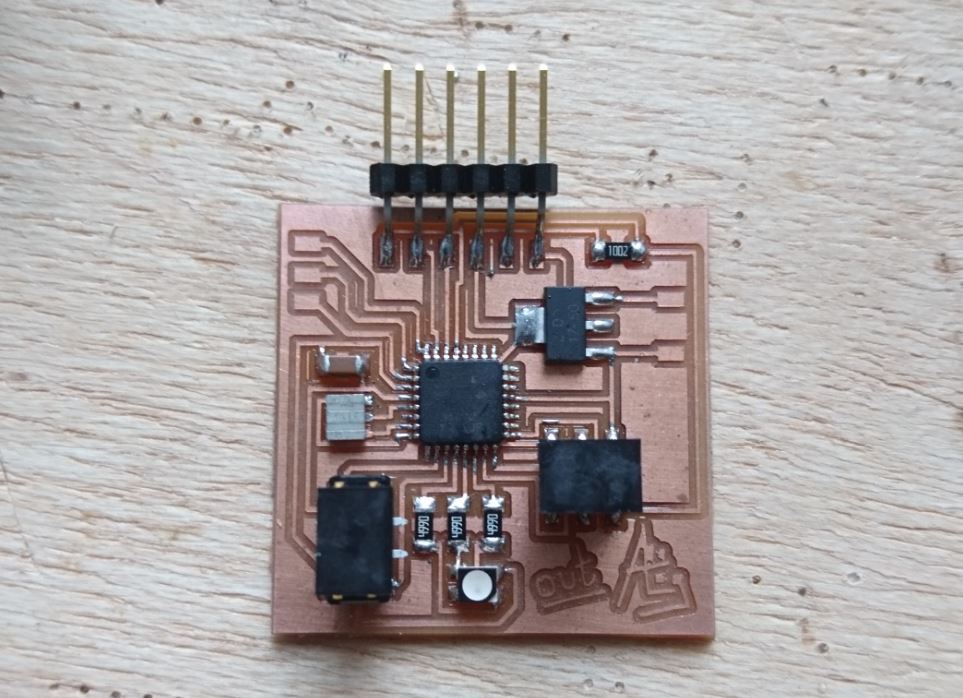

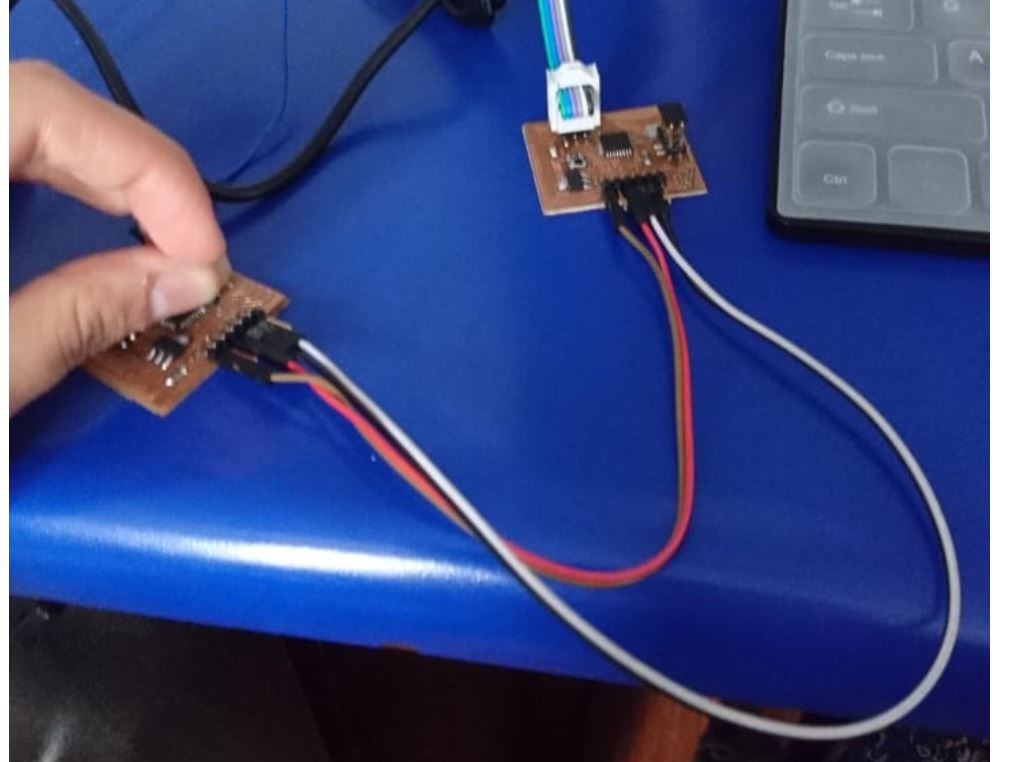

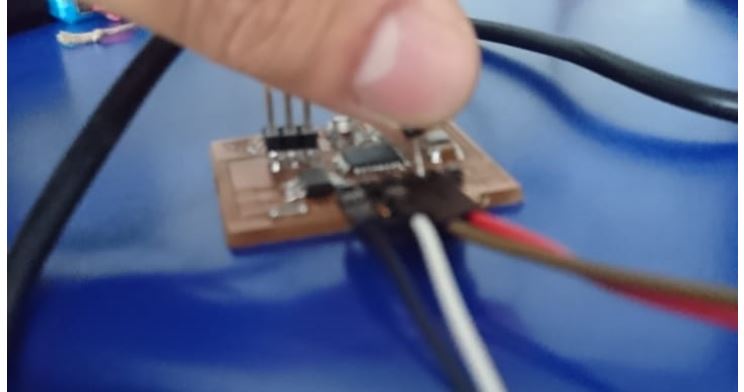

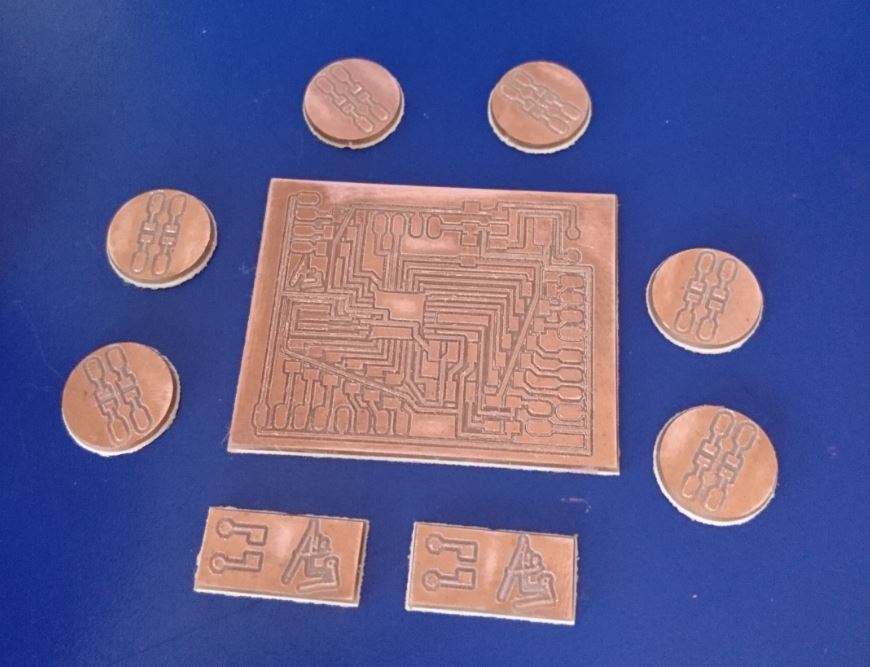

For that, I used the Brian version of the programmer this time, and after adding my signature to the traces (so as to change the file a bit), created the g-code and began milling.

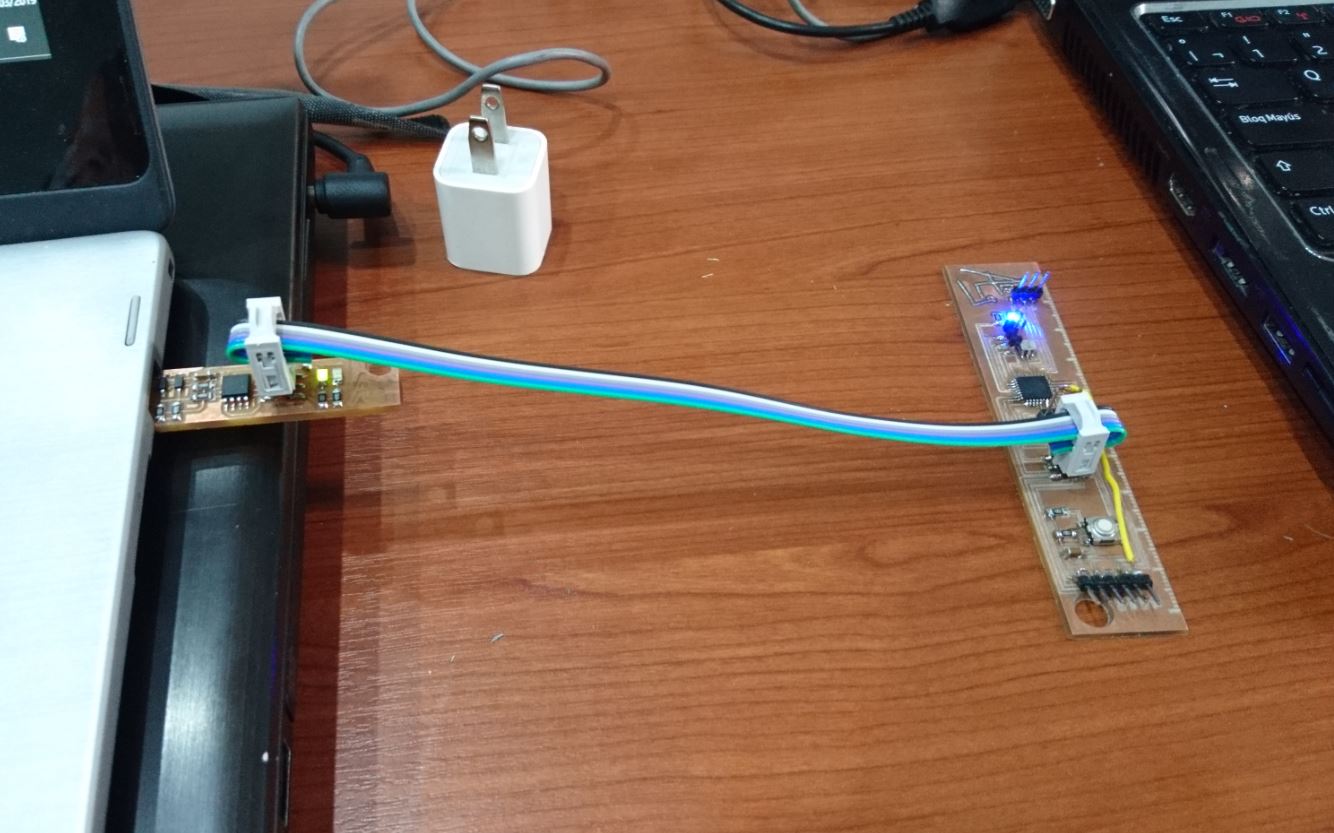

The resulting board turned out well, so I began soldering the components, checked the connections, and got ready to program the board.

The programming process was the same as for the other board (following the tutorial on Brian version). However, this time it was programmed using a different computer (windows 7), as I was concerned that the error on the first programmer might have been caused by my computer (windows 10). There was no problem this time, and the programmer worked successfully, as verified by using it to program the board from Electronic Design week .

Click on the following button to get the black and white pngs, as well as the g-codes used to mill the board.

Overall, I enjoyed this assignment more than the others, as it was something practical which I had never done before, or even imagined that I could do. I was extremely happy at being able to create a PCB and have it work, even momentarily. The next time I do this though, I will make sure that the paths on the board are thicker, as I had a lot of trouble because of the path being too thin. I would also probably prefer to take off the remaining unused copper off the board, as to avoid connections that shouldn’t be there. After having created the new programmer and making it work, I am happy with this assignment.

First attempt:

Second (working) attempt:

