Week 7: Computer-controlled machining

Group Assignment

Our group assignment was documented on this page.

Assignment

The purpose of this assignment is to Design, Mill, and Assemble something BIG.

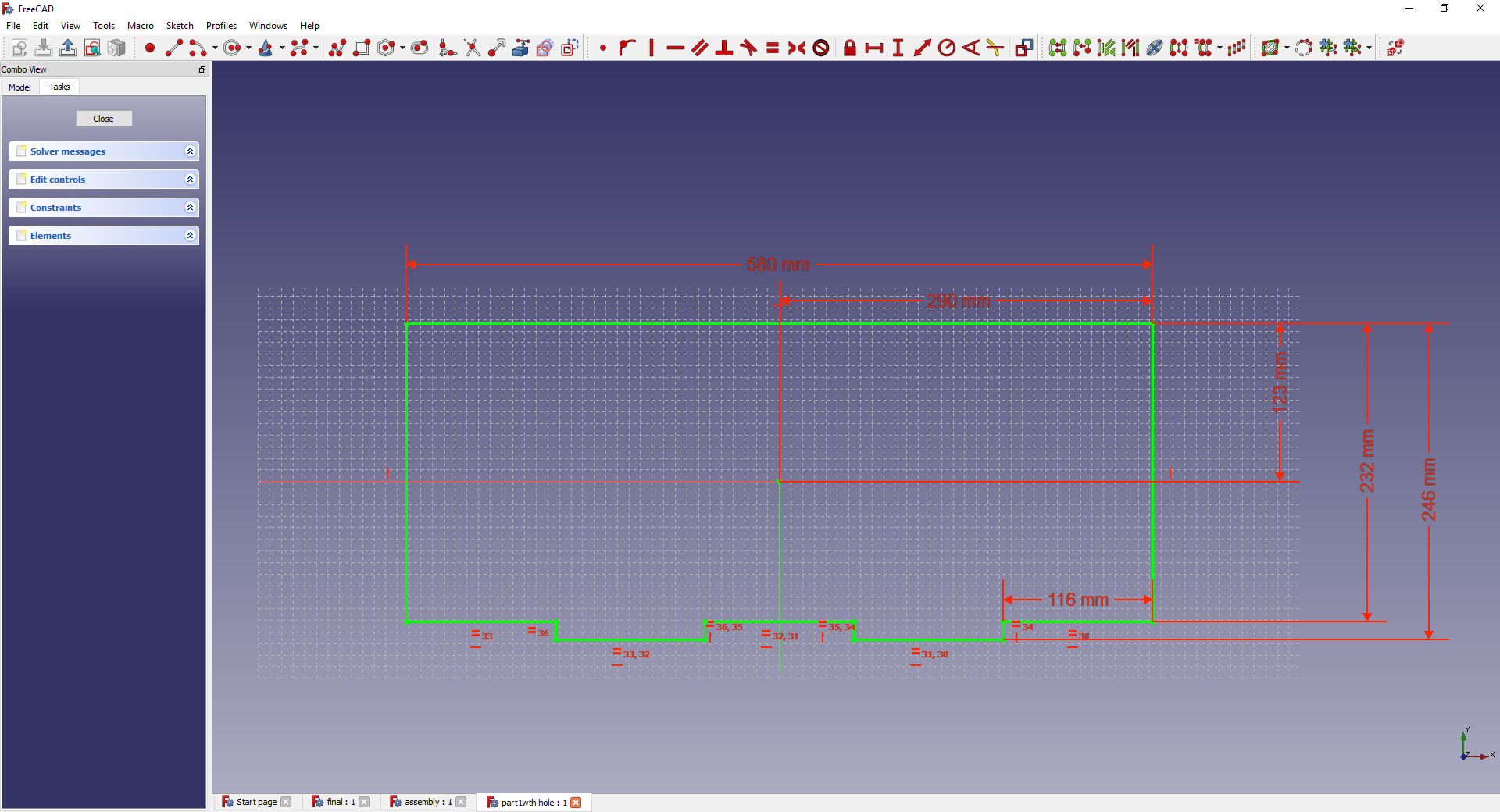

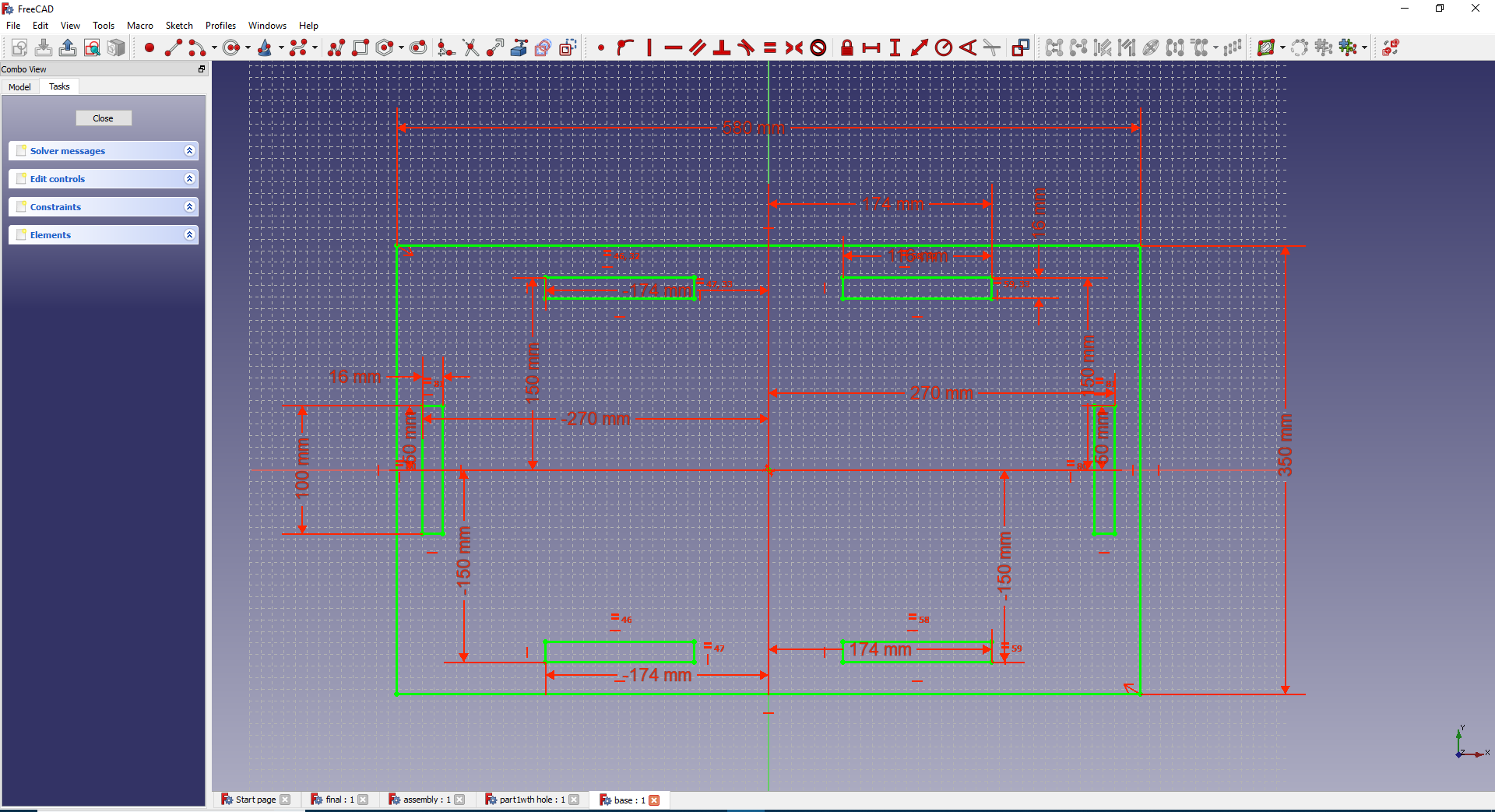

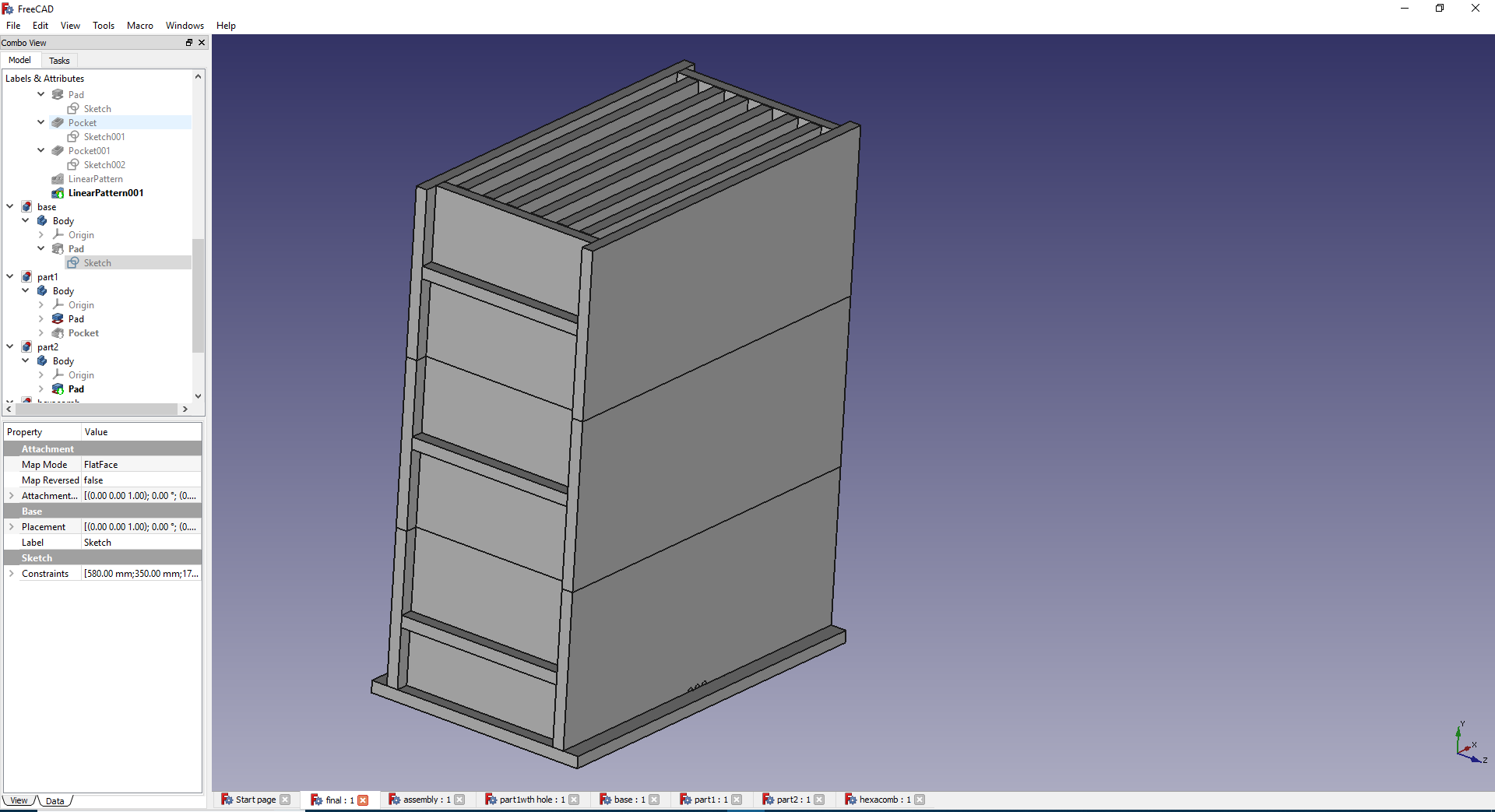

For this assignment I designed Bee Hive, I used FreeCAD software to design.

I started to design part by part so I can combine them at the end.

To combine all boards together at the end I added some joint in each board to make it easy.

