Week 14: Mechanical design

Group assignment: design a machine that includes mechanism + actuation + automation

build the mechanical parts and operate it manually

build the mechanical parts and operate it manually

This week we had to create the passive parts of our machine. me and my group,

formed by Dario Bernabini

and Tommaso Lombardi,

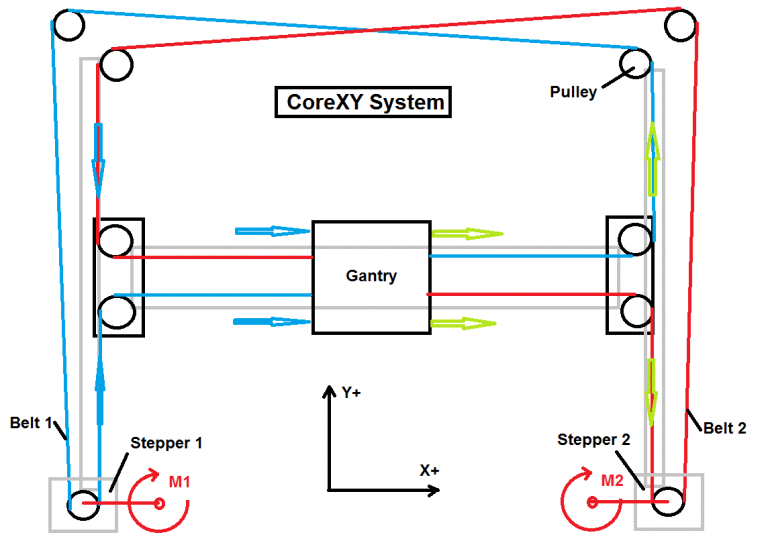

we decided to make a draw machine (the first idea was that of a grab machine but the time was lacking). After various research we opted for a corexy system

How does the corexy system work?

As you can see, the system requires only two stepper motors and provides a means of moving both axes independently or simultaneously.

The major benefit of the design is that the motors remain in a static position.

There is a very useful video where it is explained very well how this system works.