February 20-26

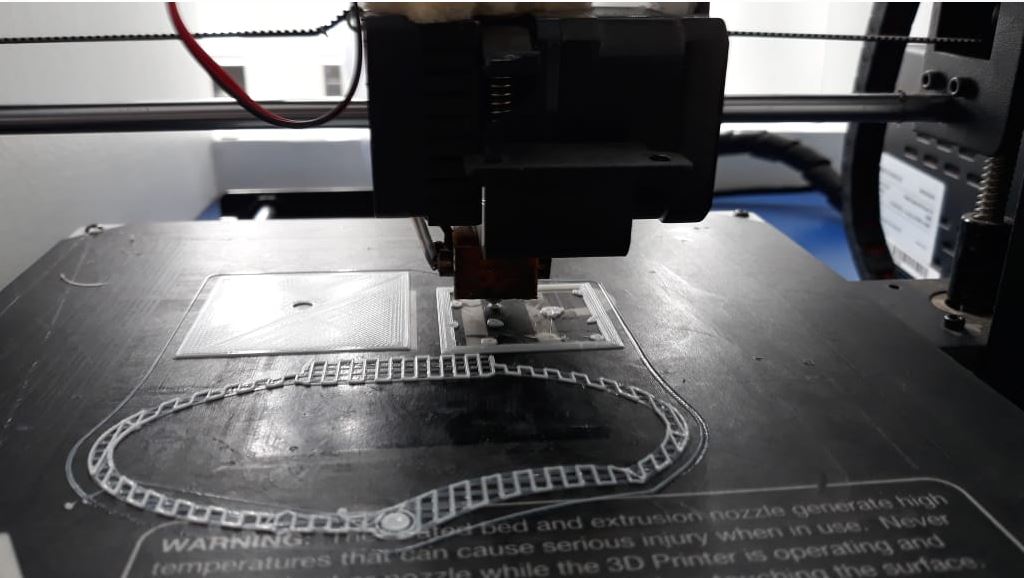

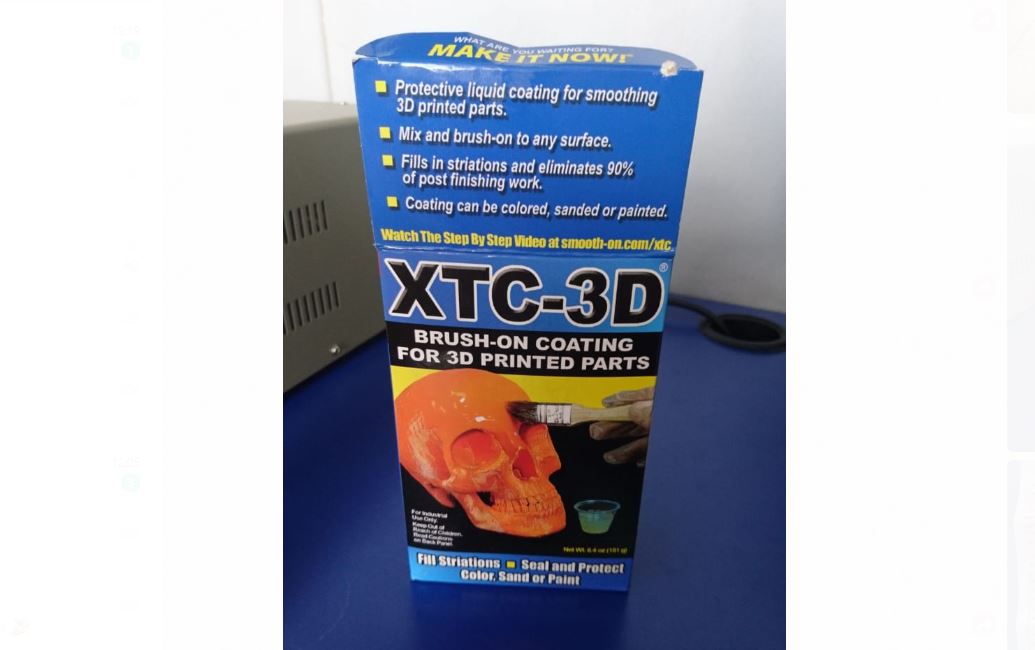

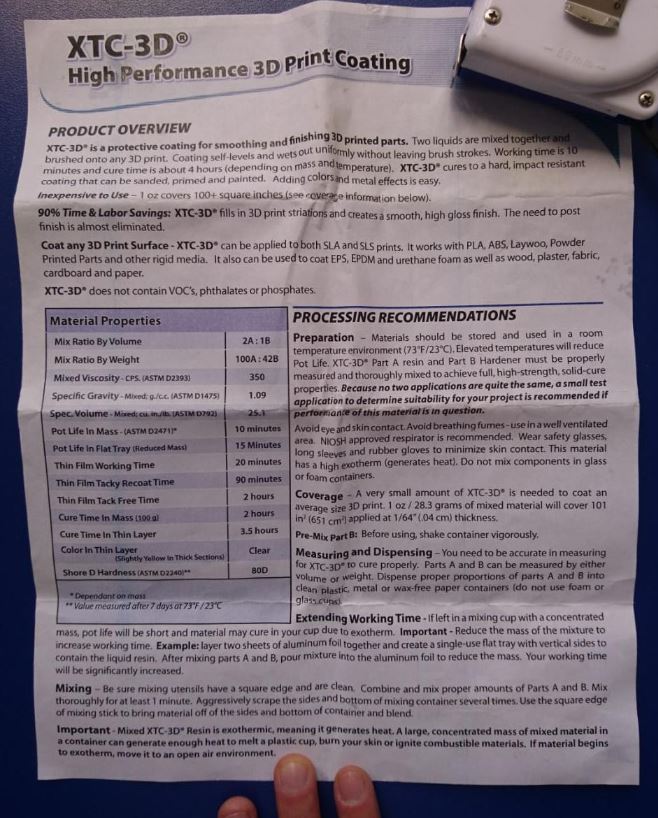

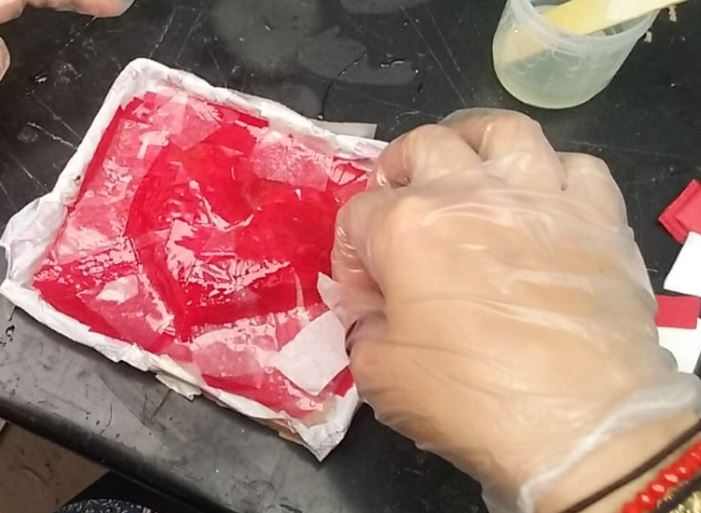

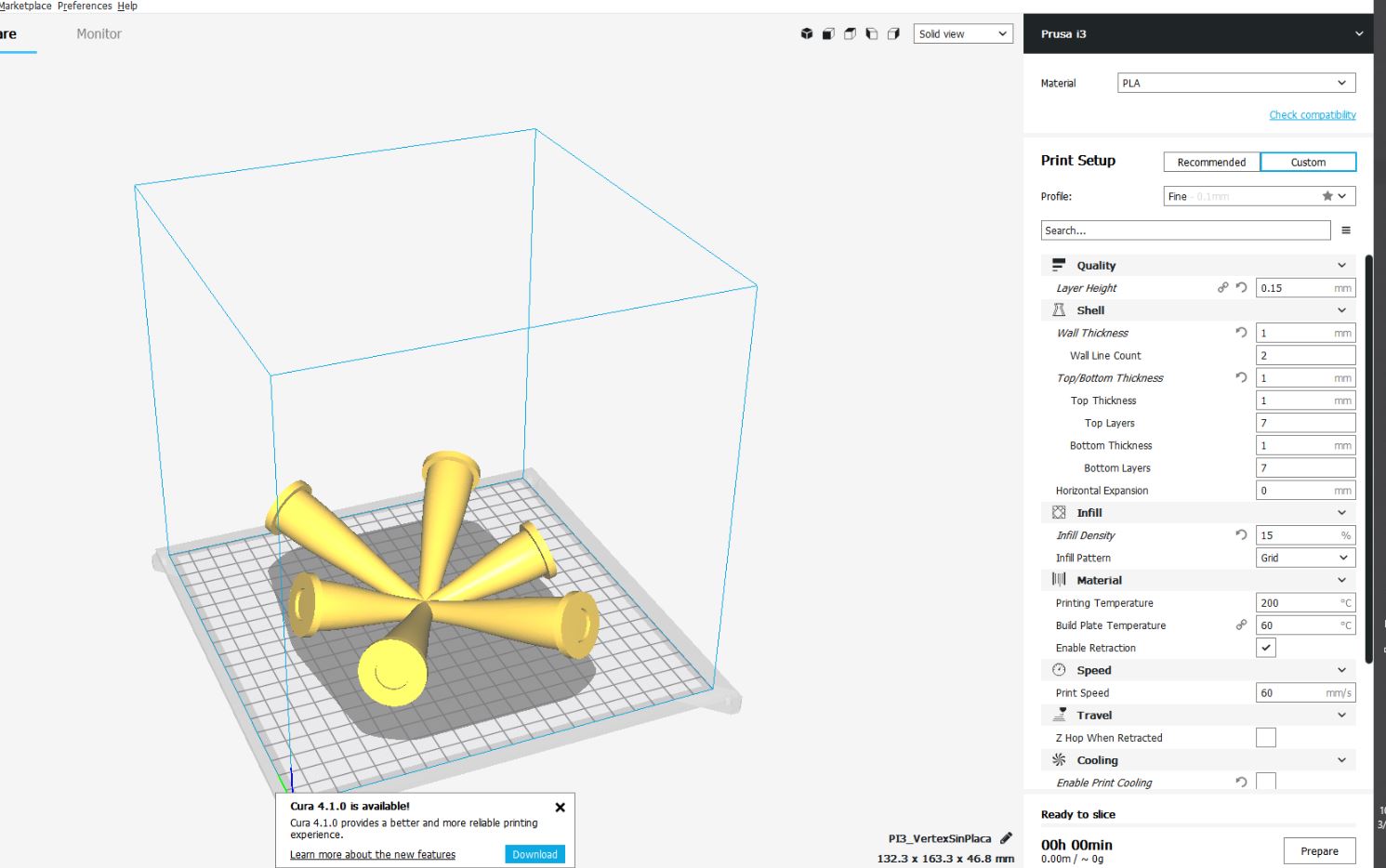

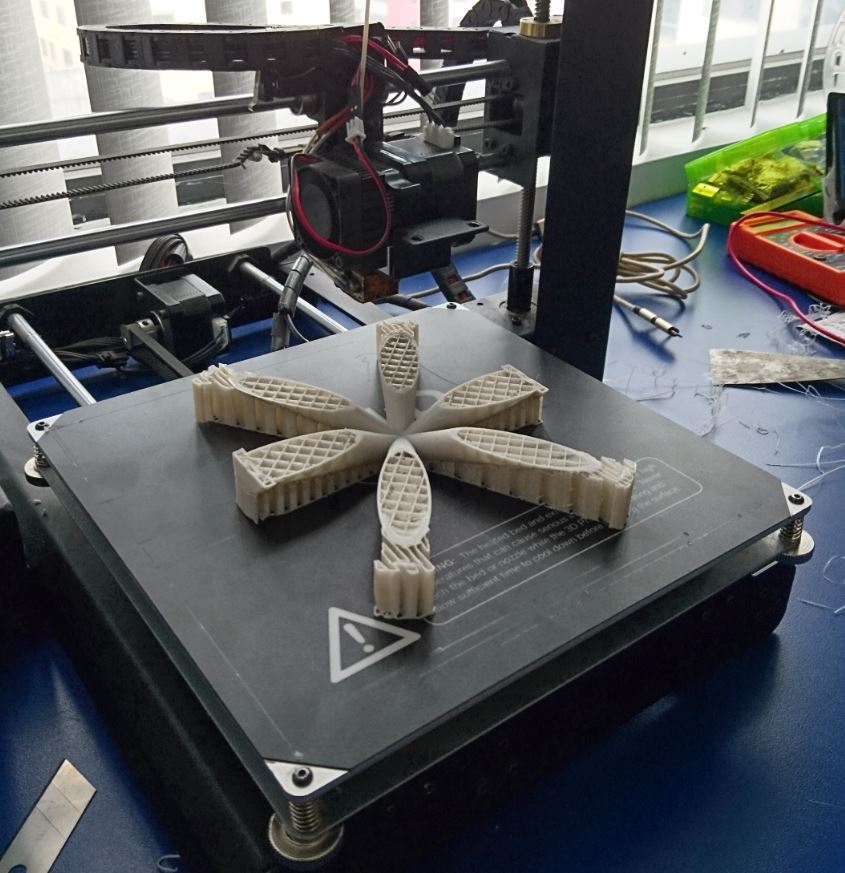

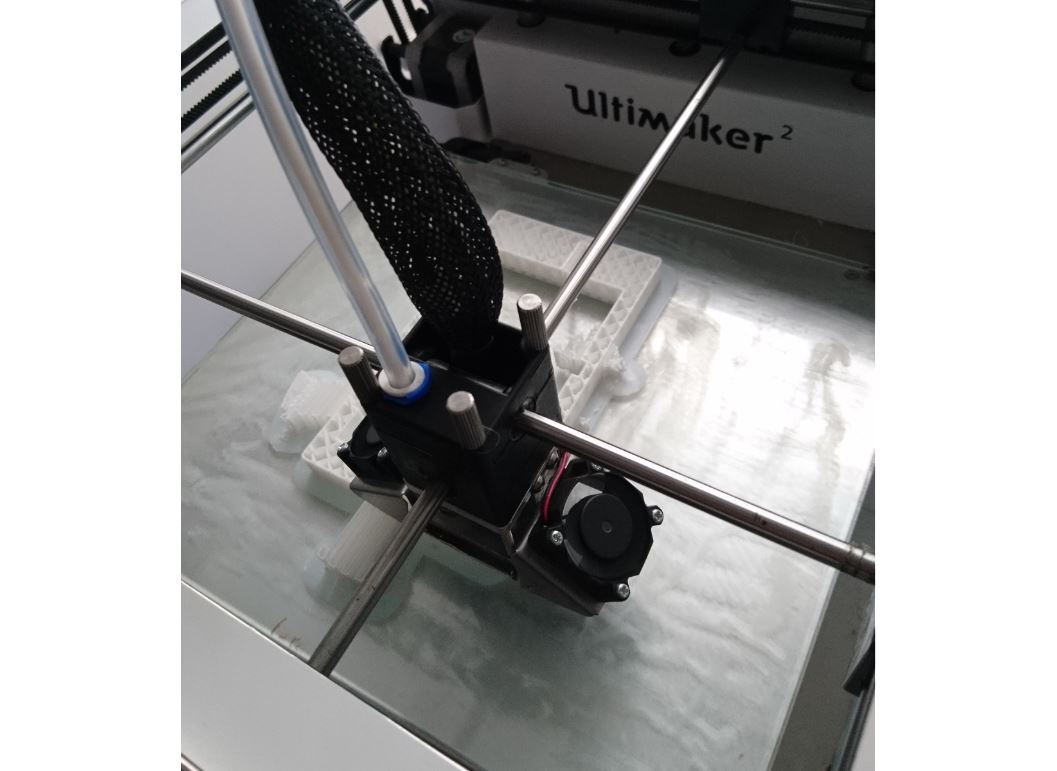

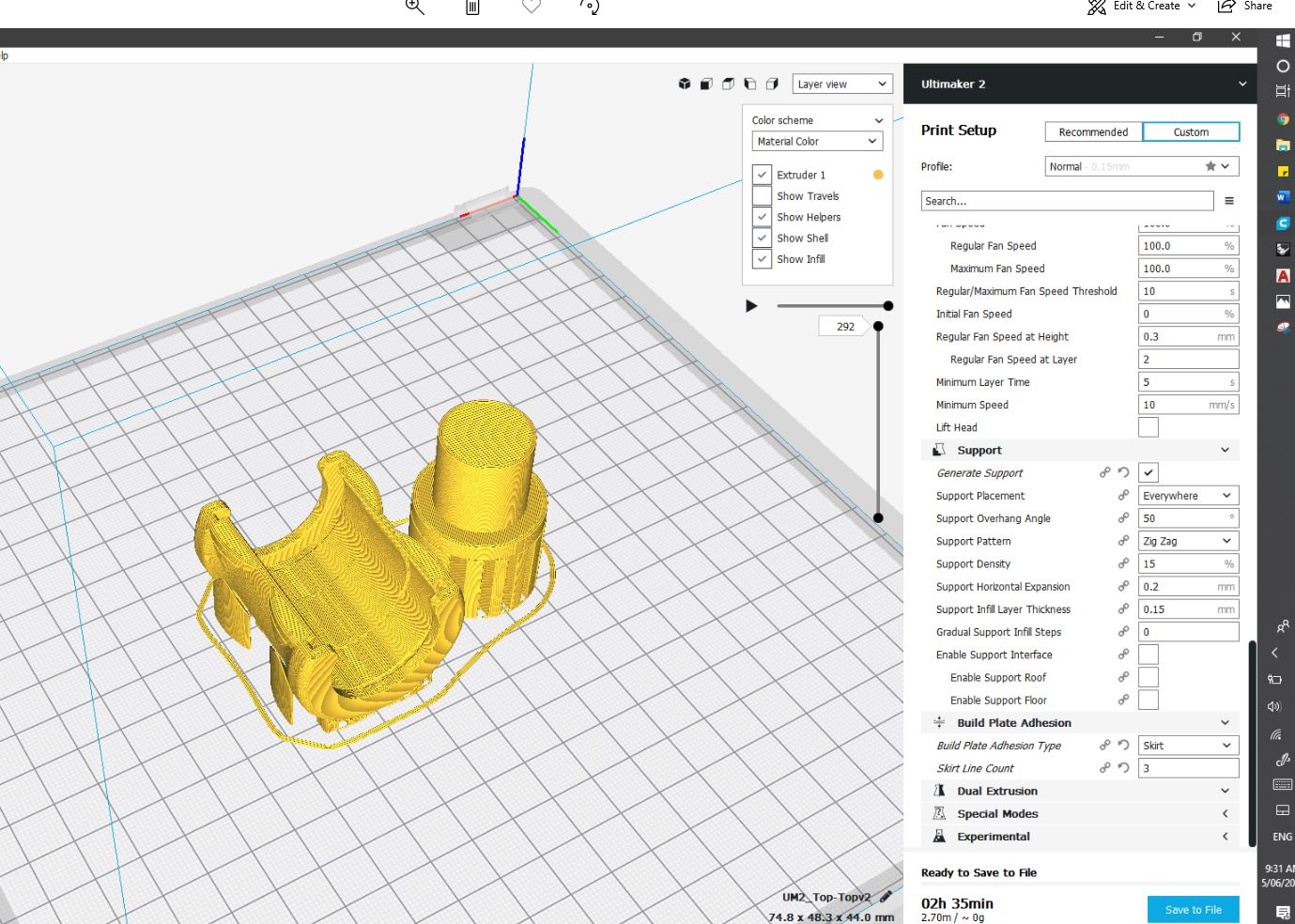

This week’s assignment is about creating a 3D model and printing it successfully. The object has to be small (to be printed quickly, seeing as the printing process is very slow), and should be something that could not be created subtractively. Also, as part of the group assignment for the week we had to send some test files to the printer, to see the capabilities and limitations of the printer. Before we started, Roberto gave us some observations:

With that in mind, we start this week’s assignment.

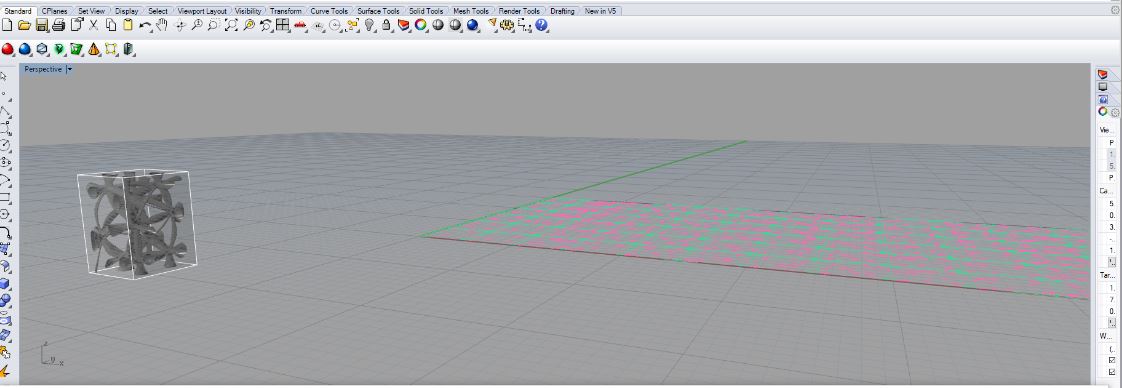

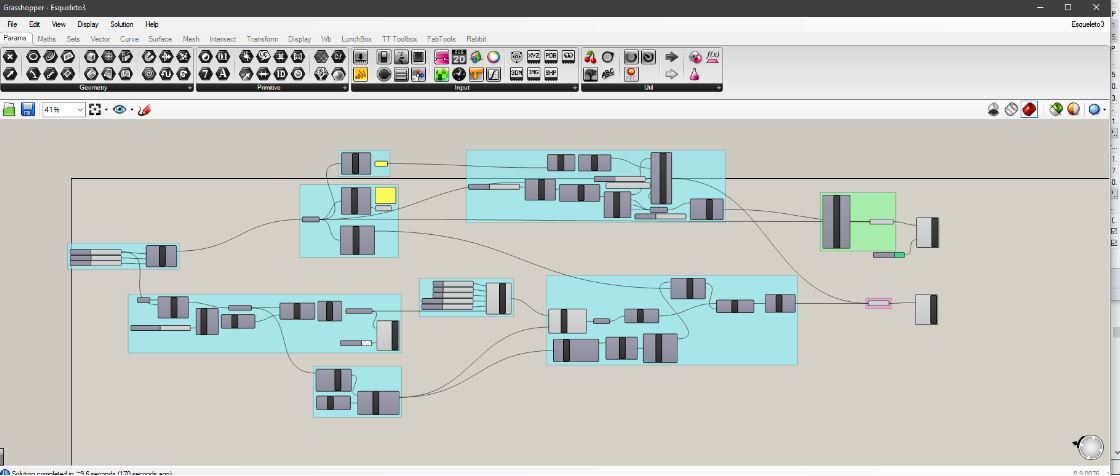

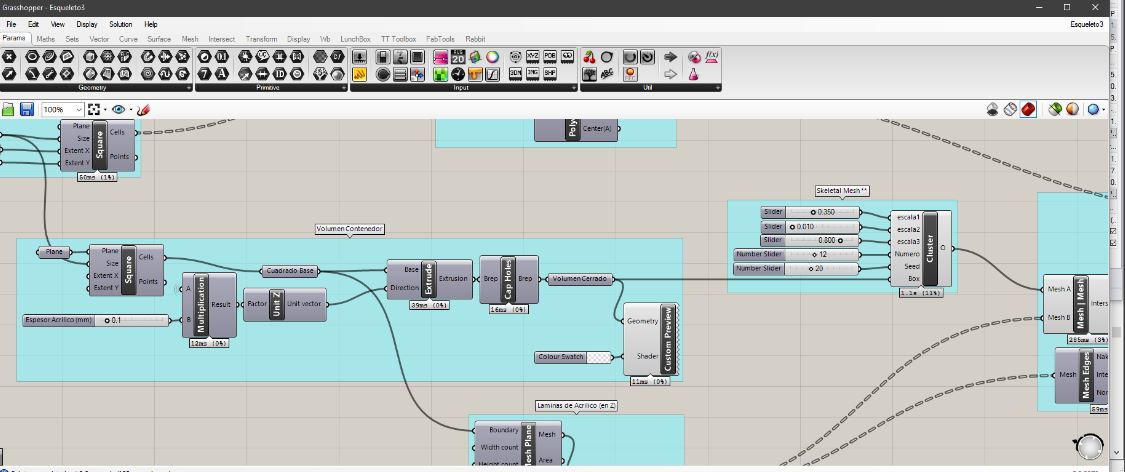

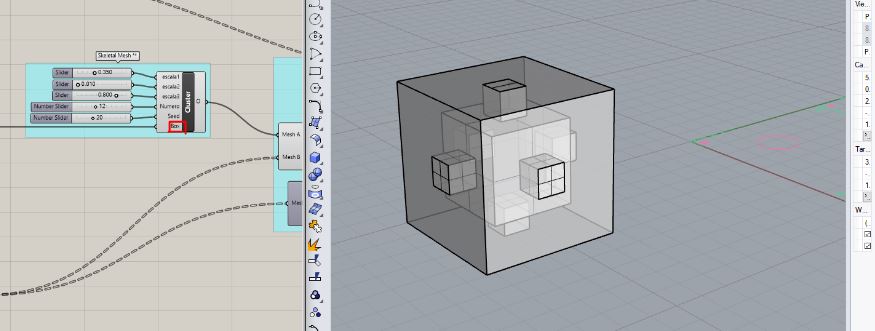

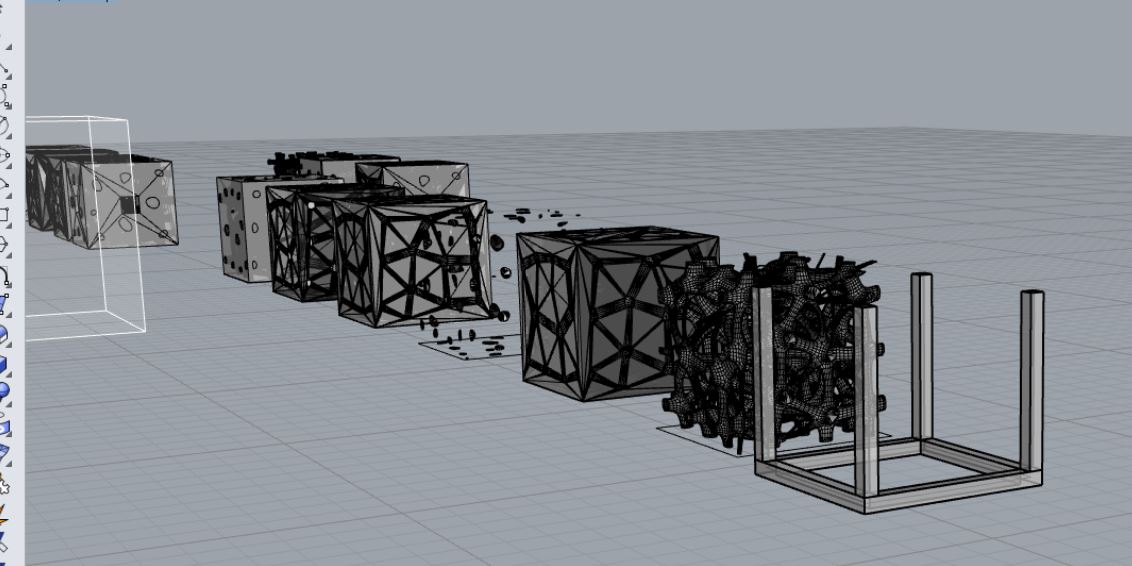

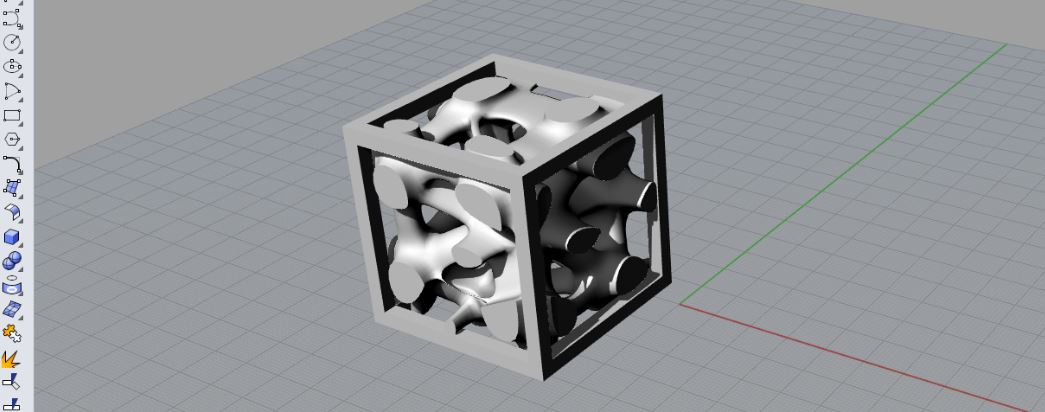

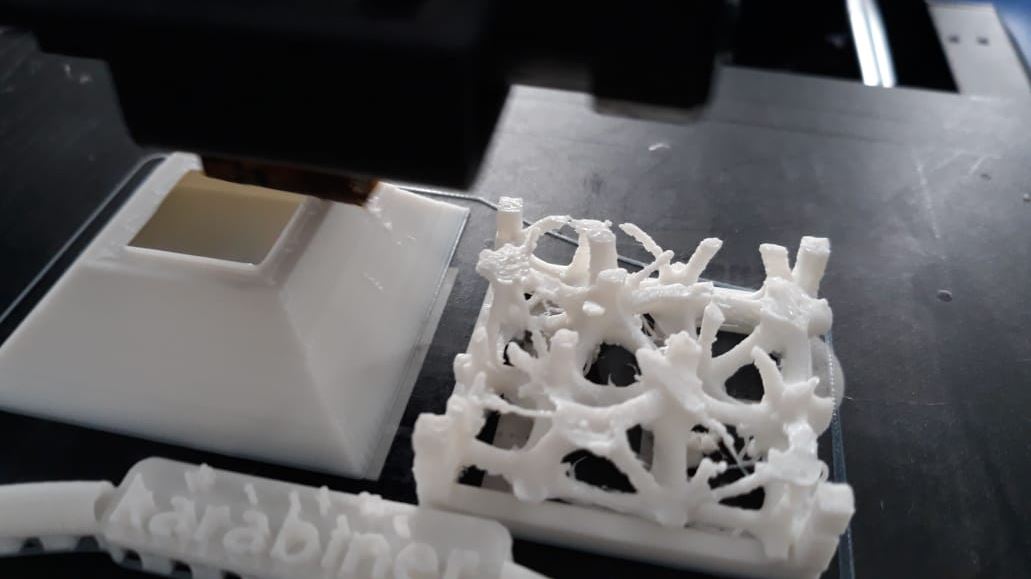

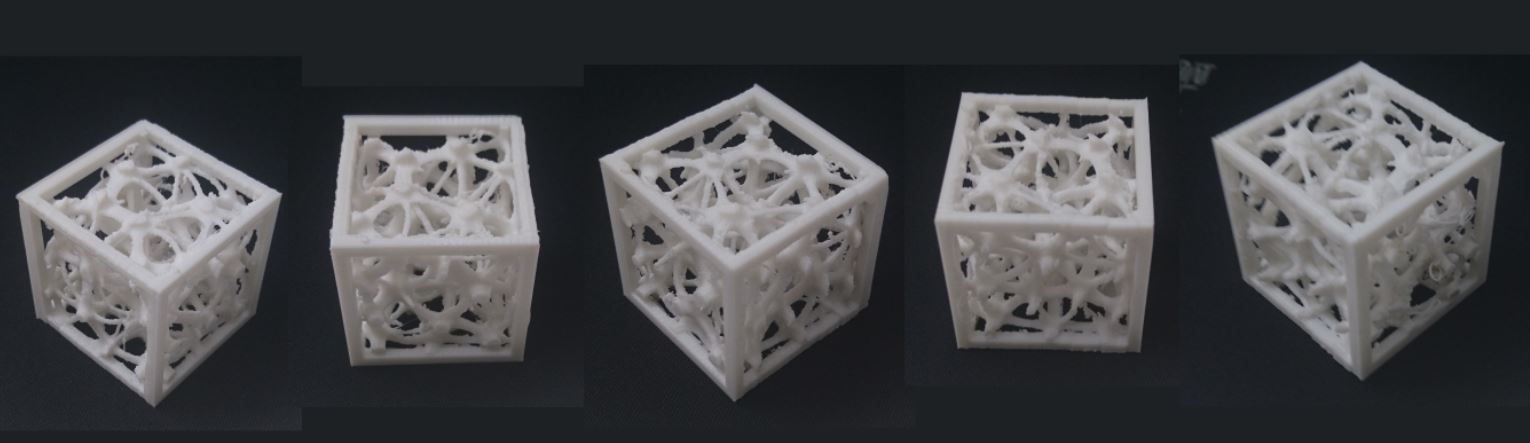

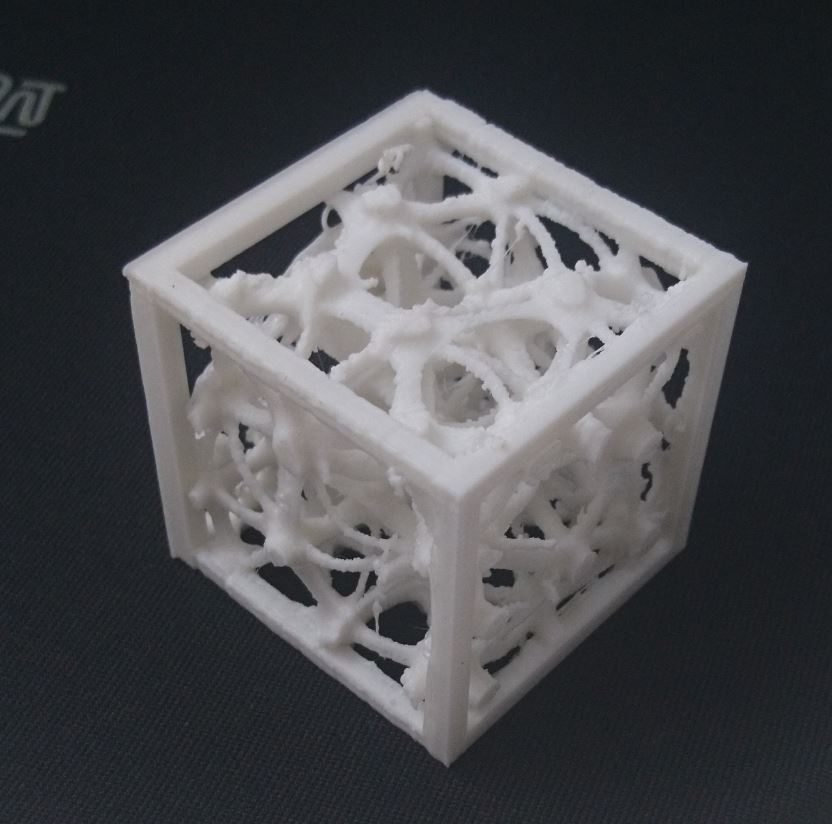

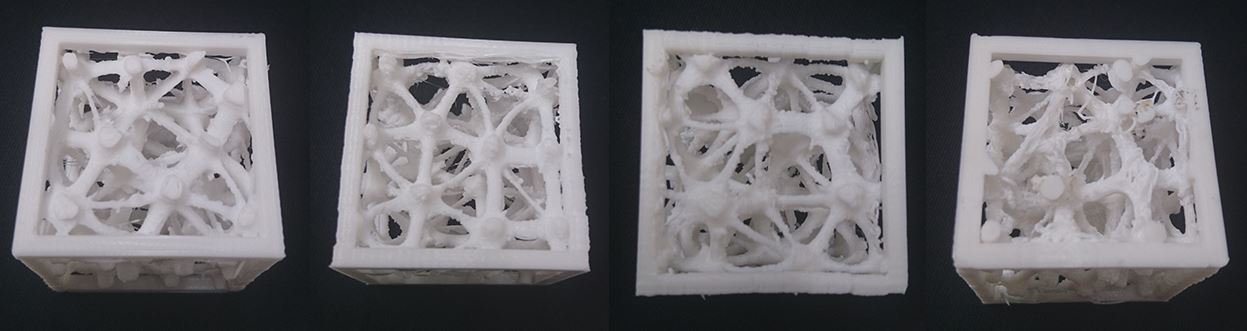

Part of our assignment was to design an object that could not be made subtractively (for example, by laser or CNC milling). Therefore, what I wanted to do was to create a sort of box with an object inside, so that it was something that would be very hard to create in CNC. I used Rhino to design, which made me remember an exercise I had done once in my Parametric Architecture class, which used grasshopper to create a very interesting shape using Weaverbird (plugin for grasshopper?).