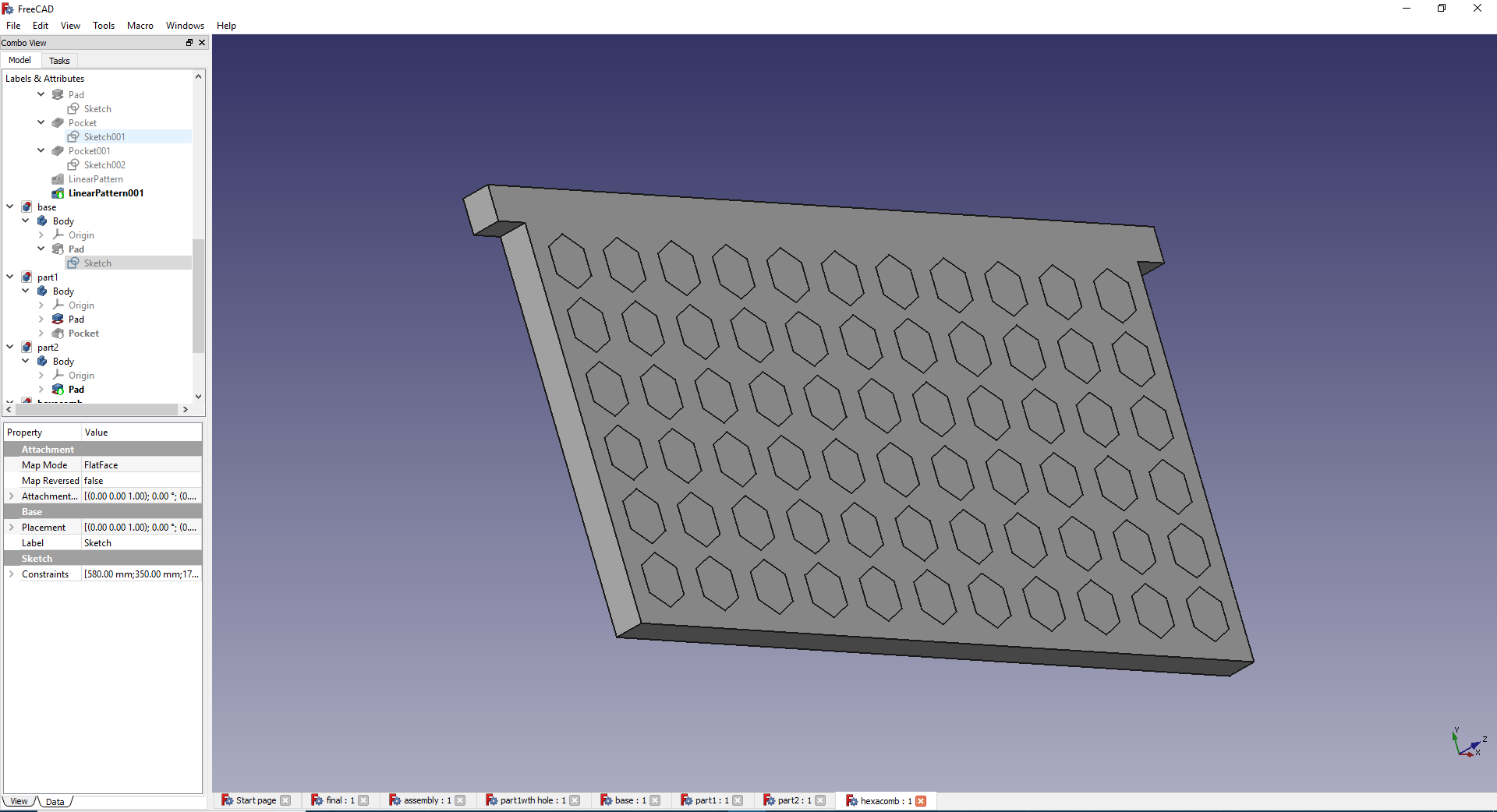

This is a part of the boards I designed with hexagone holes where bees stores honney.