My contribution

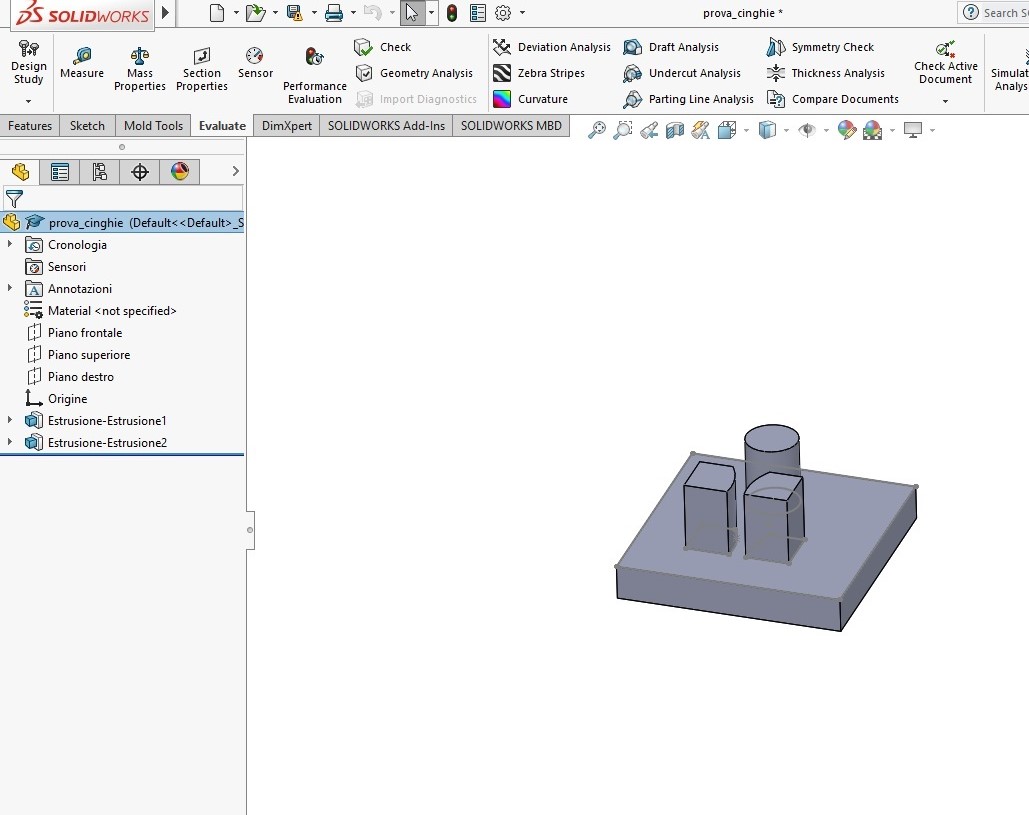

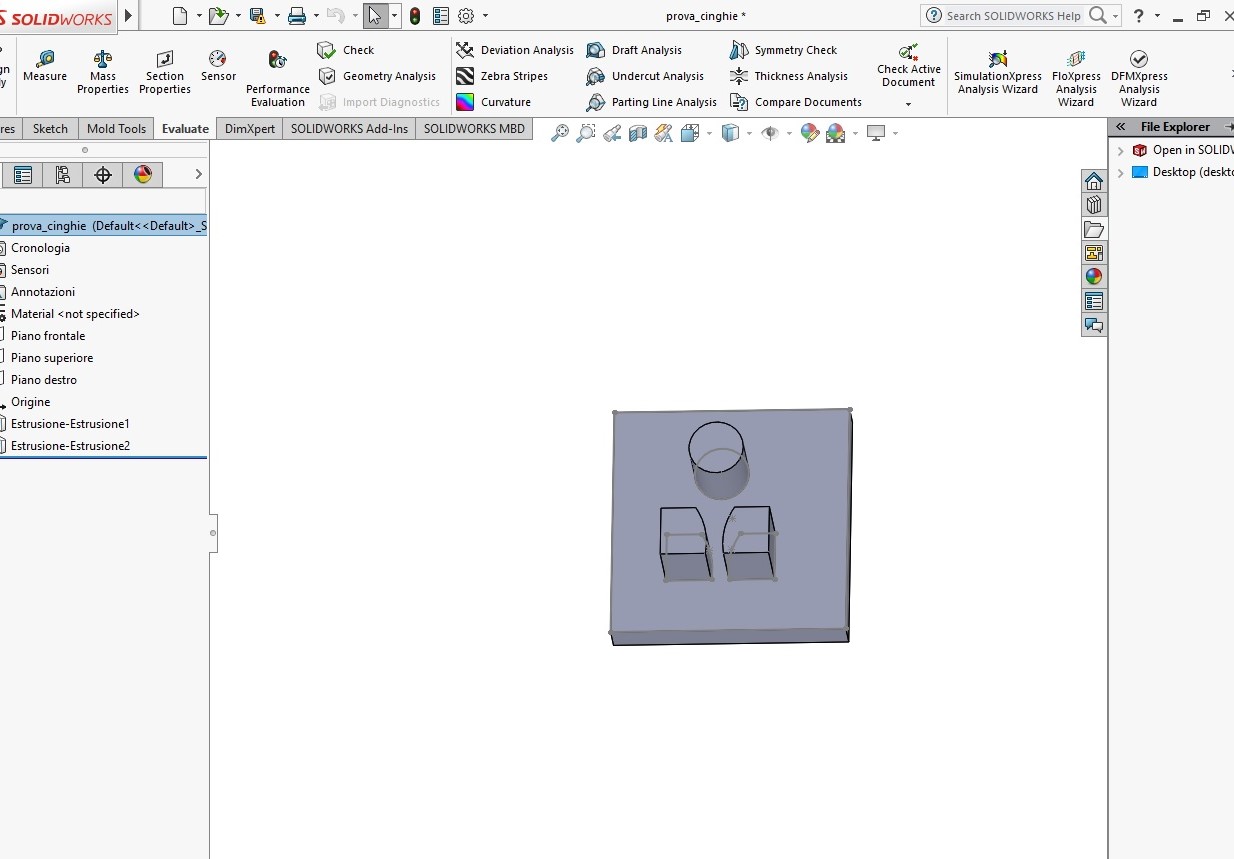

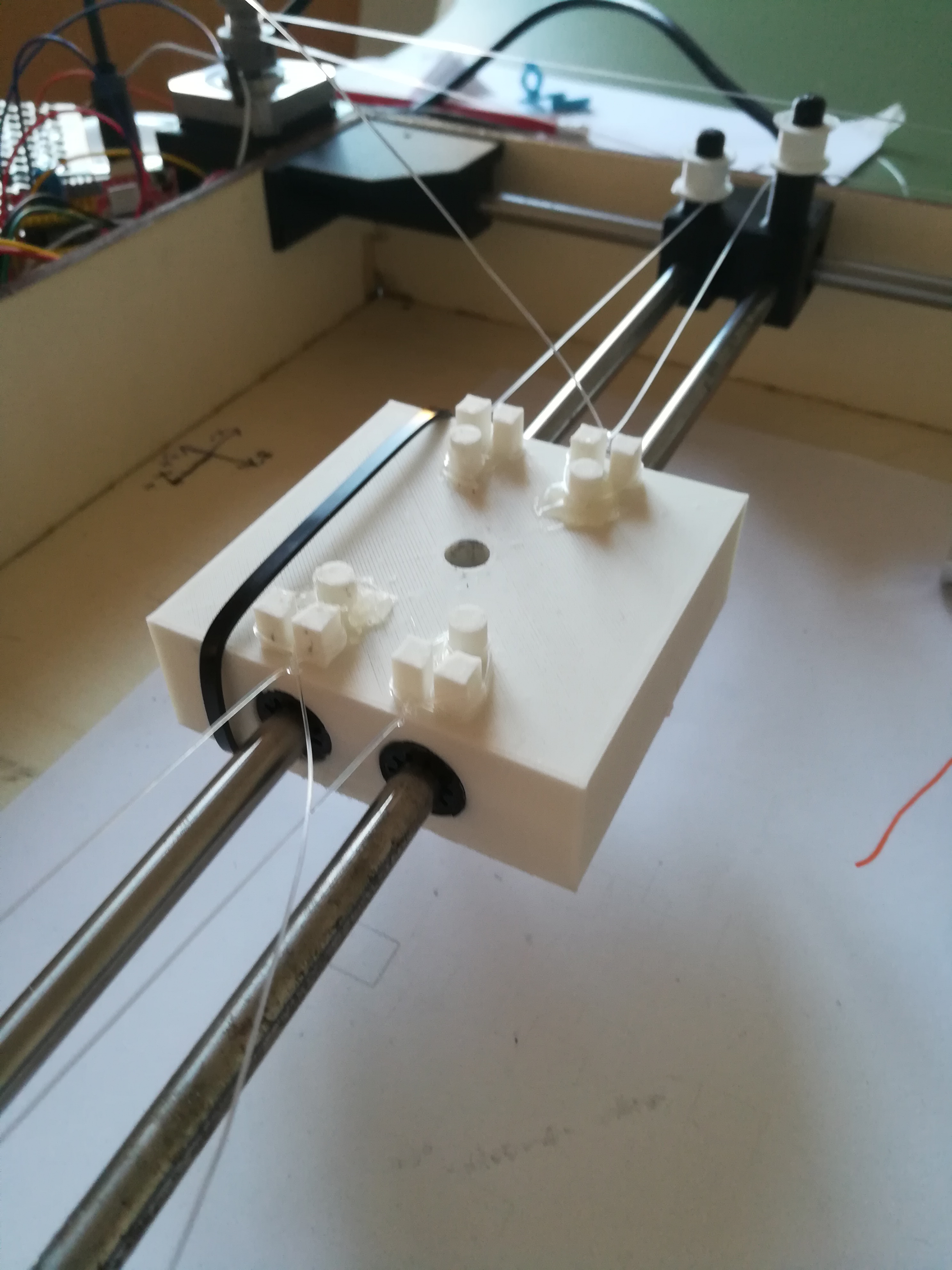

Me and my companions divided the various tasks for the construction of the machine. I mainly worked to model and printed the various parts of the machine in 3D.

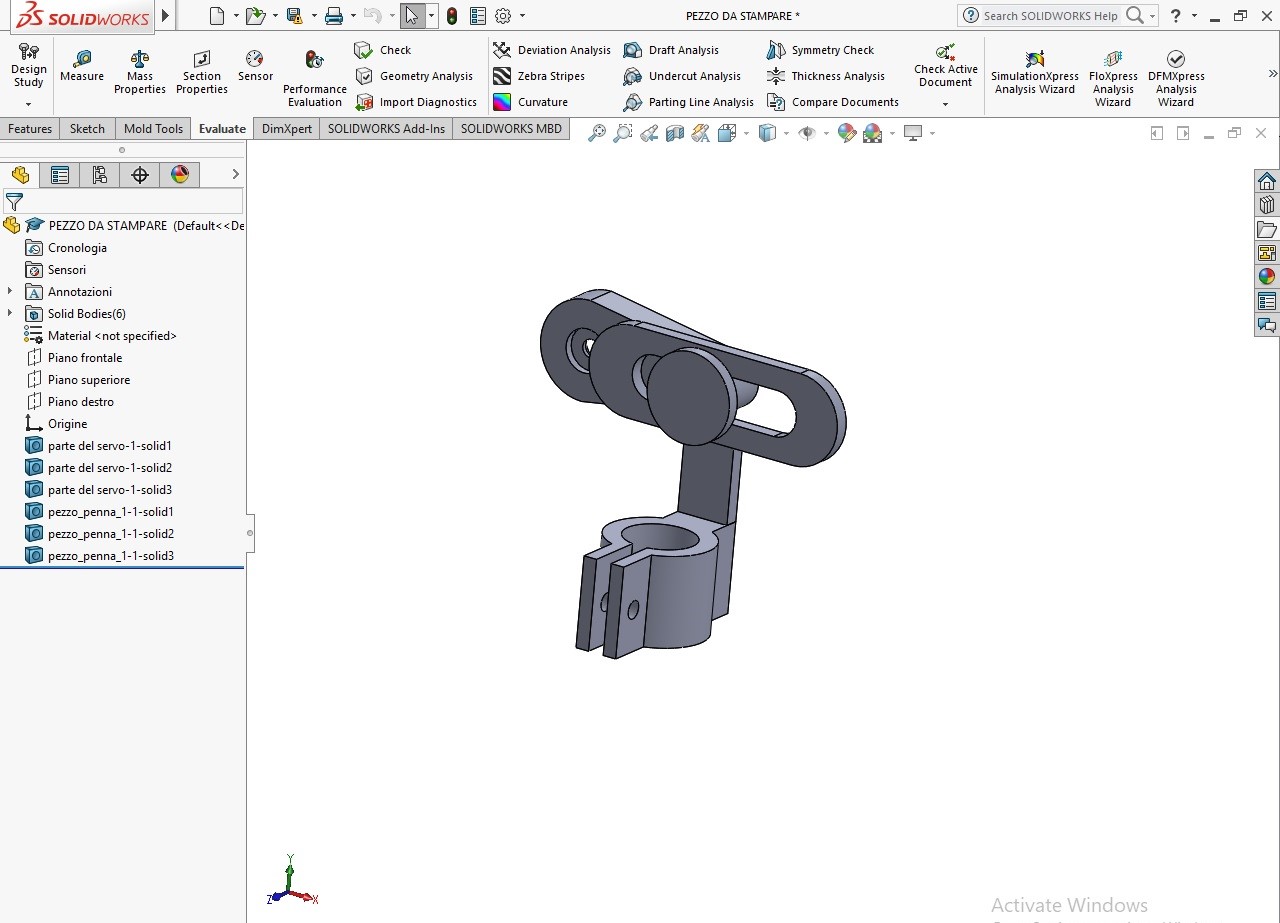

In this project I designed the central part,

the Scotch yoke mechanism (in this case is the z axis, used to hold the pen) and support for the stepper motor.