This is the original exercise I did for that class:

With that in mind, I tried changing the parameters in grasshopper so that the box where this interesting structure generated would be the box with the hole inside which I had designed. That did not work out, so then I “baked” the structure and used MeshBooleanDifference and other Boolean commands to generate all sorts of interesting shapes in the union and intersection of these two shapes.

I finally managed to do what I had wanted, which was to make this structure only exist inside the volume with a hole (a container of sorts) that I had created, however it didn’t look very nice, so I decided to change strategy. I would create this strange structure inside a 5 by 5 by 5 (cm) box, and then I would create the “outline” of the box, and that would be the object.

And so, the model of the object was completed! Time to set it up for the printer.

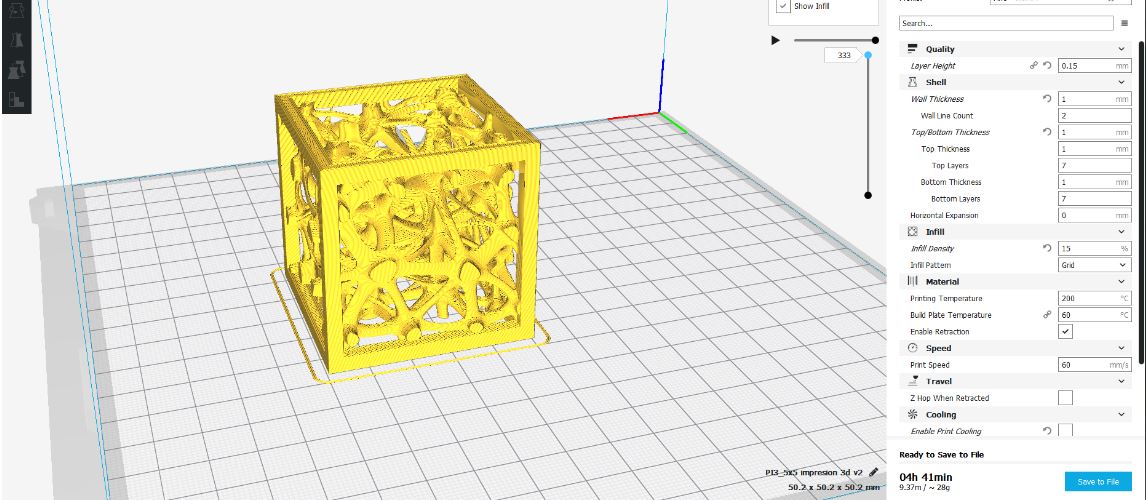

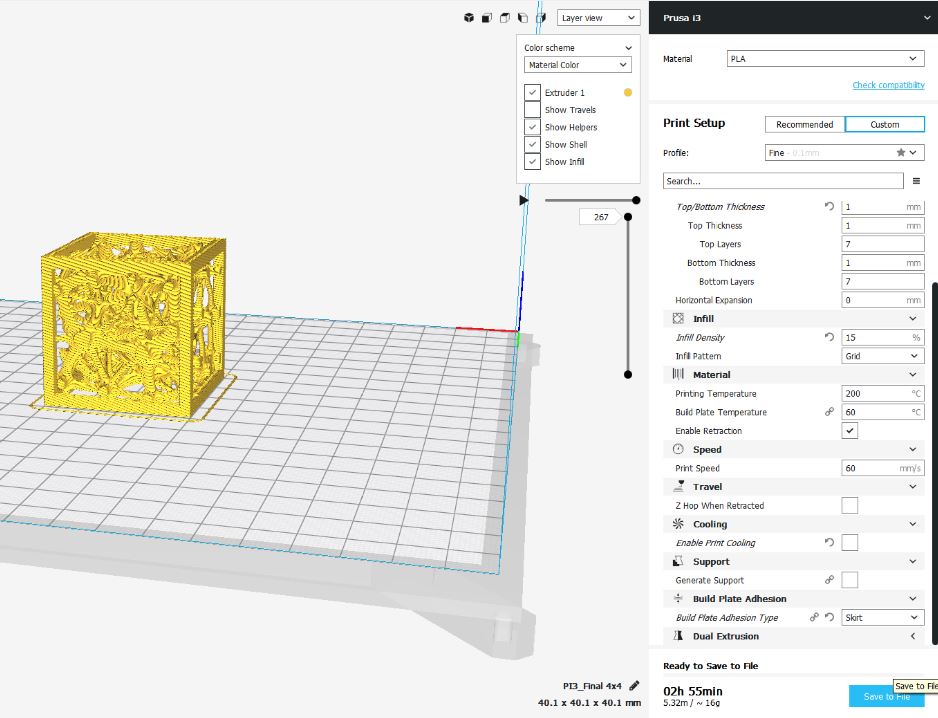

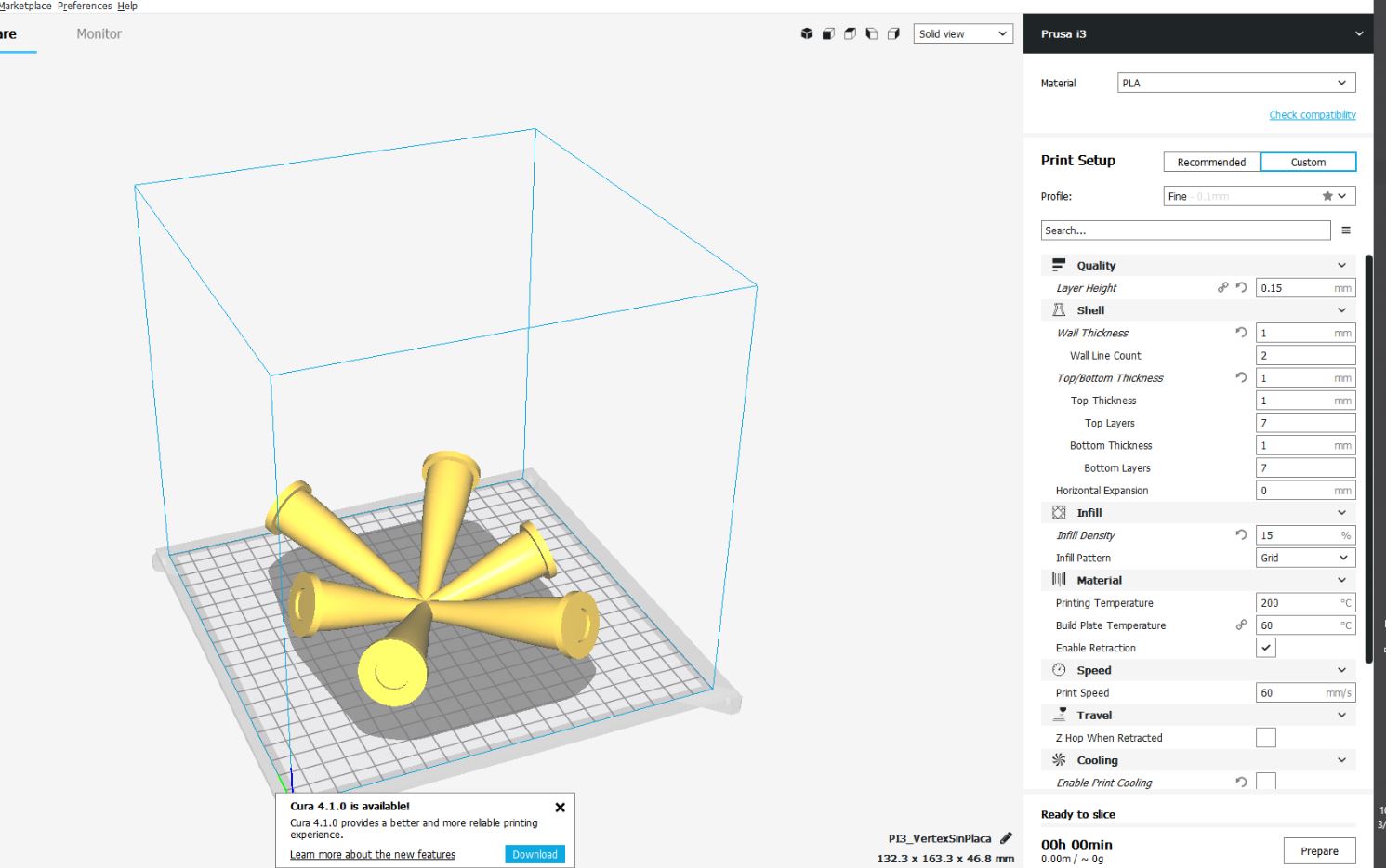

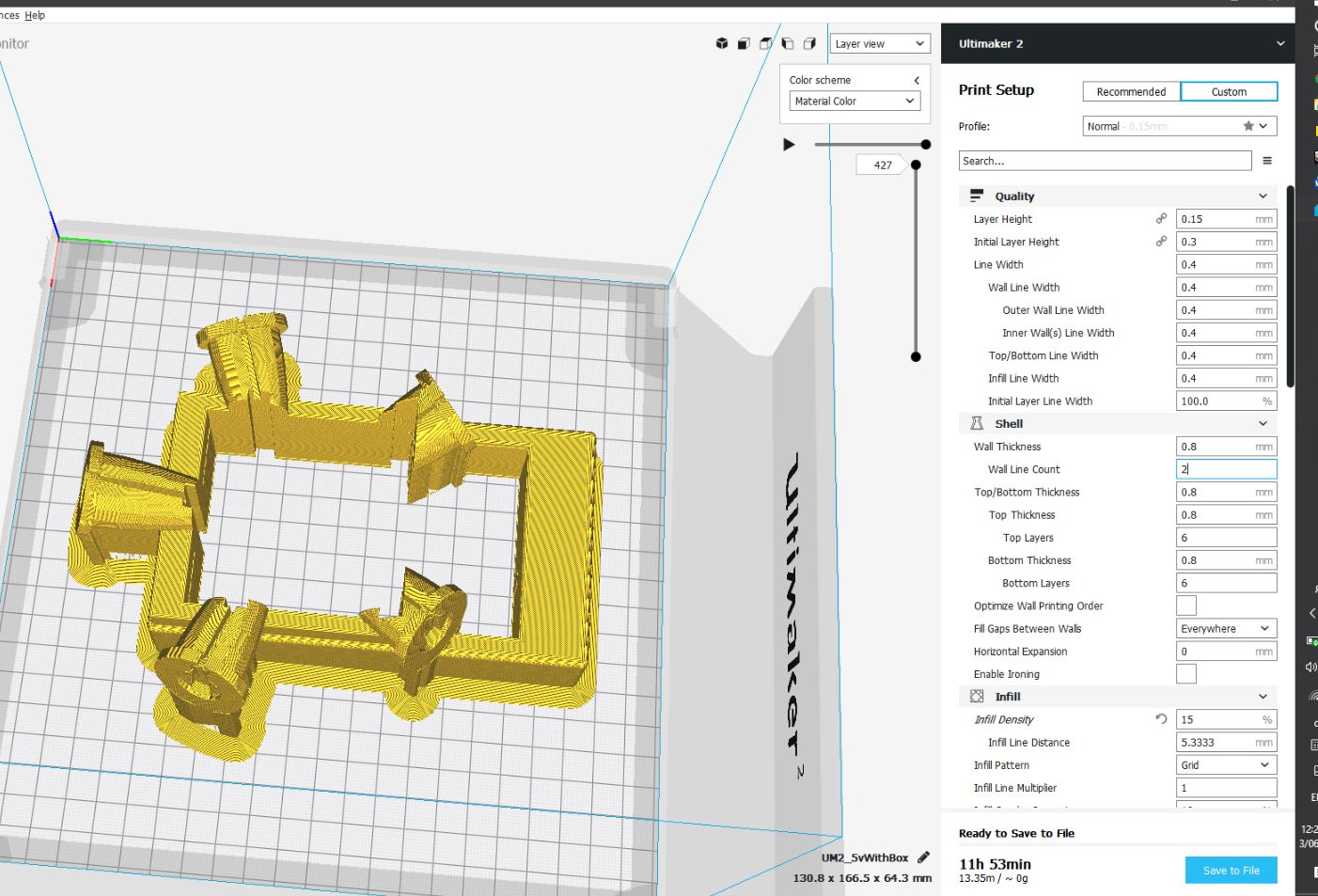

After finishing the modeling part, I exported it in OBJ format and tried to import it into Ultimaker Cura software which I had just downloaded, but I kept getting a mistake. After trying a few other things unsuccessfully, I found the STL format in which I could also export it (which I hadn’t seen at first) and that had no problem being imported into Cura.

I tweaked the settings just a little, according to what Roberto told us, and then verified that the object was ready to be printed by checking the layers. After checking how it would print with supports, which the software added automatically, I decided it would be better to print it without supports, as they would be very hard and confusing to remove from the interior of the object.

The settings used were:

Here is the object in layers with supports:

And here it is without:

After checking the time and verifying the availability of the machine, and taking into account that this is a test, I decided to go for the 3x3x3 object (1.5 hours) as opposed to the 4x4x4 (3 hours) or the 5x5x5 (5 hours), mainly because it took significantly less and I was not sure if the object would print out correctly as I hadn’t added supports.

That was decided, and so the g-code was exported and ready for printing

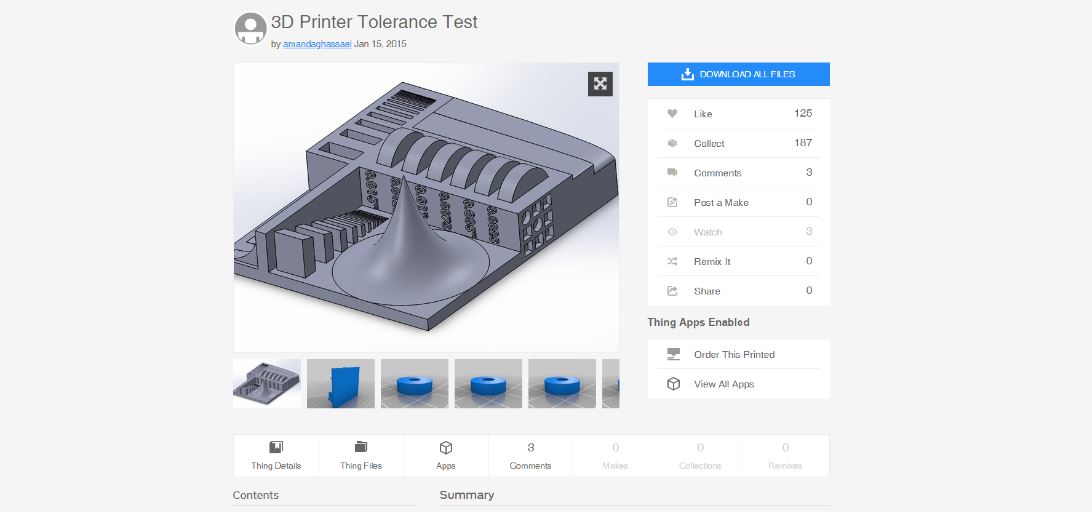

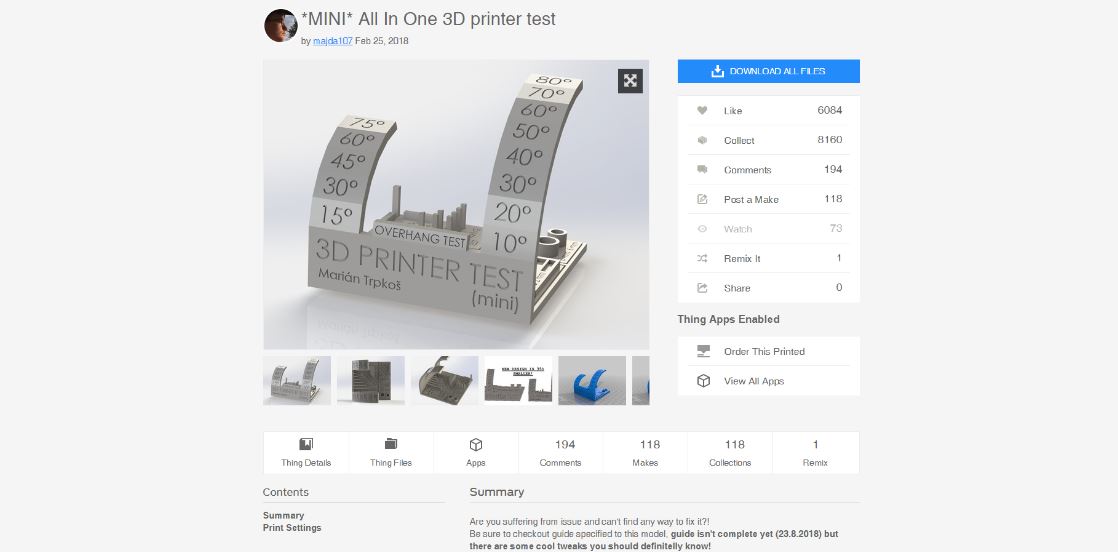

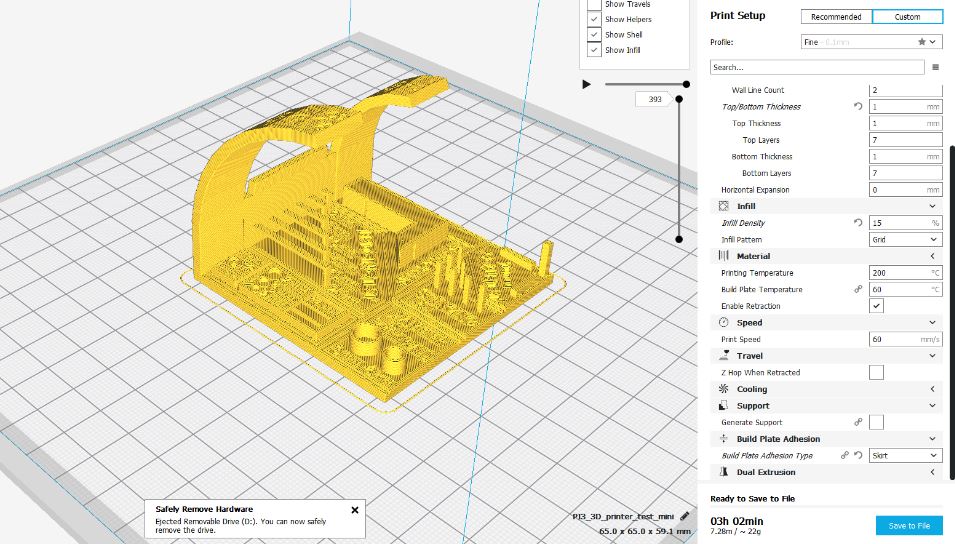

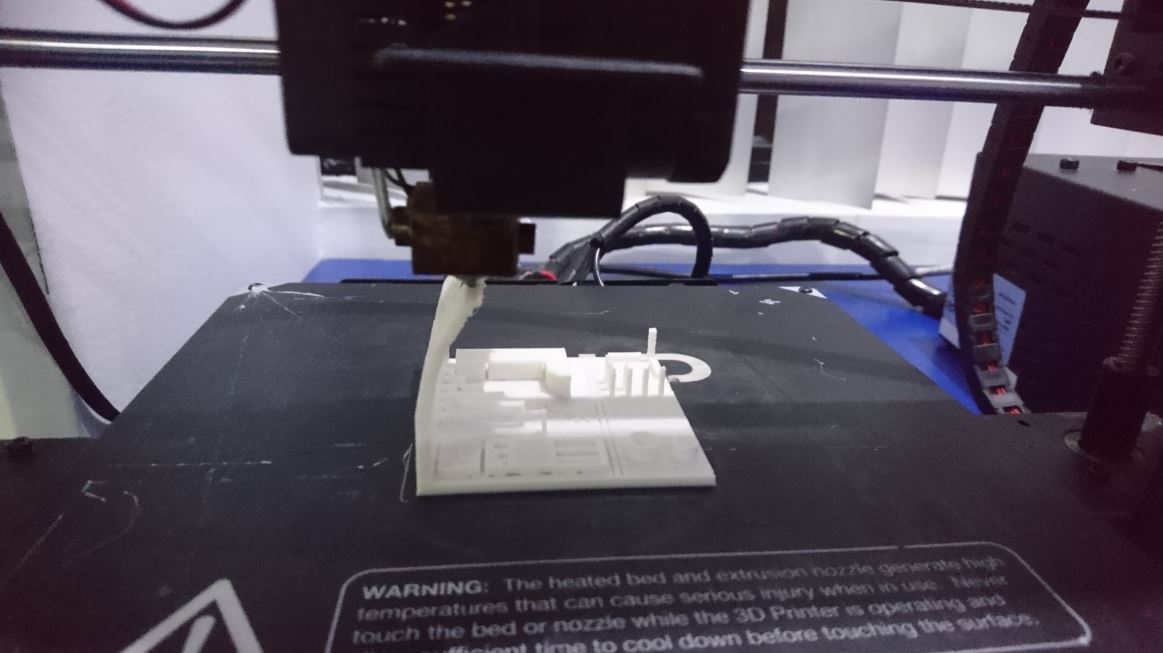

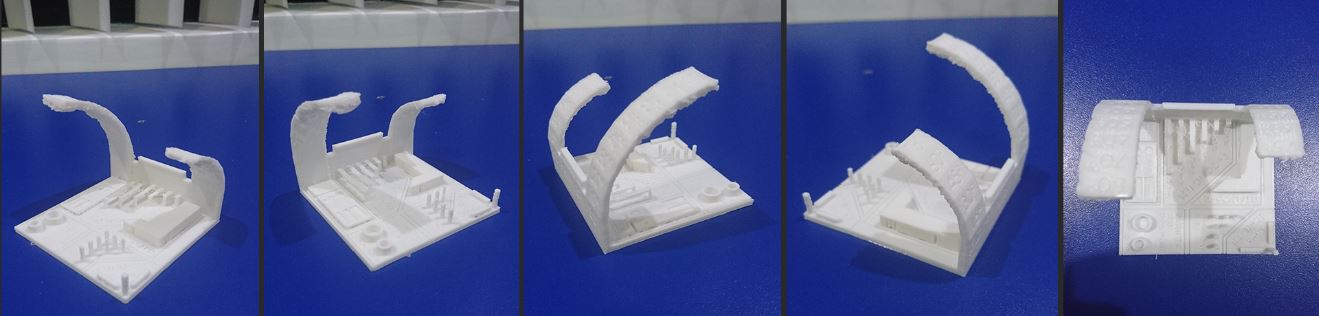

In order to understand the 3D printing design rules (as was the group assignment) we downloaded and tried two 3D printing test objects, the 3D Printing Tolerance Test and the Mini All in One 3D Printer Test. We downloaded the files, placed them in Cura Software to prepare them for printing and exported the g-code.

