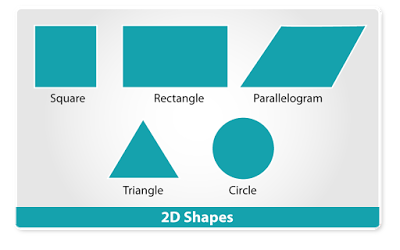

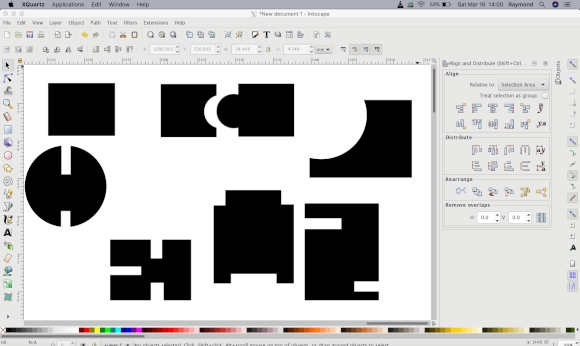

2D

- An object which has only two dimensions, i.e. length and height, is called two-dimensional space or 2D.

- 2D objects do not possess depth.

- 2D shapes are flat and do not acquire essence of solids.

- Examples: squares, rectangles, circles.

- In a mathematical expression, it is written as x-axis and y-axis.

- The movies and videos are usually recorded in 2D.

- Many creatures, such as ants, have only two-dimensional 2D They lack sense of depth.

Working in two dimensions (2D) means that you are cutting out a part with features that are all at the same depth. This is common for laser, hot-wire, water jet, and plasma cutting, along with engraving. The FlashCut CNC software's DXF Import feature automates the creation of a tool path from a 2D DXF file.

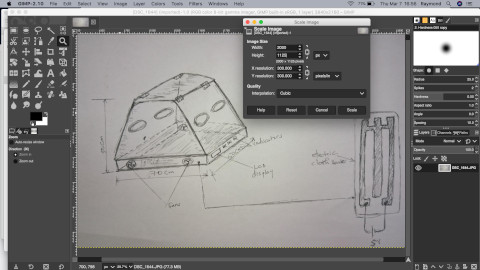

raster

Gimp

GIMP is a free and open-source raster graphics editor used for image retouching and editing, free-form drawing, converting between different image formats, and more specialized tasks. I use Gimp to edit for editing and scaling images of my assignment

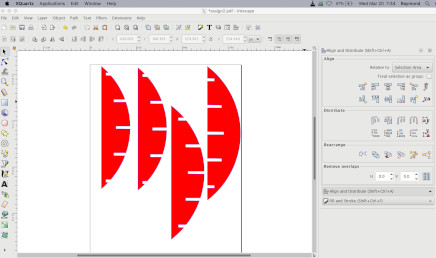

vector

inkscape

Inkscape is a free and open-source vector graphics editor. This software can be used to create or edit vector graphics such as illustrations, diagrams, line arts, charts, logos and complex paintings.

2.5D design

Working in two and a half dimensions (2.5D) means you are cutting a part that has multiple flat features at varying depths. During a 2 ½ D cutting process, the Z axis positions itself to a depth where the X and Y axes interpolate to cut a feature. The Z axis then retracts so the X and Y axes can move to the start point of the next feature, which may be cut at a different Z depth than the last feature. Most simple CAM programs deal with 2.5D parts.

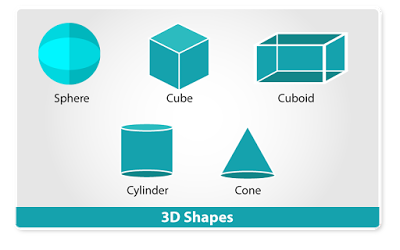

3D design

An object which possesses three dimensions, such as length, height and depth, is called three-dimensional object or 3D. Examples: humans, ball, mobile, laptop and various other physical objects. In a mathematical expression, it is written as x-axis, y-axis and z-axis. The geometrical objects in this category are cubes, cylinders, etc.

Working in three dimensions (3D) means that you have the ability to control at least three axes simultaneously. 3D contouring can then be accomplished by creating curves that use all three axes at once, like in a helical cut. You will most often need a full CAM program to create g-code files capable of performing 3D contouring.