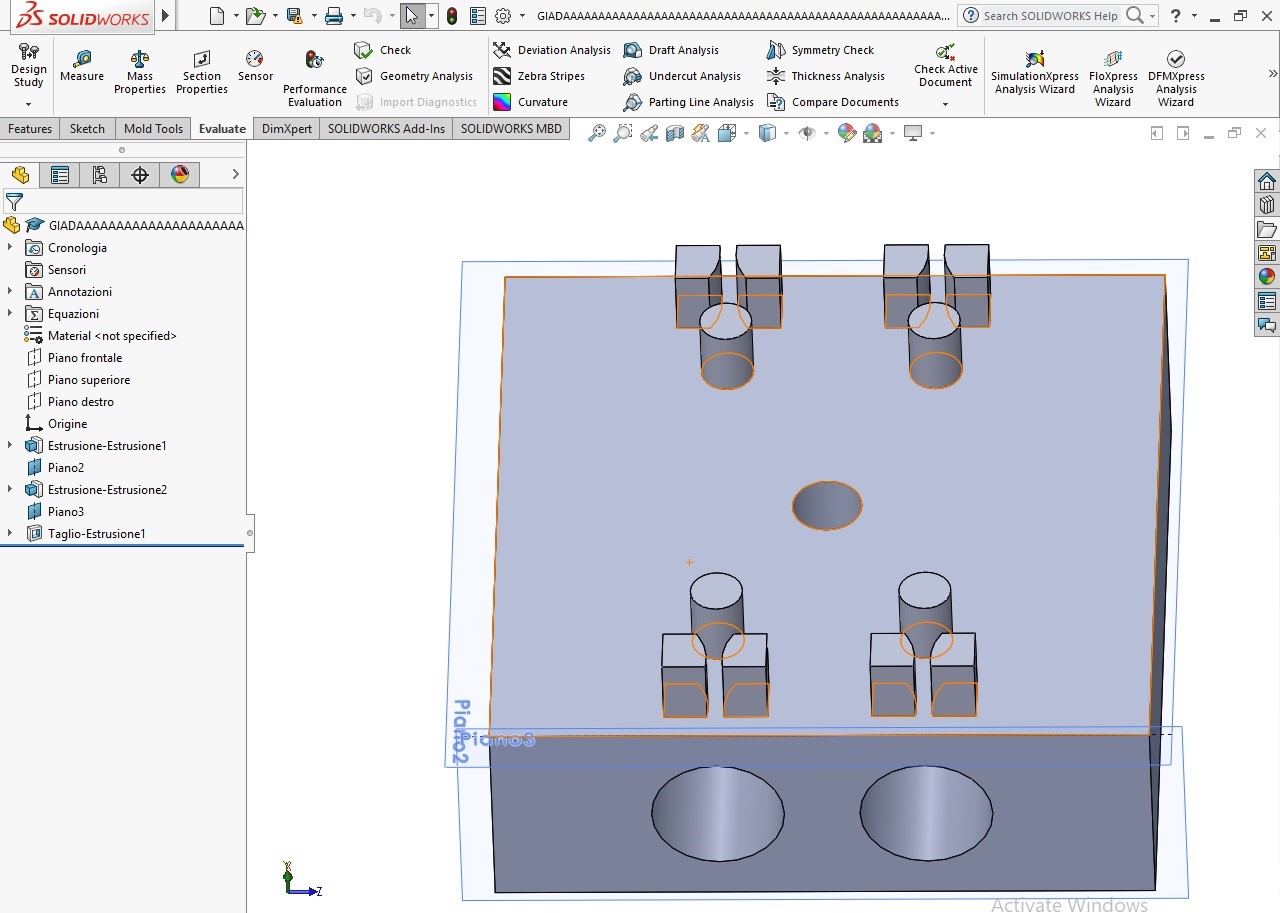

The central part

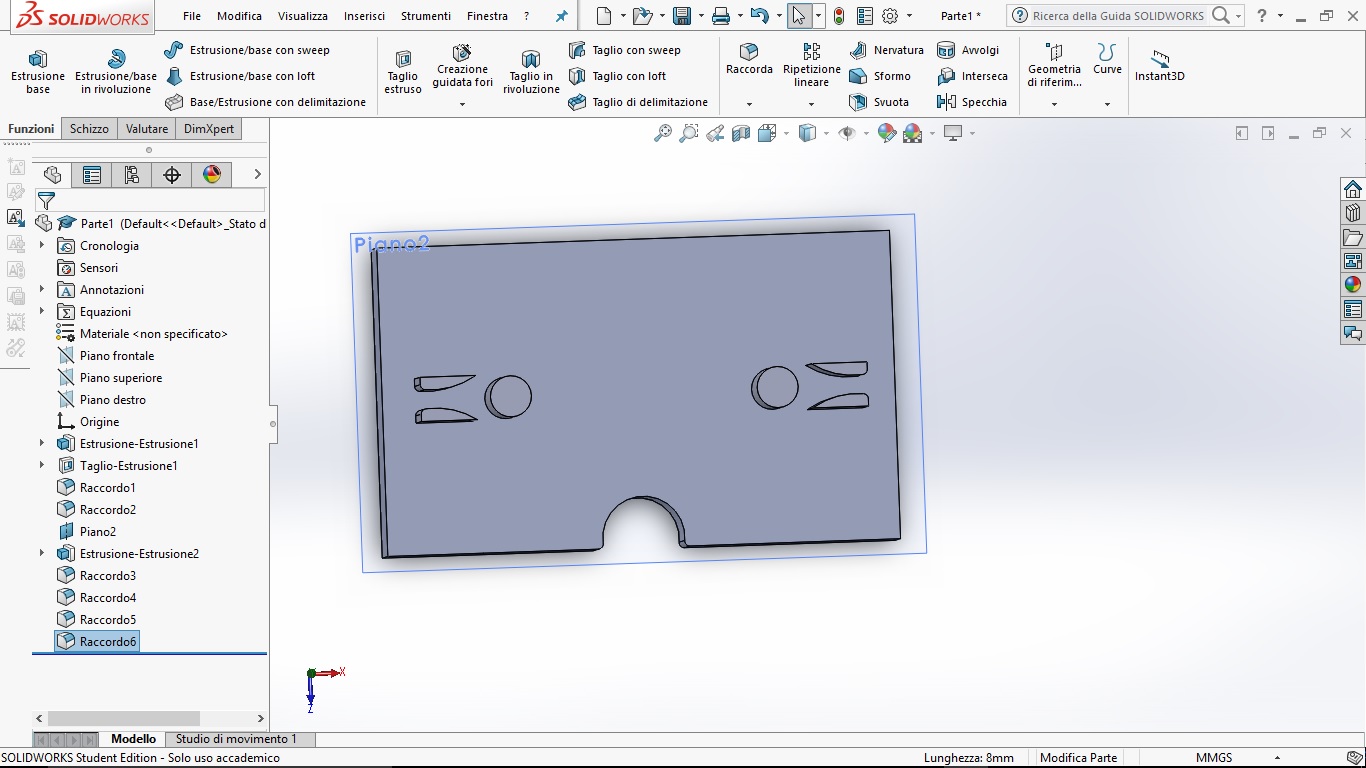

This component needs a mechanism to hold and close the open belt, so I looked to the Delta's part in our lab which had the same function and I copied it.

The first model was too thin to hold the belt tension, so I redid only the belt's attachment to test its resistance.

the central part has two holes for the rods, plus I added a hole in the center for the pen