The Mini All in One test turned out very well in our printer. I was amazed that the printer was able to create almost horizontal overhangs (even though the quality at that point was deficient). Also, for the overhangs after the 40 degree mark, we lowered the temperature of extrusion by 5 degrees (from 200 to 195 C), which helped a lot for the printing of those parts. The overall result was good.

I learned that the recommended angle for which objects can print without supports is a 45 degree angle. Also, I learned that bridges can be created without supports, although the material may bend and the result may not be as good. I used to think that tis was absolutely impossible, as I thought there always had to be something on top of which the layer could be printed.

The specifications of the printer we are using are:

We are using 200 degrees for the PLA material we used, which is also known as PLA Pro.

After the test objects were printed, we measured some parts of them to compare the digital objects with the actual object in order to see how accurate the printer was. I measured the “All in 1 printer test”. The results and comparisons are as follows (in mm):

There were no major differences in the overall digital object with the actual object, with the exception of the overhang parts, were the printing went wrong as it had no supports. Other than that, there is only a tenth of a mm of difference.

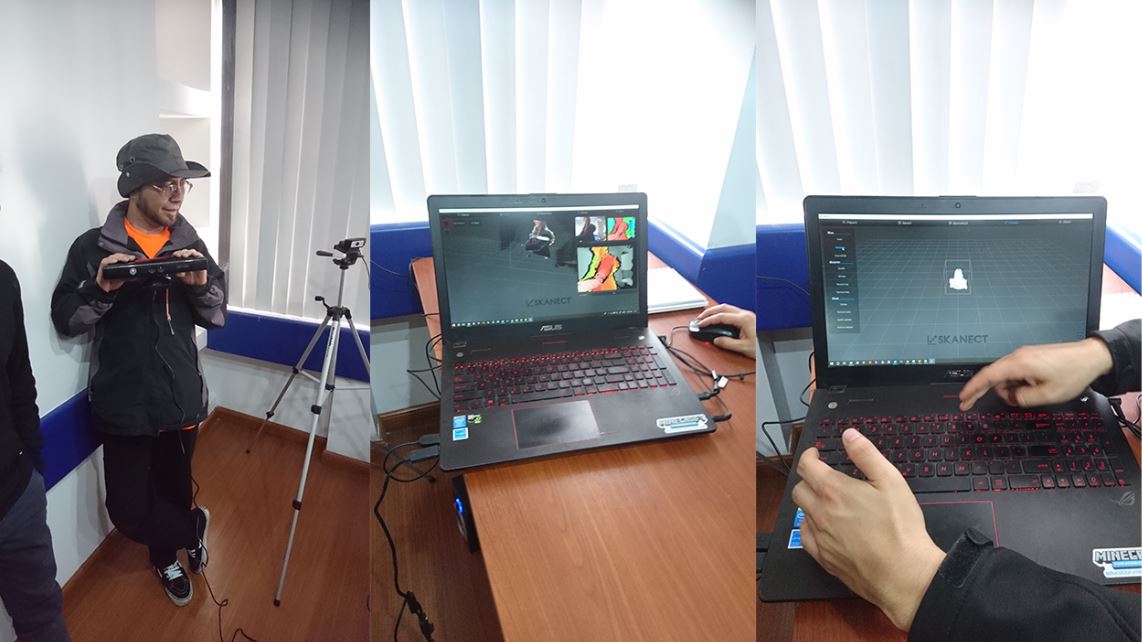

For this part of the assignment, we used a Kinect Sensor with a 3D scanning program. The program we used was Skanect, which is a paid program for which our lab has a license installed in the lab computer. It is a program which (taken directly from the website):

transforms your Structure Sensor, Structure Core, Microsoft Kinect or Asus Xtion camera into a low-cost 3D scanner able to create 3D meshes out of real scenes in a few minutes

The scanning process was easy, and worked well on large surfaces so we decided to scan ourselves. For this, one person had to hold the scanner while another clicked the button on the computer and the person that was being scanned rotated very slowly. The person with the scanner gradually moved it up and down, in order to scan the top half of the person.

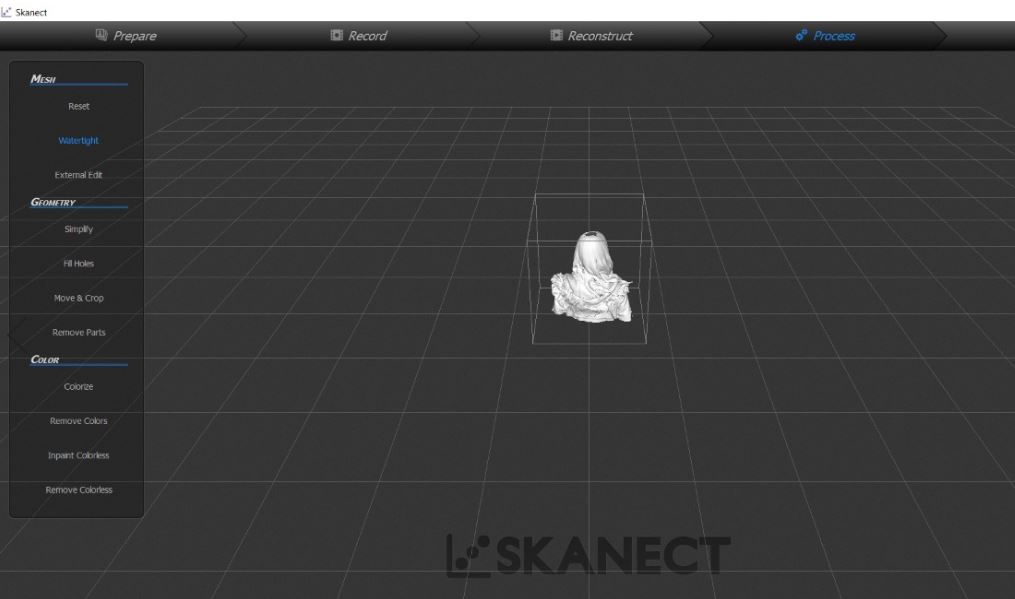

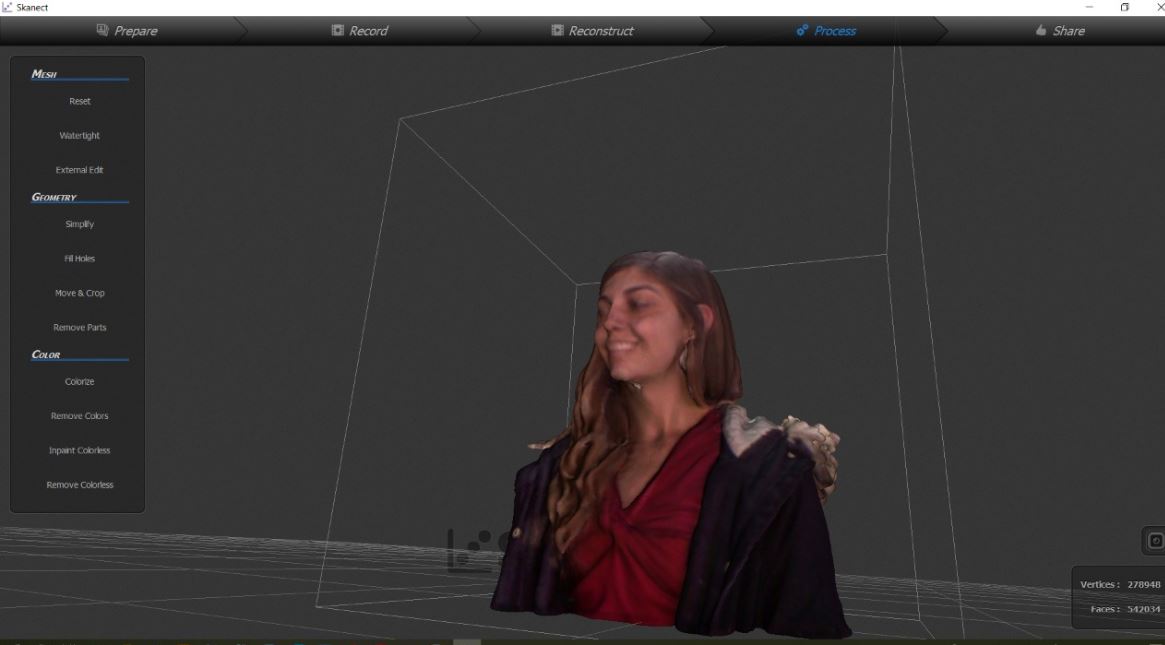

This process worked very well, and we figured out that the 3D model turned out better when the person being scanned rotated 45 degrees each time, corresponding with the up and down movement of the scanner. Also, the scanning had to start with the person’s back, otherwise the face was scanned twice and resulted in strange shapes. Once one whole turn was completed the program created the model.

Then, with the program we were using we applied the “watertight” option, which closed most of the holes left behind by the scanner. After that, we exported the resulting model in OBJ format to be read by most programs.

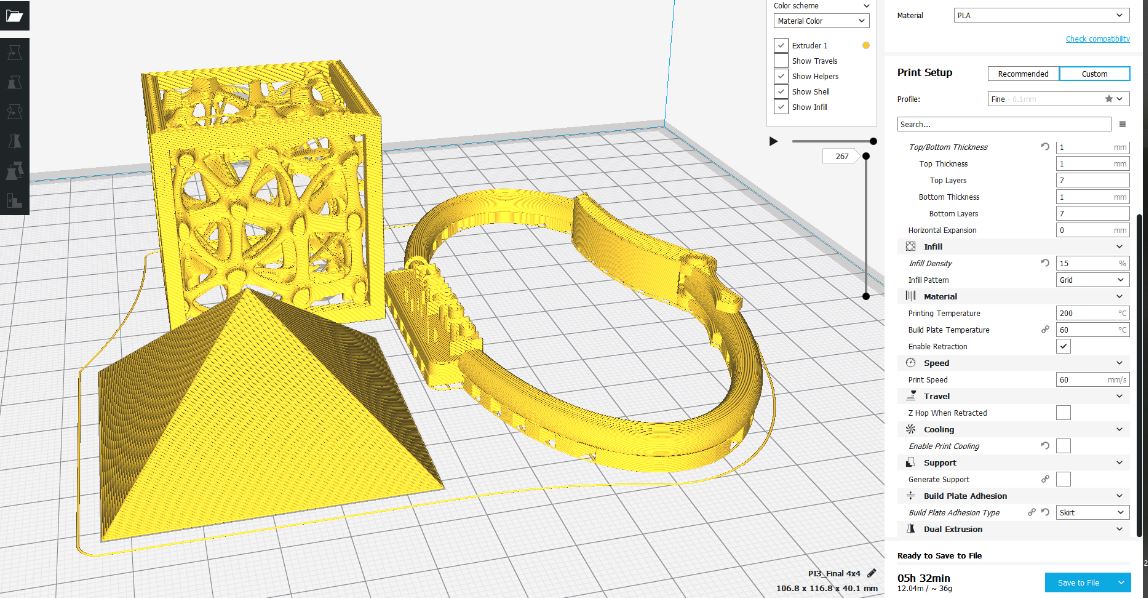

Seeing as we would have the printer creating our models by the time we left, we (Jorge, Danny and I) decided to put all our files in one printing area and send all three at once.

Our first test of that did not work out, as confirmed by Roberto, because of some unexpected printing error which made the machine stop randomly and refuse to continue the printing job. This is when the printer stopped working:

This is the code that generated the error:

I generated the g-code again, verifying the settings (instead of debugging the previous code, as I had no idea what had caused the problem before), and now the printer seemed to have no more trouble with the file.

The resulting object turned out well, especially considering that it used no supports. The bottom part has disconnected strands all over, but the top part is better. Surprisingly, the sides are the areas that look cleaner. Also, the horizontal elements are smooth and perfect, but the vertical elements are rough, and the layers are very visible.

Taking into account the complexity of the model I chose, I am very happy with the result. This model could not have made subtractively because of the complexity of the inner model. The external part (the outline of the cube) could probably be done with a 4 axis cnc, however, because of the inner “web” or “skeleton” and the amount of inner elements it has, it would be extremely hard to achieve, as there is no direct line through which the cnc mill could have been inserted to carve the piece.

One of the problems faced while printing was that, as I didn’t add supports, some parts had no base on which to be printed on top of, which caused the pieces to bend upwards. This, in turn, bumped the machine while it was passing through that spot and de-calibrated, which resulted in uneven printing vertically. This can be seen on the object that my friend printed alongside mine, which would have normally printed perfectly, but because of the de-calibrating caused by my object, the different layers on his are very notorious.

Advantages: It’s an additive form of production, which means that it can create objects that CNC milling and Laser cutting can’t produce. It can create very complex objects, and depending on the machine, it can also have very high quality.

Disadvantages: It takes a lot of time and some machines may not be very exact. The size of production is also limited to the size of the machine, so generally the objects have to be small.

Other observations:

3D printing is a great tool to create small objects or parts of an object and has lots of advantages vs CNC milling and Laser Cutting. I enjoyed this exercise as it helped me understand how the printer works, and the possibilities of it. I think it is a great way to create objects, however, because of time, it may be better to create the mold of an object using 3D printing and then use another faster process to create objects.

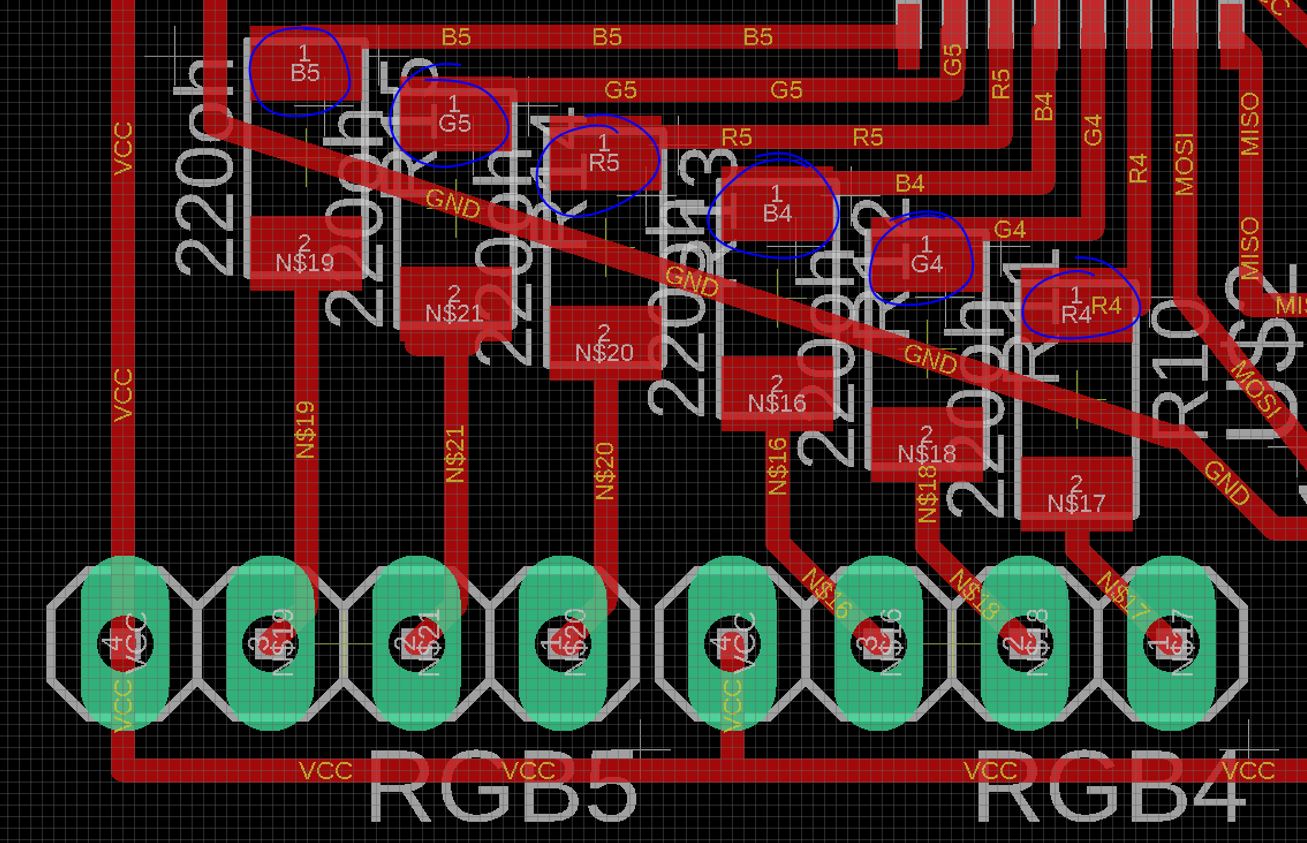

February 27 - March 5

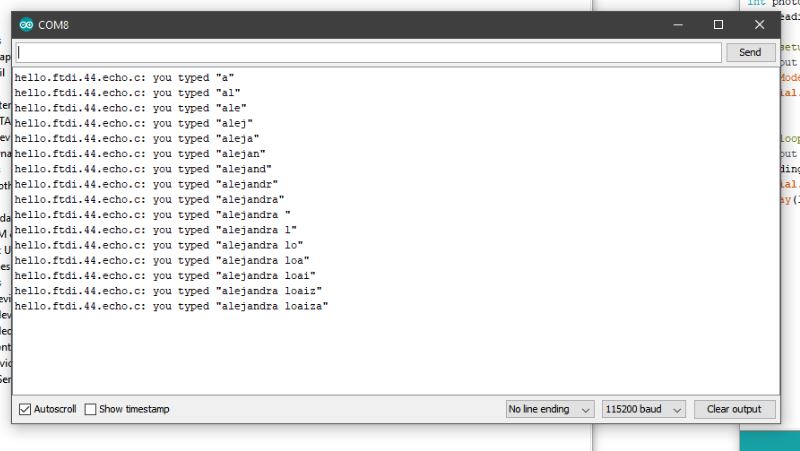

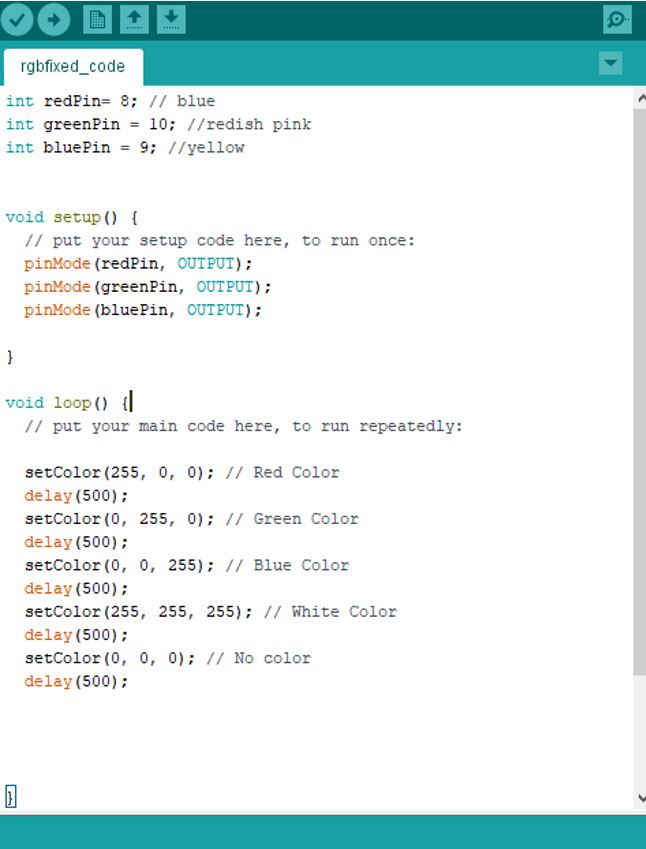

This week’s assignment (electronic design) follows up on week #5’s assignment (Electronic Production), which means that if something went wrong that week (such as the programmer not working) that doubles up on this week. That is unfortunate, as I will have to find a way to make the programmer work soon or everything will start accumulating.

The part that I am very interested in is finally understanding how PCBs work, now that I know how to fabricate one. For this, our instructor taught us a few basic things on electronic circuits:

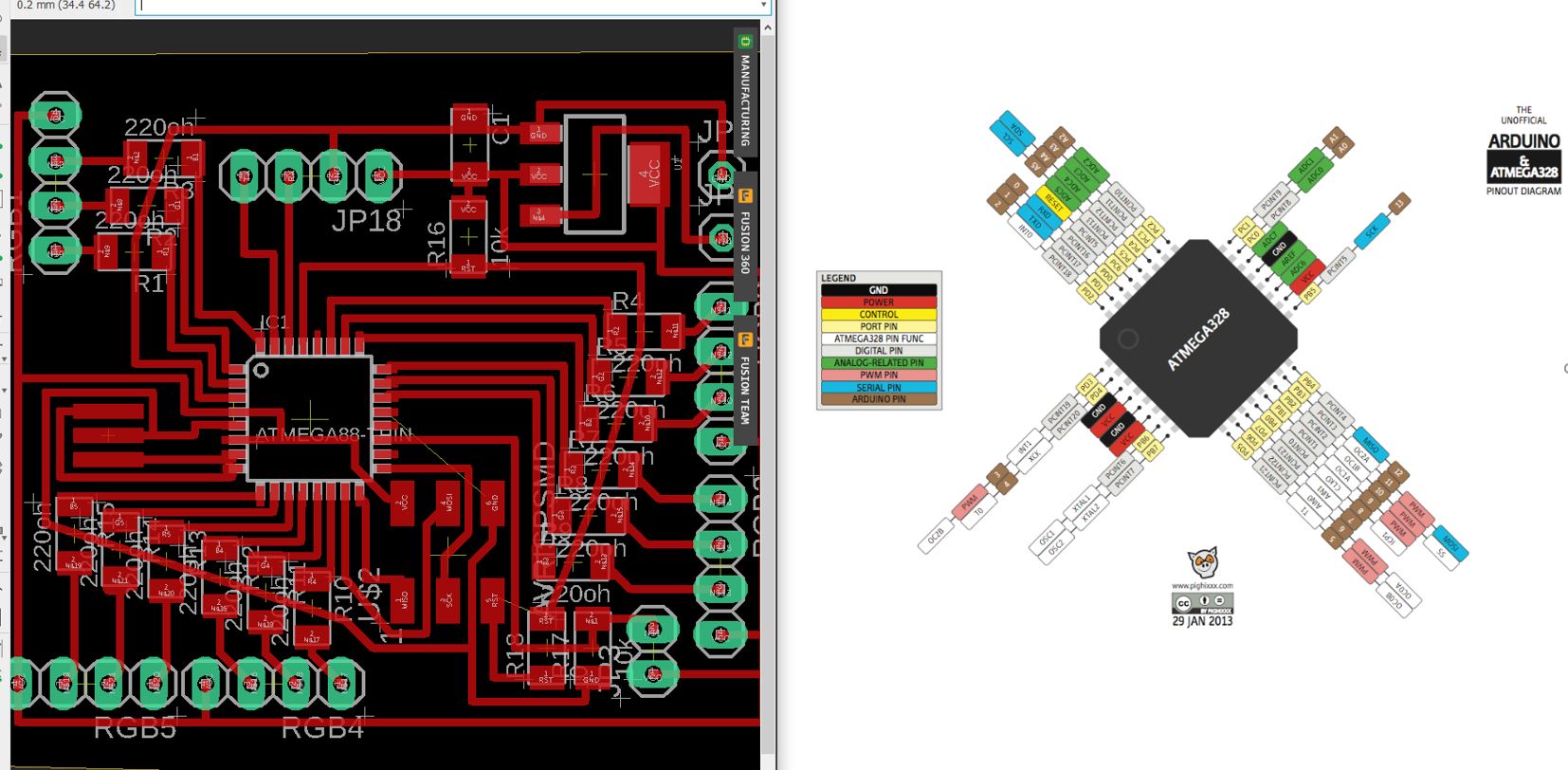

Also, the recommended program for creating PCBs is KiCAD, and then using mods we are going to create the g-code to send to the CNC mill to create the board, after which we will solder the components and (hopefully) everything will be working right and we will be able to program without a problem (again, hopefully). Having a background in architecture, FabAcademy has been the first time that I have ever had any interaction with electronic circuits, so this week should be very interesting.