Fusion 360

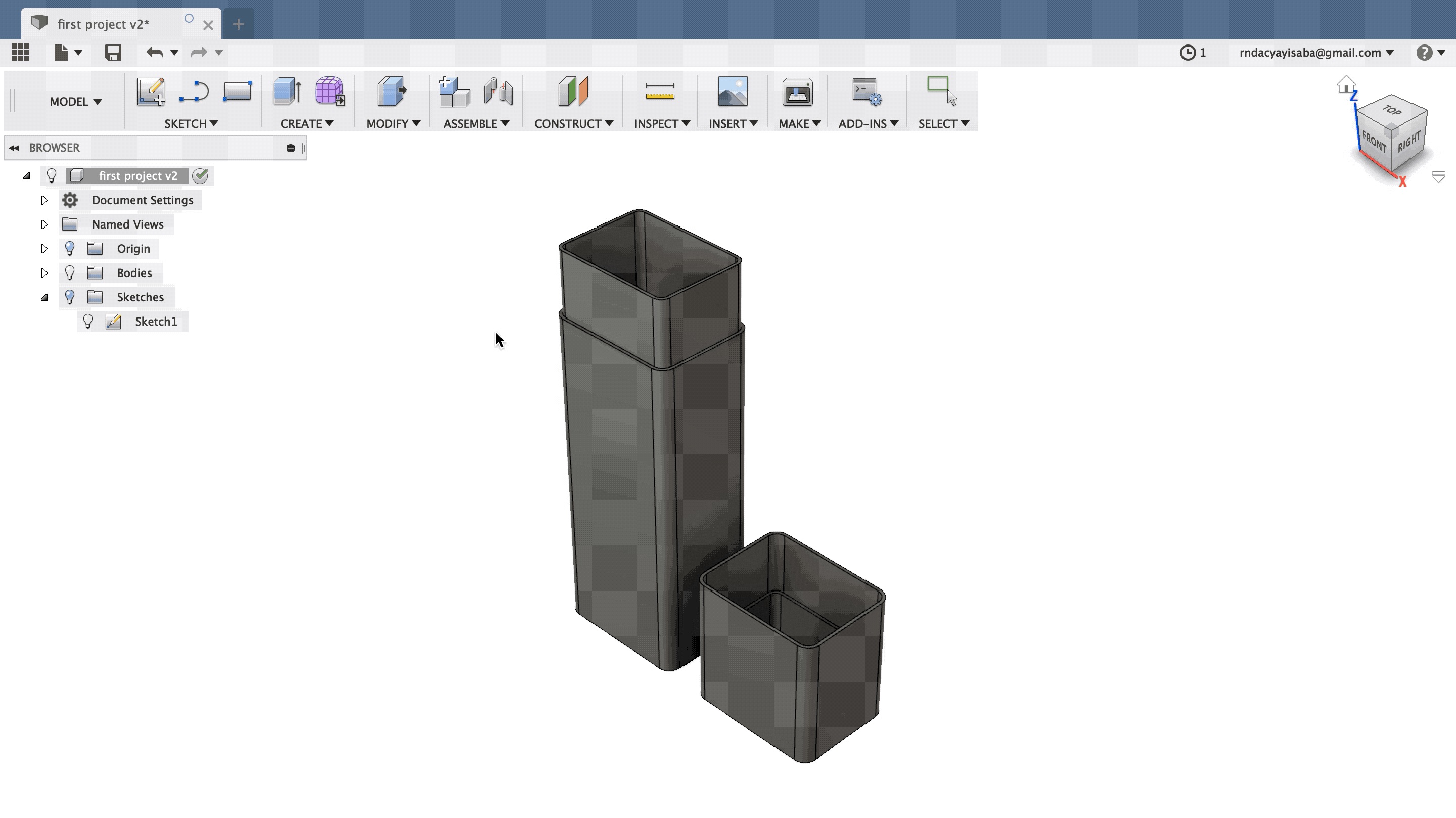

I used fusion 360 and I created a box for holding small parts like screws, beats for PCB machine or pencils.