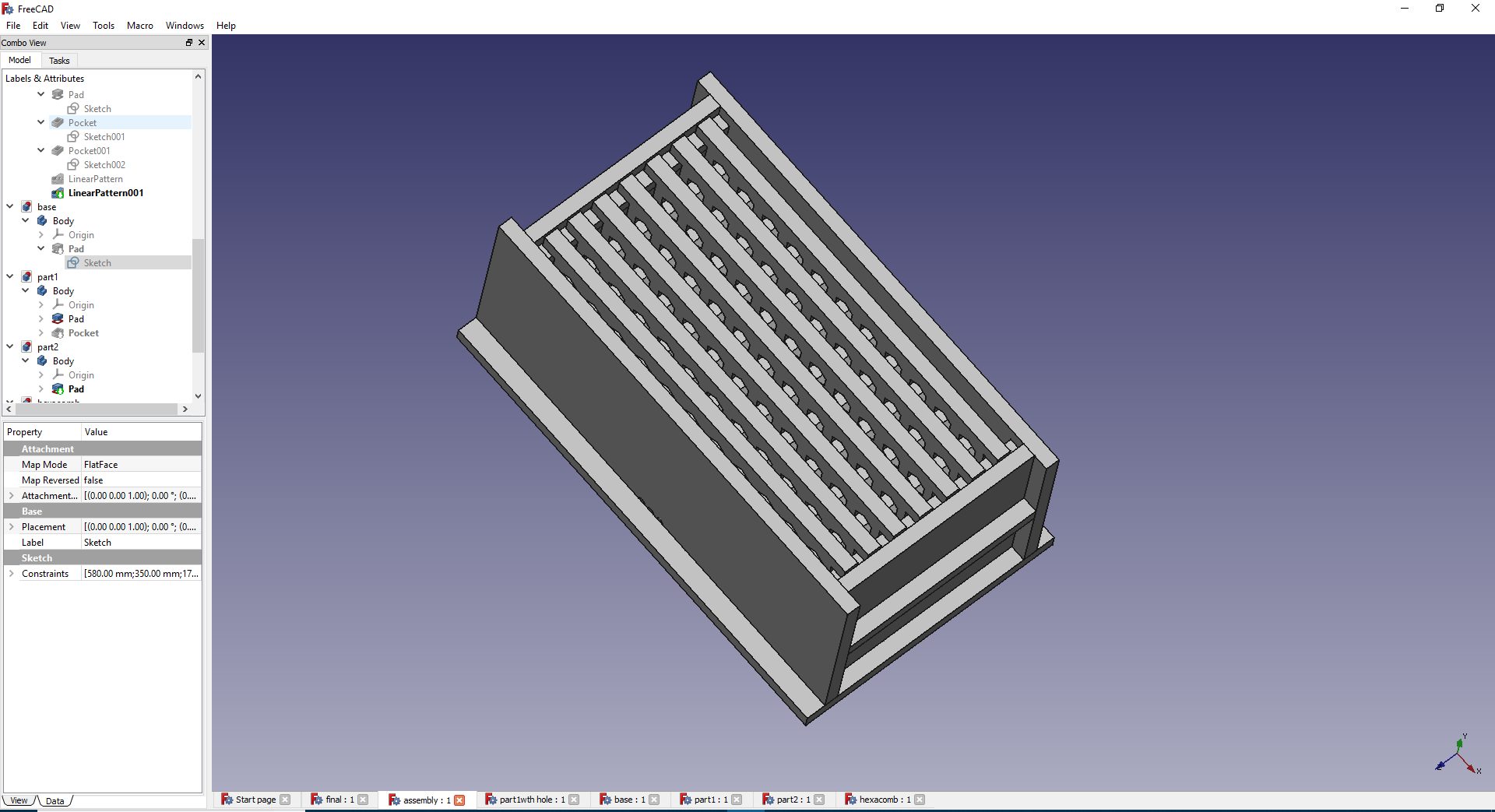

All part put together this how they will look like.

This is the assembly of the parts stacked together.

When I was satisfied with my designs I continued to export DXF files for each part so they can be milled on the CNC.