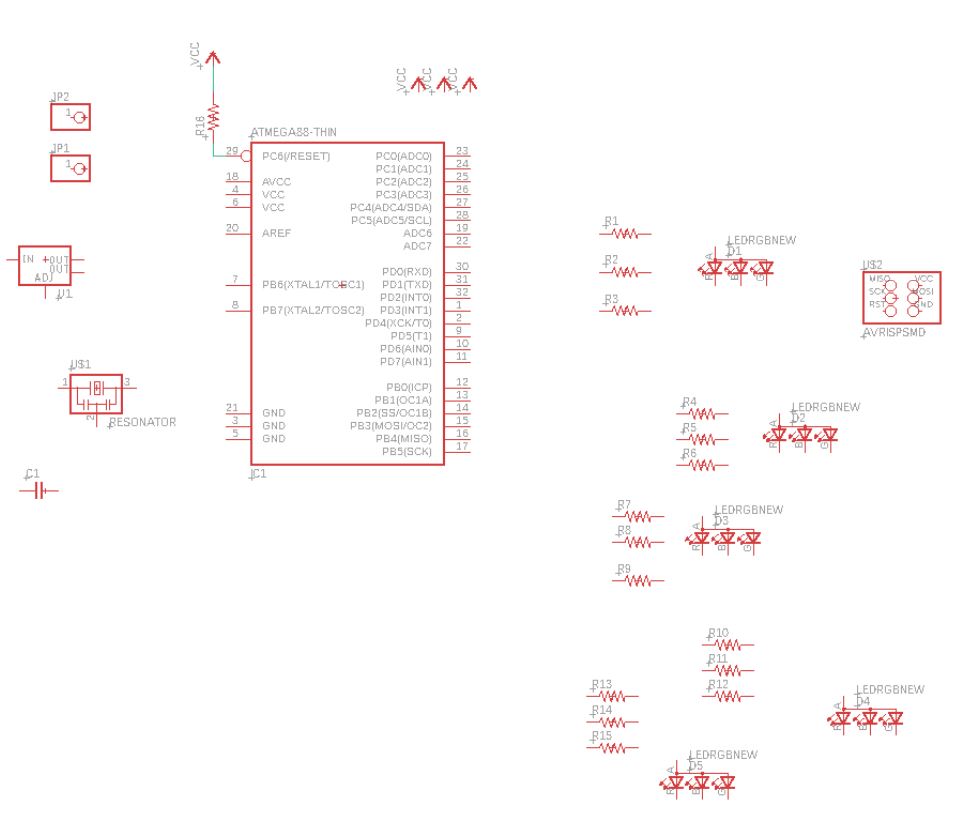

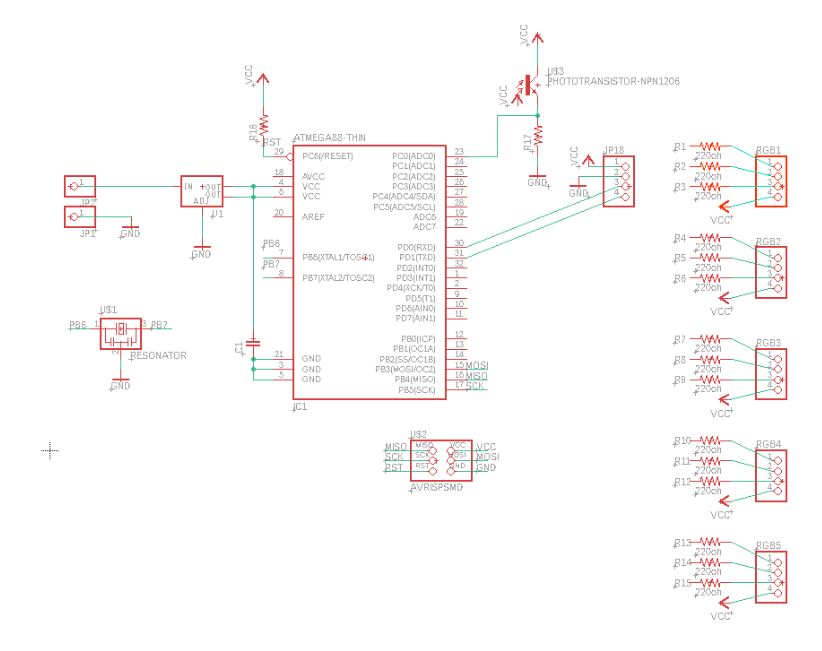

Having said all that, our assignment this week is to redraw the echo hello-world board and add (at least) a button and a LED. Let’s start.

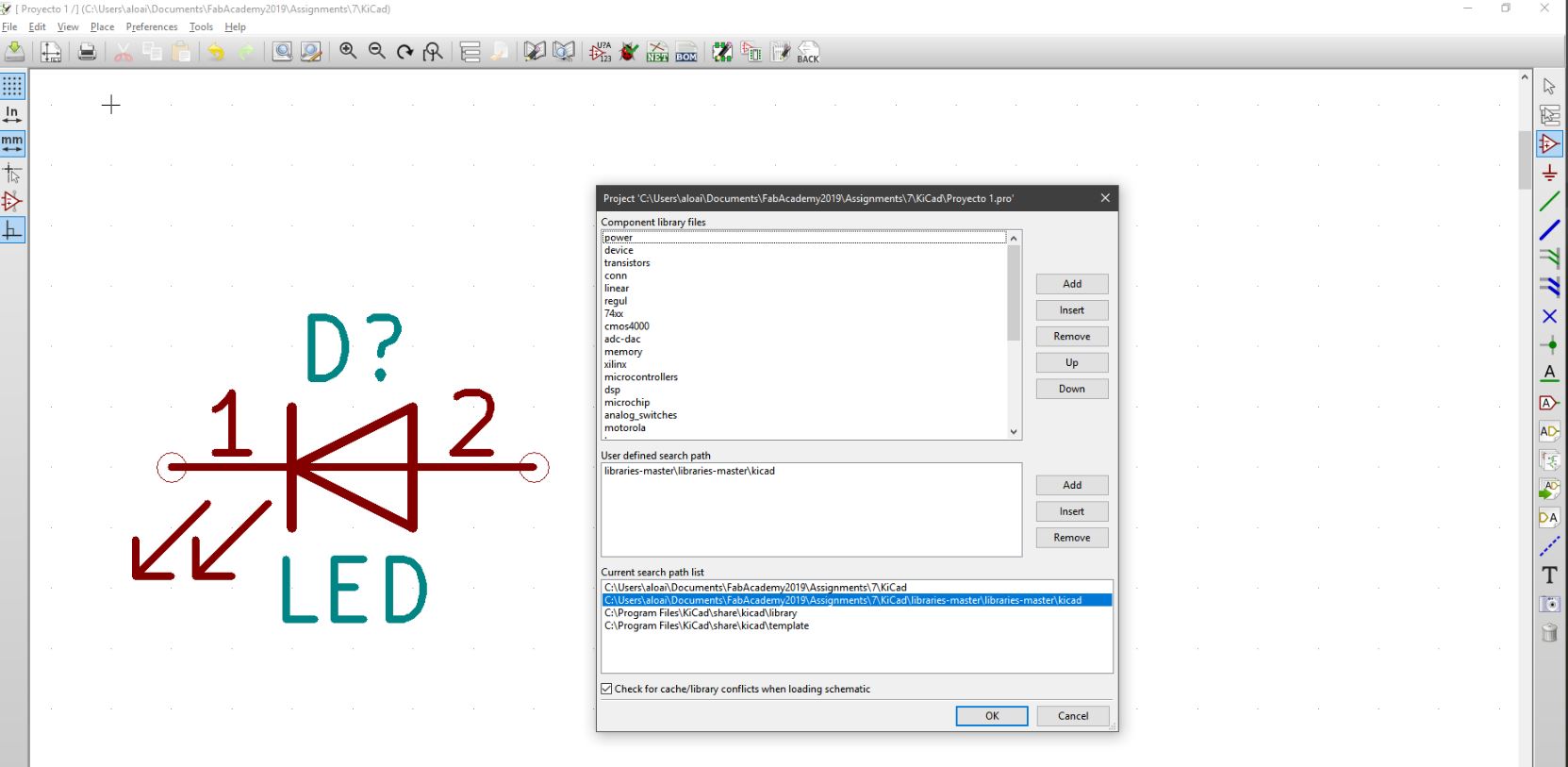

First, we downloaded the recommended software (KiCAD) to design the PCB. The program was very heavy (1GB) and took a long time to download, and when it finally downloaded, we got an error that stated that the installer file was corrupt so it couldn’t install. We tried a few steps to fix this (which didn’t work), and so we downloaded an older version of KiCAD which was smaller (300mb) and installed without a problem.

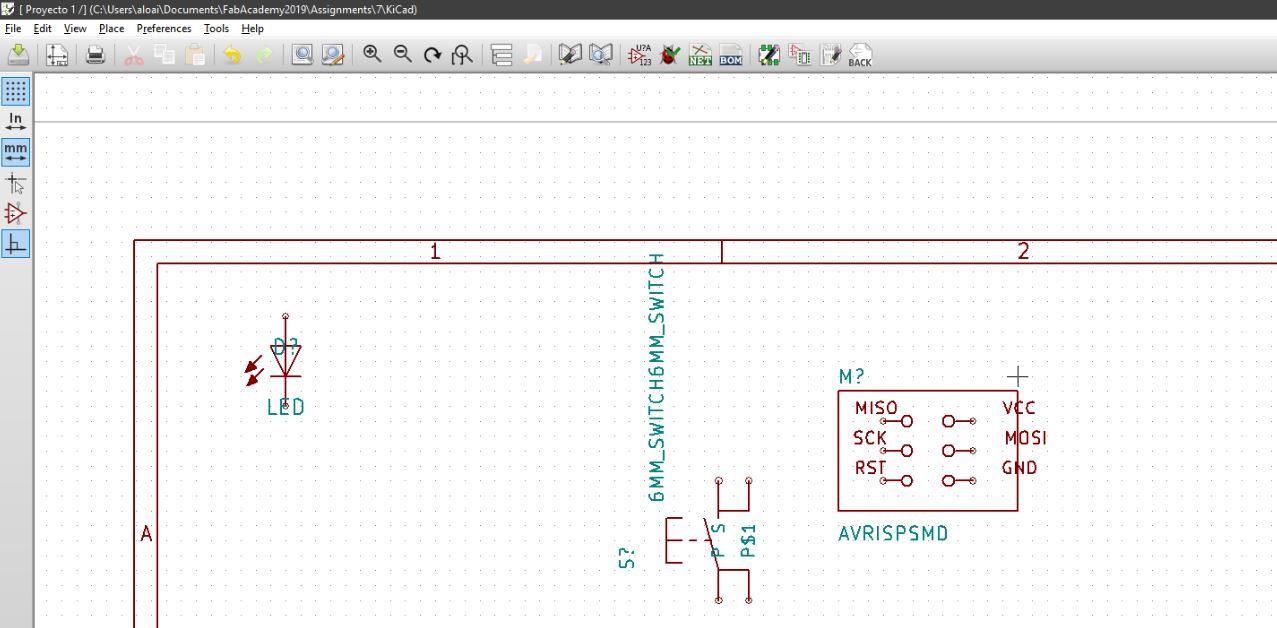

We imported the FabAcademy library of components and started replicating the Echo Hello-world board in the schematic. Loading the components was no problem, and the interface was very nice also. Everything seemed to be going well until we checked for errors and many of the wires, we thought were connected were wrong. We continuously tried to fix them, but when we fixed one another error popped up. This kept on going maddeningly for almost an hour, until we realized that it could be a bug of the program or something, and seeing as it wouldn’t let us continue, we decided to change programs.