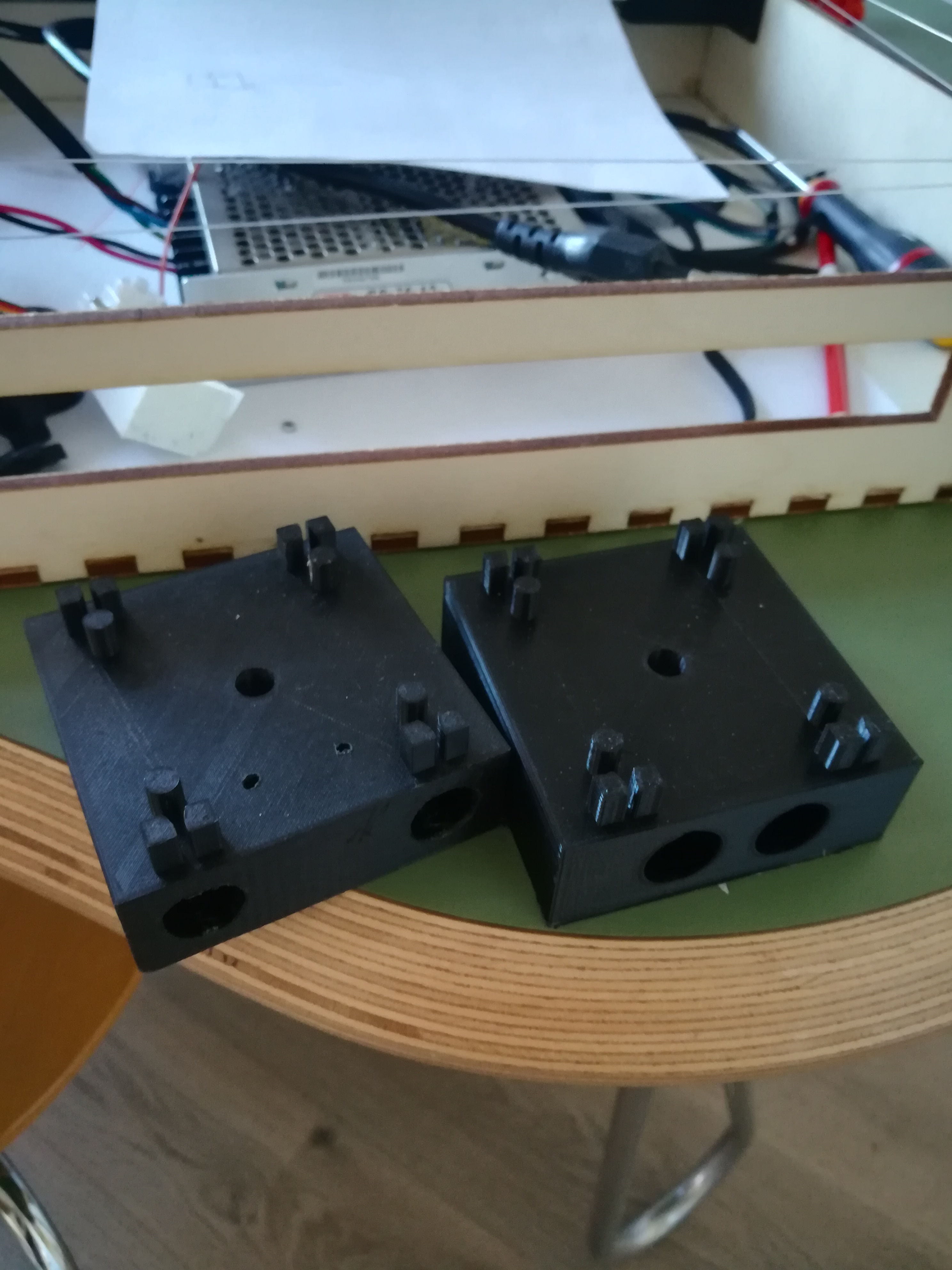

obviously this is the end result of various failed experiments, like these

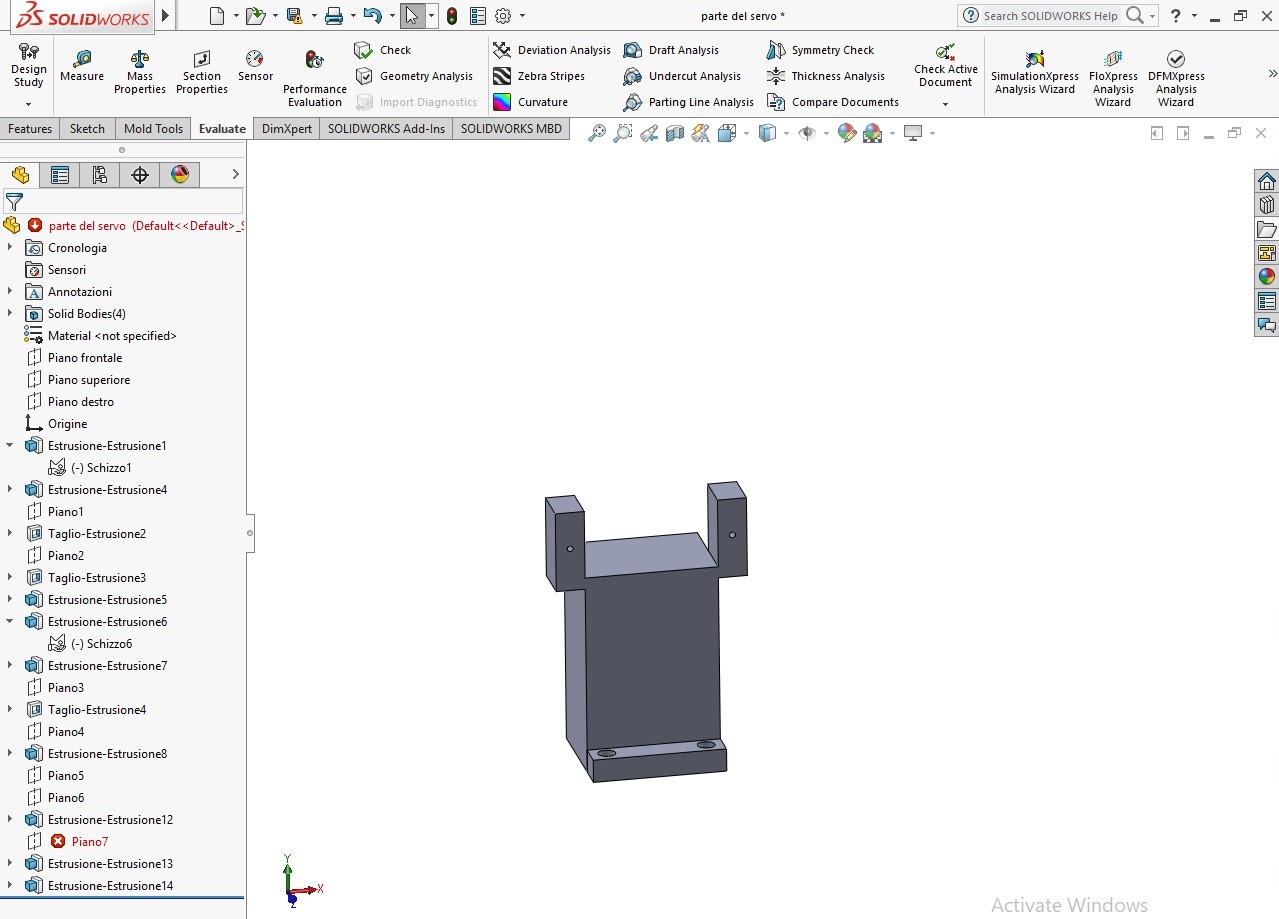

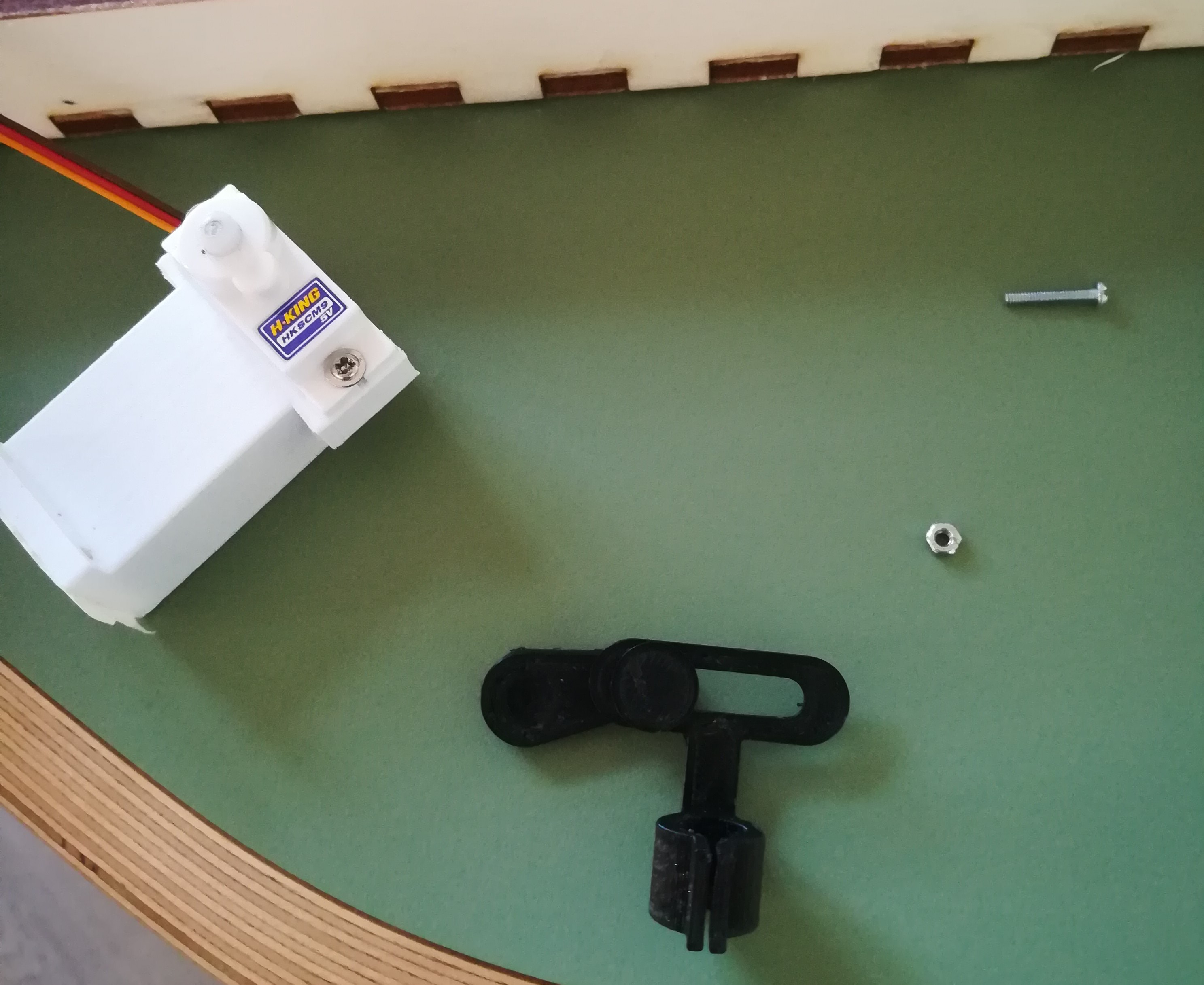

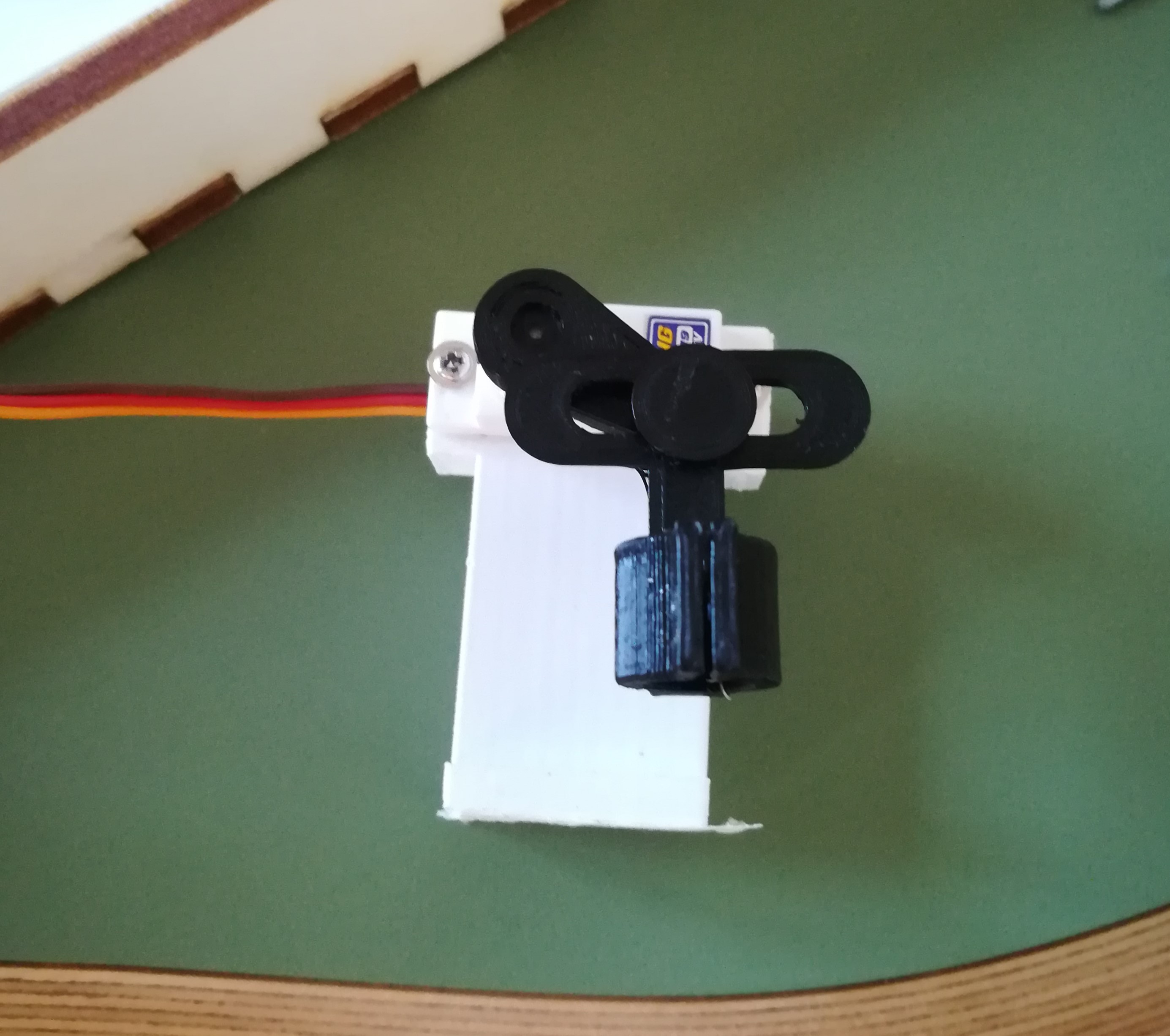

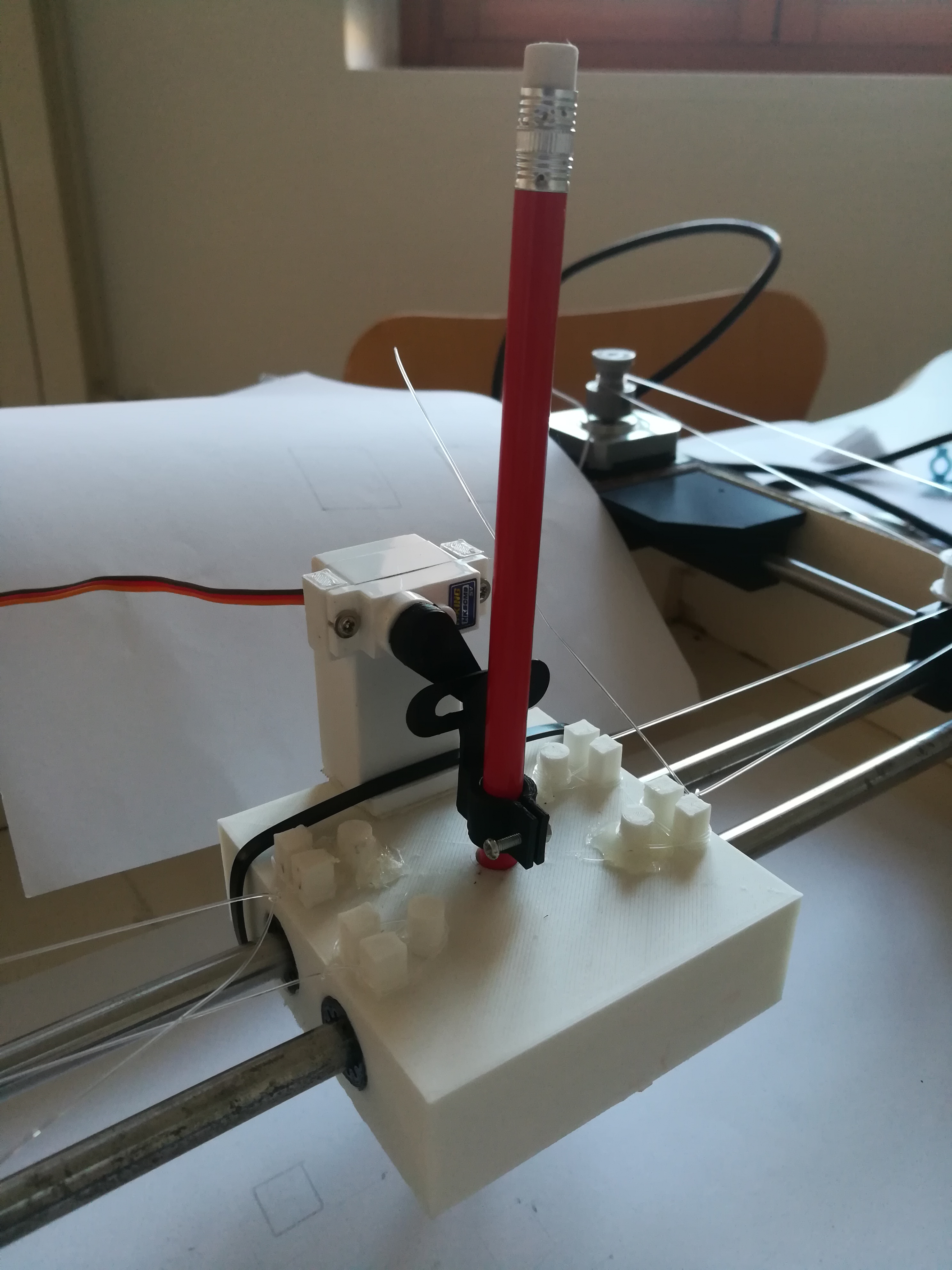

To move our z axis we decided to use a servo motor which needs a support. I took the various sizes to make the perfect servo motor holder (or at least I think).

To move the pen up and down on the z axis we thought of a scotch yoke mechanism, you can see how it works in the video below