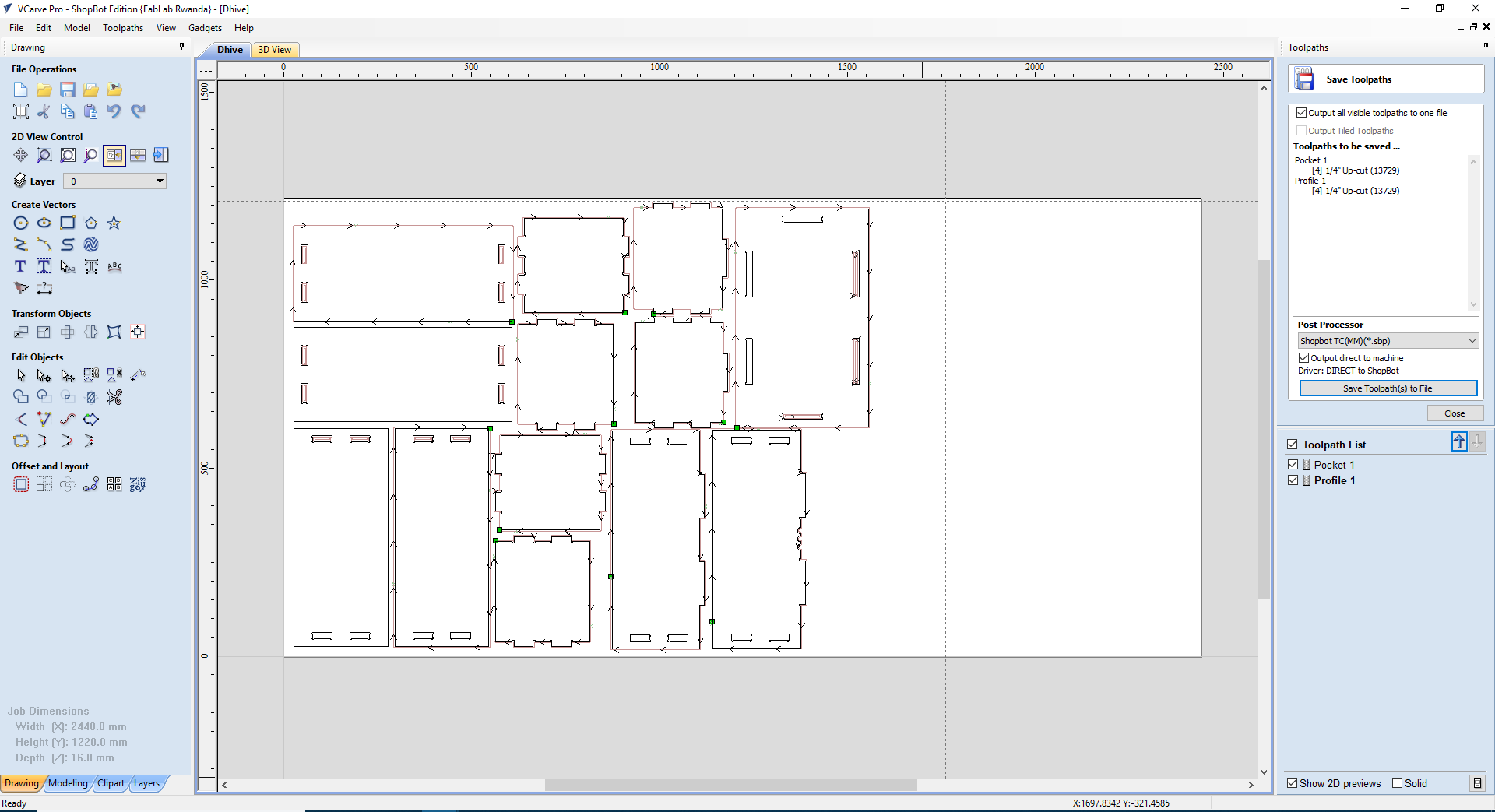

I imported the DXF file in VCarve software for generating command that will be executed by the shopbot.

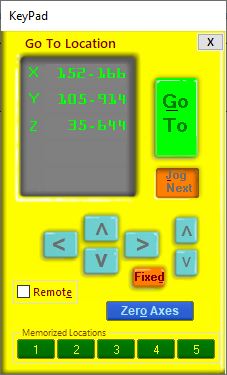

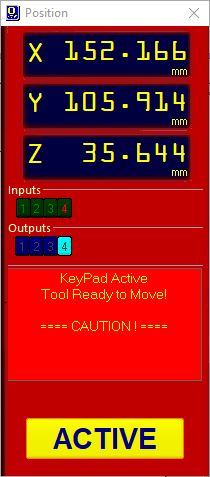

First I had to set XYZ coordinate and this is the window I used to make it.