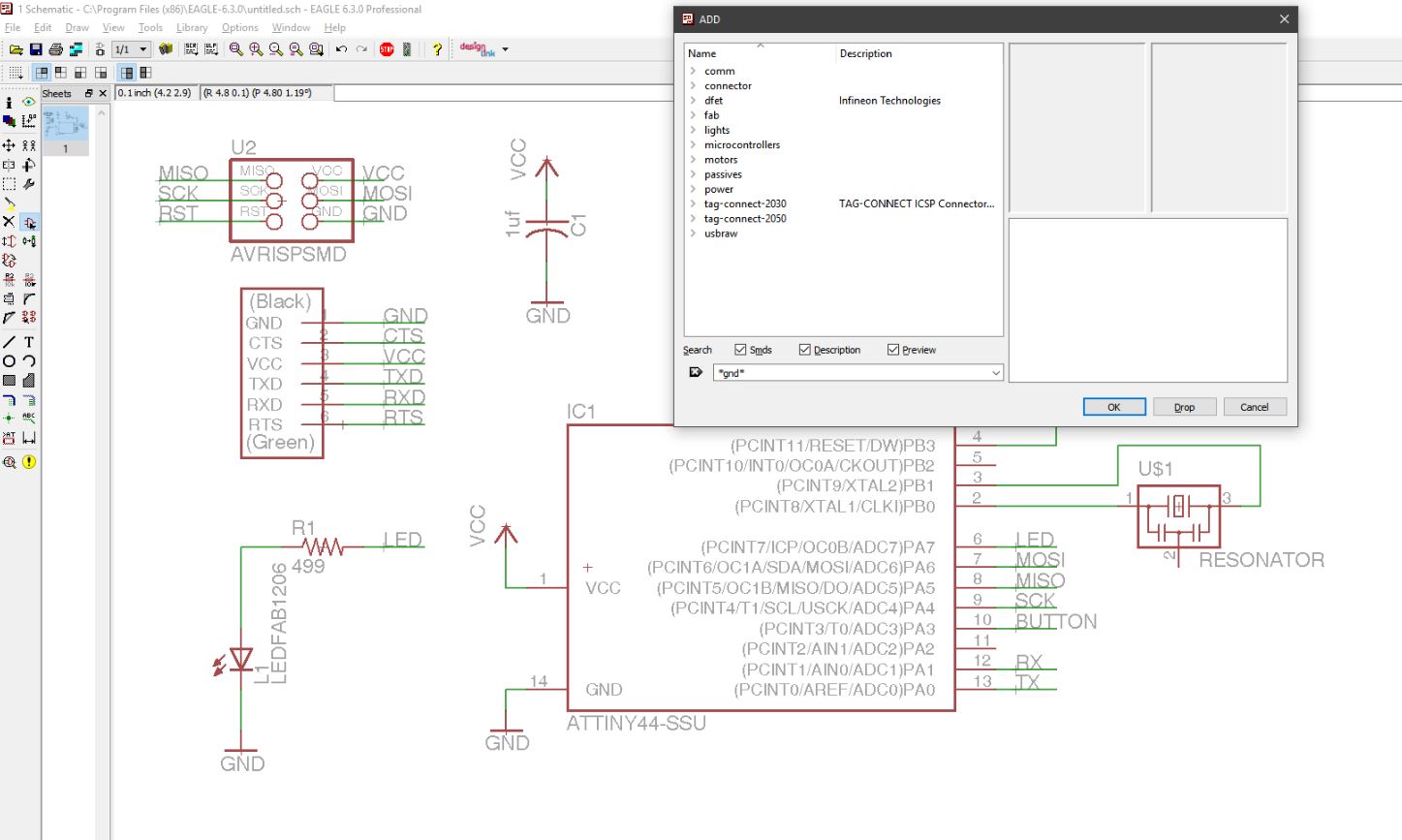

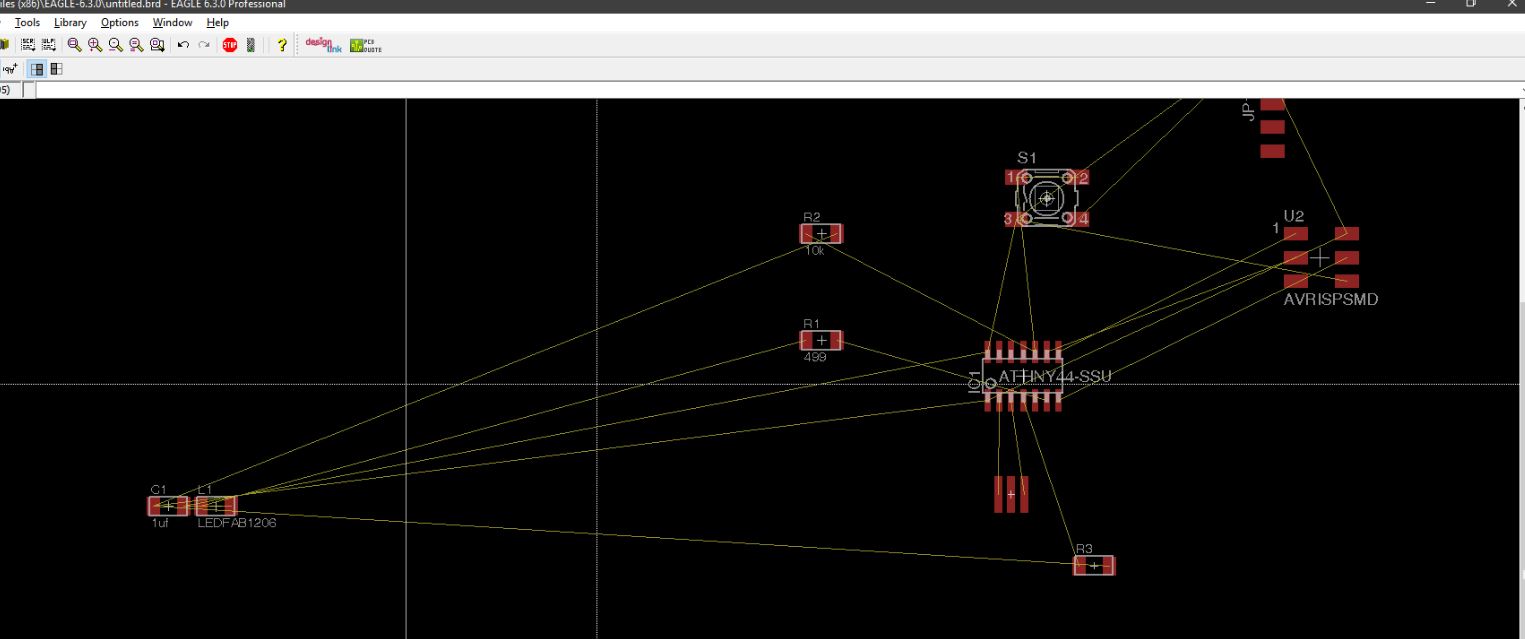

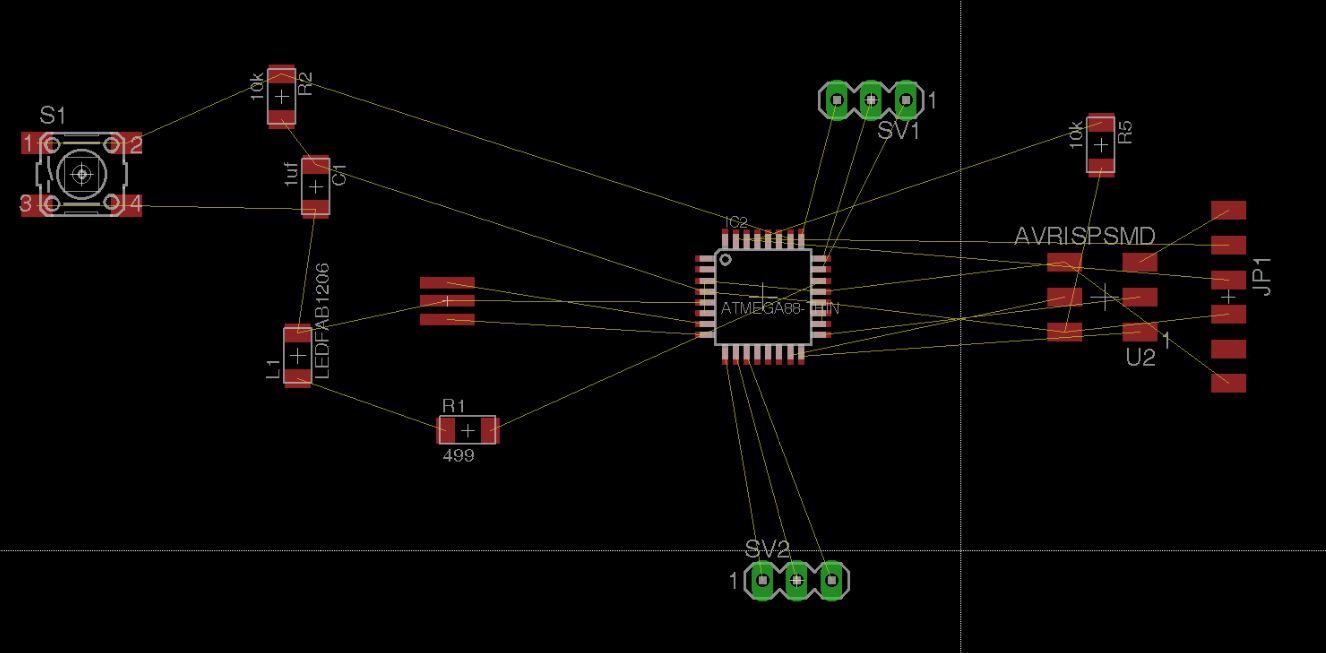

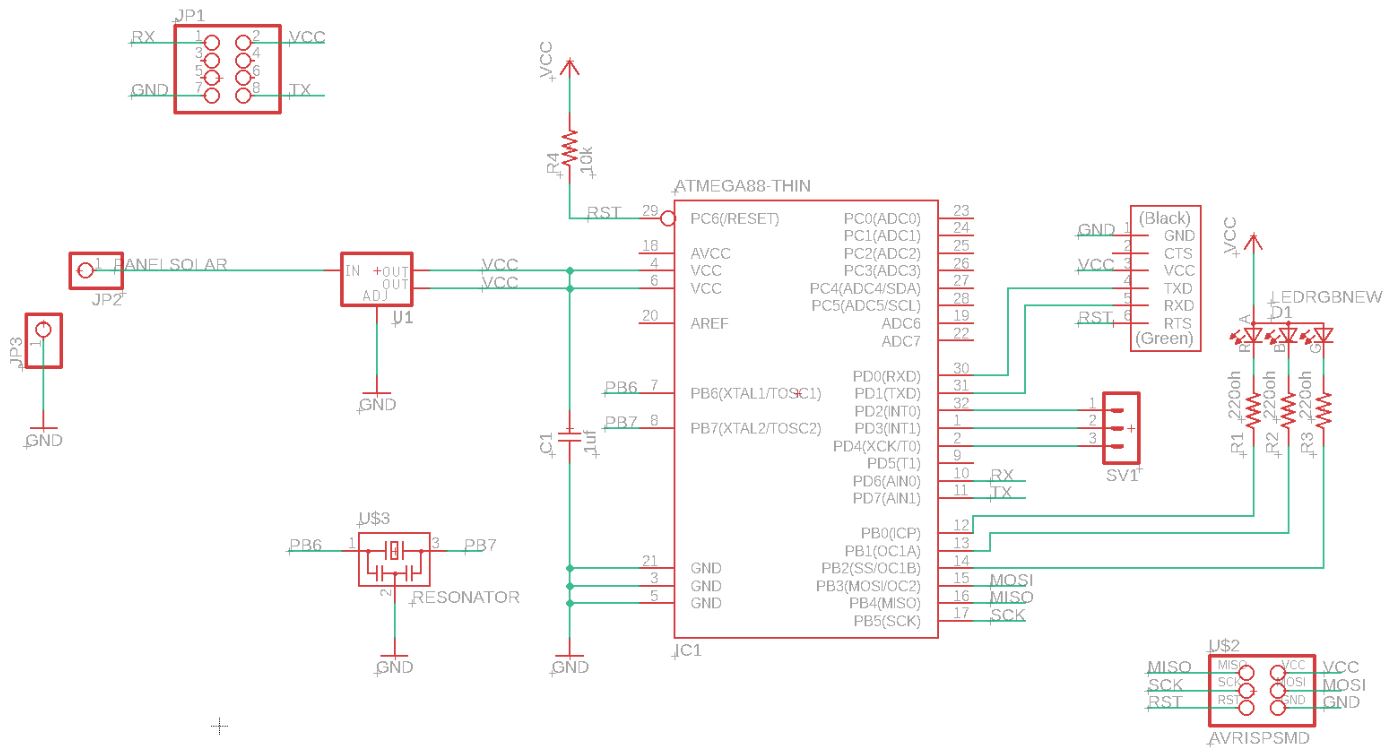

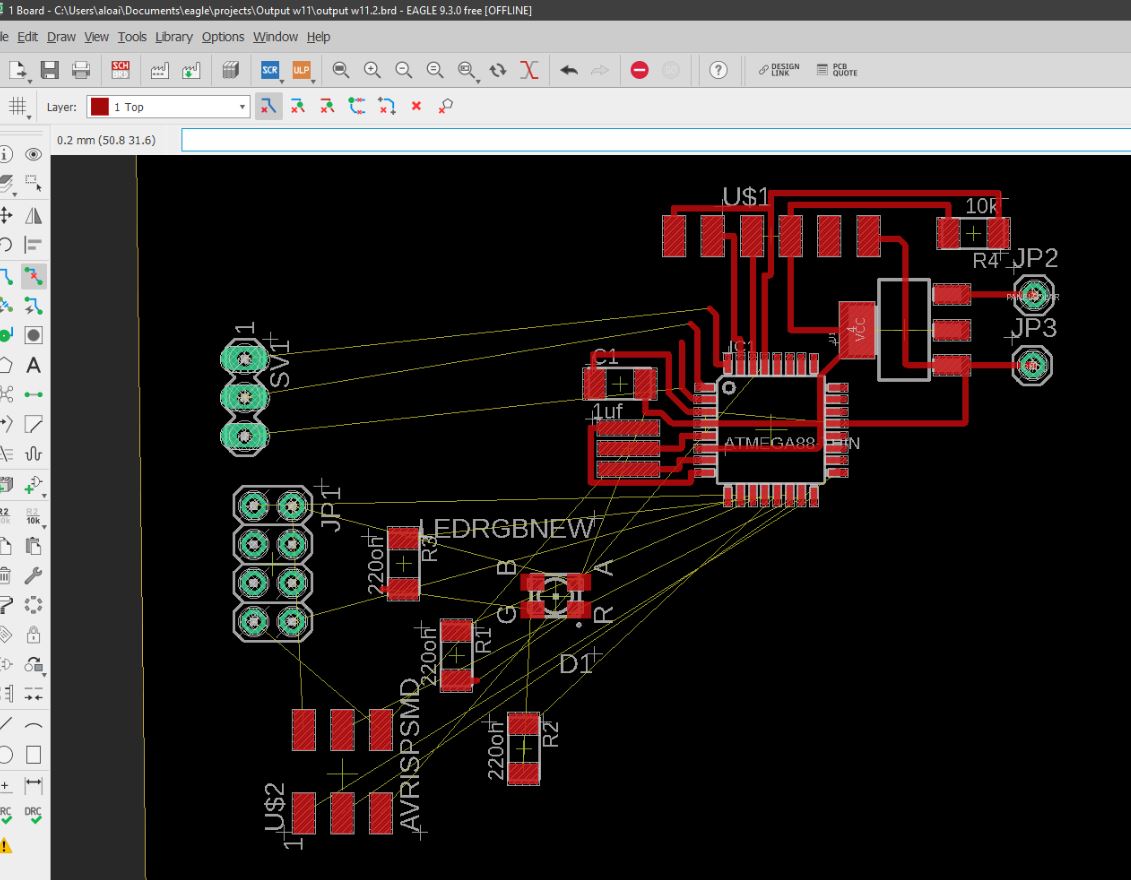

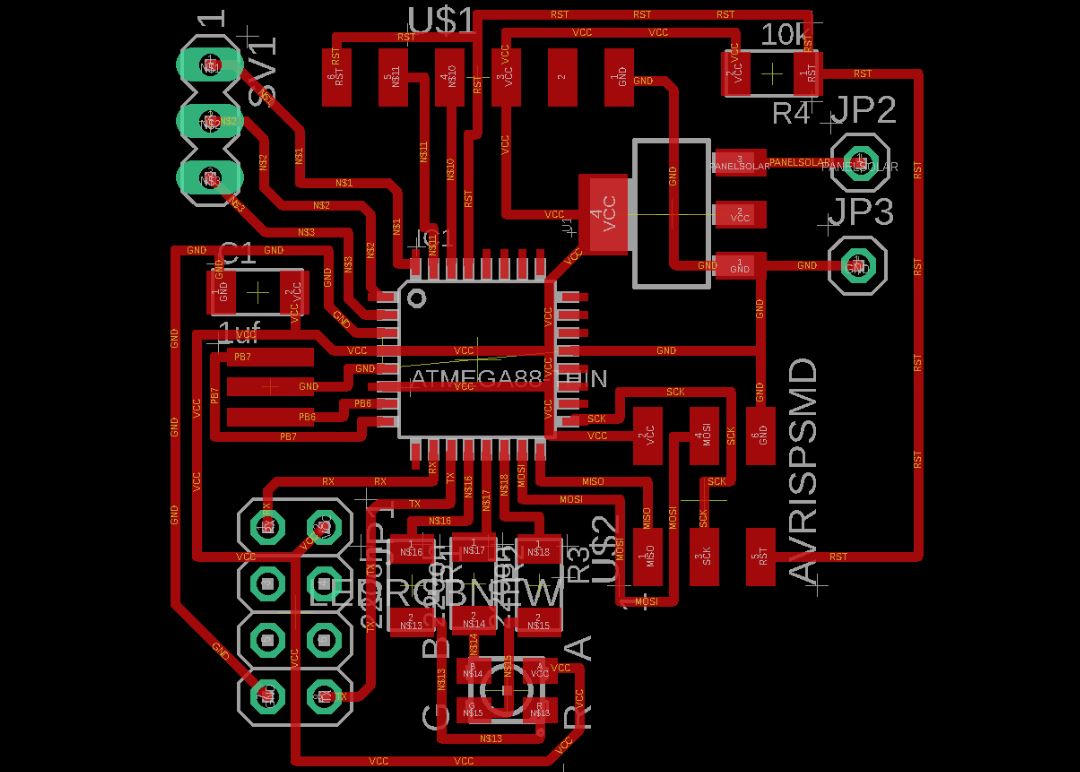

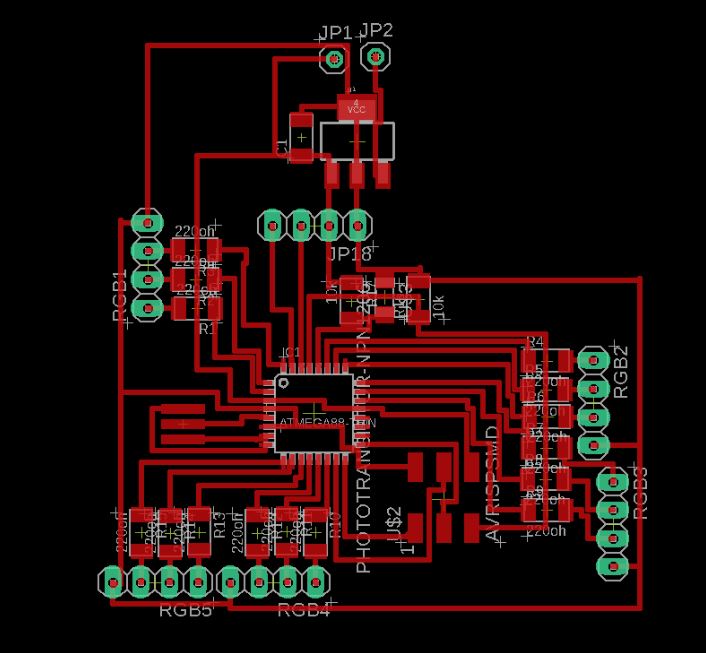

The program we decided to use after KiCAD didn’t work was Eagle. The interface was not as friendly as KiCAD, but on the up side, in the schematic the wires were much easier to attach and remained attached even if we moved the component (which didn’t happen in KiCAD). We redid the schematic we had done on the other program, and then moved on to the footprint of the board.

The workflow used to design a circuit board is:

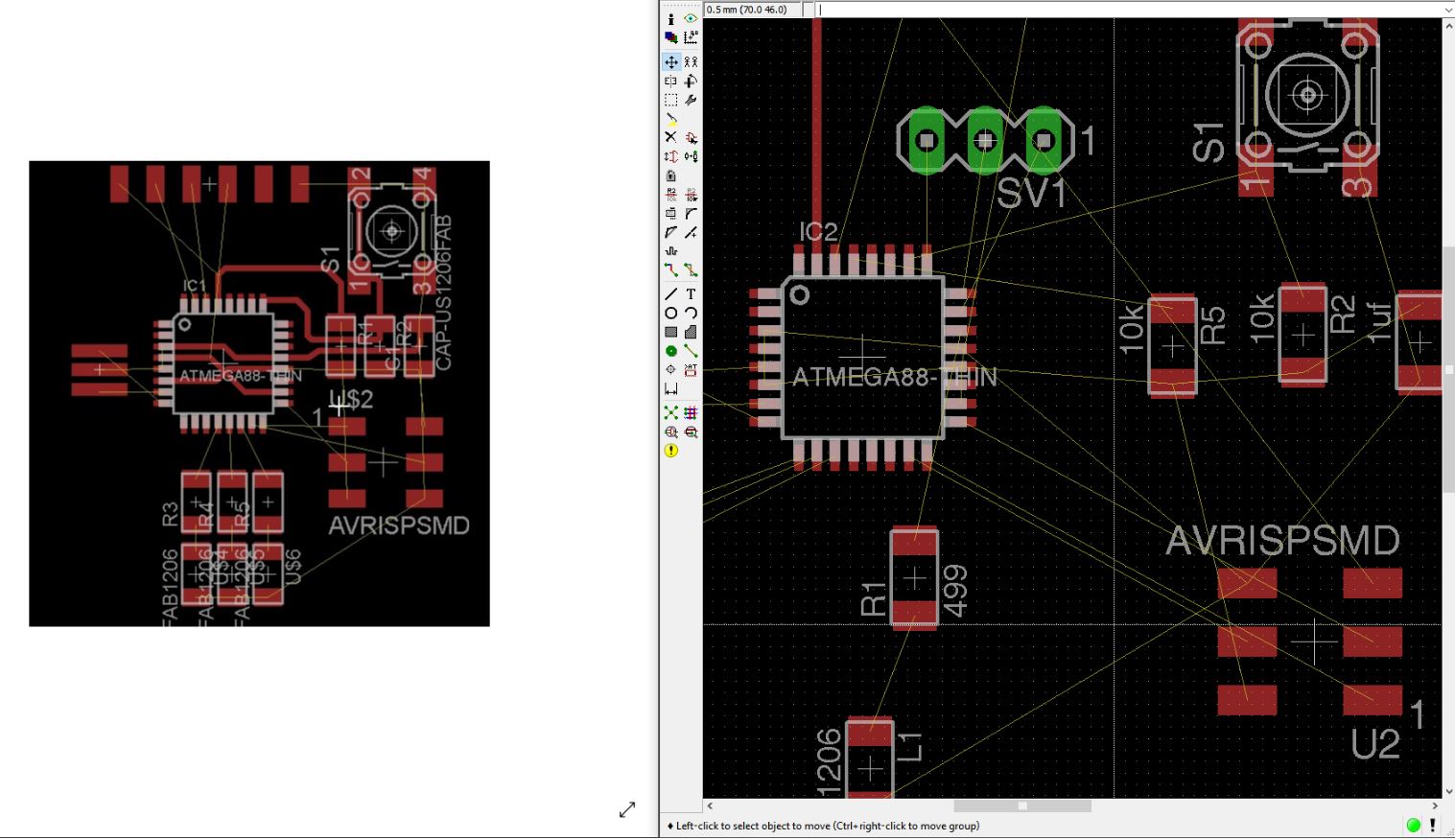

At first I was excited to try to route the board… that was until I realized how complicated it was to be able to make all the traces get to where they are supposed to without crossing all over. It took a very long time, and Alex eventually had to help us out by giving us some tips on how to start creating the connections.

After all the connections were done, I decided to add another 3 point pin and also change the shape of the board. Having understood how to make the connections, I spaced out the components horizontally until they were occupying a 10x2cm area, as I had decided that my board would also double as a ruler.

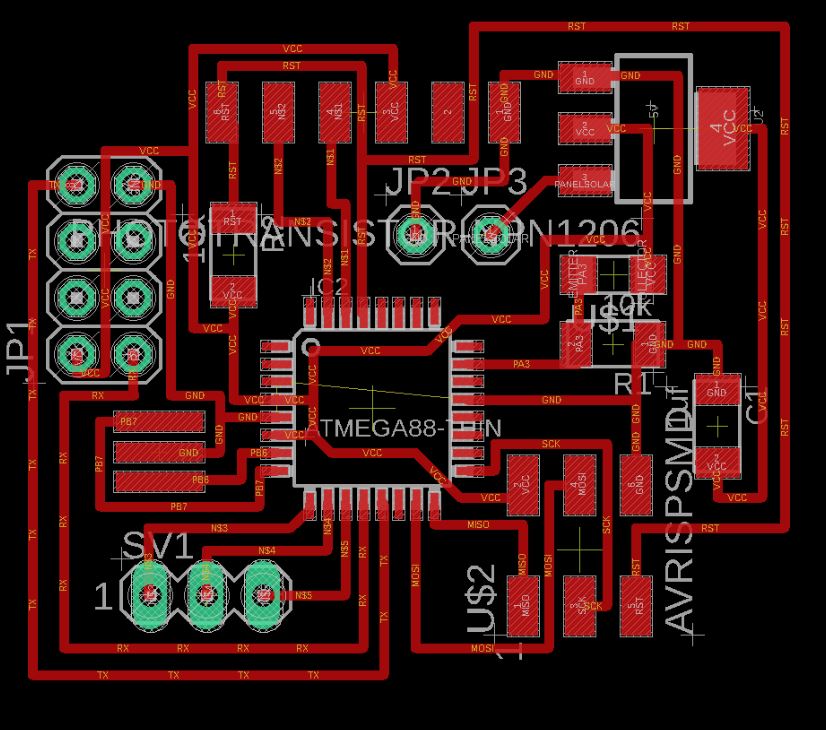

After turning off all layers except for the “top” layer in eagle, I exported the traces as an image in 1000dpi and placed that in photoshop, where I added a few designs and the lines for it to become a ruler. With that done, I was ready to prepare the file for milling.

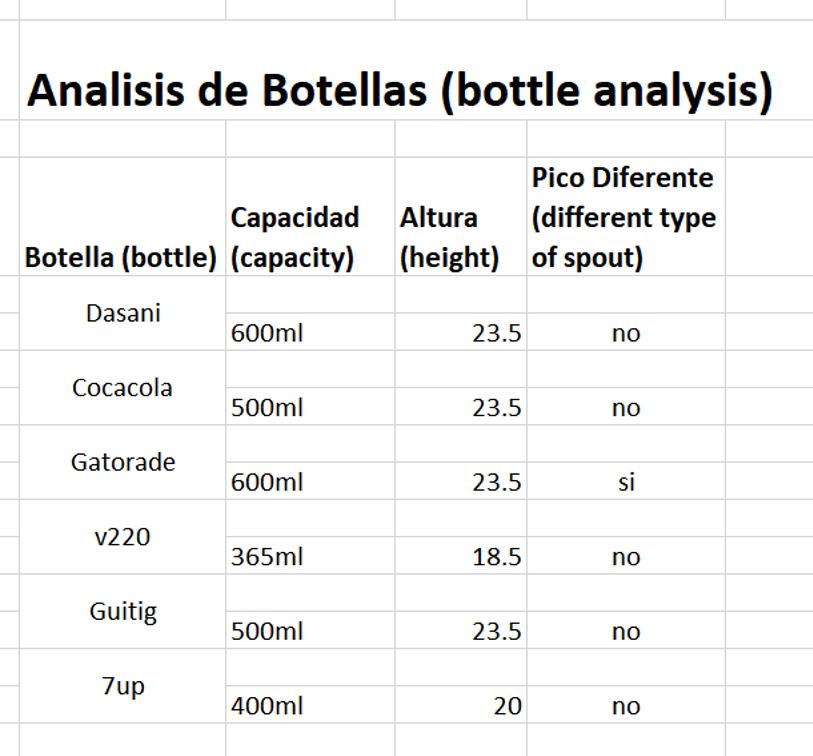

I arranged the board and created the outline, and finally I placed the images in mods so that I could export the G-code. For this, the parameters I used were (in mm):

All other parameters were the default ones in the g-code milling mods program

Milling and cutting the board was done without any problem. The problem was when I checked the board afterwards, and noticed that the traces were extremely thin. They were so thin that there were parts where the copper was either removed or too thin to allow current to pass, as checked by the multimeter. Therefore, the board had to be redone, with thicker traces. That made sense as in the beginning, having little sense of scale, I used 0.25 mm thick traces in eagle (the recommended thickness being 0.4).

The design rules I used are: minimum 0.4mm thickness of the paths and at least 0.4 mm distance between routes. Regarding the milling process, I used 3 offsets and 0.1 cut depth (to get the copper off). For more information on design rules, check this link

After changing the thickness of the traces in eagle to 0.5mm, and then editing the board in photoshop and recreating the outline, I uploaded the images to mods to create the g-code. I had to change the tool size though, because the spaces between traces were not being recognized with the 0.35 tool, and after checking, they were recognized with the 0.2 tool. Having changed these parameters, I exported the g-code and this time I had no problem with the board connections.

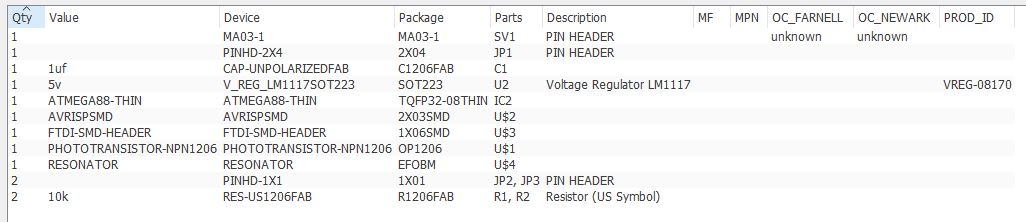

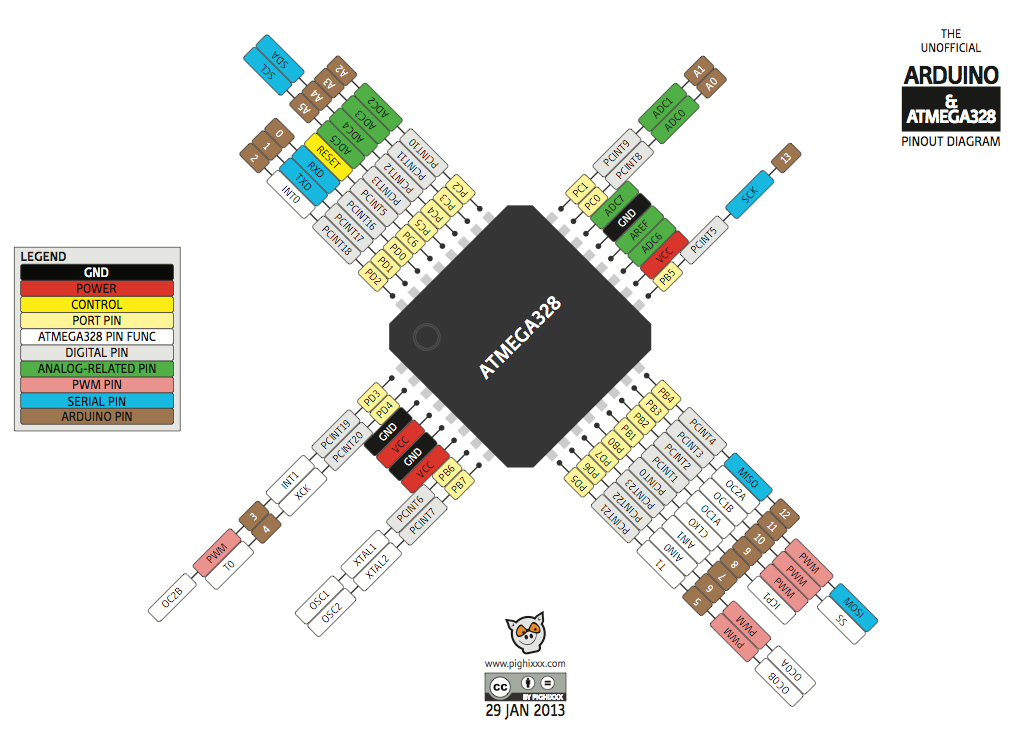

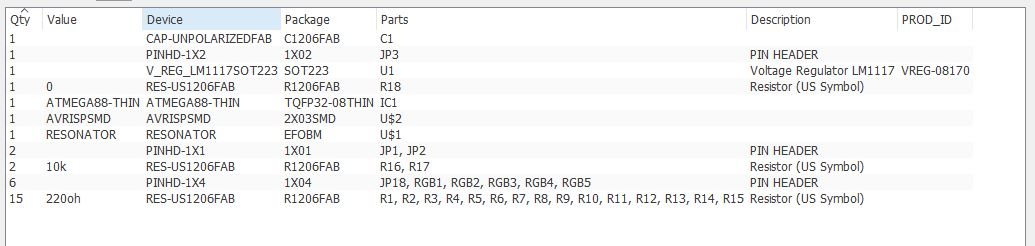

The components needed for my PCB are:

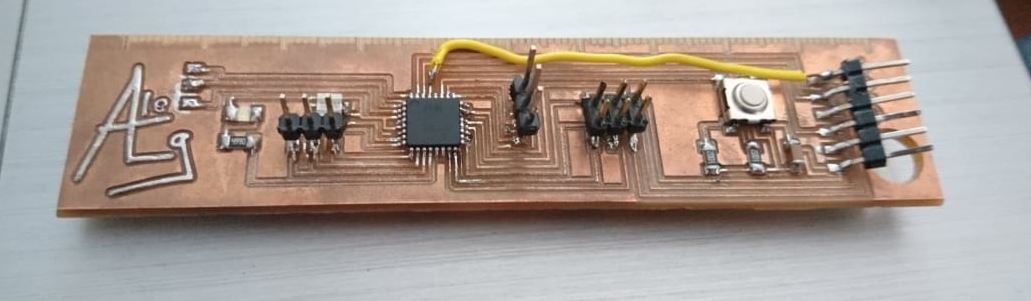

I started soldering my pcb, and having had more practice this time the process was a lot faster than before.