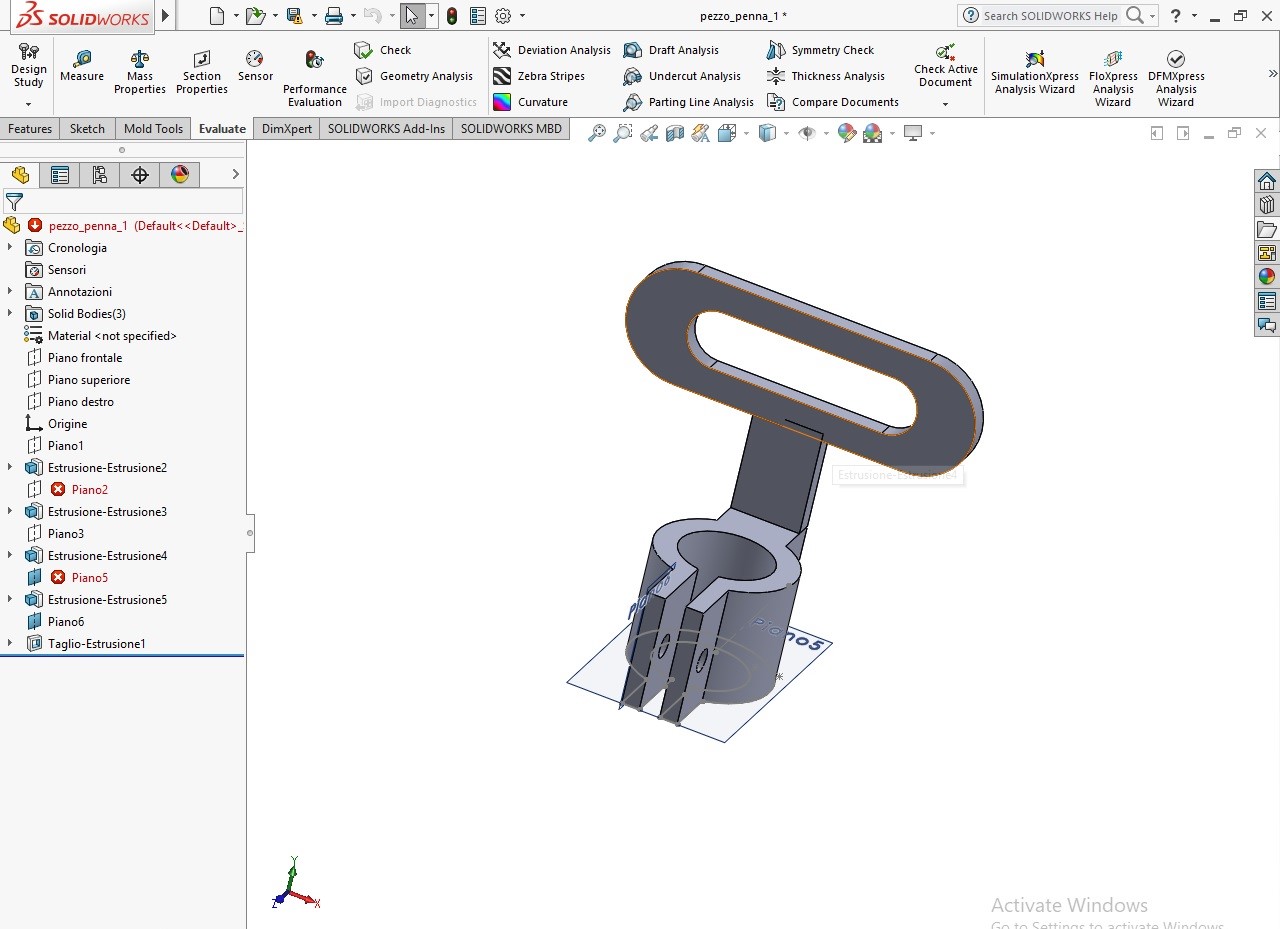

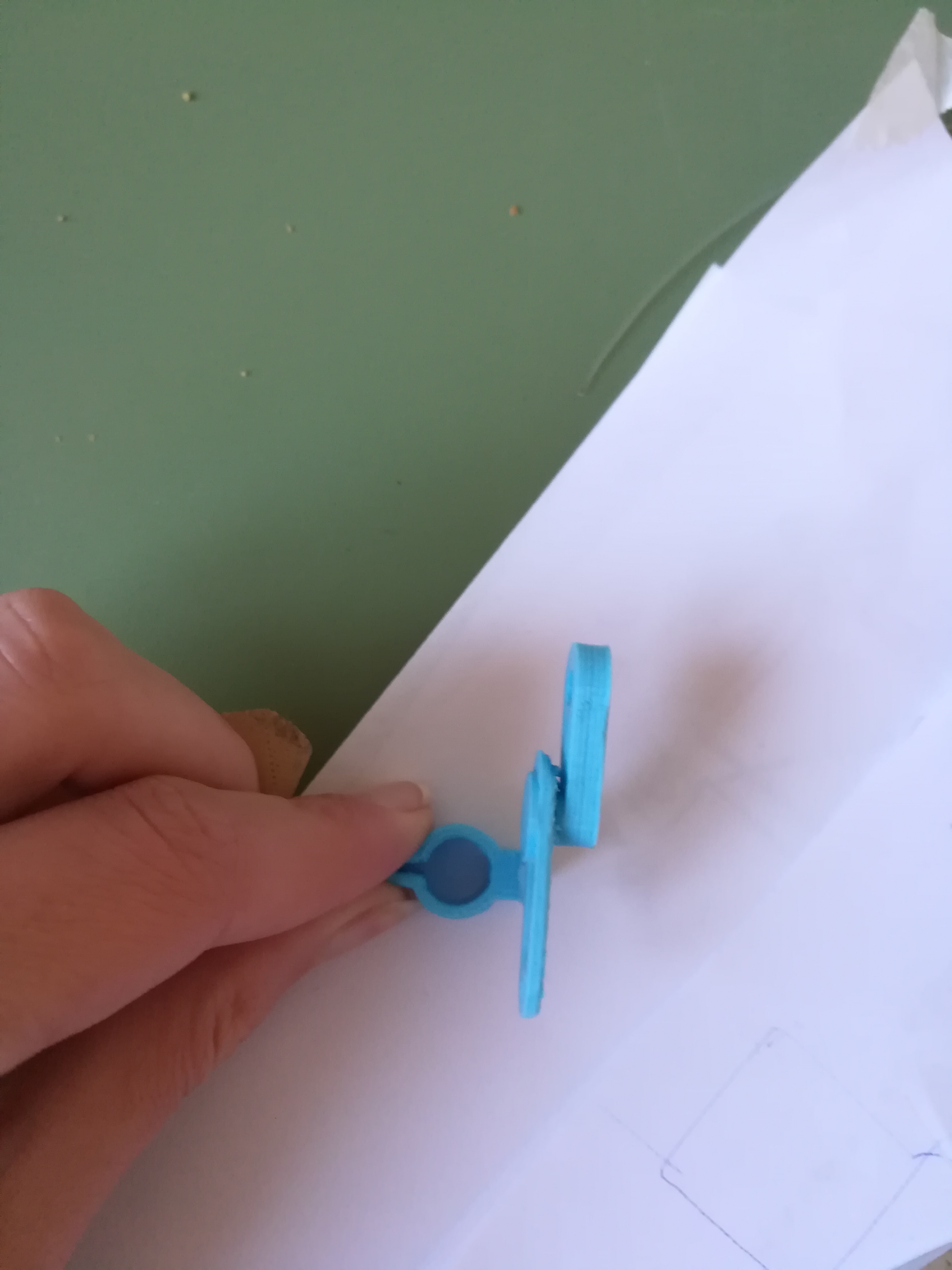

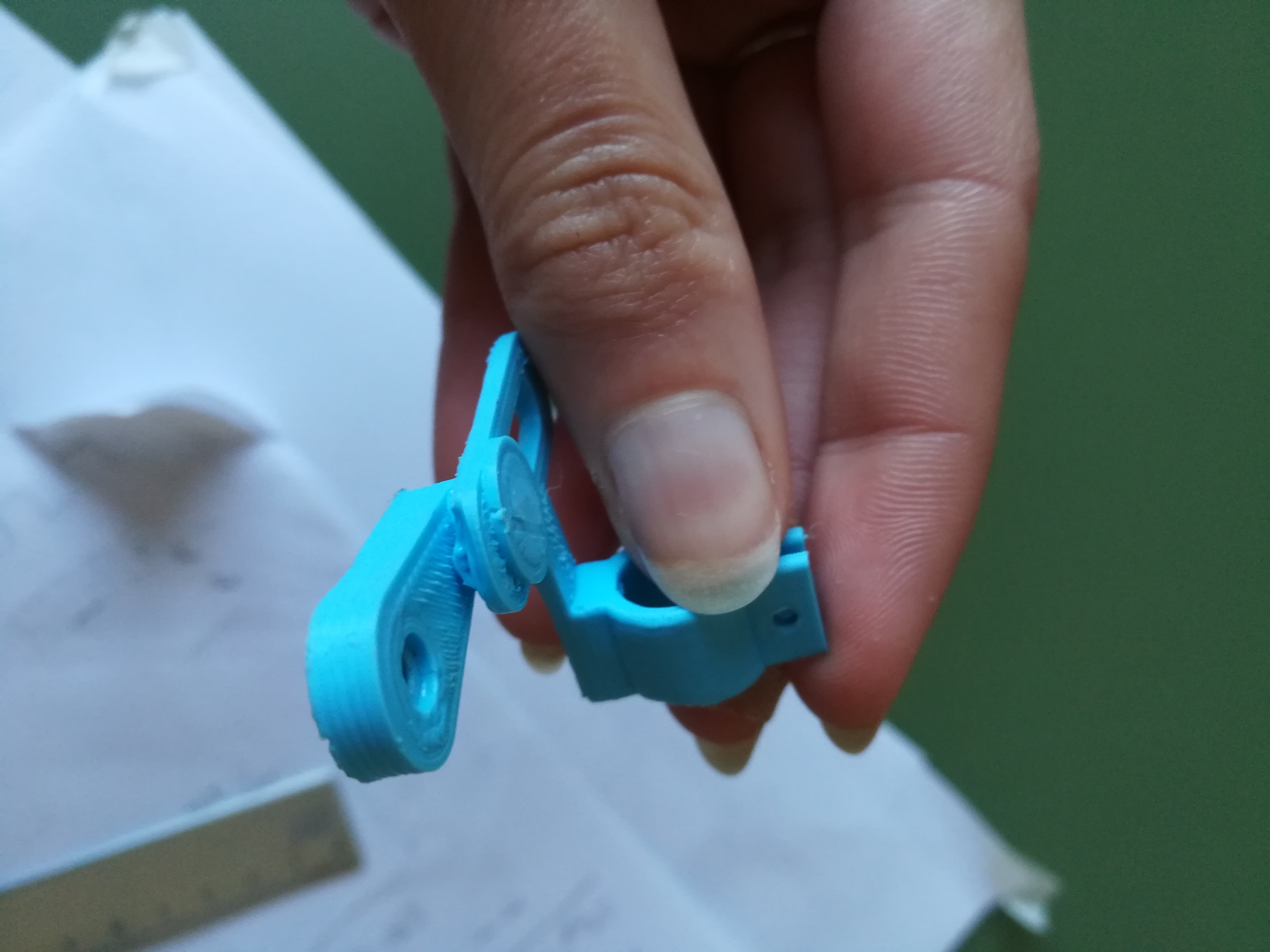

This mechanism transforms a circular movement into a linear movement. I started modeling the part that holds the pen, creating the holes to insert a screw and tighten as needed.