<

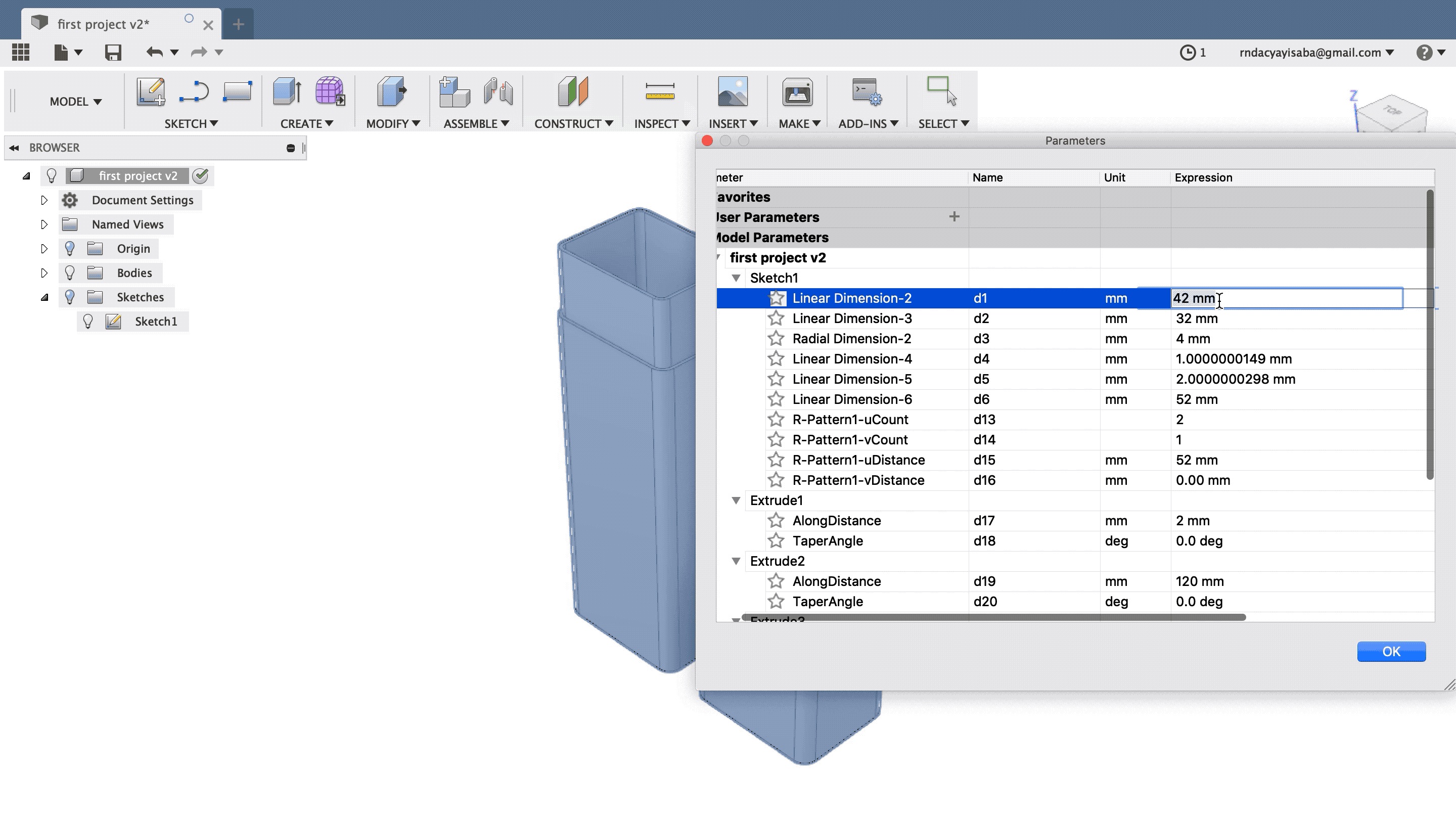

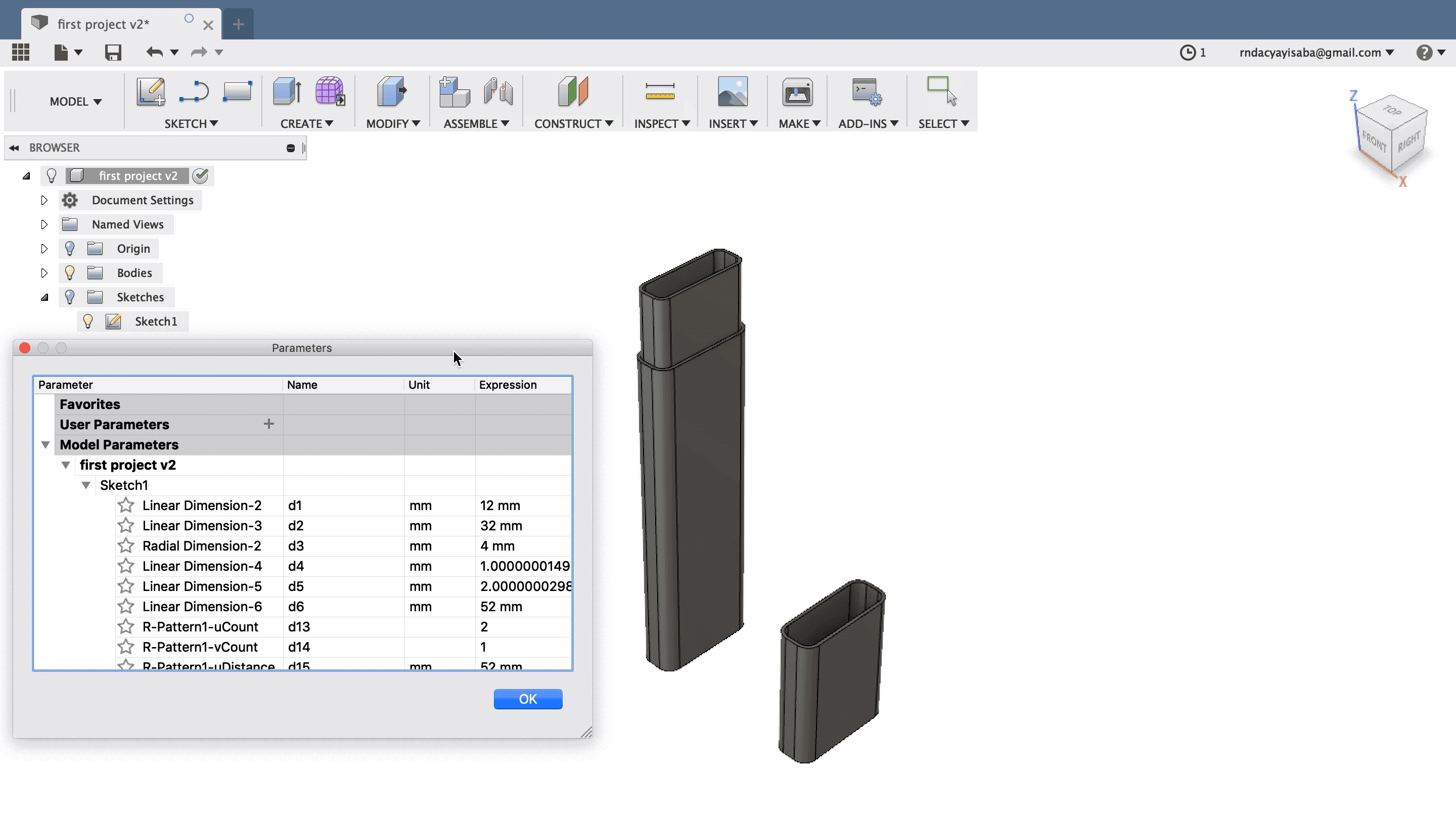

Parametric Modeling

.Parametric is a term used to describe a dimension’s ability to change the shape of model geometry as soon as the dimension value is modified.

I used fusion 360 and I created a box for holding small parts like screws, beats for PCB machine or pencils.

Simulation of the parametric Modeling

Solidwork

I used CAD(SOLIDWORKS2018) for designing each part that build my incubator(Bottom, Top cover, side panels). Afterward, I put all part together and give them appearance.

Used files

. Download link