My friend Jorge gave me a great tip to solder better, which was to first put a little paste in the board and then add the solder and the tin, as there it is a lot faster and less of a hassle for the tin to stick well to the copper and the components. Using this method I was done soldering in no time, including the microprocessor which had many tiny legs.

After soldering I checked that the components were properly soldered and had good connectivity, and I realized there were a lot of legs of the microprocessor that were not connecting. I fixed them as best as I could, but one of the legs, trying to fix it by pressing it (bad idea), turned backwards into the micro. The good news is that that particular leg didn’t connect to anything, so, seeing as it was not giving me any trouble, I let it be. However, I now know never to try to fix connectivity by pressing on the legs of the micro.

After having had to create another programmer (as the other one had stopped working after having programmed it), I connected it to my computer and to the board and…. Nothing. It didn’t recognize the board. I checked the connectivity in the board, found a few places that the connection was kind of weird, fixed it, and tried again and… nothing. It still didn’t recognize it. I went on this loop over and over again a couple of times to see if there was something wrong in the connection and nothing.

Finally, Roberto suggested I check the pathways from the connector to the micro, and make sure everything was going were it was supposed to. Of course, the problem was there.

I had been so concerned with the aesthetic design of the board that I never noticed that the RST path didn’t connect to the processor but to the other RST path from the other connector (the 1x6). I suppose that is what happens when I rely too much on the software without really checking the logic of the connections. Luckily, creating the connection using a jumper wire was no too complicated, and after that was soldered (though my board became very fragile) I connected it (via the programmed I fabricated in Week 5)and it worked!

Finally, the computer recognized it and it was ready to be programmed.The programming was done in Week 9: Embedded Programming

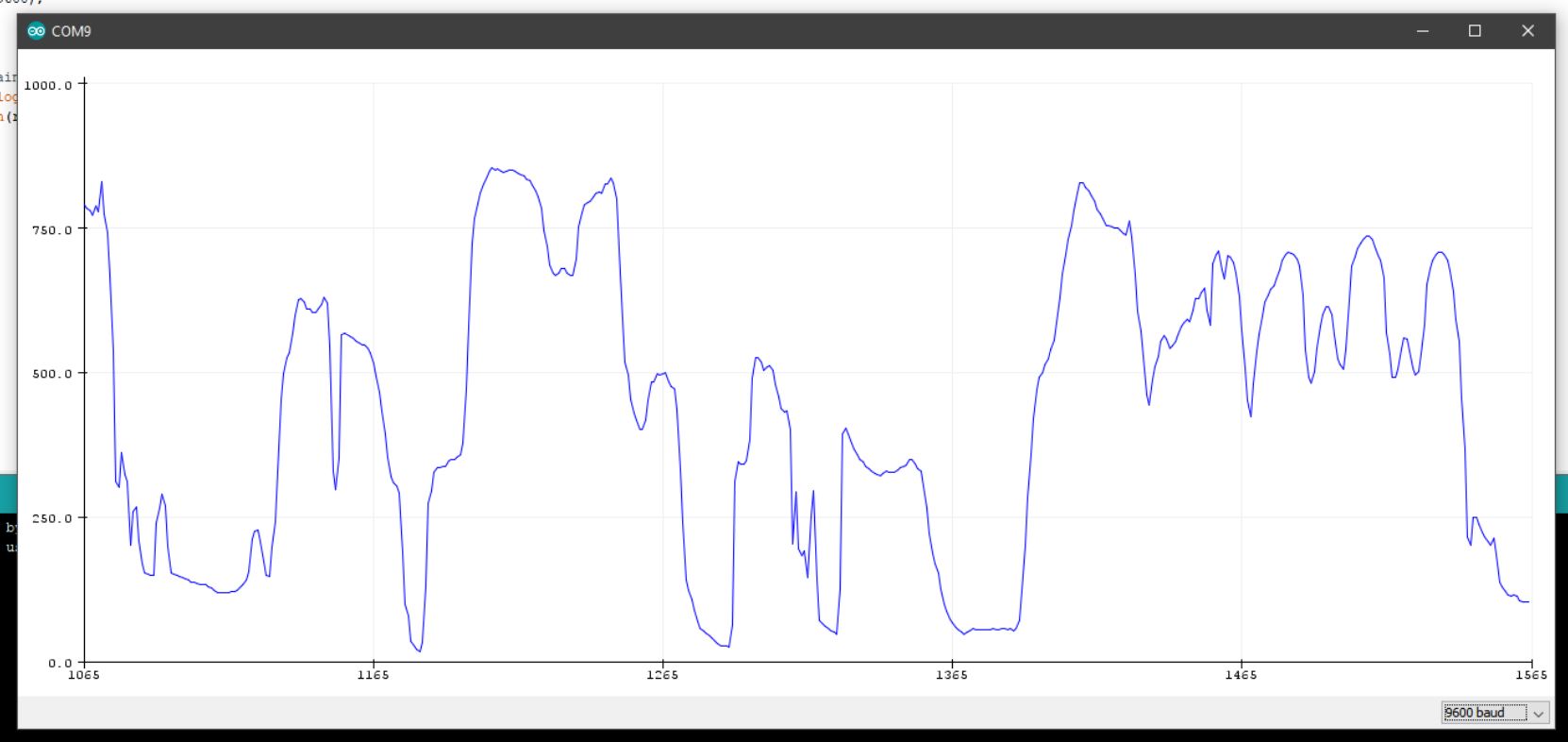

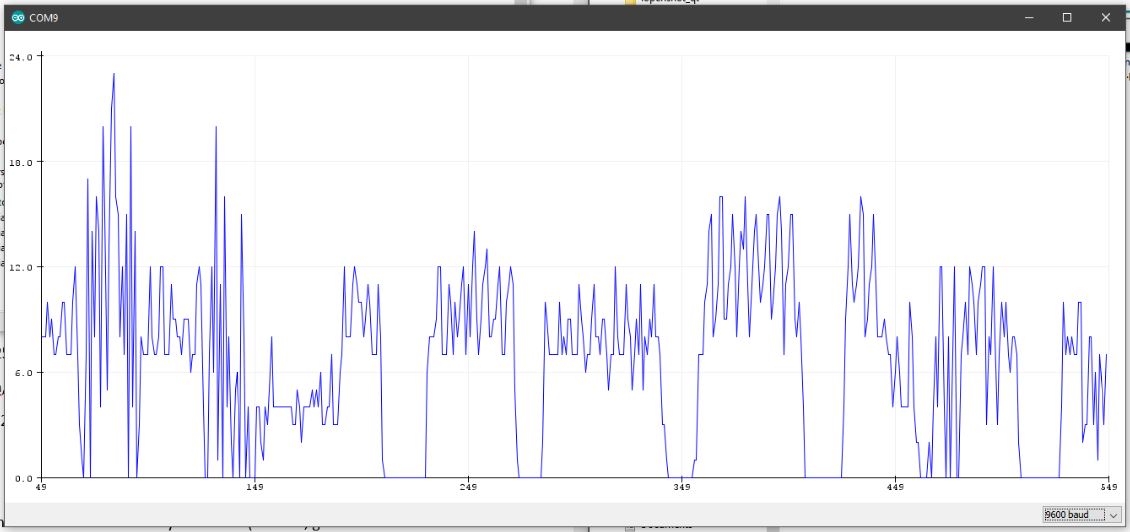

There are two test machines in the lab which I used to observe the operation of the circuit board: the multimeter and the oscilloscope.

With the multimeter I was able to check how the micro works by checking the connection between the internal circuits of the micro (as in, checking that there is an internal connection between the different GND pins and VCC pins inside the micro).

With the oscilloscope and my Output week board, I saw the changing current which varied as each different led lit up. The connection was tested on each side of one of the resistances connected to the leds.

I learned a lot this week. I enjoyed understanding the logic behind PCBs, and how important it is to always double check the connections. Also, no matter how much you design your board to look nice, if it doesn’t work, it is useless. Always make sure the paths between the connectors and the microprocessor are where they are supposed to. But most important of all, it is very important to do -and document- the assignment the week you are supposed to. At the time of writing this, I am finishing week 9 according to schedule, but still have 3 or 4 weeks of catching up on documentation to do, which I really hope to accomplish soon.

Overall, this assignment was a great learning opportunity and I really liked being able to design, understand and create a PCB which is something I always wanted to know more about but wouldn’t have had it not been for FabAcademy.