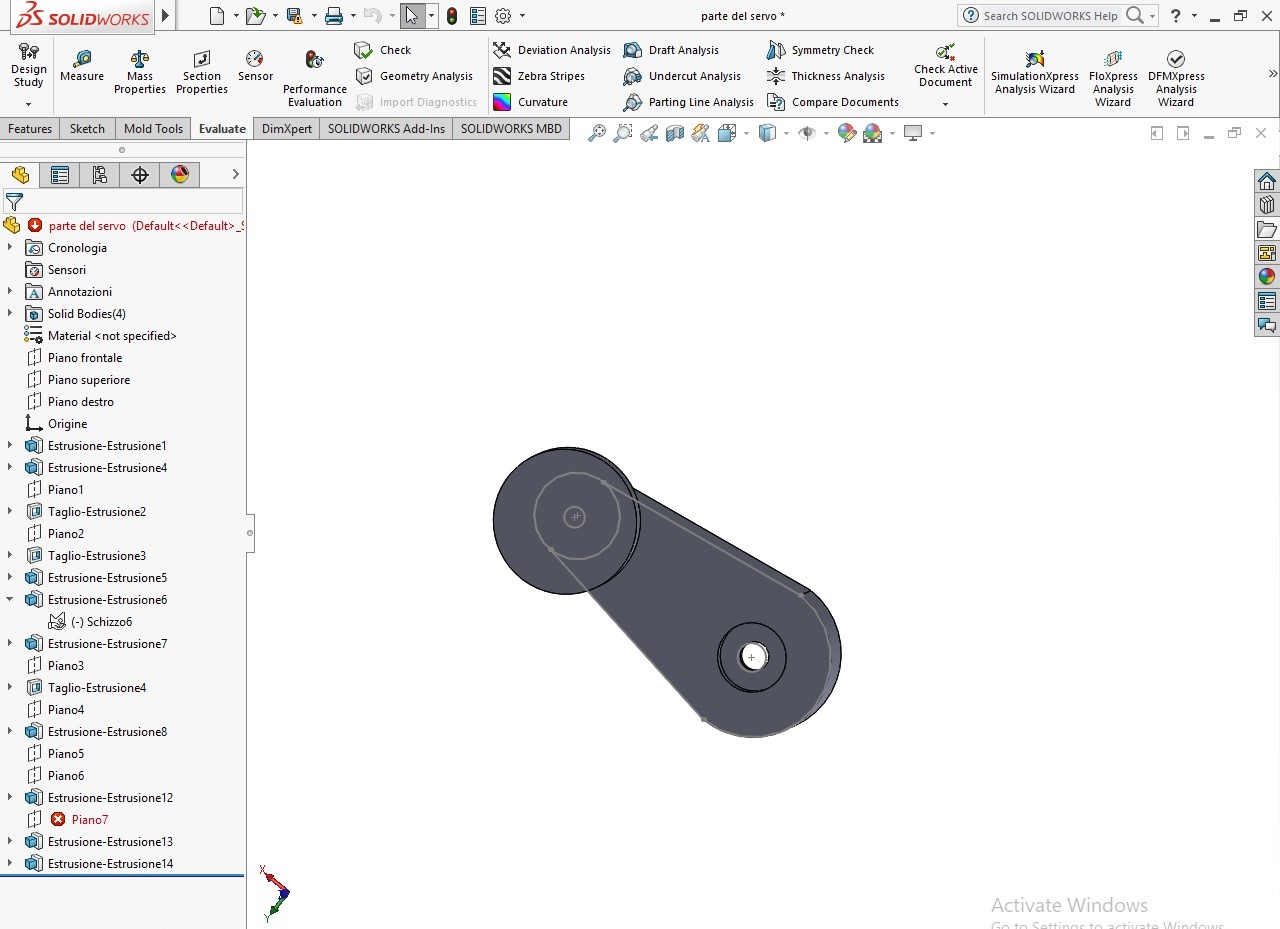

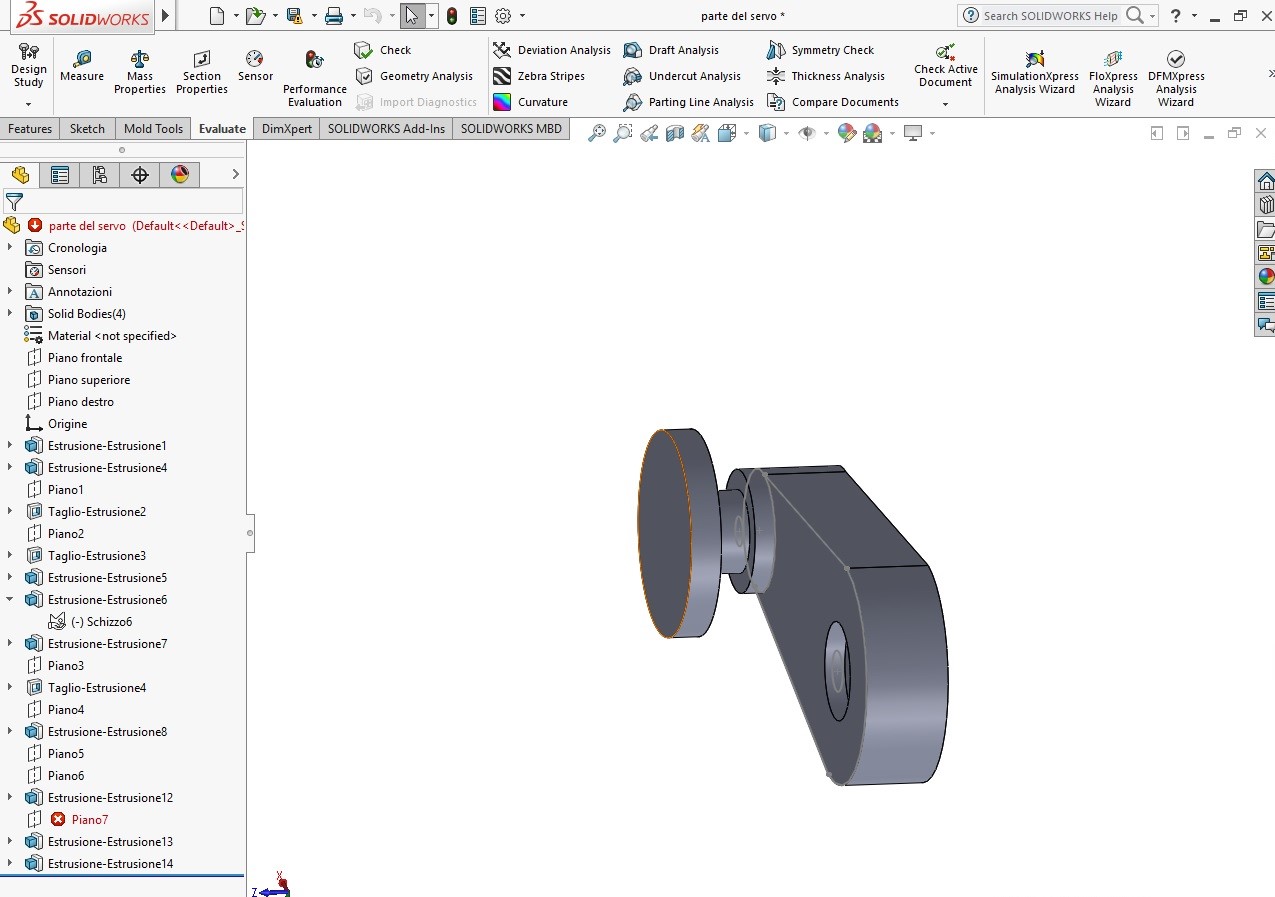

Then I modeled the part to attach to the servo motor, which practically replaces the default's "arm" (after several tests apparently it was the best solution)

Then I did the assembly of the two parts and I printed it

The first model came too thin and in the tests it broke, so I did it more thick and I assembled the parts together