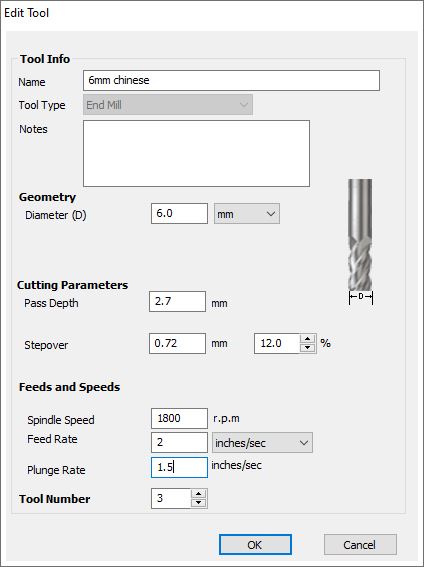

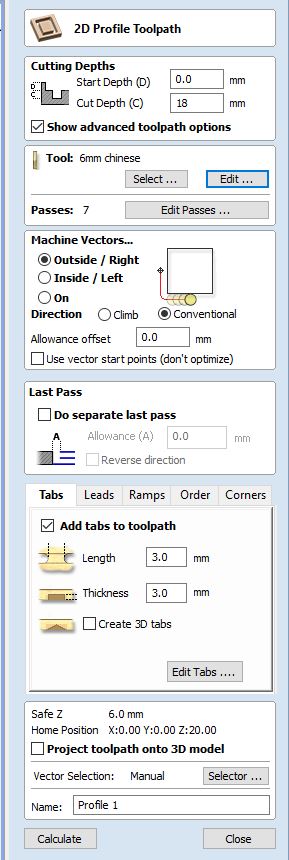

And I continued to set steps to follow when cutting out my designs.

Below is the toolpath used to cut out the designs.

This is how parts will be alligned on MDF.

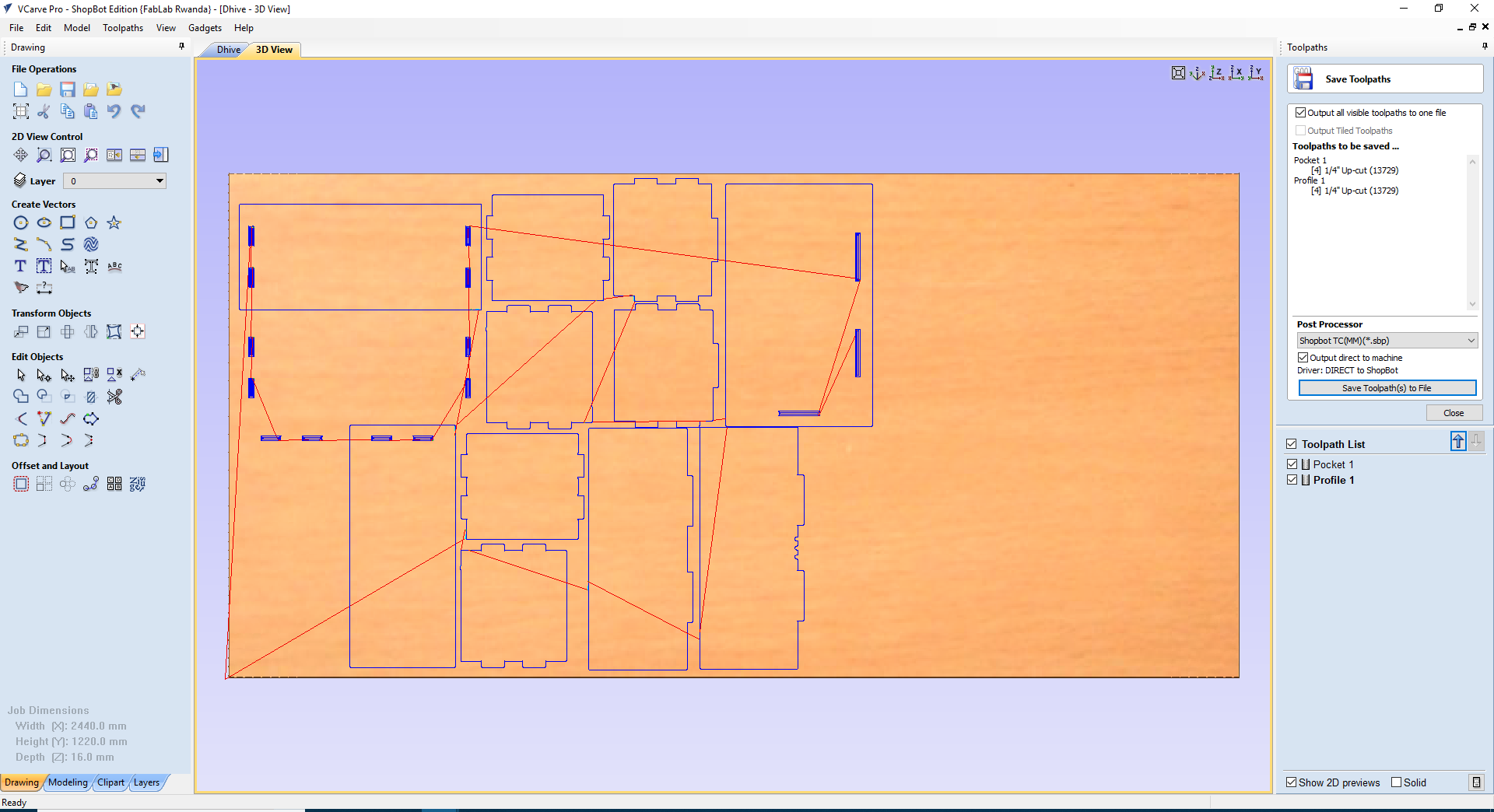

Here I was viewing how those parts will be aligned on MDF sheet.