March 6 - 12

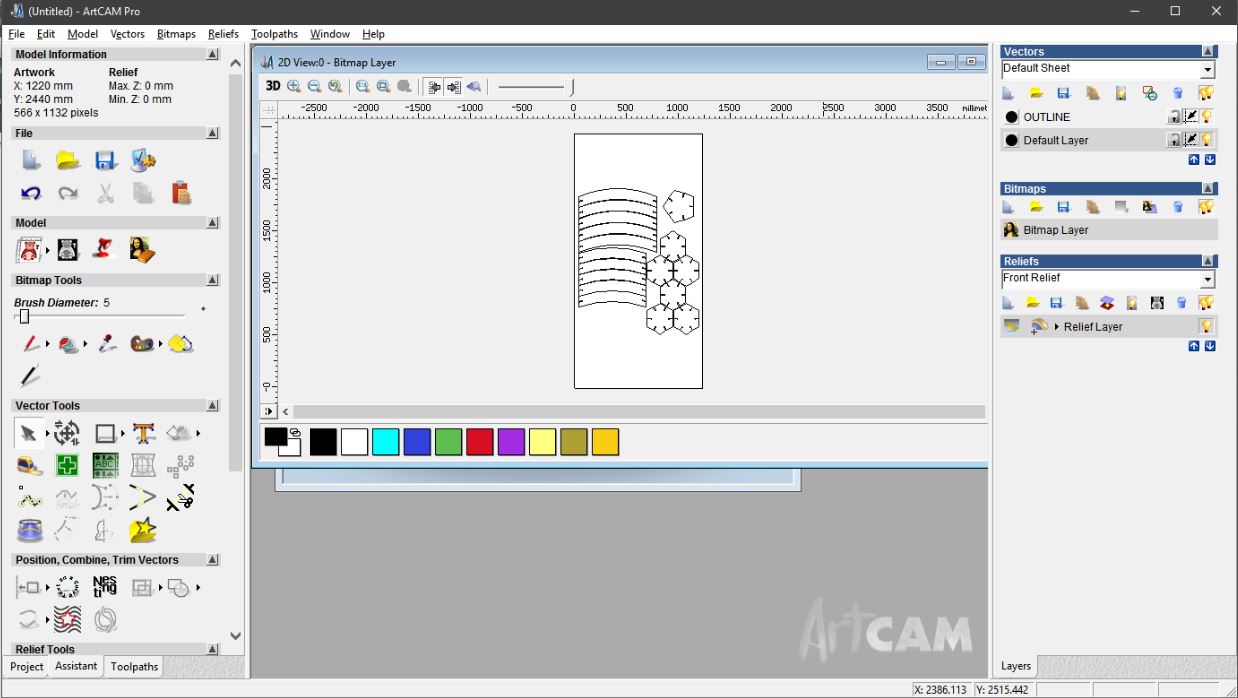

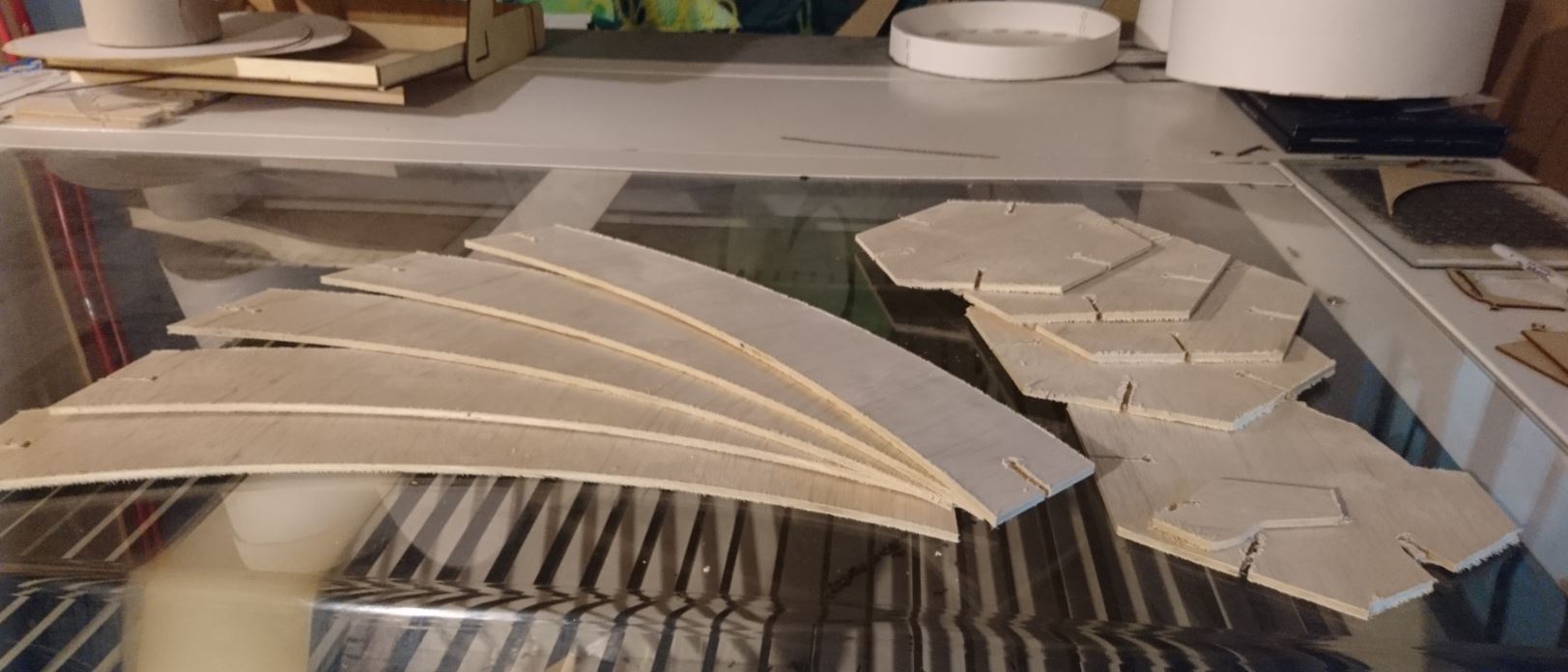

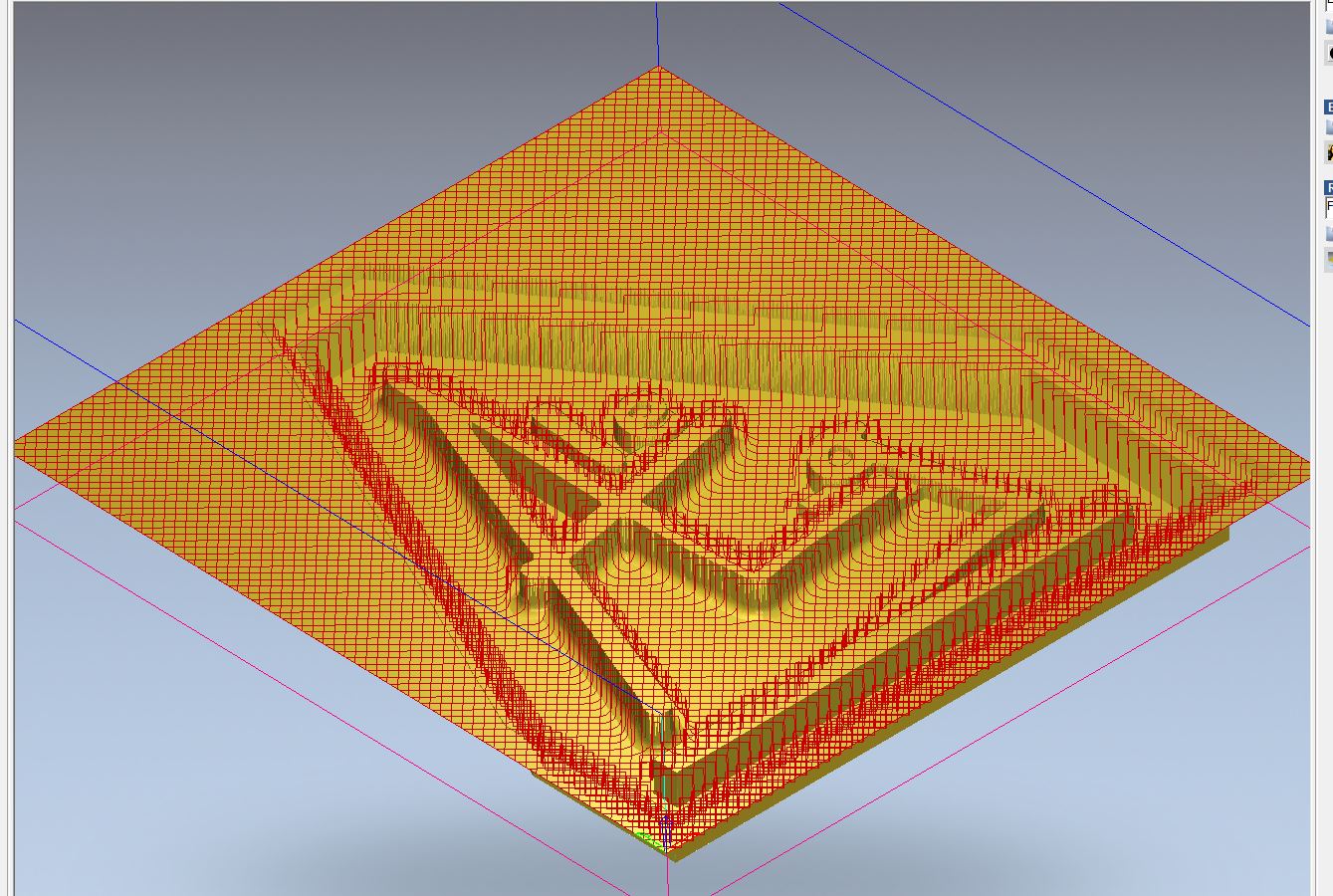

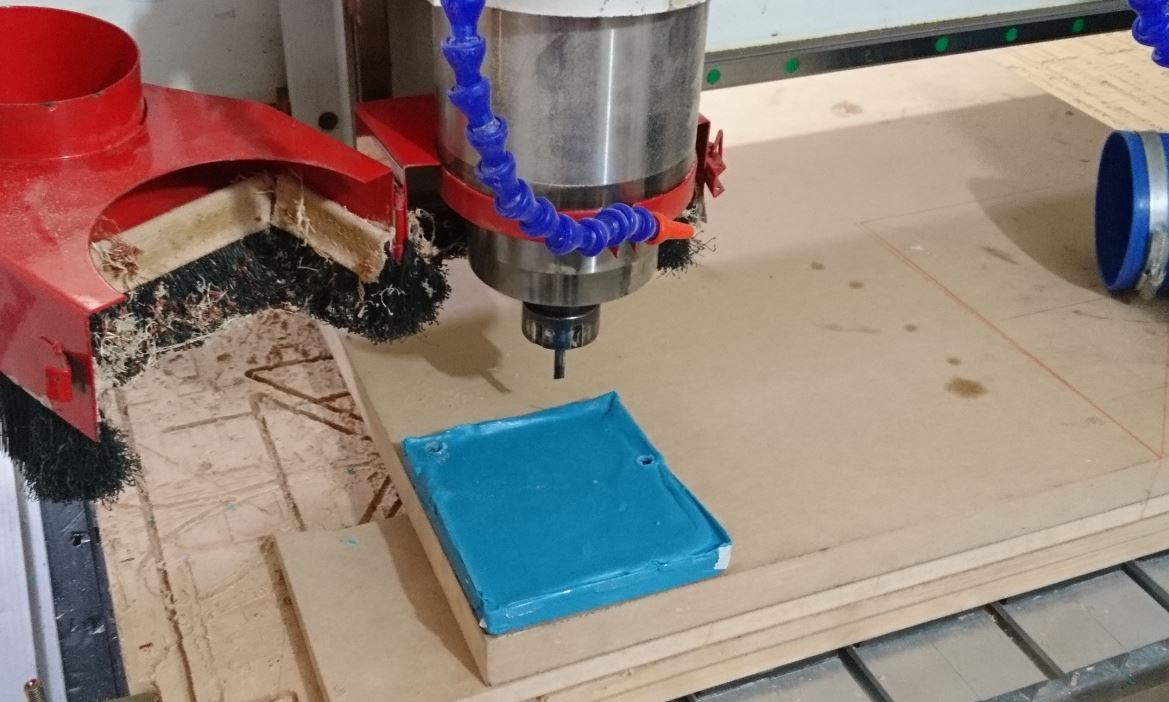

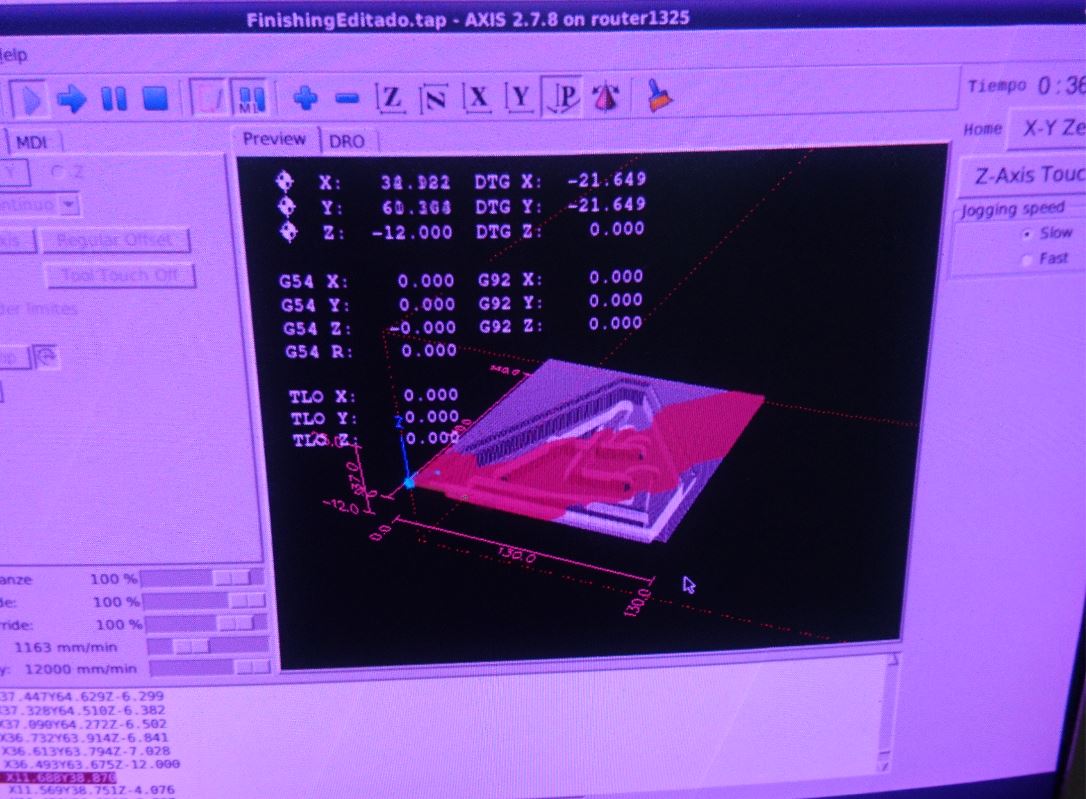

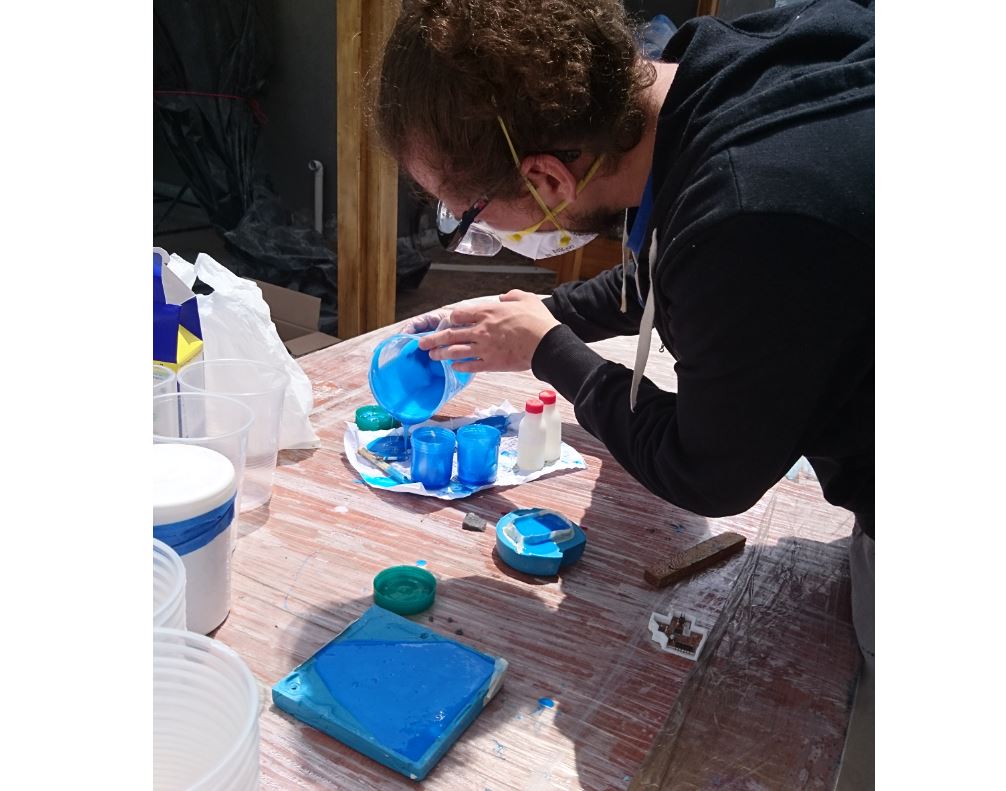

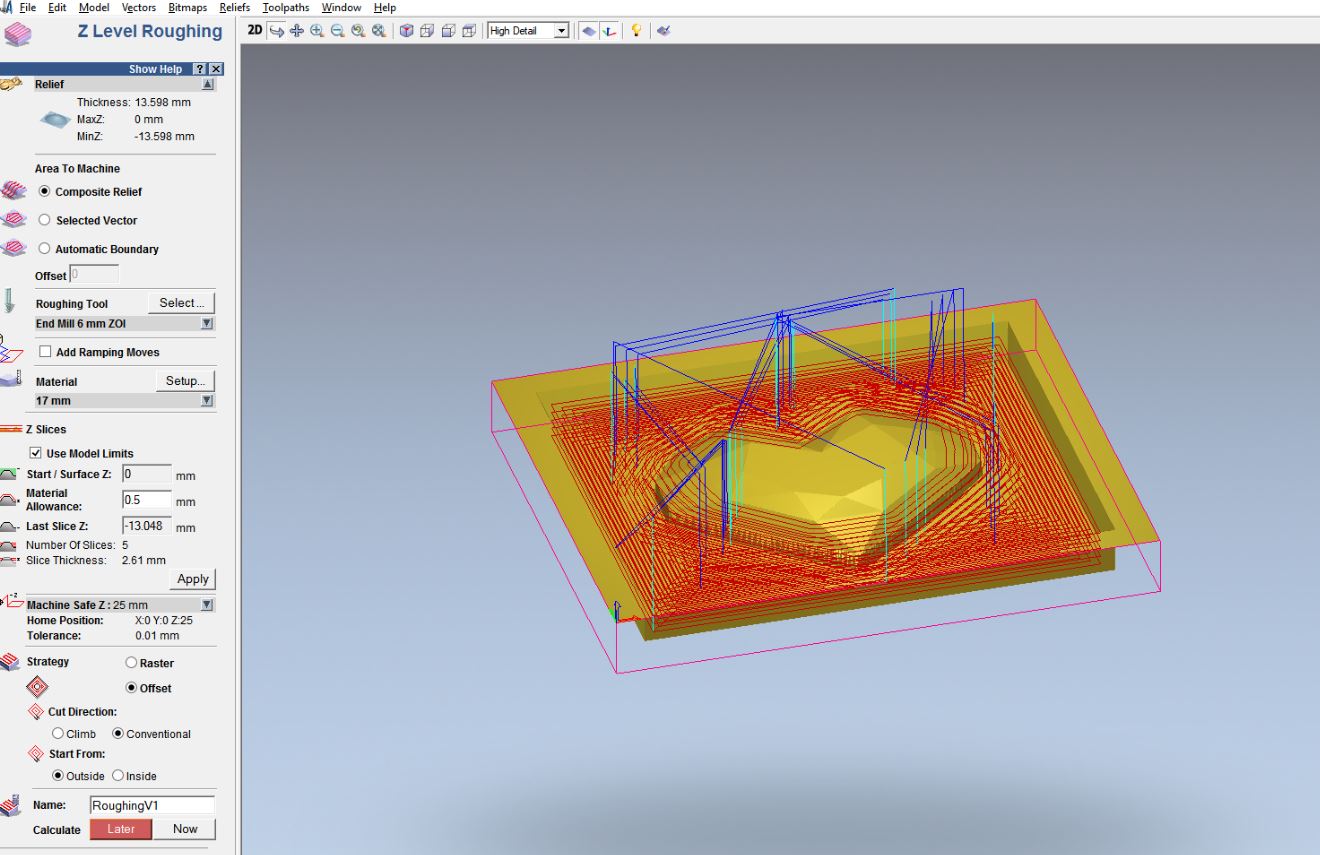

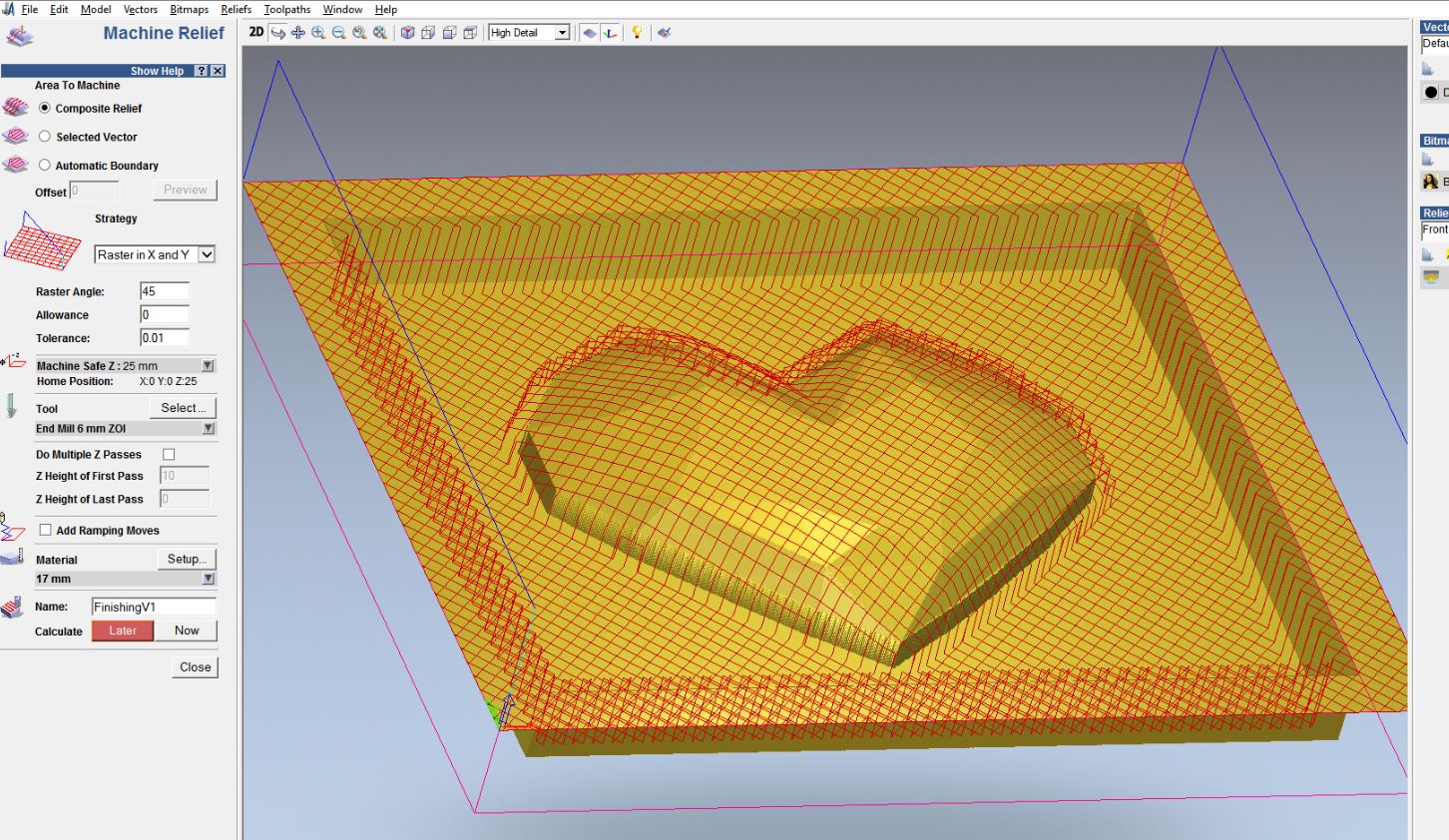

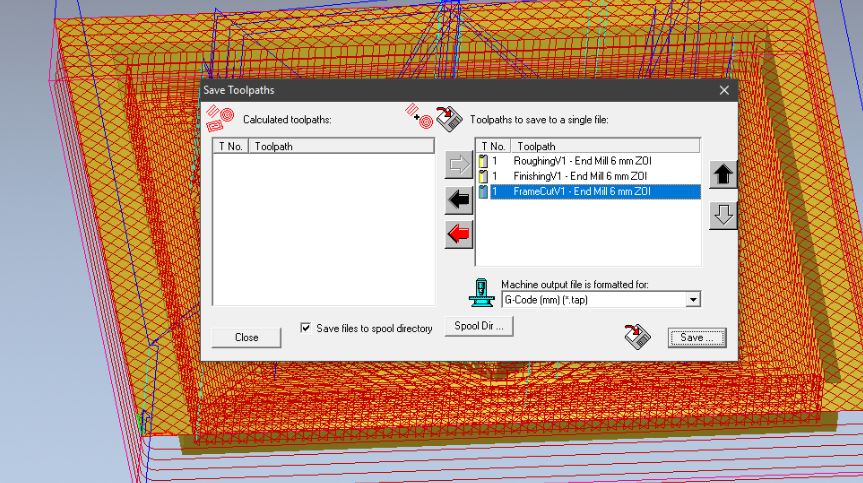

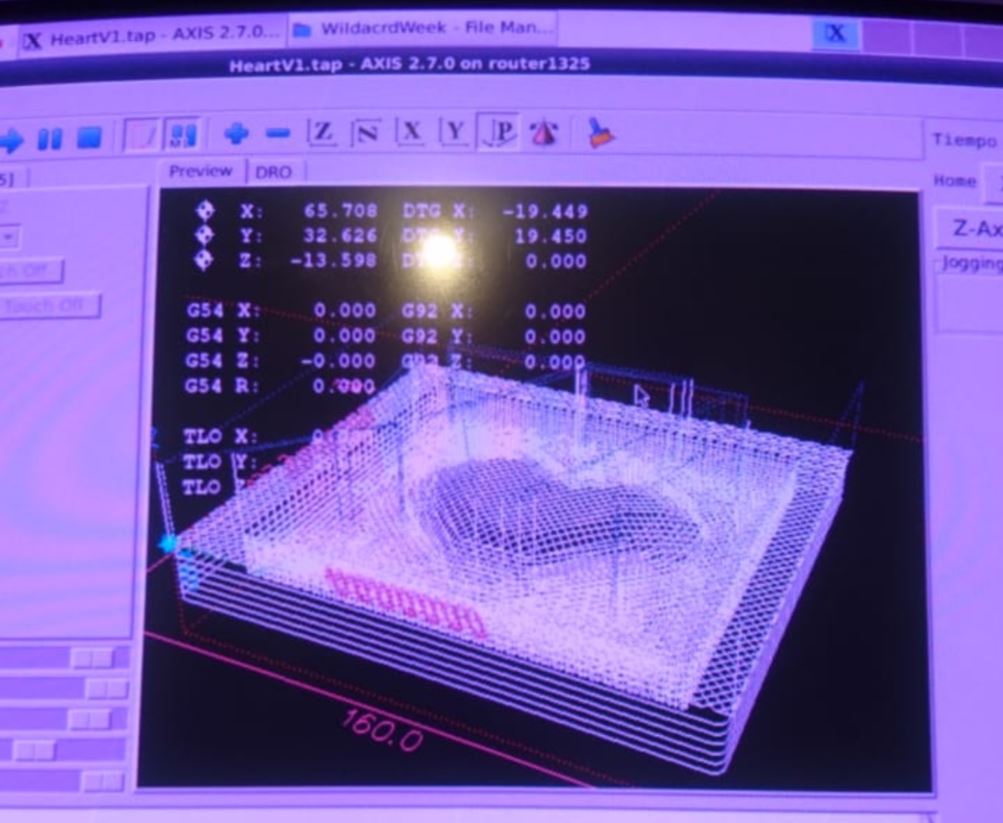

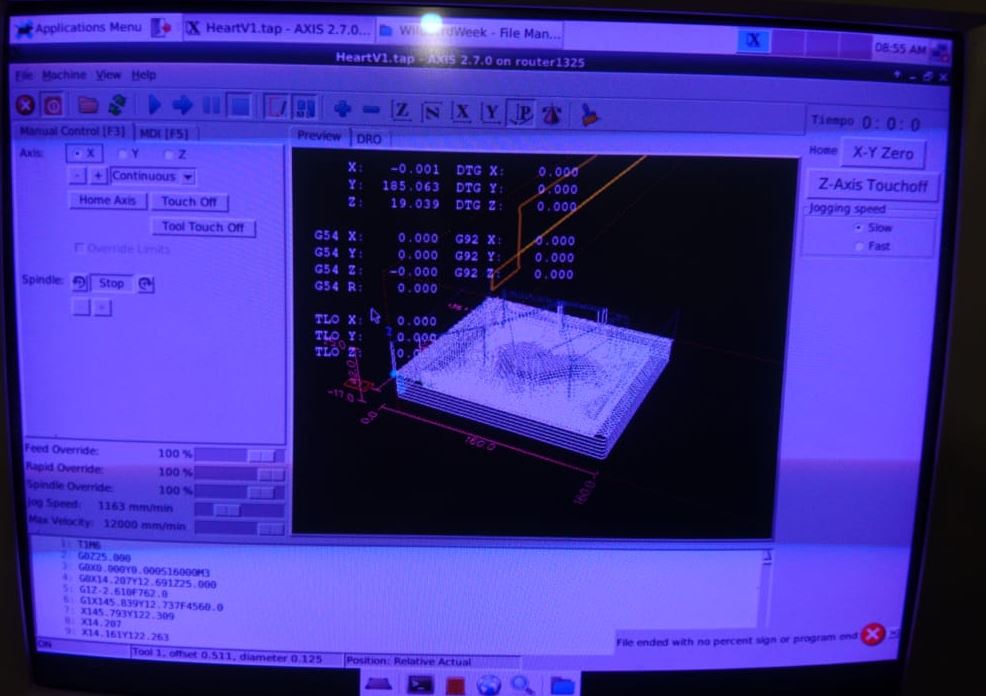

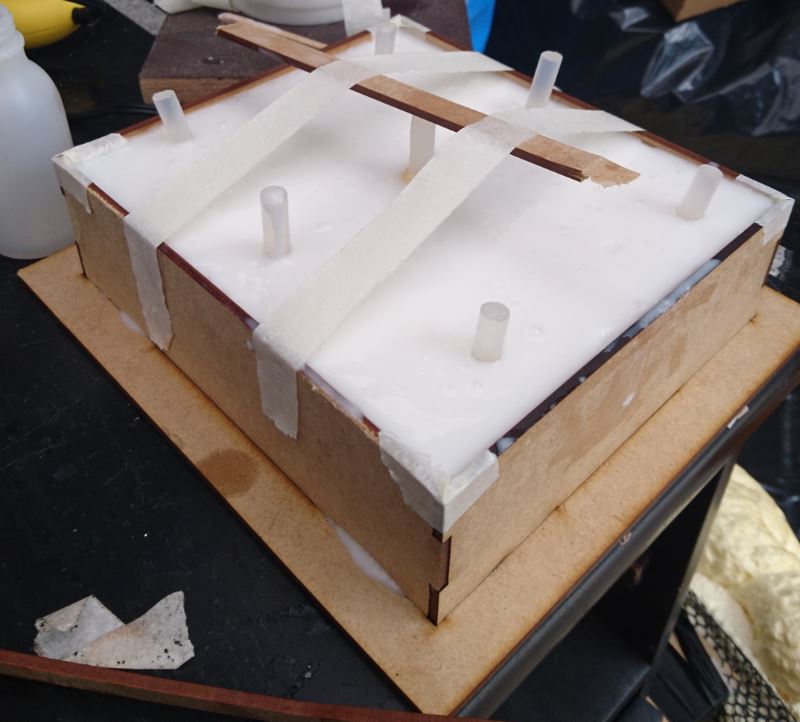

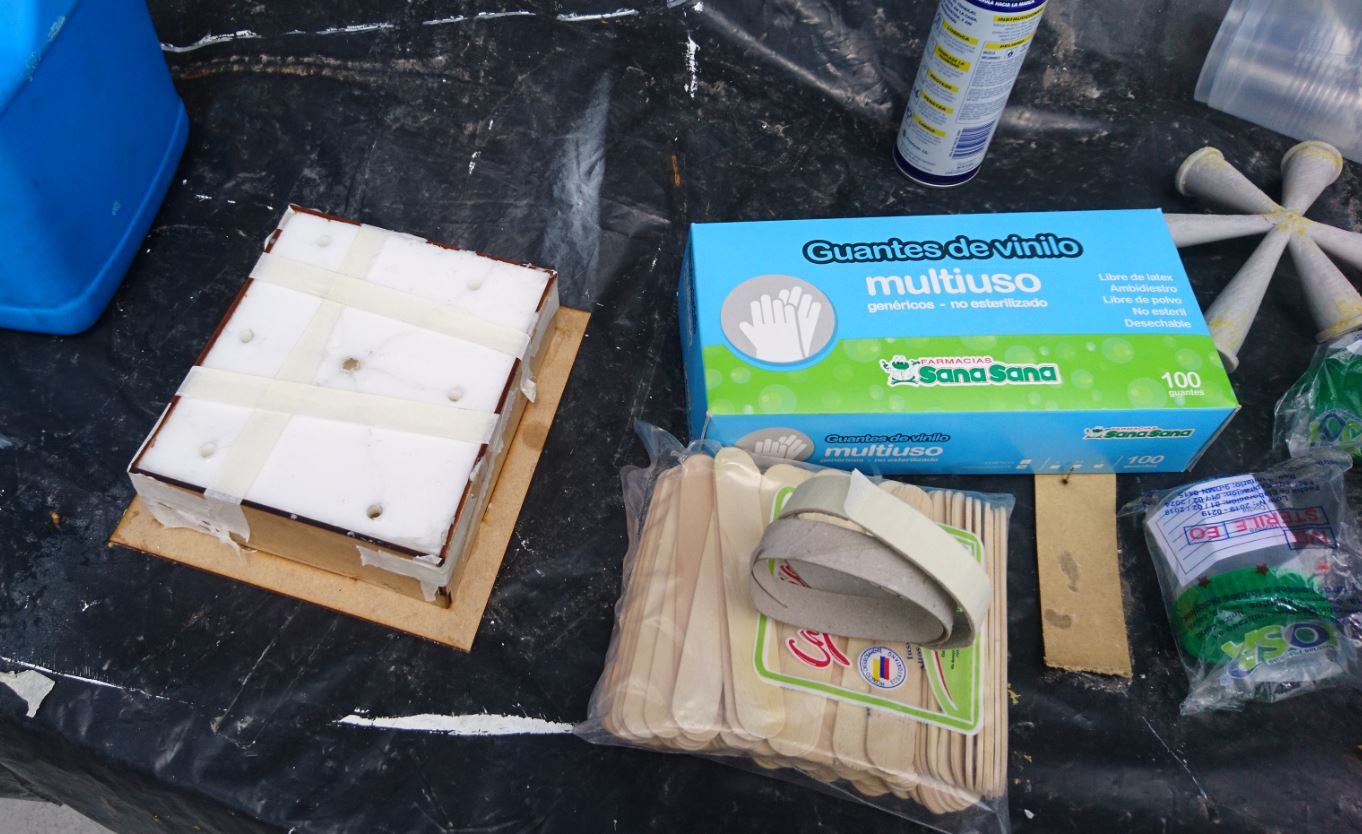

For this week, the assignment was to Make something BIG. Seeing as my final project is to create a dome (using recycled bottles), I wanted to make use of this opportunity to verify that the angles that I had calculated during Computer Controlled Cutting would work on a larger scale (which they should). Learning to use the CNC on larger materials should be interesting. During Electronic Production week we learned how to use the CNC and the processes involved, so I will not repeat the documentation of the safety precautions and observations.

Seeing as I had successfully created the press-fit kit and it worked well in week 4, and it was relating to my final project, I decided to create a dome in large scale. For this, I modified the pieces that I had created for the press-fit kit so that they adjusted well to the new material and scale.