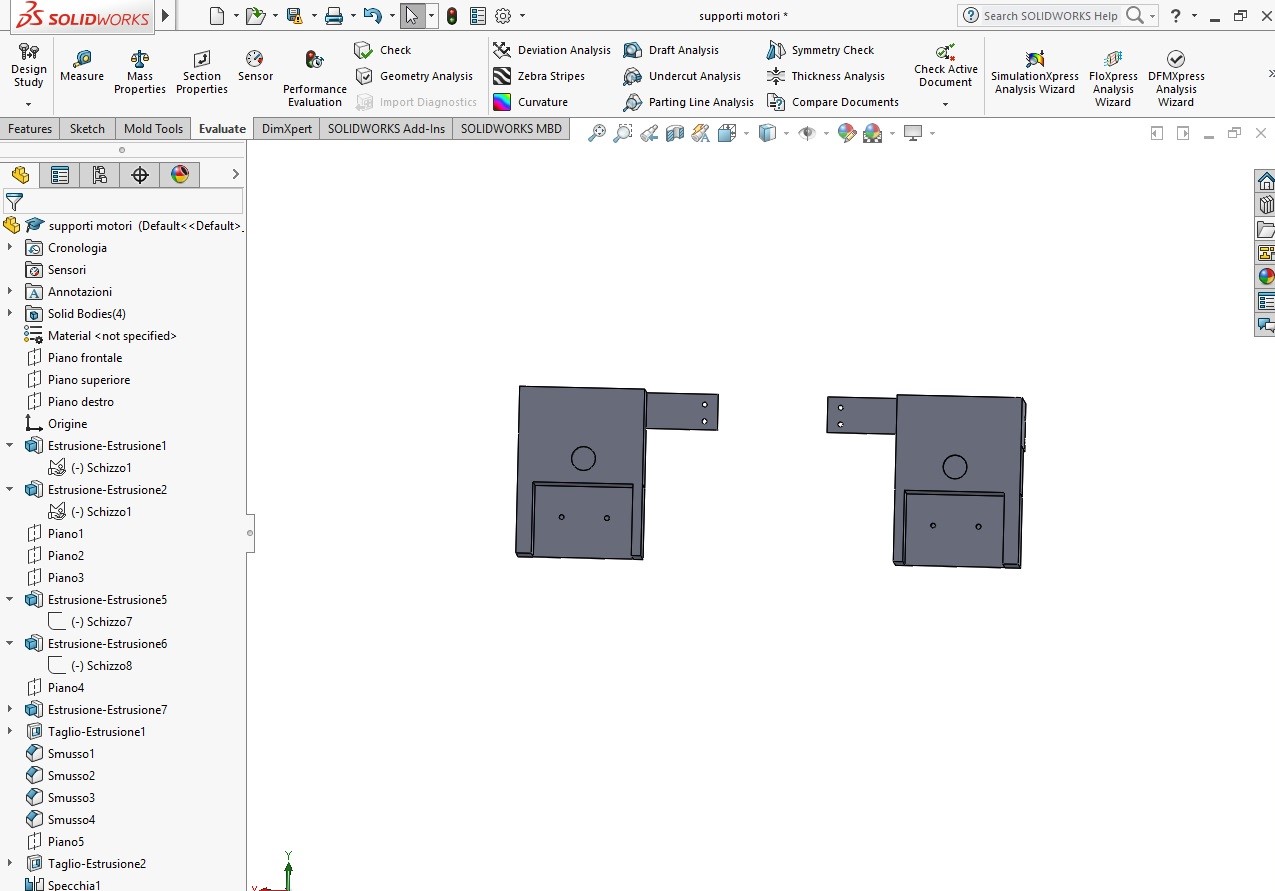

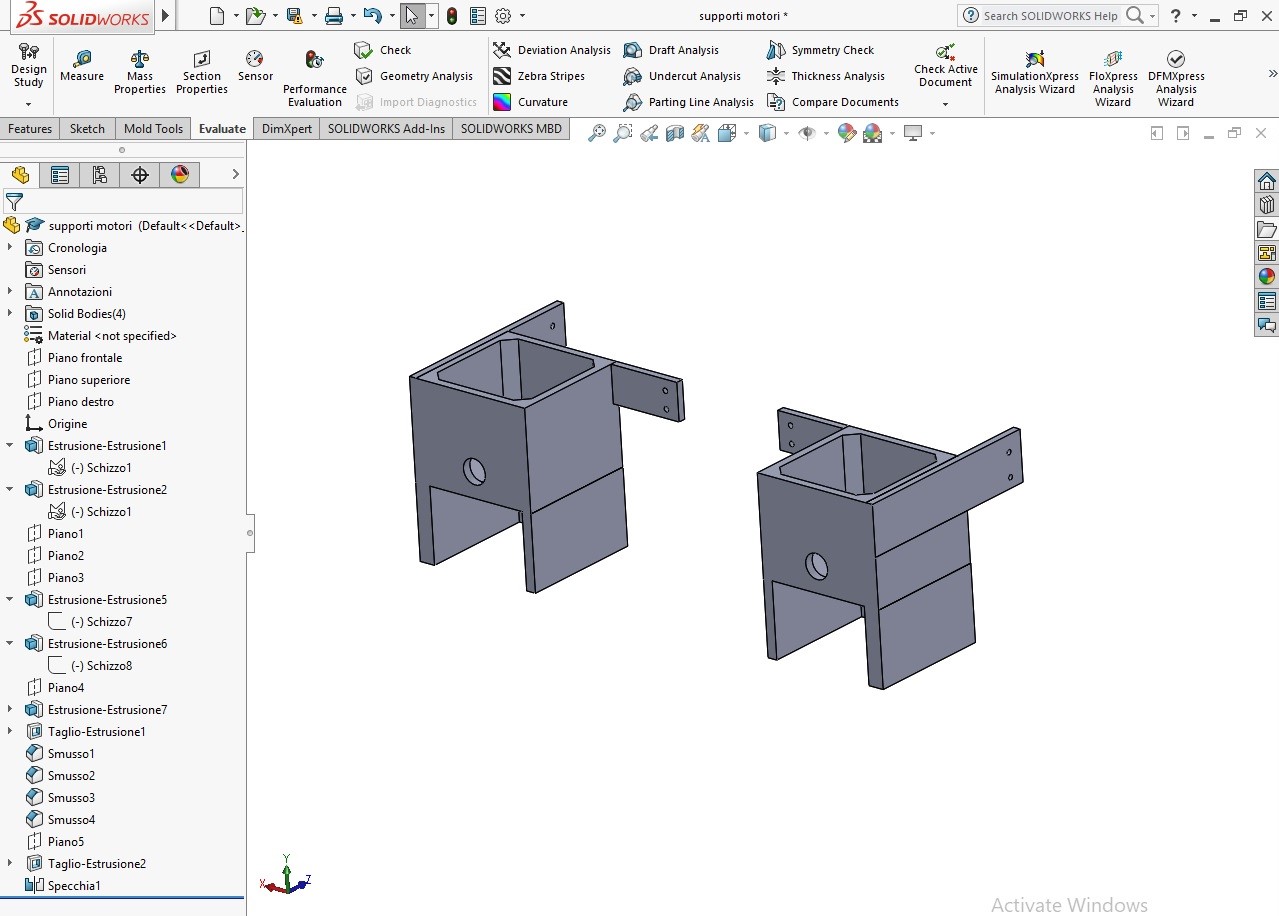

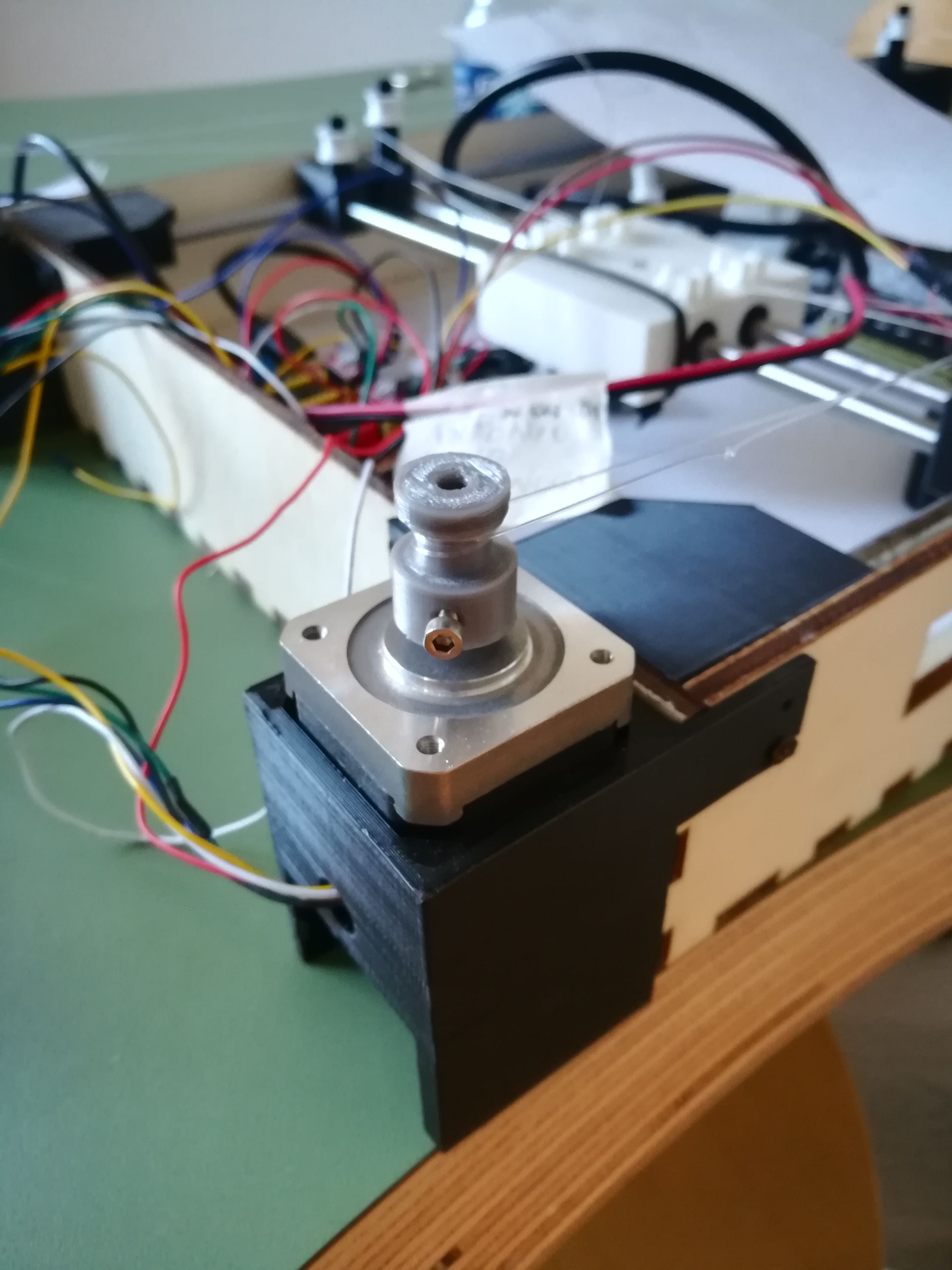

And finally for the stepper motors we decide to make some supports, like these

Go here for the group documentation

Here Bernabini's documentation

Here Lombardi's documentation

The first model was too thin to hold the belt tension, so I redid only the belt's attachment to test its resistance.

the central part has two holes for the rods, plus I added a hole in the center for the pen

obviously this is the end result of various failed experiments, like these

To move our z axis we decided to use a servo motor which needs a support. I took the various sizes to make the perfect servo motor holder (or at least I think).

Scotch yoke

To move the pen up and down on the z axis we thought of a scotch yoke mechanism, you can see how it works in the video below

This mechanism transforms a circular movement into a linear movement. I started modeling the part that holds the pen, creating the holes to insert a screw and tighten as needed.

Then I modeled the part to attach to the servo motor, which practically replaces the default's "arm" (after several tests apparently it was the best solution)

Then I did the assembly of the two parts and I printed it

The first model came too thin and in the tests it broke, so I did it more thick and I assembled the parts together

And finally for the stepper motors we decide to make some supports, like these

The final result

Go here for the group documentation

Here Bernabini's documentation

Here Lombardi's documentation