Assignment

individual assignment: design a mold around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

The idea of today is making pen and pencils holders with amazing designs to put them on your desk of your home or office that makes your desk much more organized.

What Are Molds & What Are They Used For?

Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The resulting cast will be an exact likeness of the shape of the hollow mold form. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The hollow forms of the mold get filled with water (the casting material) to produce ice cubes. The cubes are released from the mold and voila! Finished cast pieces.

Many industries use mold making as a way of producing their wares. Commercial ceramic factories use plaster molds and slip (liquid clay) to produce bowls, cups, candlesticks, figurines, and more. Plastic factories use metal molds and different processes like injection molding, rotational molding, and blow molding to produce plastic parts. The glass industry blows molten silica into metal or graphite molds to produce drinking glasses, bowls, vases, etc. Most parts of any car's body and engine are made in molds.

There are 3 basic types of molds:

- One part

- Two part

- Multi-part (advanced)

Casting

Casting is a manufacturing process in which a molten material is introduced into a solid mold and allowed to solidify. The solid material takes the shape of the mold. The term usually refers to metals but can also apply to the same process for other materials.

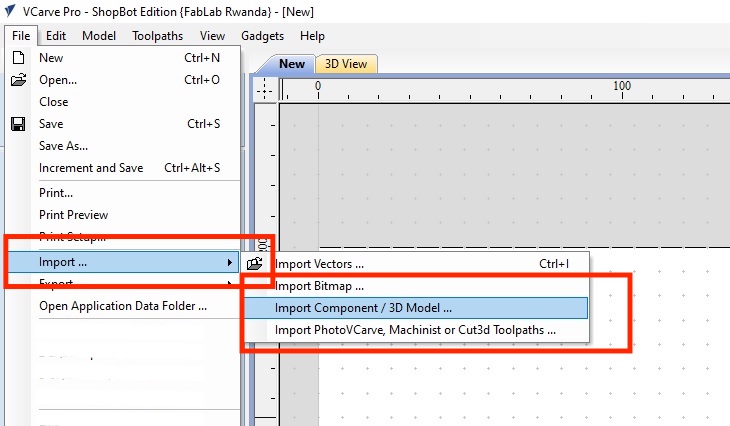

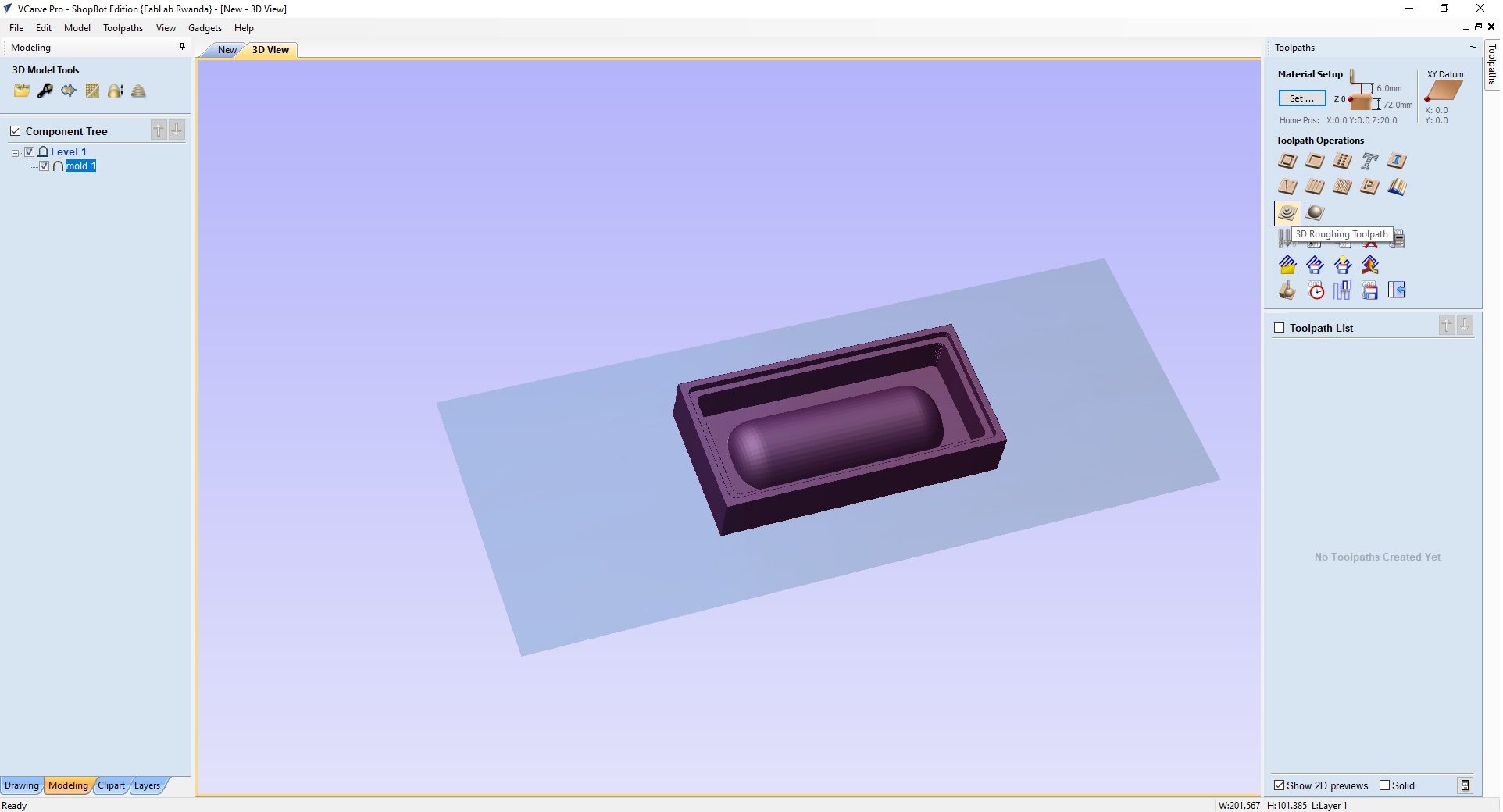

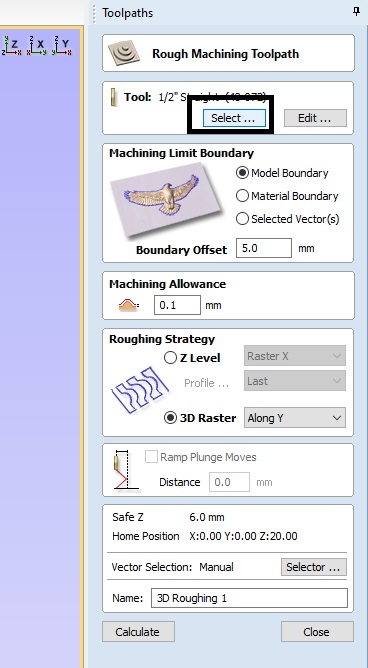

Designing the 3D model of pencils holder

3D Mold design

To build the mold, I used a MDF of wood and the CNC machine

Casting

I was supposed to use OOMOO 25 & 30 silicone, unfortunately chemical products we have in our Fablab were expired. I decided to use white cement and water as an alternative solution.

Casting with cement can be fun , easy to get and cement is a lot cheaper comparing to the OOMOO 25 & 30.

CONCRETE CASTING

I was supposed to use OOMOO 25 & 30 silicone, unfortunately chemical products we have in our Fablab were expired. I decided to use white cement and water as an alternative solution.

I was guided by the following tutorial, which is giving more details about concrete casting more details.

While you are pouring you should be vibrating your mold to allow the bubbles to escape and for the cement to fill in the open spaces. I tapped my mold on the side and wiggle it around to make sure my mix is everywhere.

This mold was exposed to the sun for more than 7 hours afterwards, I separeted the concrete with the mold

To separate the concrete and mold was not easy and the result was not good as you can see on the pictures below, the concrete is fragile and the finishing is not smooth. I am still waiting the new OOMOO 25 & 30 silicone to be purchased by my Fablab and if time allows I rework again on this assignment

Used files