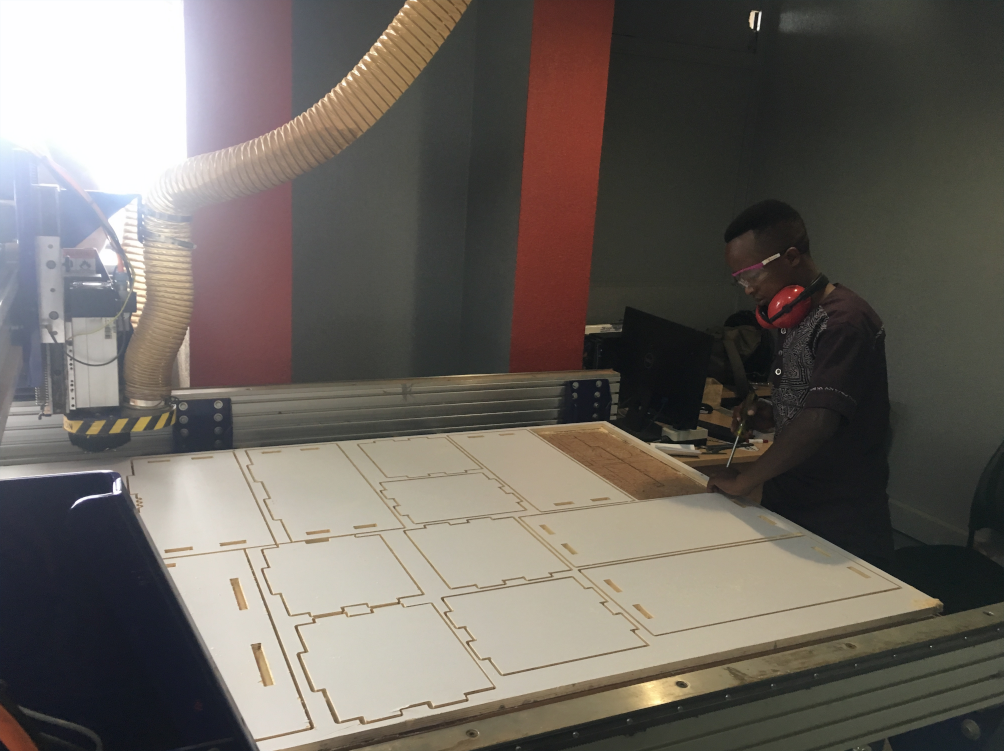

I placed the MDF I was going to work with on the shopbot bed, fixed it and send the command to cut it.

Here after cutting all parts I removed them and prepared them for assembly.

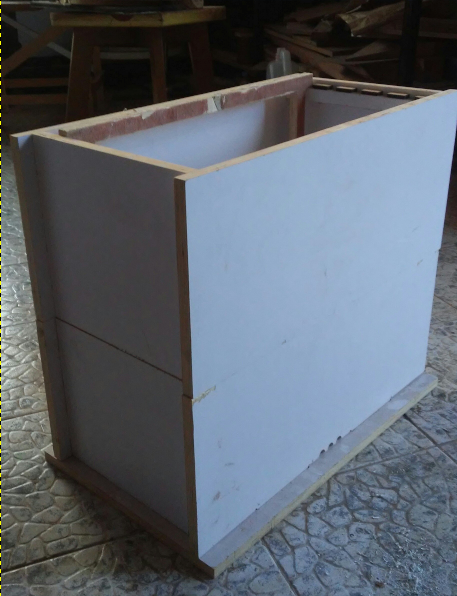

This is the assembly of all parts together to form a bee hive.

Conclusion

From this assignment I did get to expirience with design dedicated to CNC, meaning I had to customize the design I have to be assembled after cutting it from the CNC. I added dogBone joints to help in removing fillet left by the milling bit/tool since they are round.

The dogBone I used had diameter of a half diameter of the tool I used.

All file for the design can be dowloaded here.